|

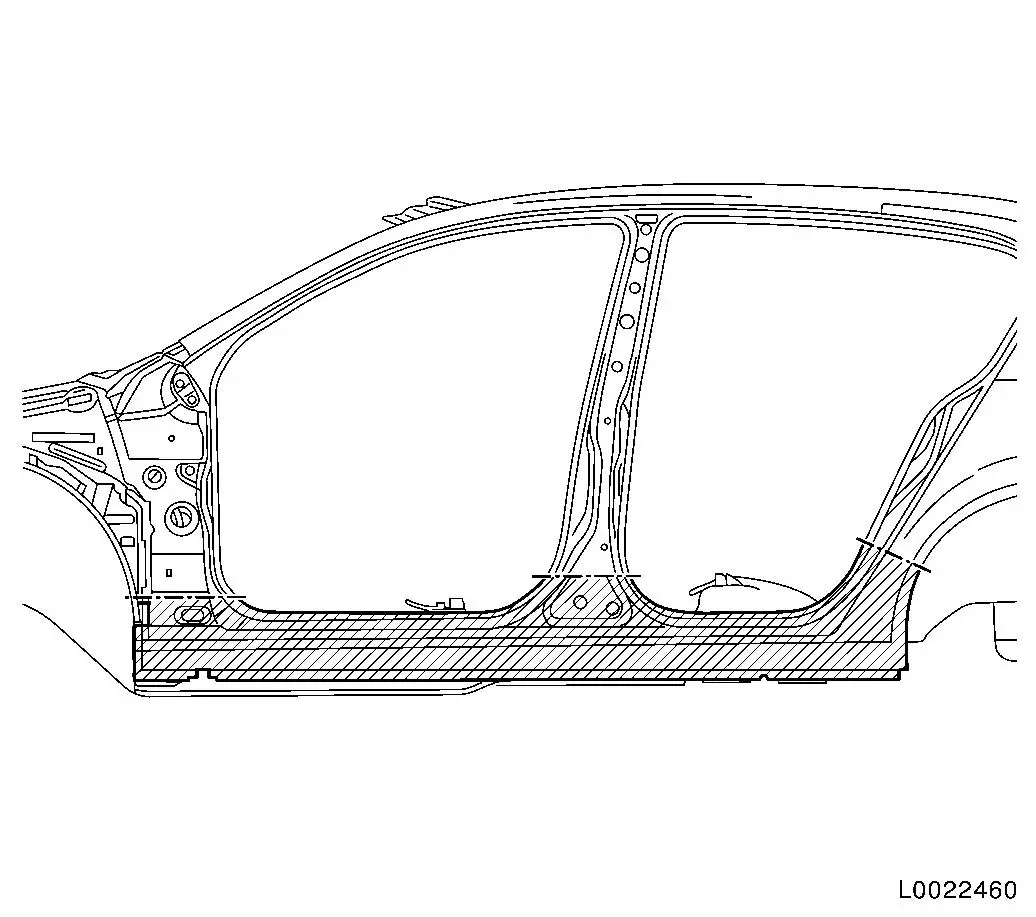

Replace sill panelling complete (models L35, L48,

L69)

Important: Note

specification for welded, brazed and riveted joints  and body repair

with structural adhesive ! and body repair

with structural adhesive !

Important: Observe

SPP, PSO welding parameters for resistance spot welding! See TIS

Newsletter for equipment recommendations!

Remove Remove

| 1. |

Detach attaching parts

|

|

| 2. |

Detach and drill away sill panelling

|

|

Install

Install

|

| 3. |

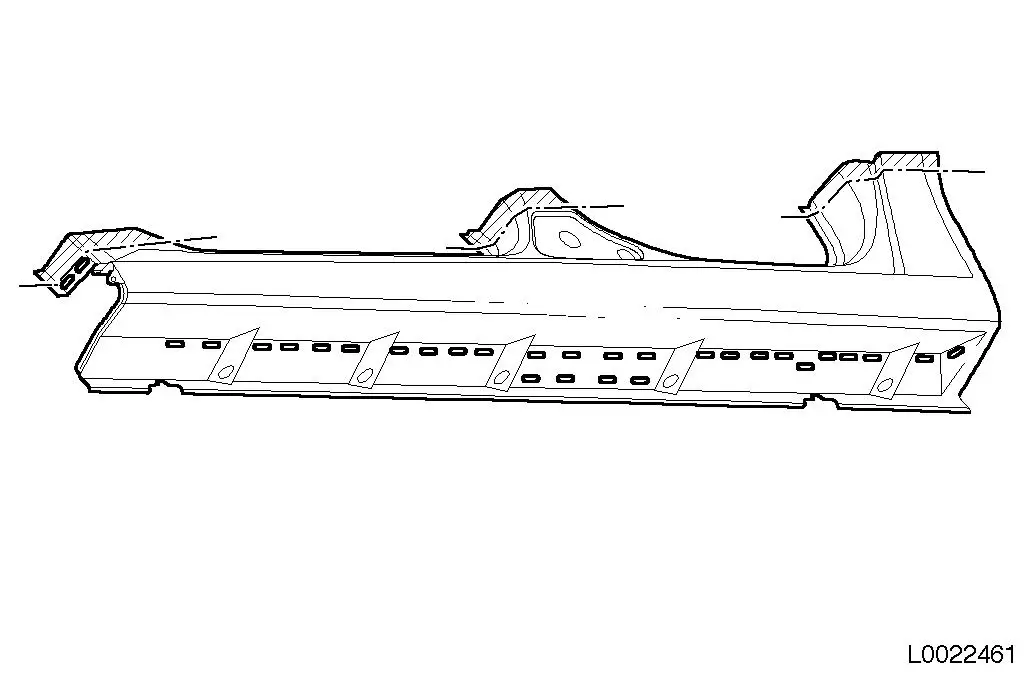

Prepare new sill panelling

| • |

Incorporate 30x (5x18 mm)

slots

|

|

|

|

| 4. |

Apply corrosion protection adhesive system

|

|

| 5. |

Adjust new sill panelling to fit

|

|

| 6. |

Weld in sill panelling

|

|

|

| 7. |

Weld in front sill panelling and MIG-braze

|

|

|

| 8. |

Weld in lower sill panelling and MIG-braze

|

|

|

| 9. |

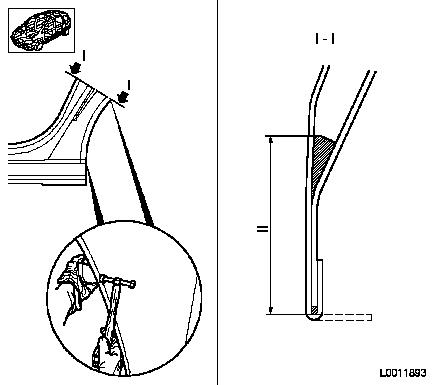

Bend the wheel arch

| • |

Using a suitable hammer, bend over the flanged edge, at the

same time holding a small mallet or block against it.

|

| • |

Bend over flanged edge using bending pliers KM-6396

|

| • |

Apply excess adhesive as a seam seal and corrosion protection

using a spatula or flat paintbrush

| – |

Use structural adhesive in area (II)

|

|

|

|

|

| 10. |

MIG-braze rear sill panelling

|

|

| 11. |

Grind MIG-brazed seams in visible areas to match contour

|

| 12. |

Seal body, weld and brazing seams

Note: Observe corrosion

protection measures for seam seals.

|

| 13. |

Apply underseal.

Note: Observe corrosion

protection measures for PVC protection.

|

| 14. |

Seal cavity

Note: Observe

protective wax corrosion protection measures.

|

|