|

Crankshaft, Remove and Install

Remove Remove

|

Remove engine – see operation "Engine, Remove and

Install".

Mount engine on Installation Stand KM-412 with Adapters KM-412-9

and KM-412-12 – remove attaching parts as necessary.

Remove transmission from cylinder block.

Remove lower part of oil pan – see operation "Oil Pan,

Lower Part, Remove and Install".

Remove upper part of oil pan – see operation "Oil Pan

– Upper Part, Remove and Install".

Remove oil pump – see operation "Oil Pump, Remove and

Install".

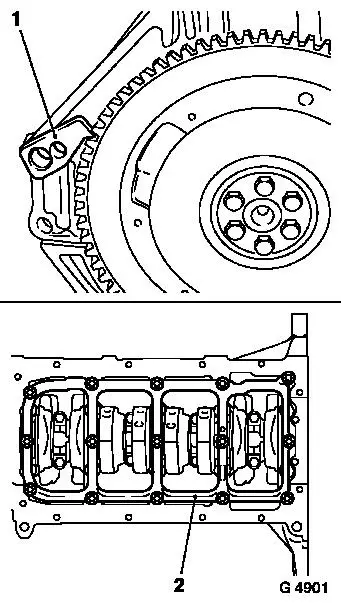

Counterhold flywheel with KM-652 (1) and remove from

crankshaft.

Remove crankshaft bearing bridge (2) from cylinder block and

crankshaft bearing caps – note installation position.

|

|

|

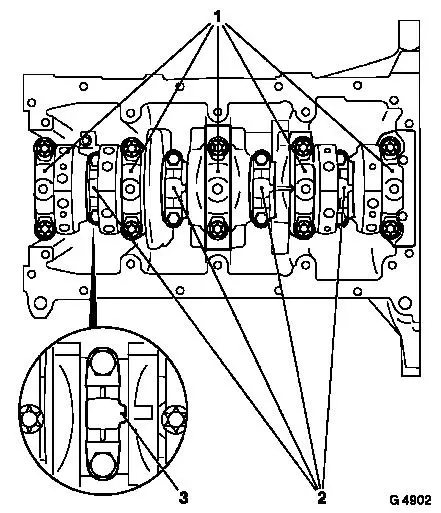

Mark order of crankshaft bearing caps (1) and order of con-rod

bearing caps (2) – bead (3) on con-rod bearing cap faces

transmission side.

Remove con-rod bearing cap from con-rod.

Remove crankshaft bearing caps from cylinder block.

Remove crankshaft from cylinder block.

|

|

Clean Clean

Clean all parts and remove gasket residue.

Inspect

Inspect

Check all parts for wear and replace if necessary.

Check crankshaft – see operation "Crankshaft, Check".

Install

Install

|

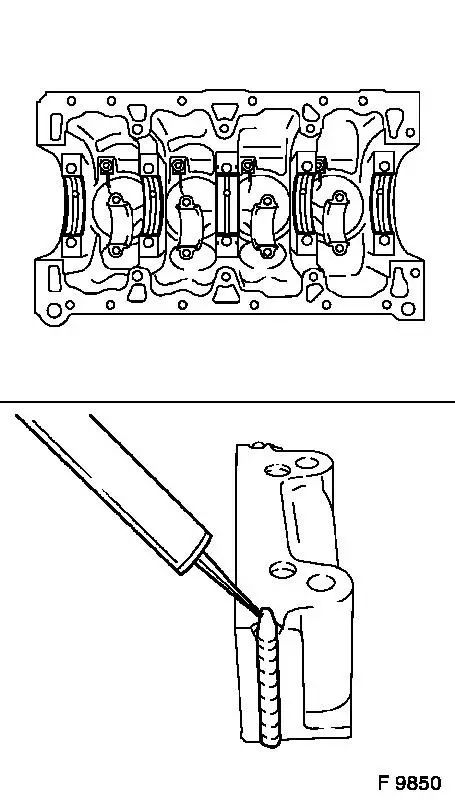

Coat crankshaft bearing shells with engine oil and insert in

cylinder block and crankshaft bearing caps.

Insert crankshaft into cylinder block – the seating of the

crankshaft can be corrected by lightly tapping on the crankshaft

webs with a rubber hammer.

Apply bead of adhesive sealing compound (black) to rear grooves

of the crankshaft.

|

|

|

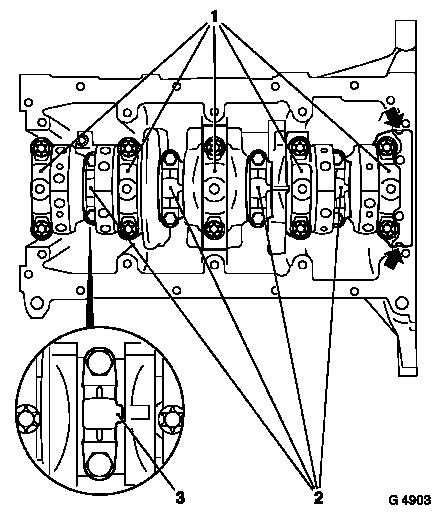

Attach crankshaft bearing cap (1) with new bolts to cylinder

block – note identification code – tightening torque 50

Nm / 37 lbf. ft. + 45° + 15°.

After assembly of rear crankshaft bearing cap, again press in

adhesive sealing compound (black) from above (arrows) until it

emerges at the joints.

Insert new con-rod bearing shells with engine oil and insert in

con-rod and con-rod bearing cap.

Note order of con-rod bearing caps (2) – observe mark.

Attach con-rod bearing caps to con-rods with new bolts –

bead (3) on con-rod bearing cap faces transmission side –

tightening torque – 35 Nm / 26 lbf. ft. + 45° +

15°.

|

|

Install crankshaft rear seal ring – see operation "Rear

Seal Ring, Crankshaft, Replace".

Attach crankshaft bearing bridge. to cylinder block and

crankshaft bearing caps – note installation position –

tightening torque – 20 Nm / 15 lbf. ft. + 45°.

Attach flywheel to crankshaft – lock with KM-652 –

tightening torque – 65 Nm / 48 lbf. ft. + 30° +

15°.

Install oil pump – see operation "Oil Pump, Remove and

Install".

Install upper part of oil pan – see operation "Oil Pan

– Upper Part, Remove and Install".

Install lower part of oil pan – see operation "Lower Part

of Oil Pan, Remove and Install".

Attach transmission to cylinder block.

Remove engine from Installation Stand KM-412. Remove Adapters

KM-412-9 and KM-412-12 from engine – install attaching parts

as necessary.

Install engine – see operation "Engine, Remove and

Install".

|