|

Camshaft, Remove and Install

Remove Remove

Remove air cleaner housing and got film mass air flow meter and

air intake hose - see illustration "Air duct X 20 DTL, Y 20 DTL"

and "Air duct Y 20 DTH up to MY 2003" and "Air duct Y 20 DTH as of

MY 2003, Y 22 DTR".

Remove cylinder head cover – see operation "Cylinder Head

Cover, Remove and Install".

Remove vacuum pump from cylinder head and lay aside to rear

– see operation "Vacuum Pump, Remove and Install".

Remove ribbed V-belt tensioner – see operation "Ribbed

V-belt Tensioner Assembly, Remove and Install".

Lock engine at 1st cylinder TDC – see operation "Engine,

Lock at 1st Cylinder TDC (Timing, Check)".

|

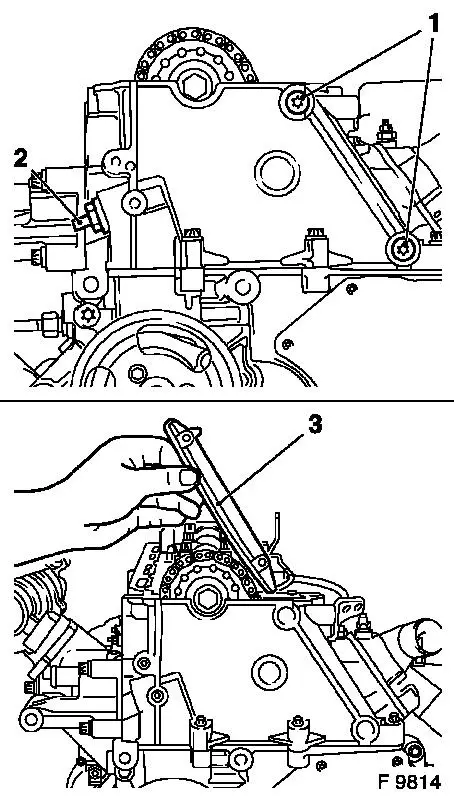

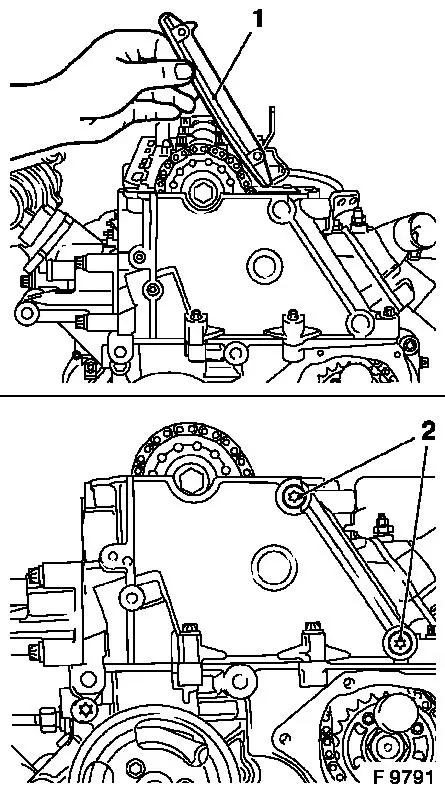

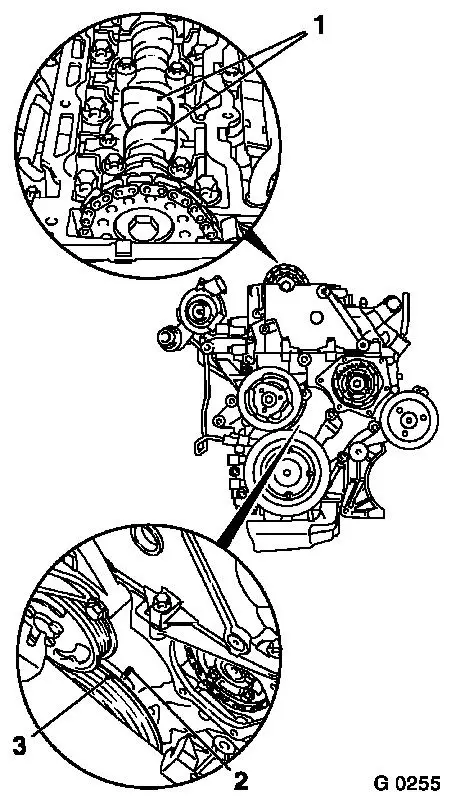

Remove simplex chain tensioner (2) – note installation

position.

Caution

Use sheet metal plate or suitable heat shielding to avoid

damaging the guide rails.

Remove Remove

Heat fastening bolts (1) intensively with hot air blower and

remove. Remove simplex timing chain guide rail (3) upwards –

note installation position.

Clean thread for the fastening bolts (1) in cylinder head.

|

|

Caution

|

Remove Test Gauge KM-932 from cylinder head and Injection Pump

Lock Pin KM-927 from lock bore.

Remove Remove

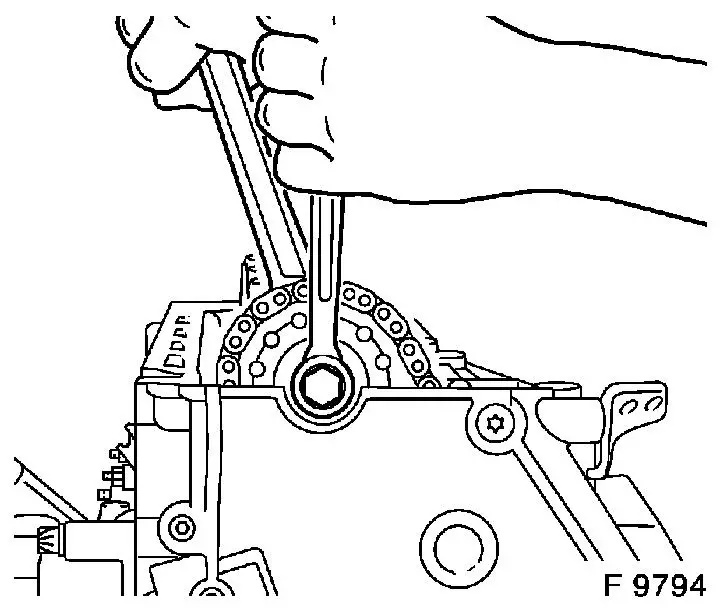

Remove camshaft sprocket from camshaft – counterhold with

open-ended wrench on hex of camshaft.

Note: To simplify

installation, suspend simplex timing chain at suitable point.

|

|

Caution

|

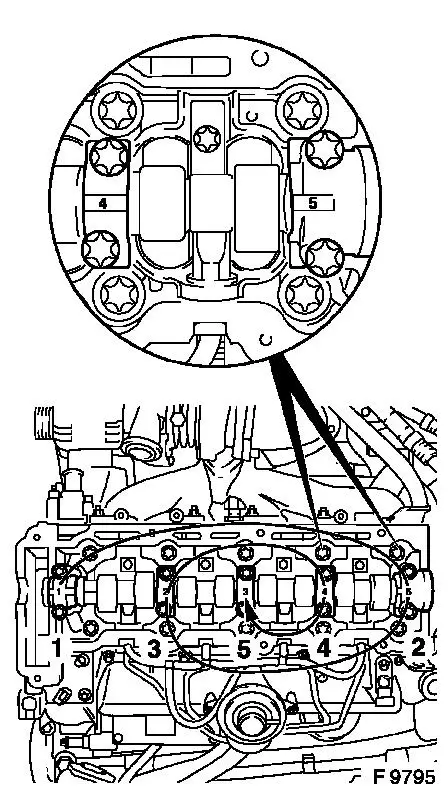

Note marking before dismantling camshaft bearing cover!

The camshaft must release evenly from the bearing seats.

Remove Remove

Release camshaft bearing cover in spiral pattern in steps of 1/2

to 1 turn in sequence illustrated.

Detach camshaft bearing caps from cylinder head and remove

camshaft.

Note: If the camshaft

is being replaced, the valve bridges must also be replaced –

note installation positions of valve bridges!

|

|

Clean Clean

Clean sealing surfaces and remove gasket residues.

Inspect

Inspect

Check camshaft and bearing seat for wear, replace if

necessary.

|

Install

Install

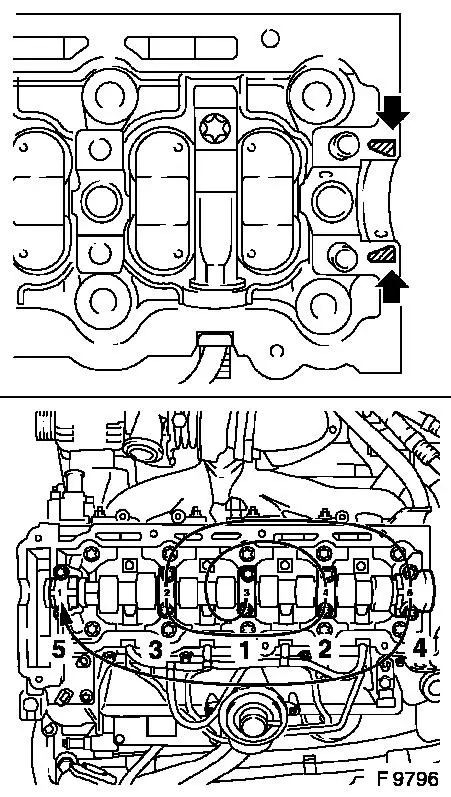

If valve bridges are being replaced – note installation

position. Marks on the valve bridges are on the injection nozzle

traverse side.

Apply surface sealant (green) to sealing surfaces (arrows).

Coat sliding surfaces of valve bridges and camshaft with MoS

2 lubricating paste (grey). Insert camshaft

into cylinder head.

Caution

Note identification on camshaft bearing caps.

Install

Install

Attach camshaft bearing caps to cylinder head and tighten using

spiral pattern in steps of 1/2 up to 1 turn in sequence illustrated

– tightening torque 15 Nm / 11 lbf. ft.

|

|

Insert camshaft sprocket in simplex timing chain.

Attach camshaft sprocket with new fastening bolt to camshaft and

tighten by hand.

Caution

Ensure that the camshaft sprocket is not askew on the camshaft

– camshaft sprocket must lie plane on the camshaft.

Install

Install

|

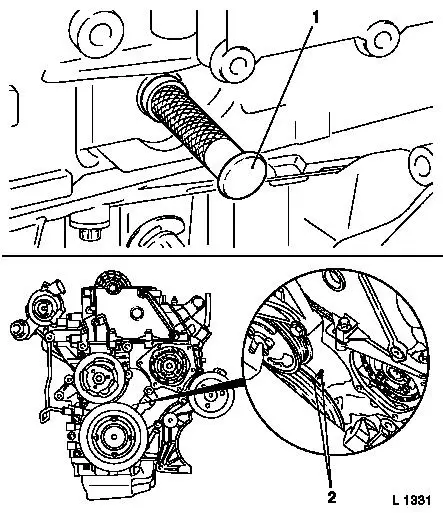

Insert and install simplex timing chain guide rail (1) –

use new fastening bolts (2) – note installation position

– tightening torque 8 Nm / 6 lbf. ft.

|

|

Inspect

Inspect

|

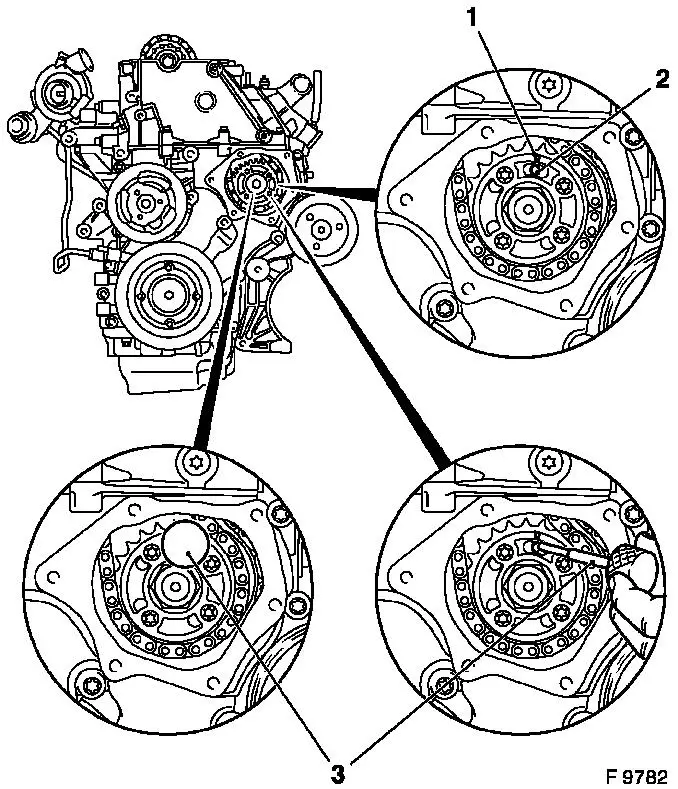

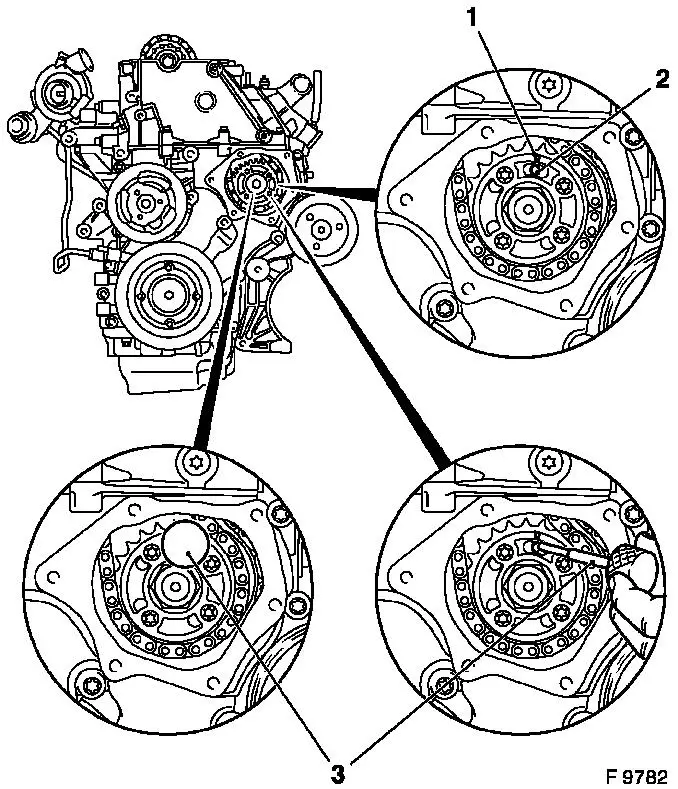

Arrow (1) on simplex fuel injection pump sprocket must align

with recess in fuel injection pump flange and lock bore (2) in fuel

injection pump.

Install

Install

Insert Injection Pump Lock Pin KM-927 (3) in lock bore of fuel

injection pump.

|

|

|

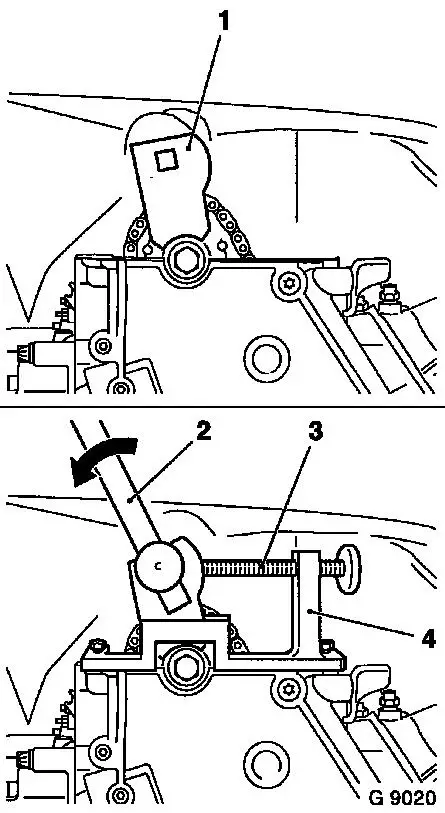

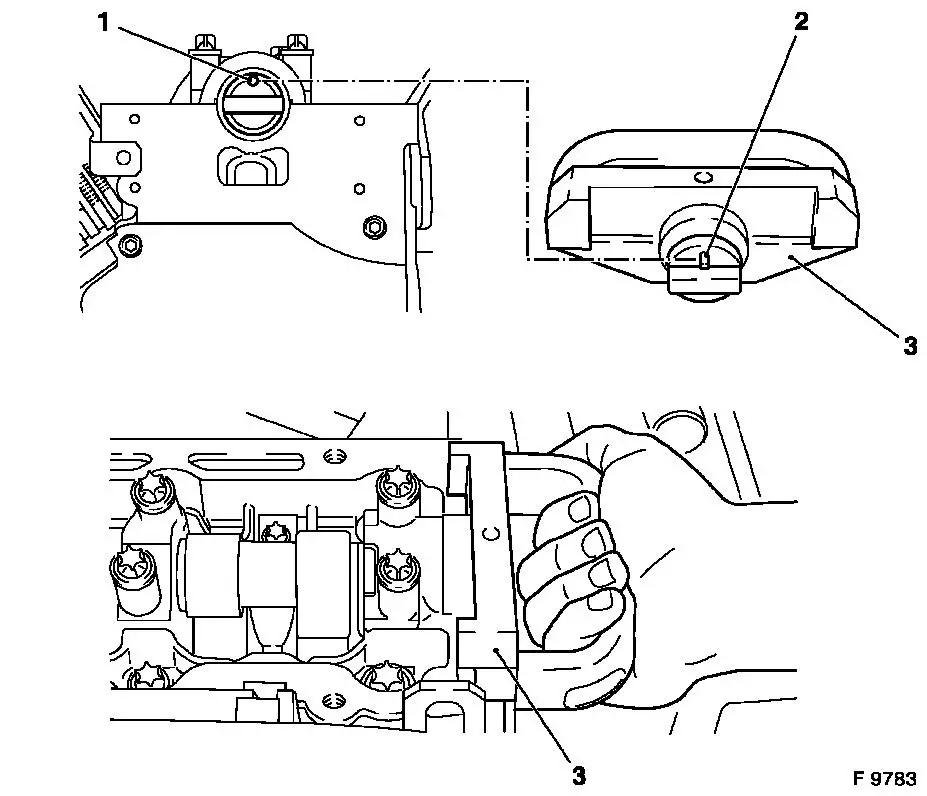

Insert carrier (1) of Adjuster KM-933 (4) vertically into

camshaft sprocket.

Install Adjuster KM-933 on cylinder head.

Adjust Adjust

Use handle (2) to exert slight pressure on the carrier in the

direction of arrow (counter engine rotational direction) and fix in

place with holder bolt (3).

Injection Pump Lock Pin KM-927 must be able to be installed and

removed under suction. If this is not the case, decrease the

pressure on the carrier disk slightly via the holder bolt.

|

|

Install

Install

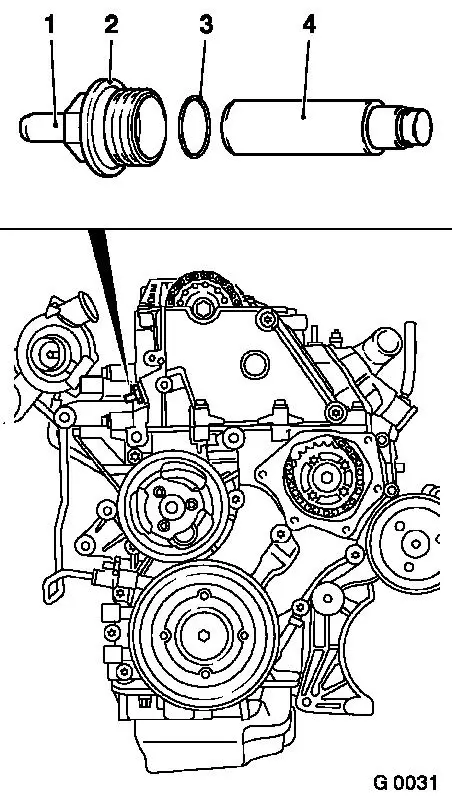

Fasten camshaft sprocket to camshaft – tightening torque

90 Nm / 66 lbf. ft. + 60° + 30°.

|

Insert Simplex chain tensioner (4) into cylinder head –

closed side of chain tensioner must point to tensioner blade.

Install Simplex chain tensioner screw plug (2) with new seal ring

(3) – tightening torque 60 Nm / 44 lbf. ft.

Caution

A distinction must be made between versions with and without

release bolts (1).

In versions with release bolts the chain tensioner must be

untightened using the release bolt after installation!

Inspect

Inspect

Press in the release pin with a hammer shaft until a click is

heard.

It must be possible to push in release bolt up to stop with

thumb and for it to slide back to its original position

automatically – the release bolt can no longer be pushed in

once the oil pressure has built up.

|

|

Remove Remove

Remove all locking and adjusting tools.

Adjust Adjust

|

At fastening bolt of torsional vibration damper, turn crankshaft

two turns (approx. 720°) in engine rotational direction to just

before "1st cylinder TDC" – mark (3) on torsional vibration

damper is just before lug (2) on timing case.

Inspect

Inspect

In this position, the cams (1) of the 1st cylinder are just

before TDC (both cams point upwards).

|

|

Install

Install

|

Insert Crankshaft Lock Pin KM-929 (1) in aperture for crankshaft

pulse pick-up and simultaneously slowly turn crankshaft further in

engine rotational direction at fastening bolt of torsional

vibration damper until crankshaft lock pin engages to stop in

cylinder block or crank web.

Inspect

Inspect

In this position, marks (2) must align.

|

|

|

Arrow (1) on simplex fuel injection pump sprocket must align

with recess in fuel injection pump flange and lock bore (2) in fuel

injection pump.

Install

Install

Insert Injection Pump Lock Pin KM-927 (3) in lock bore of fuel

injection pump.

|

|

|

Apply Test Gauge KM-932 (3) to cylinder head – pin (2)

must engage in bore (1) of camshaft.

|

|

Remove Remove

Remove all locking tools.

Clean Clean

Clean sealing surfaces on timing case cover and timing case

– cover aperture in timing case with lint-free cloth.

|

Install

Install

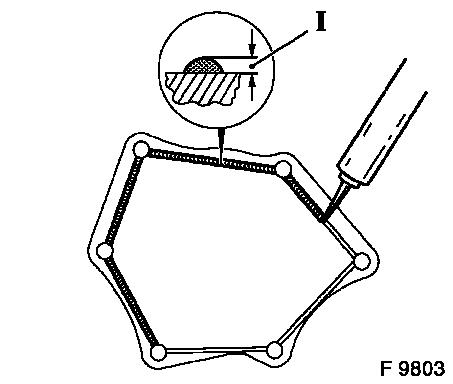

Apply an approx. 2 mm (Dimension I) thick bead of silicone

sealing compound (grey) to timing case cover. Attach timing case

cover to timing case with new fastening bolts – secure using

2 threaded bolts (M6) – tightening torque 6 Nm / 4.5 lbf.

ft.

Caution

The silicone sealing compound (grey) must be applied and the

timing case must be installed (including torque checking) within 10

minutes.

|

|

Install

Install

Attach upper coolant hose to thermostat housing and

radiator.

Attach crankshaft pulse pick-up to cylinder block with new

O-ring – tightening torque 8 Nm / 6 lbf. ft.

Attach coolant pipe to cylinder block.

Install ribbed V-belt tensioner – see operation "Ribbed

V-belt Tensioner Assembly, Remove and Install".

Install vacuum pump – see operation "Vacuum Pump, Remove

and Install".

Install cylinder head cover – see operation "Cylinder Head

Cover, Remove and Install".

Install air cleaner housing with hot film mass air flow meter

and air intake hose - see illustration "Air duct X 20 DTL, Y 20

DTL" and "Air duct Y 20 DTH up to MY 2003" and "Air duct Y 20 DTH

as of MY 2003, Y 22 DTR".

Close coolant drain bolt.

Inspect

Inspect

Charge cooling system – see operations "Cooling System,

Charge and Bleed" and "Cooling System, Check for Leaks".

|