| –

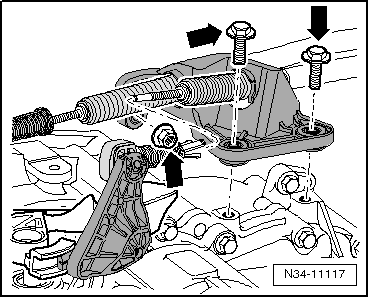

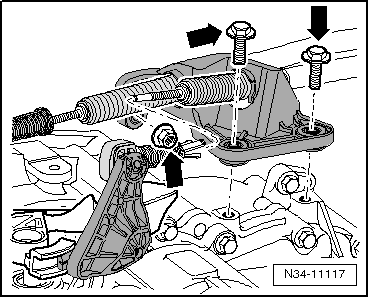

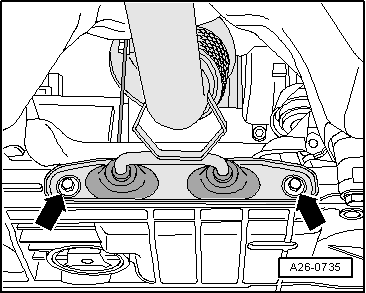

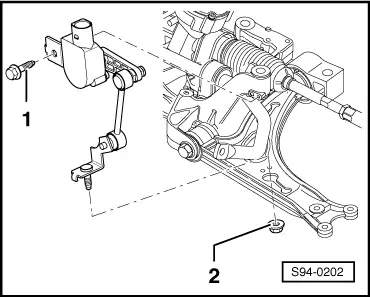

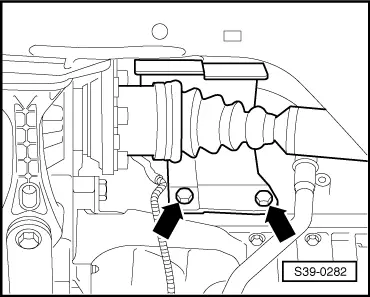

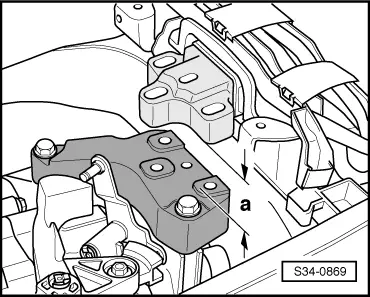

| Disconnect cable support from gearbox -arrows-, lay aside and tie up. |

Note | t

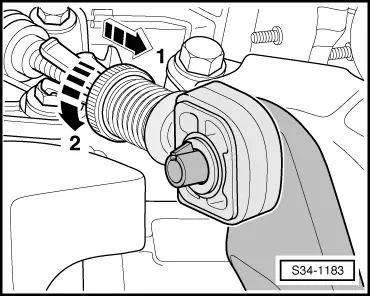

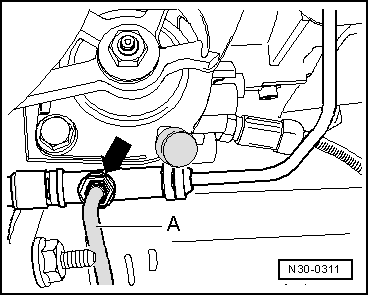

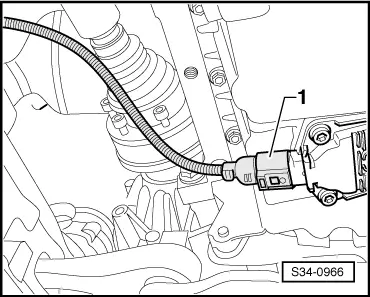

| A plastic line is fitted between the master cylinder and the bleeder/slave cylinder. This plastic line must not be disconnected (do not use hose clamp -MP7–602-). |

| t

| When performing the following work, make sure that no brake fluid comes into contact with the frame side rail or the gearbox. If this is the case, these points must be cleaned thoroughly. |

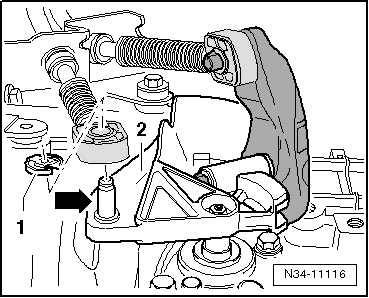

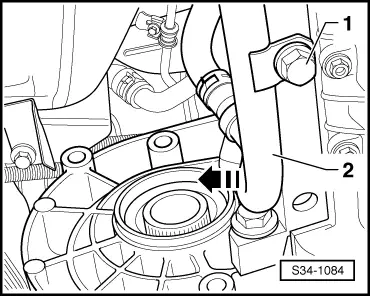

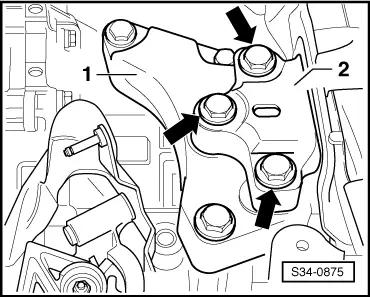

| To ensure that the brake fluid does not completely flow out of the clutch control, carry out the following work procedure: |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note