| –

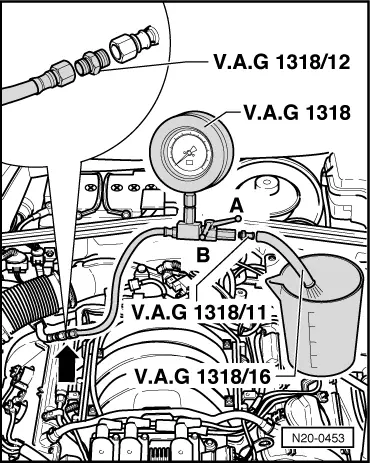

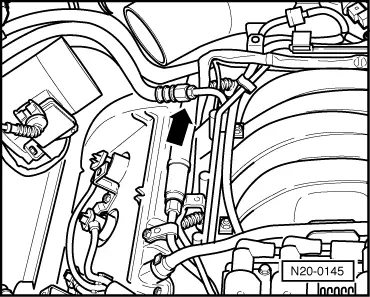

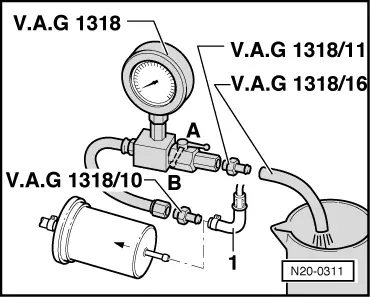

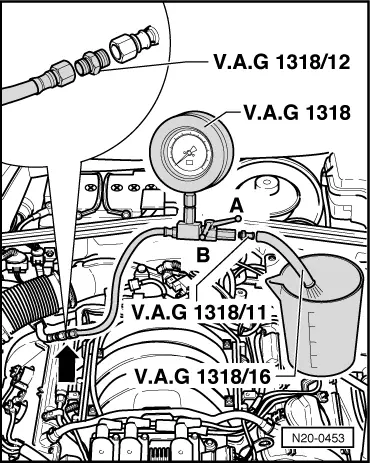

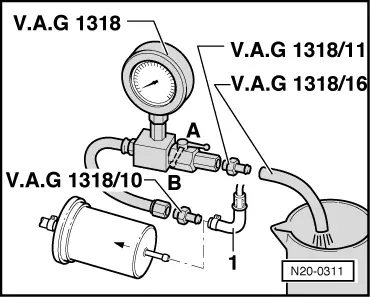

| Connect the pressure gauge - V.A.G 1318- with the adapter -V.A.G 1318/12- to the fuel feed line. |

| –

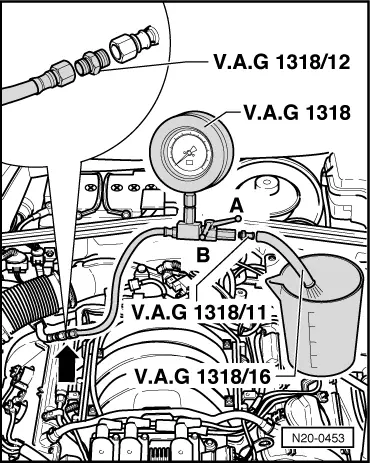

| Fit the hose -V.A.G 1318/16- onto the adapter -V.A.G 1318/11- of the pressure measuring device and hold it in a measuring glass. |

| –

| Open shut-off cock of the pressure gauge. The lever then points in the direction of flow -A-. |

| –

| Activate remote control -V.A.G 1348/3 A-. While doing so, slowly close the shut-off cock until the pressure gauge displays 0.4 MPa (4 bar) overpressure. Now do not make any further changes to the position of the shut-off cock. |

| –

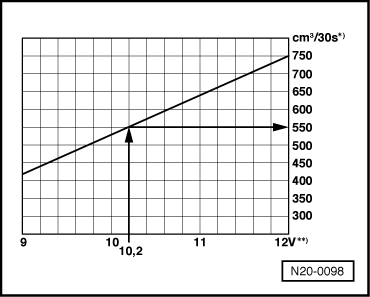

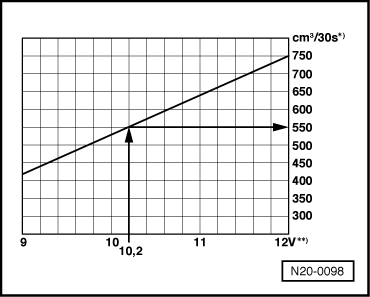

| The fuel flow rate of the fuel pump is dependent on the battery voltage. Therefore connect the multimeter with adapter cables from the measuring tool set, e.g. -V.A.G 1594 C-, to the vehicle battery. |

| –

| Activate remote control for 30 seconds while measuring the battery voltage. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note