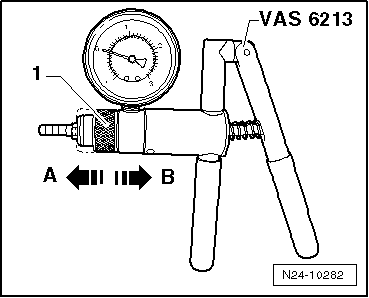

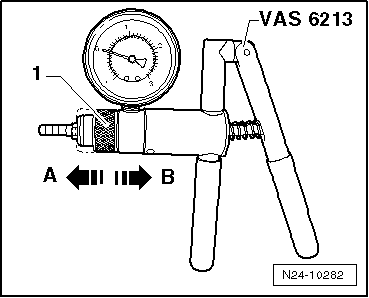

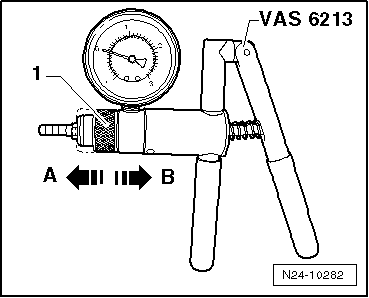

| In order to generate „vacuum“, push the ring -1- for the hand vacuum pump -VAS 6213- into position -A-. |

| –

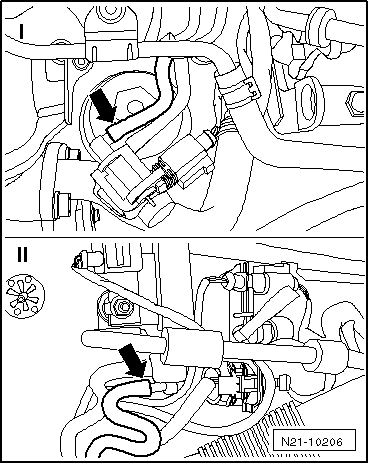

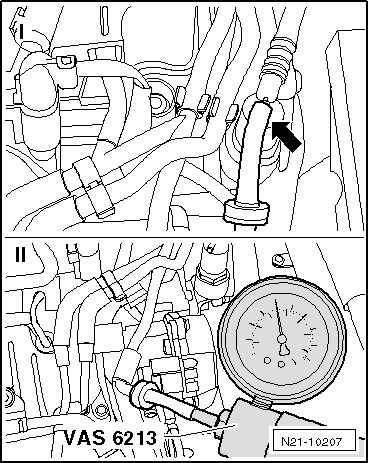

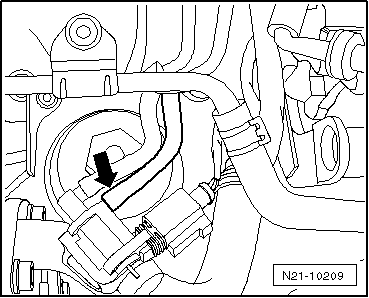

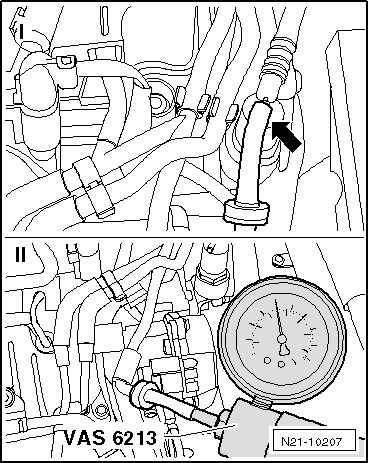

| Attach the hand vacuum pump -VAS 6213- to the detached hose and generate a vacuum of 0.06 MPa (0.6 bar). |

| –

| Observe the pressure gauge of the hand vacuum pump for approx. 30 seconds. |

| l

| The vacuum must not drop. |

| –

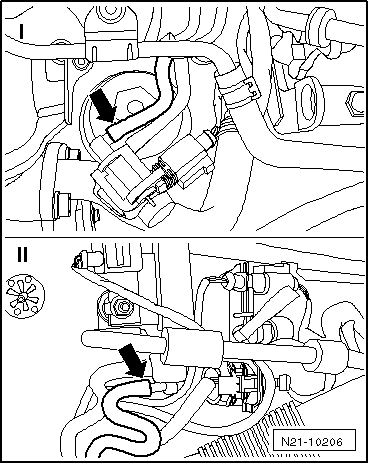

| Search for damage, for example a leaky connection in the hose line, and replace the corresponding part. |

| If the vacuum does not drop: |

| –

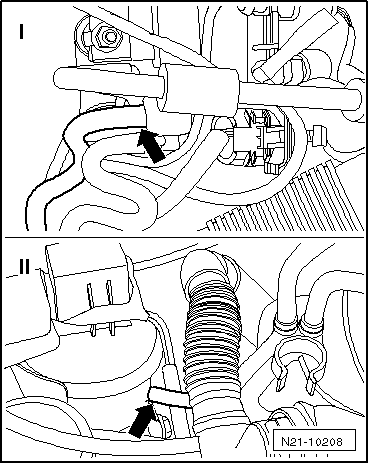

| First of all, detach the hose at the hand vacuum pump -VAS 6213-. |

| –

| Remove one of the plugs from the hose ends. |

| If the non-return valve is functional, a significant spluttering can now be heard when the pressure is compensated for in the vacuum reservoir. |

| If no spluttering can be heard: |

| –

| Replace non-return valve. |

| –

| Re-connect all vacuum hoses. |

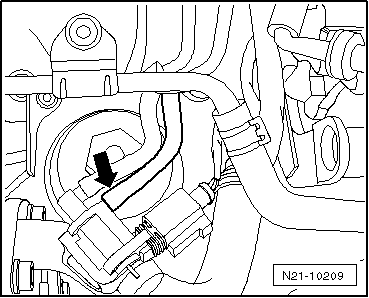

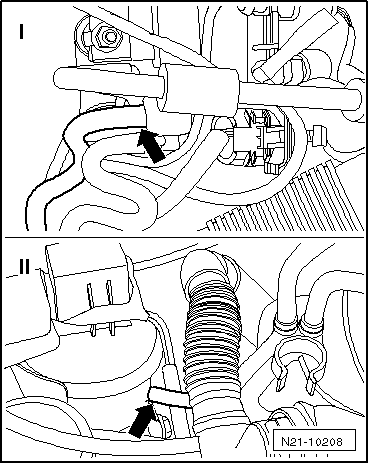

| Check the control vacuum line to the exhaust turbocharger |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note