|

Timing, Adjust

Option 1: Injection pump retaining pin cannot be

inserted.

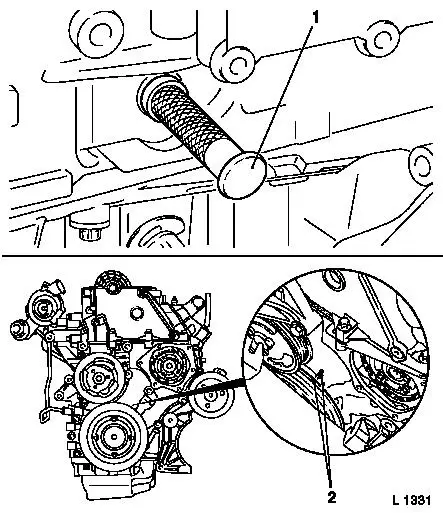

Note: Crankshaft is

locked at "1st cylinder TDC" with Lock Pin KM-929.

Remove Remove

|

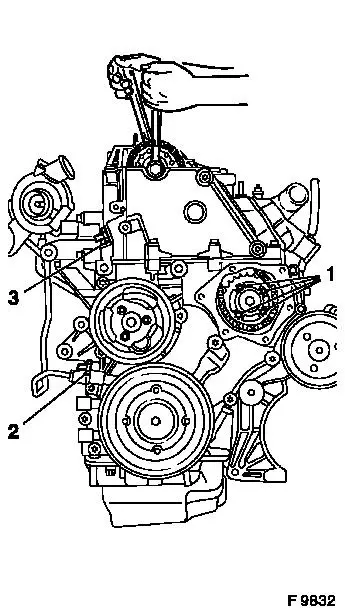

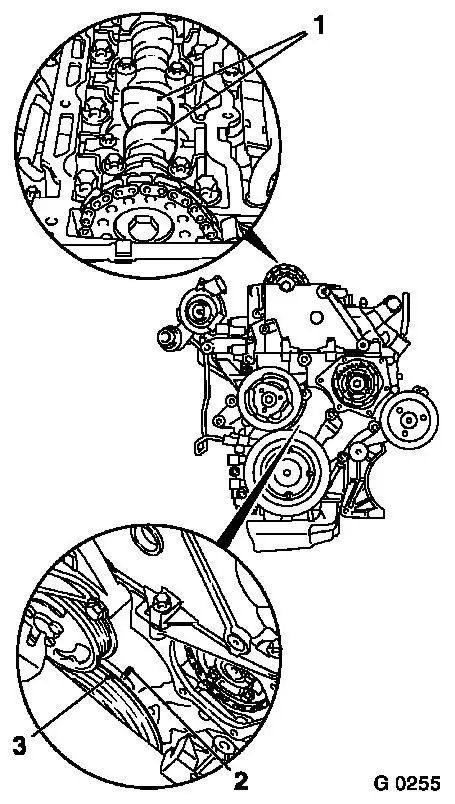

Remove simplex chain tensioner (3) and duplex chain tensioner

(2) – note installation position. Remove fastening bolt for

camshaft sprocket from camshaft – counterhold with open-ended

wrench on hex of camshaft.

Install

Install

Insert new bolt for camshaft sprocket and tighten hand-tight

– ensure that the camshaft sprocket is not tilted on the

camshaft. Camshaft sprocket must lie plane on the camshaft.

Remove Remove

Remove fastening bolts (1) and loosely screw in new fastening

bolts (ensure that bolt strength is 10.9) - 5 fastening bolts for Y

20 DTH as of MY 2003 and Y 22 DTR.

|

|

Adjust Adjust

|

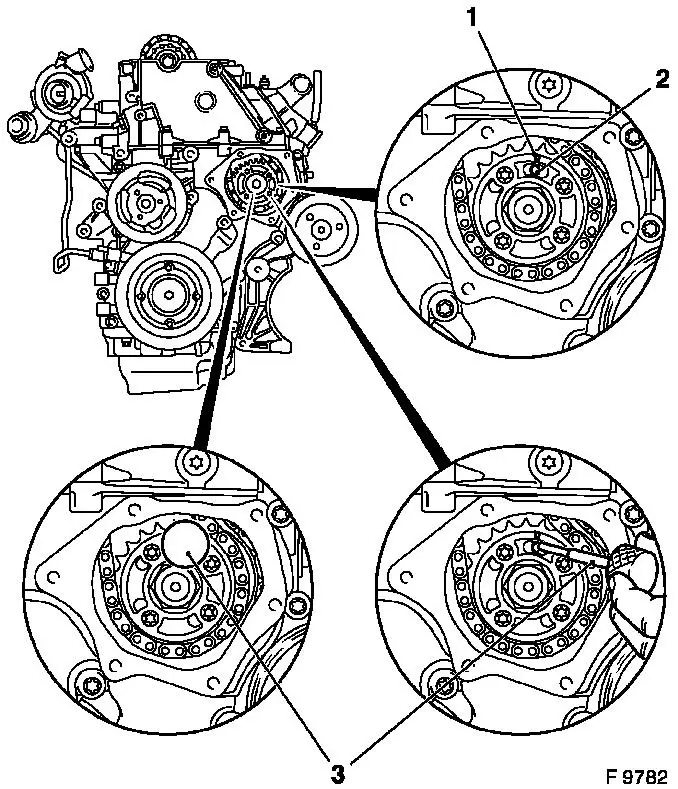

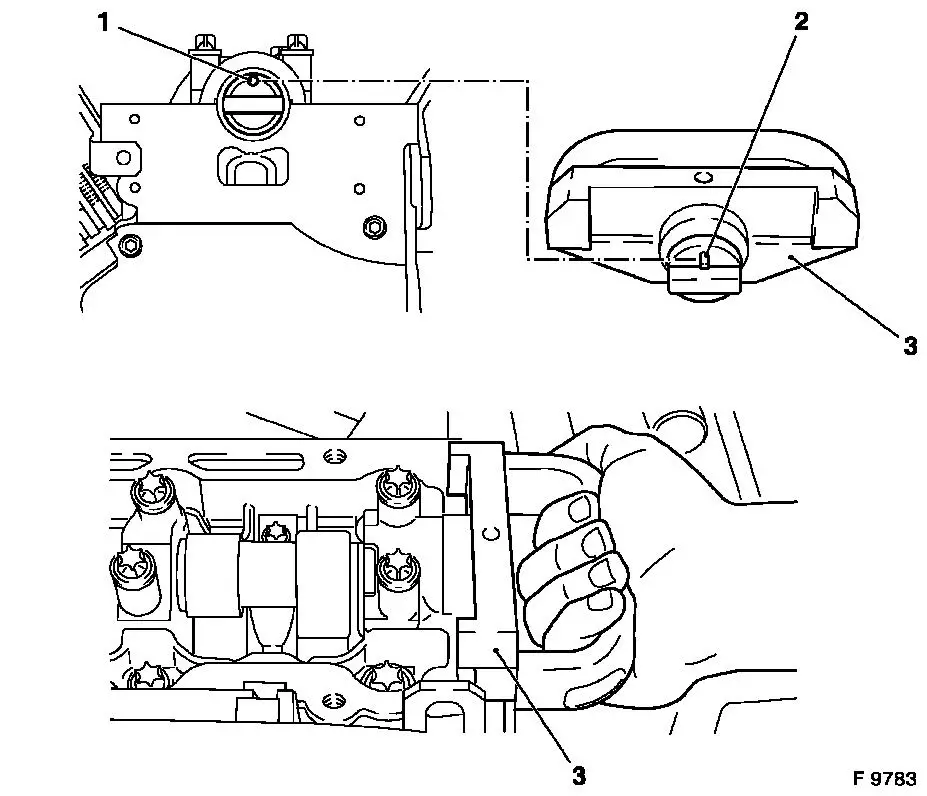

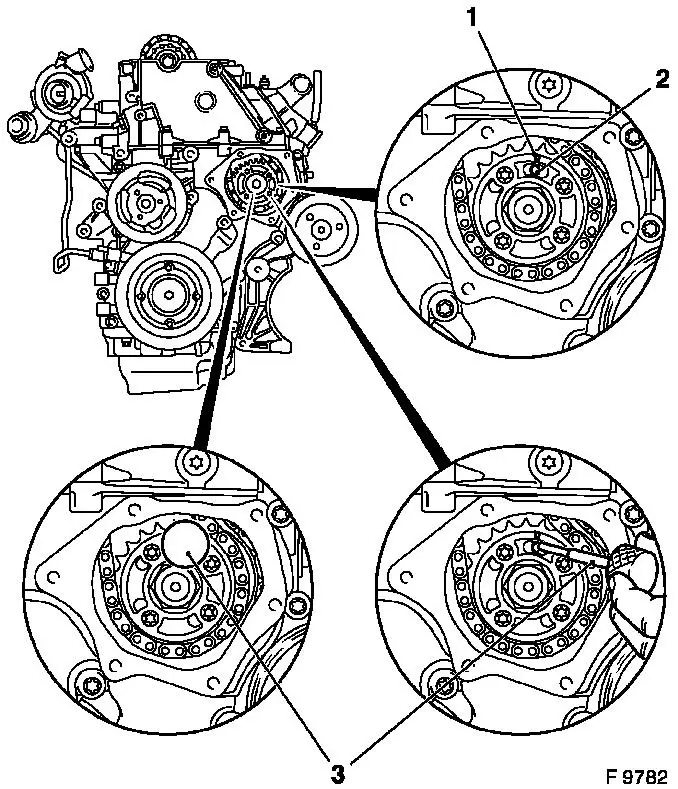

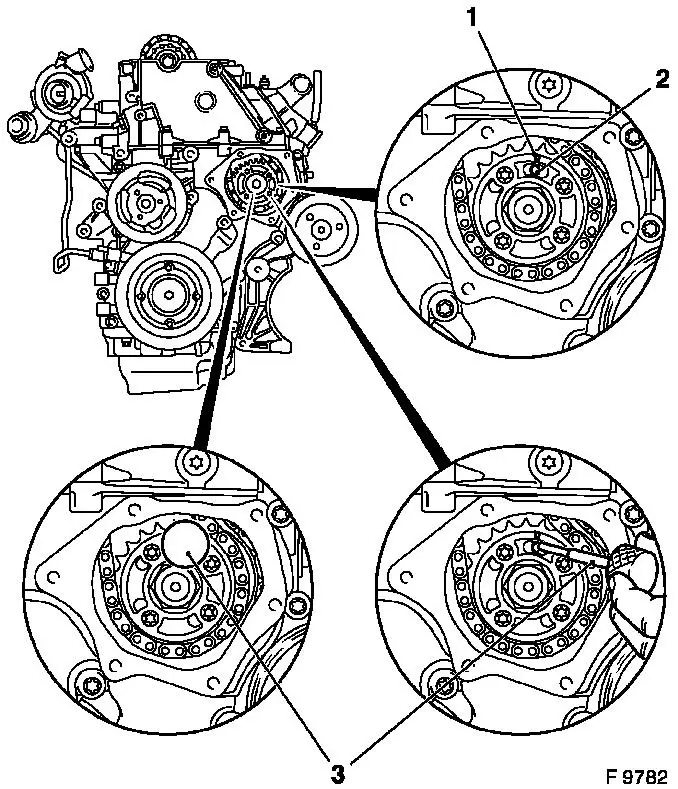

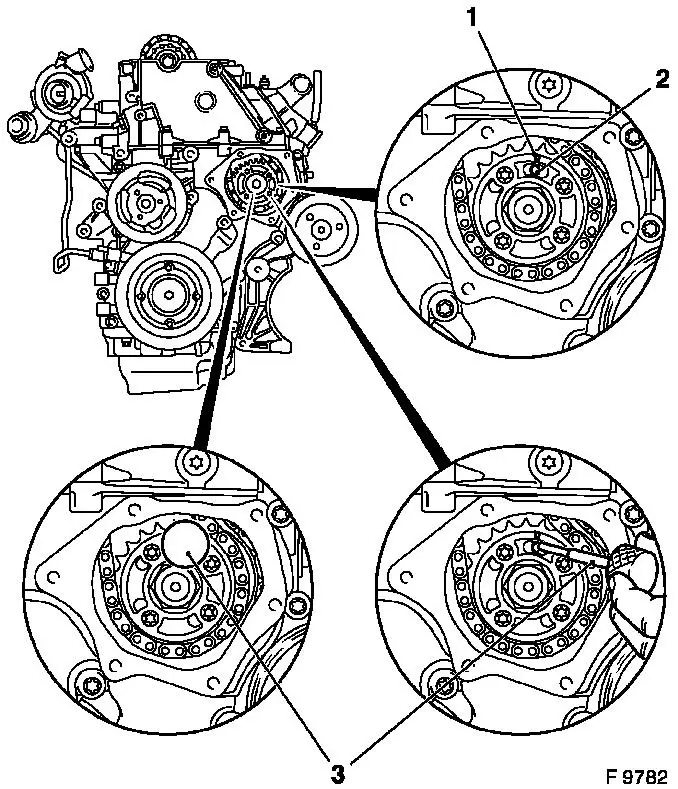

Turn fuel injection pump sprocket until arrow (1) on simplex

fuel injection pump sprocket aligns with recess in fuel injection

pump flange and lock bore (2) in fuel injection pump.

Install

Install

Insert Injection Pump Lock Pin KM-927 (3) to stop in lock bore

fuel injection pump.

|

|

|

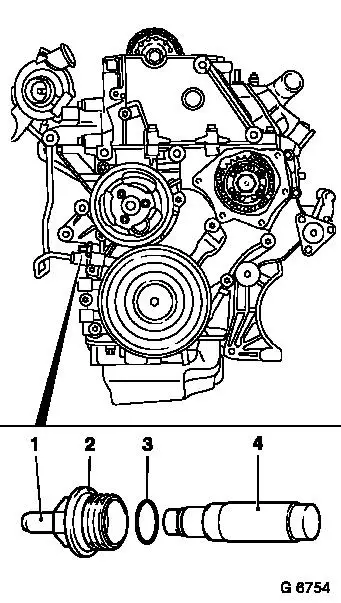

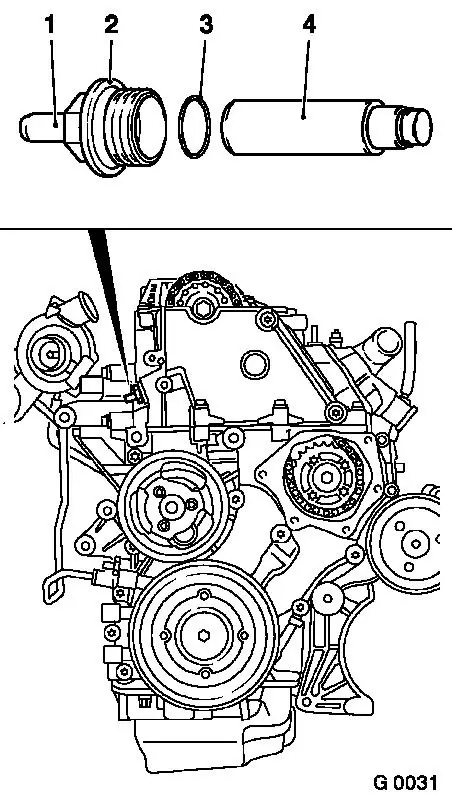

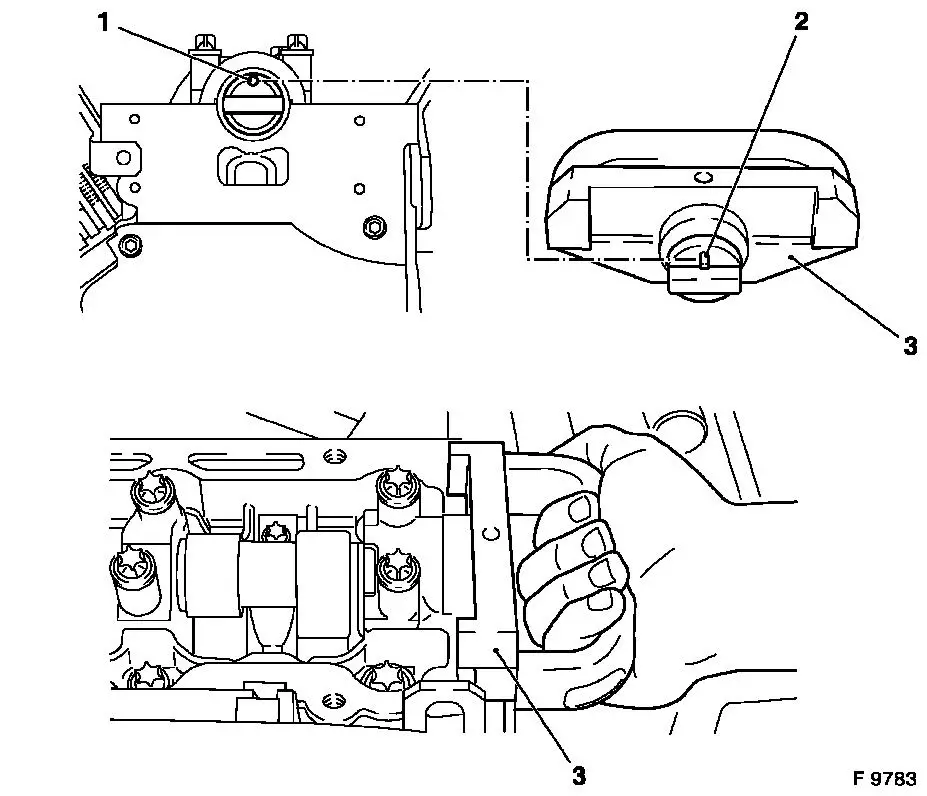

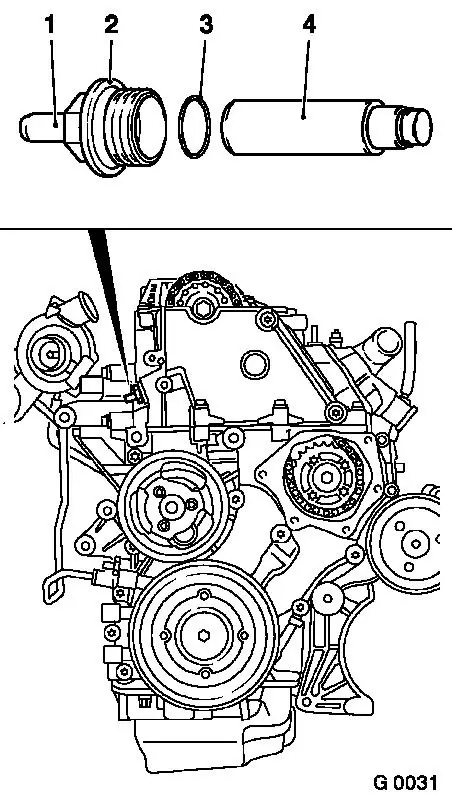

Insert Duplex chain tensioner (4) into timing case –

closed side of chain tensioner must point to tensioner blade.

Install Duplex chain tensioner screw plug (2) with new seal ring

(3) – tightening torque 60 Nm / 44 lbf. ft.

Caution

A distinction must be made between versions with and without

release bolts (1). In versions with release bolts the chain

tensioner must be untightened using the release bolt after

installation!

Inspect

Inspect

Press in the release pin with a hammer shaft until a click is

heard.

It must be possible to push in release bolt up to stop with

thumb and for it to slide back to its original position

automatically – the release bolt can no longer be pushed in

once the oil pressure has built up.

|

|

Remove Injection Pump Lock Pin KM-927.

Install

Install

|

Tighten fastening bolts (1) with bolt strength of 10.9 for

Simplex injection pump wheel (tightening torque 28 Nm / 20.6 lbf.

ft.) - 5 fastening bolts for Y 20 DTH as of MY 2003 and Y 22

DTR.

Insert Injection Pump Lock Pin KM-927 into fuel injection pump

lock bore again.

|

|

|

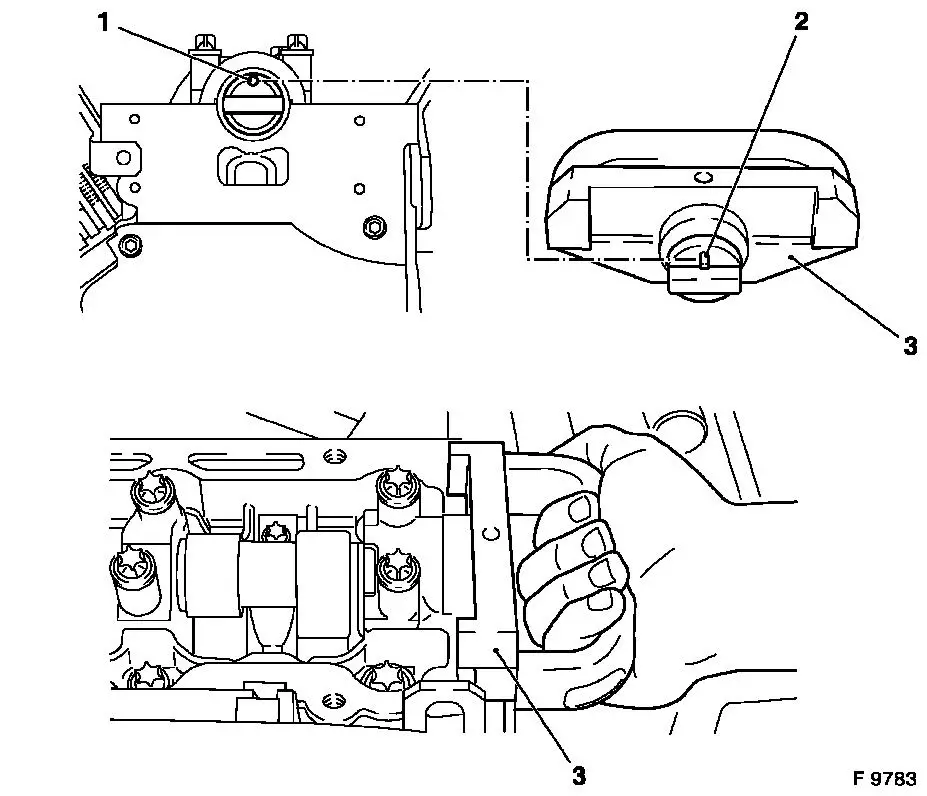

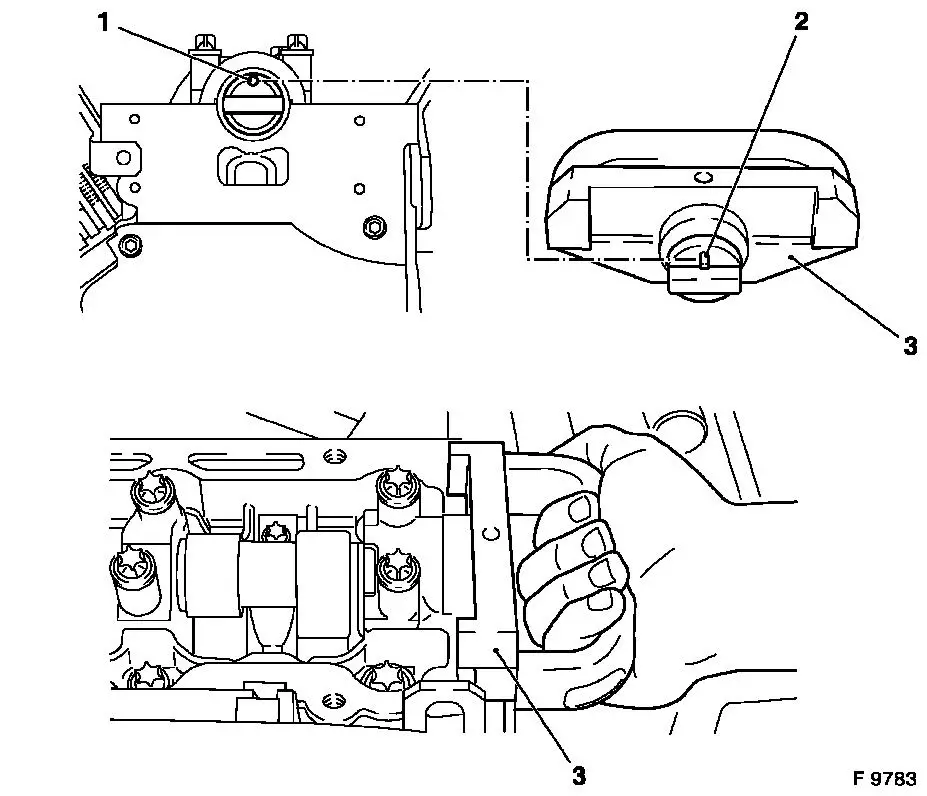

Apply Test Gauge KM-932 (3) to cylinder head – pin (2)

must engage in bore (1) of camshaft – if necessary, turn

camshaft at hex (short path).

Caution

Turn camshaft carefully and smoothly.

|

|

Install

Install

|

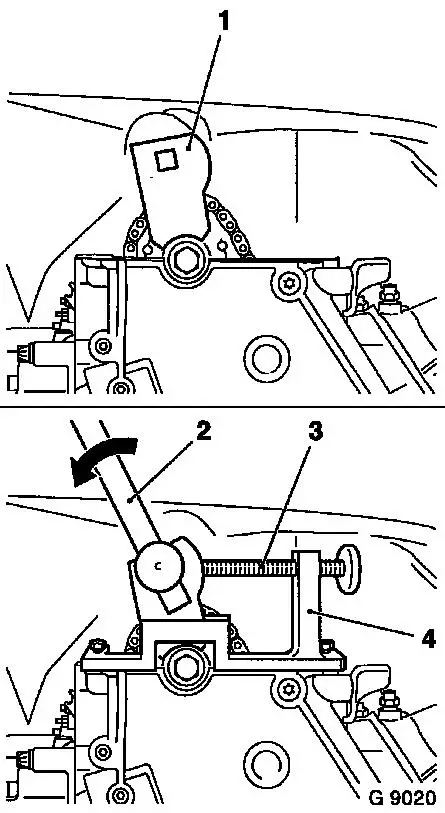

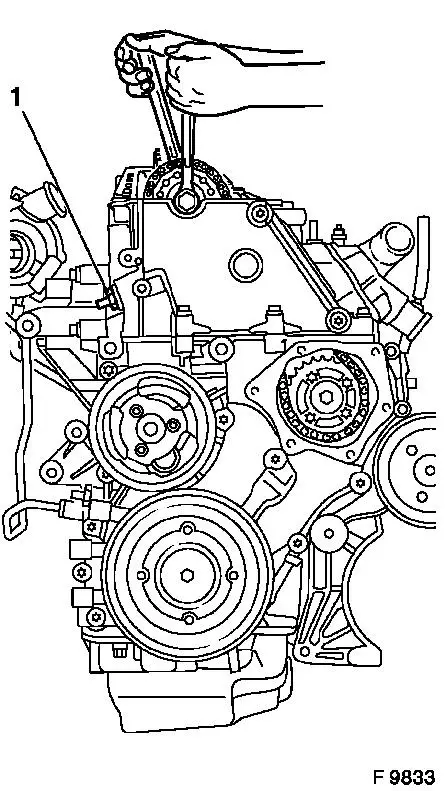

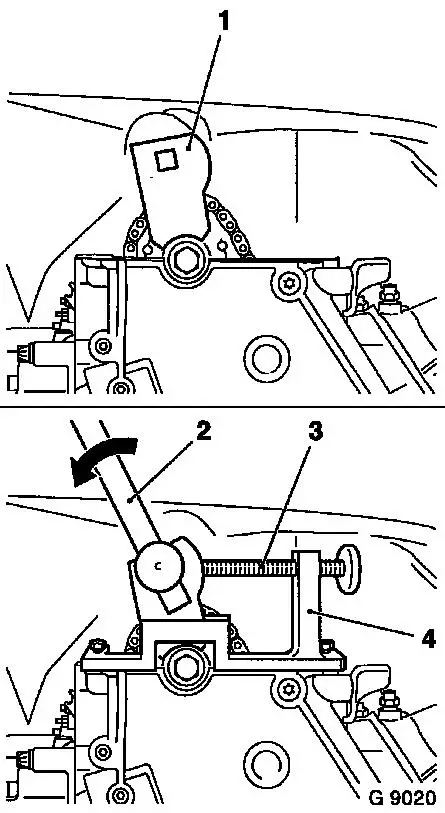

Insert carrier (1) of Adjuster KM-933 (4) vertically into

camshaft sprocket. Install Adjuster KM-933 on cylinder head.

Adjust Adjust

Use handle (2) to exert slight pressure on the carrier in the

direction of arrow (counter engine rotational direction) and fix in

place with holder bolt (3).

Injection Pump Lock Pin KM-927 must be able to be installed and

removed under suction. If this is not the case, decrease the

pressure on the carrier disk slightly via the holder bolt.

|

|

Install

Install

Fasten camshaft sprocket to camshaft – tightening torque

90 Nm / 66 lbf. ft. + 60° + 30°.

|

Insert Simplex chain tensioner (4) into cylinder head –

closed side of chain tensioner must point to tensioner blade.

Install Simplex chain tensioner screw plug (2) with new seal ring

(3) – tightening torque 60 Nm / 44 lbf. ft.

Caution

A distinction must be made between versions with and without

release bolts (1). In versions with release bolts the chain

tensioner must be untightened using the release bolt after

installation!

Inspect

Inspect

Press in the release pin with a hammer shaft until a click is

heard.

It must be possible to push in release bolt up to stop with

thumb and for it to slide back to its original position

automatically – the release bolt can no longer be pushed in

once the oil pressure has built up.

|

|

Remove Remove

Remove all locking and adjusting tools.

|

Adjust Adjust

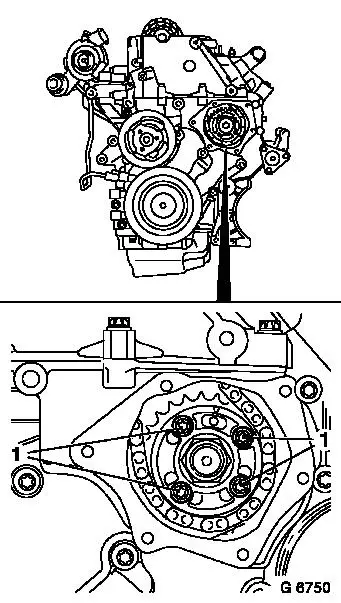

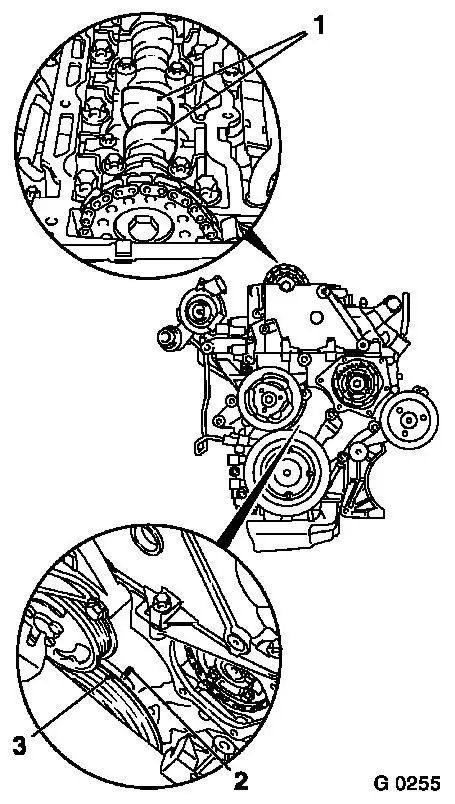

At fastening bolt of torsional vibration damper, turn crankshaft

two turns (approx. 720°) in engine rotational direction to just

before "1st cylinder TDC" – mark (3) on torsional vibration

damper is just before lug (2) on timing case.

Inspect

Inspect

In this position, the cams (1) of the 1st cylinder are just

before TDC (both cams point upwards).

|

|

Install

Install

|

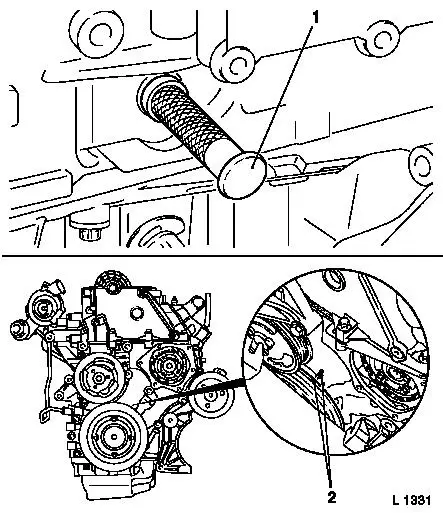

Insert Crankshaft Lock Pin KM-929 (1) in aperture for crankshaft

pulse pick-up and simultaneously slowly turn crankshaft further in

engine rotational direction at fastening bolt of torsional

vibration damper until crankshaft lock pin engages to stop in

cylinder block or crank web.

Inspect

Inspect

In this position, marks (2) must align.

|

|

|

Arrow (1) on simplex fuel injection pump sprocket must align

with recess in fuel injection pump flange and lock bore (2) in fuel

injection pump.

Install

Install

Insert Injection Pump Lock Pin KM-927 (3) in lock bore of fuel

injection pump.

|

|

|

Apply Test Gauge KM-932 (3) to cylinder head – pin (2)

must engage in bore (1) of camshaft.

|

|

Remove Remove

Remove all locking tools.

Install

Install

Install removed components – see operation "Engine, Lock

at 1st Cylinder TDC (Timing, Check)".

Option 2: Camshaft test gauge cannot be inserted

in cylinder head.

Note: Crankshaft is

locked at "1st cylinder TDC" with Lock Pin KM-929 and fuel

injection pump with Lock Pin KM-927.

Remove Remove

Remove Injection Pump Lock Pin KM-927.

|

Remove simplex chain tensioner (1) – note installation

position.

Remove fastening bolt for camshaft sprocket from camshaft

– counterhold with open-ended wrench on hex of camshaft.

Install

Install

Insert new bolt for camshaft sprocket and tighten hand-tight

– ensure that the camshaft sprocket is not tilted on the

camshaft. Camshaft sprocket must lie plane on the camshaft.

|

|

Inspect

Inspect

|

Arrow (1) on simplex fuel injection pump sprocket must align

with recess in fuel injection pump flange and lock bore (2) in fuel

injection pump.

Install

Install

Insert Injection Pump Lock Pin KM-927 (3) in lock bore of fuel

injection pump.

|

|

|

Apply Test Gauge KM-932 (3) to cylinder head – pin (2)

must engage in bore (1) of camshaft – if necessary, turn

camshaft at hex (short path).

Caution

Turn camshaft carefully and smoothly.

|

|

Install

Install

|

Insert carrier (1) of Adjuster KM-933 (4) vertically into

camshaft sprocket. Install Adjuster KM-933 on cylinder head.

Adjust Adjust

Use handle (2) to exert slight pressure on the carrier in the

direction of arrow (counter engine rotational direction) and fix in

place with holder bolt (3).

Injection Pump Lock Pin KM-927 must be able to be installed and

removed under suction. If this is not the case, decrease the

pressure on the carrier disk slightly via the holder bolt.

|

|

Install

Install

Fasten camshaft sprocket to camshaft – tightening torque

90 Nm / 66 lbf. ft. + 60° + 30°.

|

Insert Simplex chain tensioner (4) into cylinder head –

closed side of chain tensioner must point to tensioner blade.

Install Simplex chain tensioner screw plug (2) with new seal ring

(3) – tightening torque 60 Nm / 44 lbf. ft.

Caution

A distinction must be made between versions with and without

release bolts (1). In versions with release bolts the chain

tensioner must be untightened using the release bolt after

installation!

Inspect

Inspect

Press in the release pin with a hammer shaft until a click is

heard.

It must be possible to push in release bolt up to stop with

thumb and for it to slide back to its original position

automatically – the release bolt can no longer be pushed in

once the oil pressure has built up.

|

|

Remove Remove

Remove all locking and adjusting tools.

|

Adjust Adjust

At fastening bolt of torsional vibration damper, turn crankshaft

two turns (approx. 720°) in engine rotational direction to just

before "1st cylinder TDC" – mark (3) on torsional vibration

damper is just before lug (2) on timing case.

Inspect

Inspect

In this position, the cams (1) of the 1st cylinder are just

before TDC (both cams point upwards).

|

|

Install

Install

|

Insert Crankshaft Lock Pin KM-929 (1) in aperture for crankshaft

pulse pick-up and simultaneously slowly turn crankshaft further in

engine rotational direction at fastening bolt of torsional

vibration damper until crankshaft lock pin engages to stop in

cylinder block or crank web.

Inspect

Inspect

In this position, marks (2) must align.

|

|

|

Arrow (1) on simplex fuel injection pump sprocket must align

with recess in fuel injection pump flange and lock bore (2) in fuel

injection pump.

Install

Install

Insert Injection Pump Lock Pin KM-927 (3) in lock bore of fuel

injection pump.

|

|

|

Apply Test Gauge KM-932 (3) to cylinder head – pin (2)

must engage in bore (1) of camshaft.

|

|

Remove Remove

Remove all locking tools.

Install

Install

Install removed components – see operation "Engine, Lock

at 1st Cylinder TDC (Timing, Check)".

|