|

Engine, Lock at 1st Cylinder TDC (Timing,

Check)

Remove Remove

Open coolant drain bolt – collect escaping coolant.

Remove air cleaner housing with hot film mass air flow meter and

air intake hose - see illustration "Air duct X 20 DTL, Y 20 DTL"

and "Air duct Y 20 DTH up to MY 2003" and "Air duct Y 20 DTH as of

MY 2003, Y 22 DTR".

Remove cylinder head cover – see operation "Cylinder Head

Cover, Remove and Install".

Remove vacuum pump from cylinder head and lay aside to rear

– see operation "Vacuum Pump, Remove and Install".

Remove ribbed V-belt tensioner – see operation "Ribbed

V-belt Tensioner Assembly, Remove and Install".

Detach and remove upper coolant hose from thermostat housing and

radiator.

Remove Remove

|

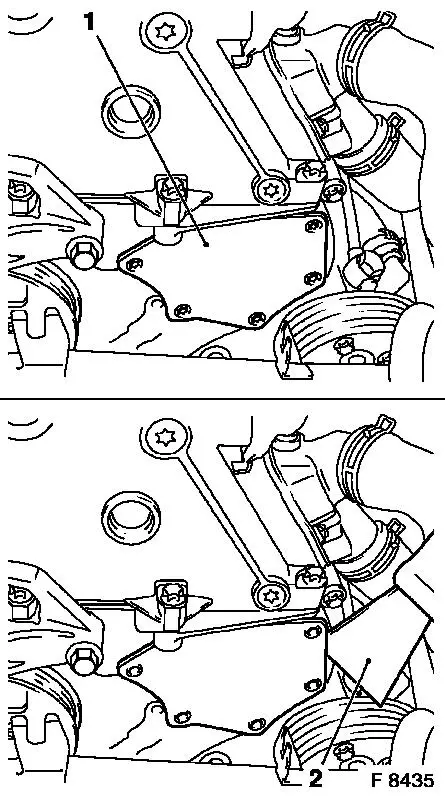

Remove fastening bolts from timing case cover (1) and carefully

separate timing case cover from timing case with a wide, flat

spatula (2).

|

|

Caution

The timing case cover must not be levered off or separated from

the timing case by force; this would lead to permanent deformity

and leaks.

Adjust Adjust

|

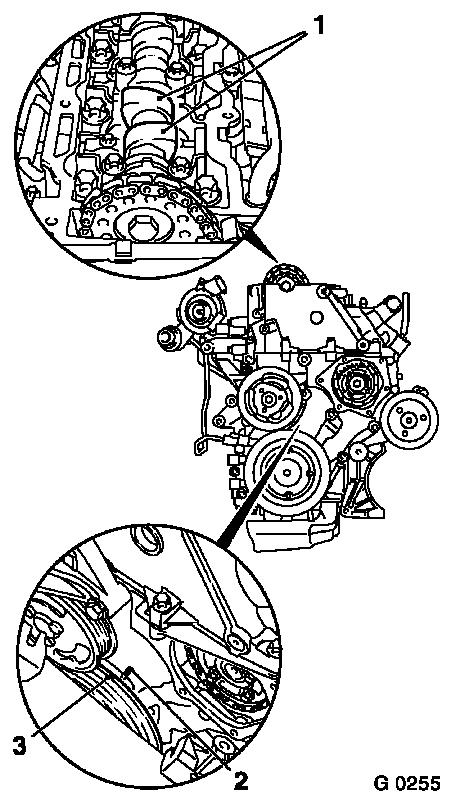

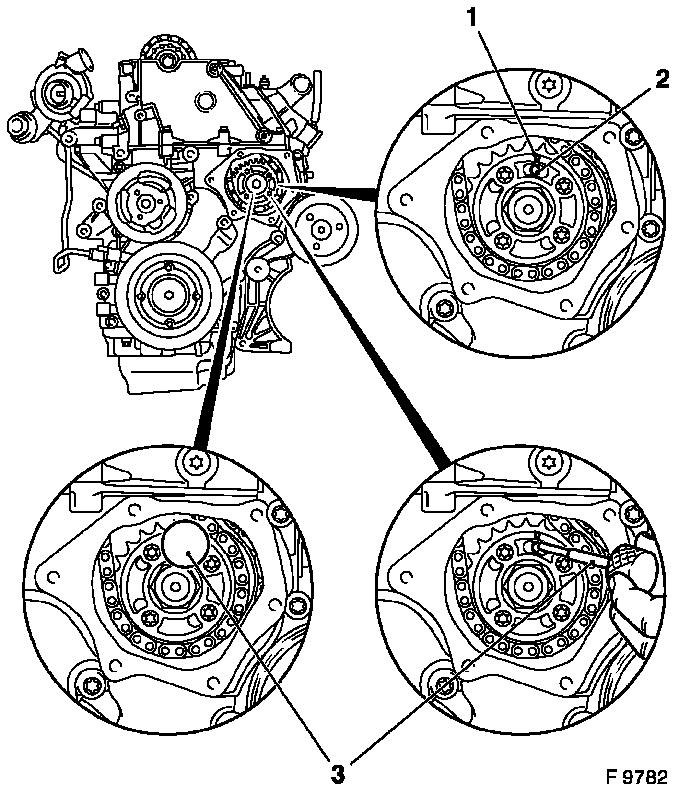

At the fastening bolt of the torsional vibration damper, turn

the crankshaft in engine rotational direction until just before

"1st cylinder TDC" – mark (3) on the torsional vibration

damper is just in front of the lug (2) on the timing case.

Inspect

Inspect

In this position, the cams (1) of the 1st cylinder are just

before TDC (both cams point upwards).

|

|

Remove Remove

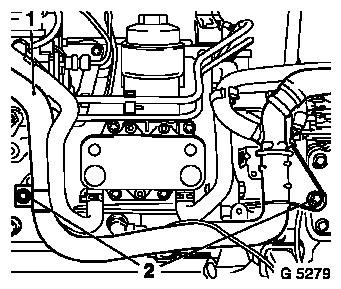

Detach wiring harness plug from dynamic oil level control and

oil temperature sensor.

|

Remove fastening bolts from coolant pipe (2) and carefully press

coolant pipe (1) forwards.

|

|

Remove Remove

|

Remove crankshaft pulse pick-up (1) with O-ring from cylinder

block.

Install

Install

Insert Crankshaft Lock Pin KM-929 (2) in aperture for crankshaft

pulse pick-up and simultaneously slowly turn the crankshaft in

engine rotational direction at the fastening bolt of the torsional

vibration damper until the crankshaft lock pin engages to stop in

the cylinder block or crank web.

Inspect

Inspect

In this position, the marks (3) must align.

|

|

Inspect

Inspect

|

Arrow (1) on simplex fuel injection pump sprocket must align

with recess in fuel injection pump flange and lock bore (2) in fuel

injection pump.

Install

Install

Insert Injection Pump Lock Pin KM-927 (3) in lock bore of fuel

injection pump.

Note: If the lock pin

cannot be inserted, carry out basic adjustment of timing –

see operation "Timing, Adjust".

|

|

Install

Install

|

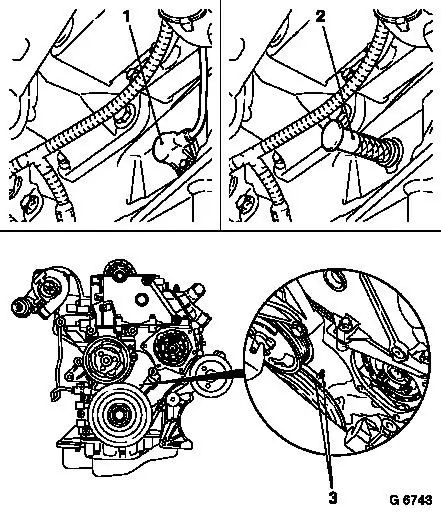

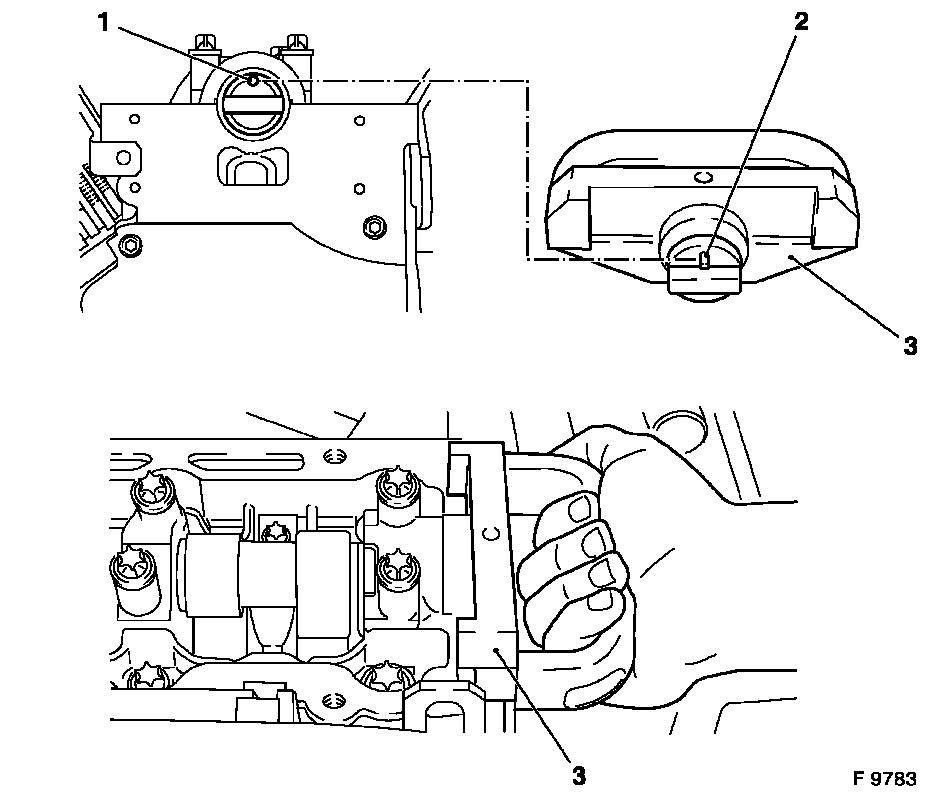

Apply Test Gauge KM-932 (3) to cylinder head – pin (2)

must engage in bore (1) of camshaft.

Note: If the test

gauge cannot be applied, carry out basic adjustment of timing

– see operation "Timing, Adjust".

|

|

Remove Remove

Remove all locking tools.

Clean Clean

Clean sealing surfaces on timing case cover and timing case

– cover aperture in timing case with lint-free cloth.

|

Install

Install

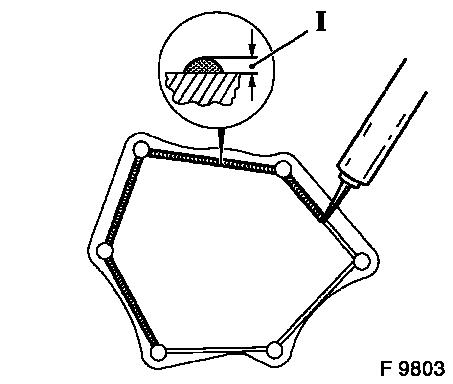

Apply an approx. 2 mm (Dimension I) thick bead of silicone

sealing compound (grey) to cover.

Attach timing case cover to timing case with new fastening bolts

– secure using 2 threaded bolts (M6) – tightening

torque 6 Nm / 4.5 lbf. ft.

Caution

The silicone sealing compound (grey) must be applied and the

timing case must be installed (including torque checking) within 10

minutes.

|

|

Install

Install

Attach upper coolant hose to thermostat housing and

radiator.

Attach crankshaft pulse pick-up to cylinder block with new

O-ring – tightening torque 8 Nm / 6 lbf. ft.

Connect wiring harness plugs to dynamic oil level control and

oil temperature sensor.

Attach fastening bolts to coolant pipe

Install ribbed V-belt tensioner – see operation "Ribbed

V-belt Tensioner Assembly, Remove and Install".

Install vacuum pump – see operation "Vacuum Pump, Remove

and Install".

Install cylinder head cover – see operation "Cylinder Head

Cover, Remove and Install".

Install air cleaner housing with hot film mass air flow meter

and air intake hose - see illustration "Air duct X 20 DTL, Y 20

DTL" and "Air duct Y 20 DTH up to MY 2003" and "Air duct Y 20 DTH

as of MY 2003, Y 22 DTR".

Close coolant drain bolt.

Inspect

Inspect

Charge cooling system – see operations "Cooling System,

Charge and Bleed" and "Cooling System, Check for Leaks".

|