|

Engine, Remove and Install

Remove Remove

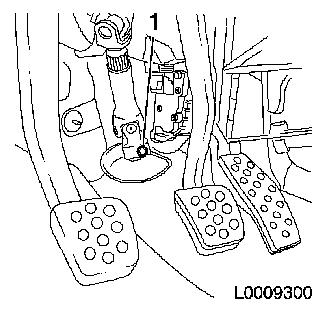

Important: Move steering wheel to

straight-ahead position

|

| 2. |

Remove steering column interim spindle

| • |

Engage steering wheel lock

|

|

|

|

| 3. |

Disconnect battery

| • |

Detach ground connection from ground terminal

|

|

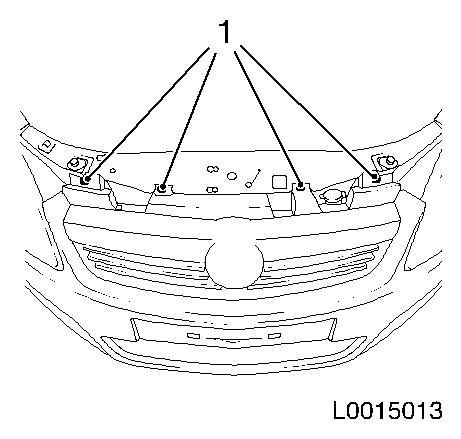

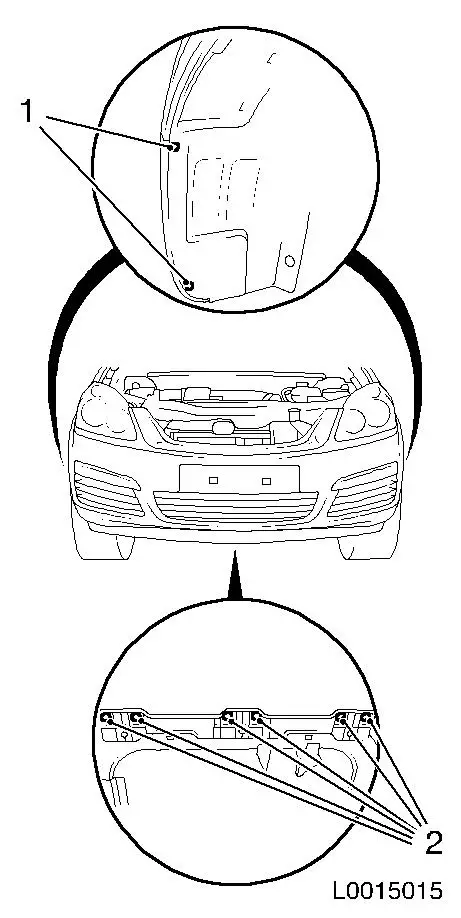

| 5. |

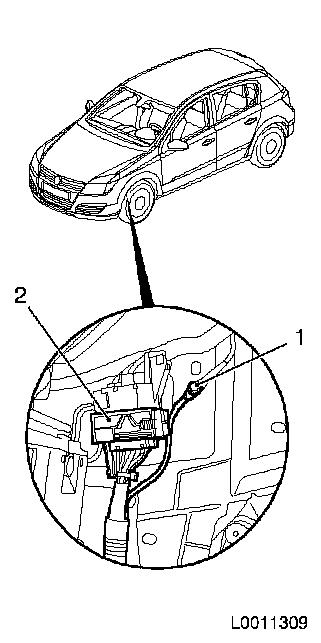

Detach radiator grille (2)

| • |

Detach 4x body-bound rivets (1)

|

| • |

Release 6x lugs from front panelling

|

|

|

|

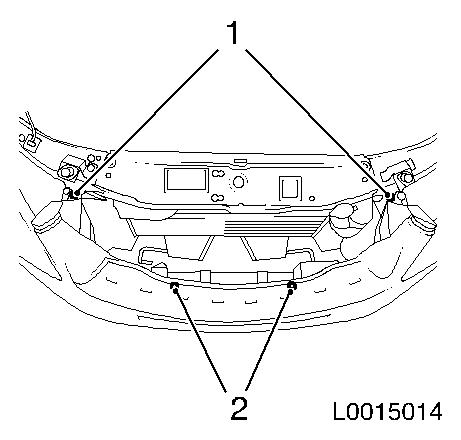

| 6. |

Detach front panelling at top

| • |

Remove 2x body-bound rivets (2)

|

| • |

Disconnect wiring harness connector.

|

|

|

|

| 7. |

Empty climate control system

| • |

Connect service station

|

| • |

Blue hose to low-pressure service connection with small

diameter

|

| • |

Red hose to high-pressure service connection with large

diameter

Note: Read Service

Station operating instructions carefully

|

| • |

Determine quantity of condenser extracted at the oil separator

of the Service Station

|

|

|

|

| 8. |

Undo 2x front wheels

| • |

Slacken 10x wheel bolts

|

|

| 9. |

Raise vehicle by half its height

|

| 10. |

Remove 2x front wheels

| • |

Unscrew 10x wheel bolts

|

|

| 11. |

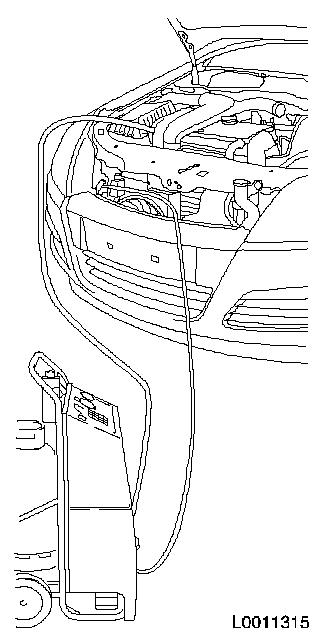

Remove front panelling

| • |

Remove 6x body-bound rivets (2)

|

|

|

|

| 12. |

Remove front panelling

Note: Use a second

person

| • |

Push front panelling upwards at side and pull out of

bracket

|

| • |

Detach front panelling from bracket

|

| • |

Unclip outside temperature sensor

|

|

| 13. |

Raise vehicle by half its height

|

| 14. |

Detach the lower engine cover and right engine splash guard

|

| 15. |

Place collecting basin underneath.

|

| 16. |

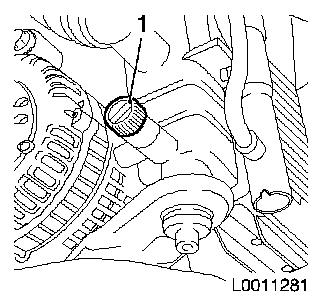

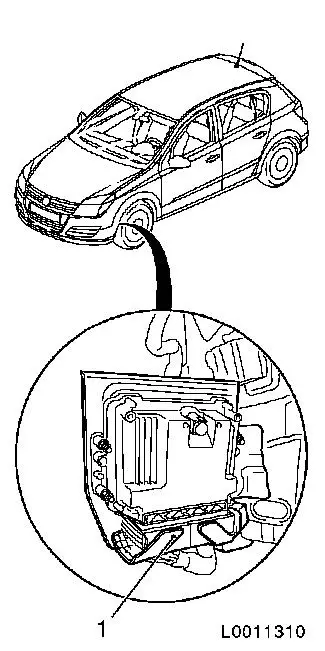

Drain coolant

| • |

Open drain bolt on radiator (1)

|

|

|

|

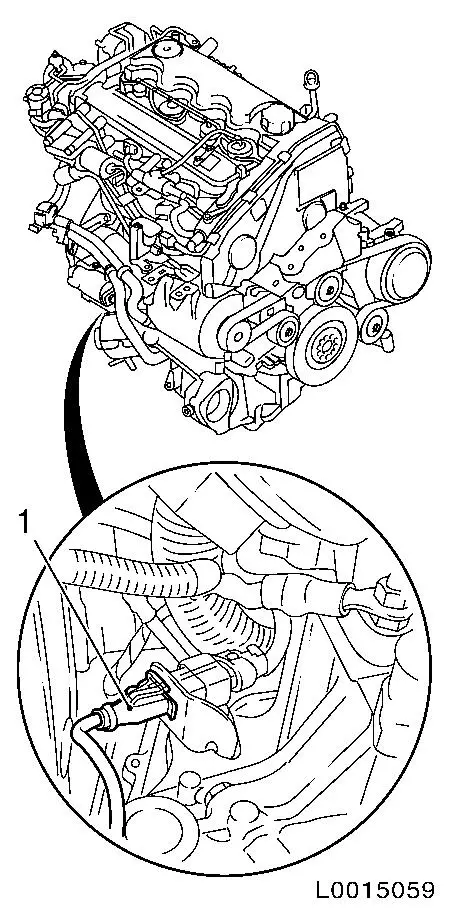

Important: Protect the exhaust

pipe from uncontrolled sagging as deflection as little as 5-10

degrees from the prescribed installation position could damage the

flex pipe housed within it.

|

| 17. |

Remove front exhaust pipe (1)

| • |

Detach from particle filter flange

|

| • |

Detach from pre-catalytic converter

|

|

|

|

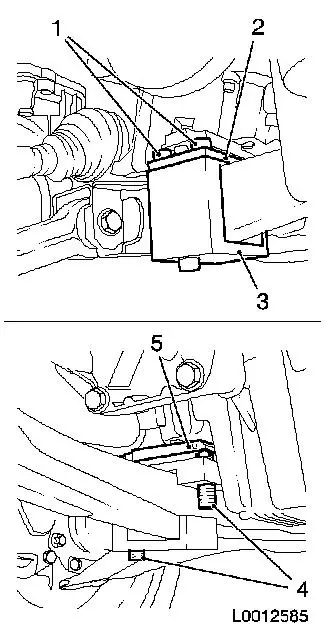

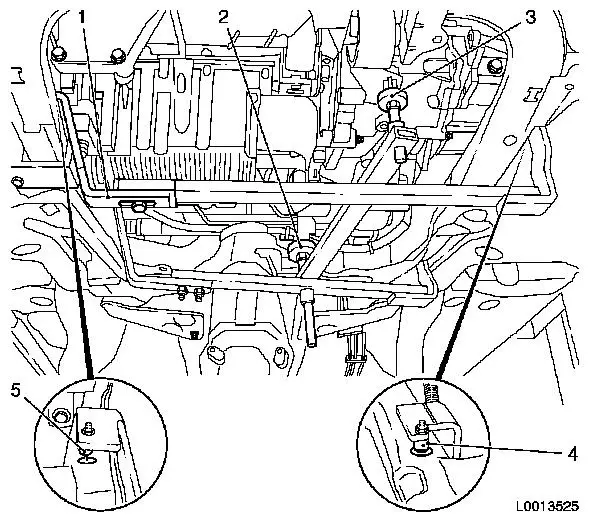

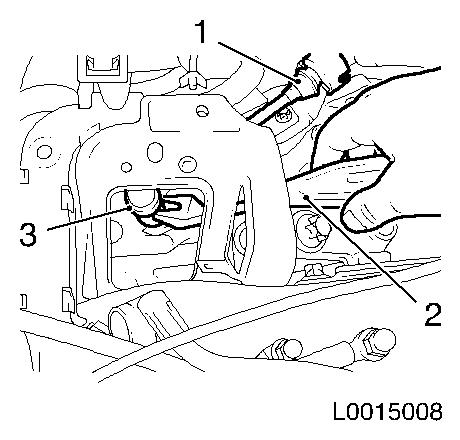

| 18. |

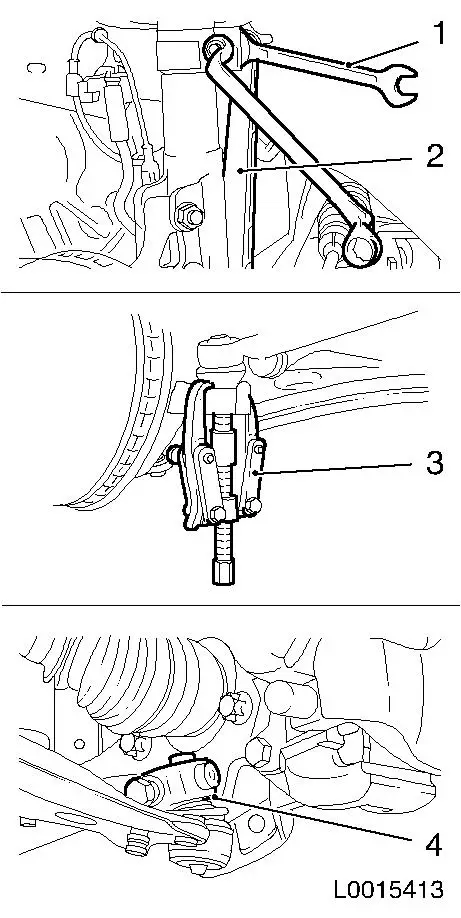

Fit and adjust KM-6397

| • |

Fit KM-6397

| – |

Insert upper bracket (2) with support plate below lower oil

pan

|

| – |

Attach lower bracket (3)

|

|

| • |

Adjust KM-6397

| – |

Screw in 2x adjusting bolts (4)

Note: Support plate (5)

must lie flat against oil pan

|

|

|

|

|

|

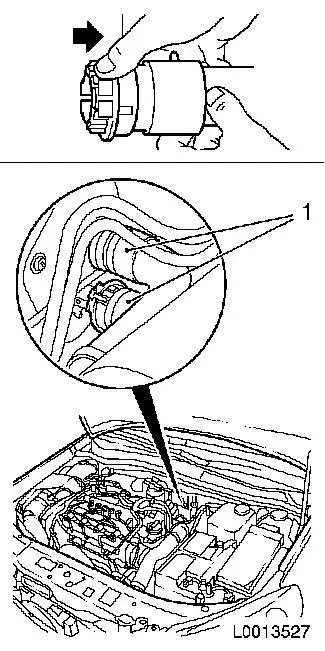

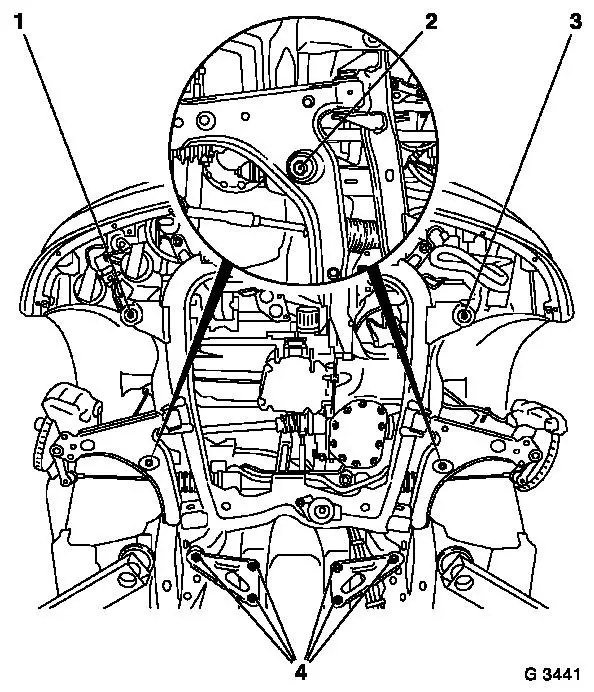

| 19. |

Fit KM-6001-A

Note: Attaching KM-6001-A guarantees perfect alignment of the

drive unit with the front axle body

| • |

Detach front right bracket (1)

|

| • |

Attach front right bracket

|

| • |

Insert journals (4) and (5) in guide holes in front axle

body

|

| • |

Tighten 2x guide rails

| – |

Tighten 3x bolted connections

|

|

| • |

Adjust support bearings (2) and (3)

Note: The guide

journals must be seated free from play in the support bearings

|

|

|

| 20. |

Lower vehicle by its full height

|

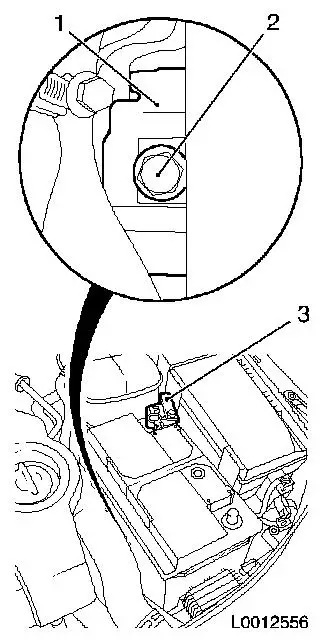

| 21. |

Remove battery

| • |

Detach positive terminal (3) from positive pole

|

| • |

Remove battery insulation

|

|

|

|

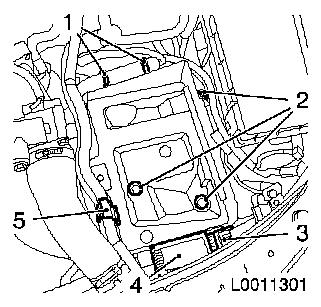

| 22. |

Remove battery support.

| • |

Remove pre-glow system control unit (4)

|

| • |

Unclip coolant hose bracket (5)

|

|

|

|

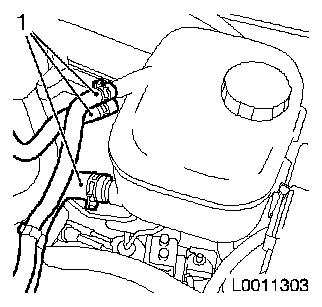

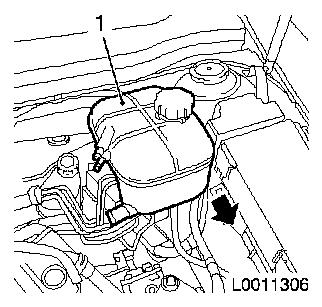

| 23. |

Detach 3x coolant hose (1) from coolant expansion tank

|

|

|

| 24. |

Remove coolant expansion tank (1)

| • |

Pull from bracket in direction of arrow

|

|

|

|

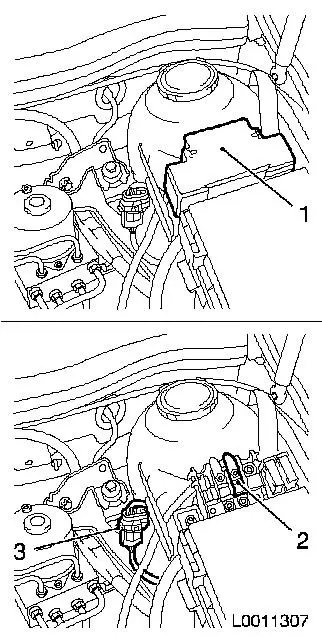

| 25. |

Disconnect steering wiring harness

| • |

Remove fuse carrier cover (1)

|

| • |

Detach positive cable (2) from fuse carrier

Note: Mark installation

position

|

| • |

Disconnect wiring harness connector (3)

|

| • |

Detach earth cable from negative battery terminal

|

| • |

Expose wiring harness and put aside on drive unit

|

|

|

|

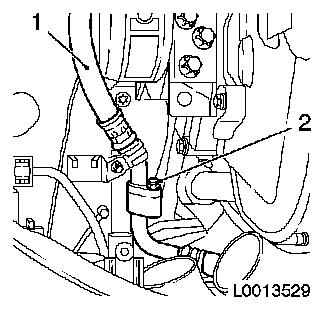

| 26. |

Disconnect upper engine timing wiring harness

| • |

Detach positive cable (1) from fuse carrier

Note: Mark installation

position

|

| • |

Release and unplug wiring harness plug (2)

|

| • |

Put engine timing wiring harness with pre-heating system

control unit (3) aside on drive unit

|

|

|

|

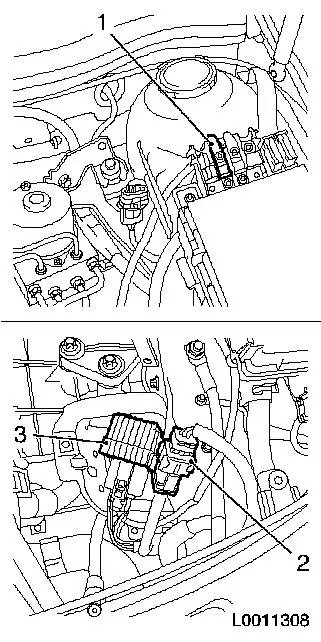

| 27. |

Disconnect starter wiring harness (1)

| • |

Disconnect wiring harness connector (3)

|

| • |

Detach wiring harness from positive terminal

|

| • |

Detach earth connection wiring harness from body

|

| • |

Put wiring harness aside onto drive unit

|

|

|

|

| 28. |

Detach selector lever actuation cable

| • |

Lever out head (3) from selector lever with KM-569-A (2)

|

| • |

Unclip cable (1) upward

|

|

|

|

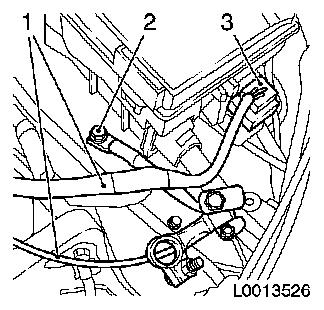

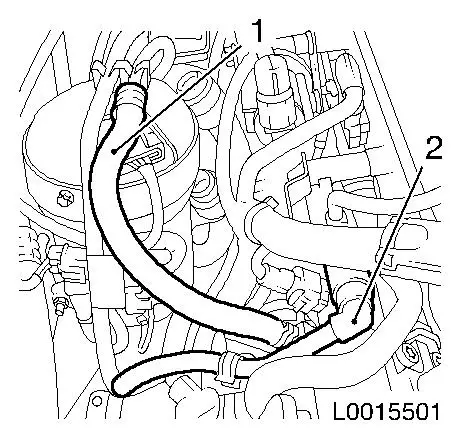

| 29. |

Disconnect 2x coolant hose (1) from heater core

| • |

Release 2x coolant hoses in direction of arrow

Note: Mark

affiliation

|

|

|

|

| 30. |

Remove brake servo vacuum line

| • |

Disconnect quick-release fitting (2)

|

|

|

|

| 31. |

Detach 2x fuel line from fuel return damping case

Note: Open fuel

connections must be sealed with appropriate plugs

| • |

Detach fuel return line (2) with KM-796-A

| – |

Unclip fuel line from bracket

|

|

| • |

Detach fuel supply line (1) from high-pressure pump

|

|

|

|

| 32. |

Remove air cleaner housing

|

| 33. |

Disconnect air conditioning low pressure line (1)

| • |

Unclip wiring harness of turbocharger solenoid valve from low

pressure line

|

|

|

|

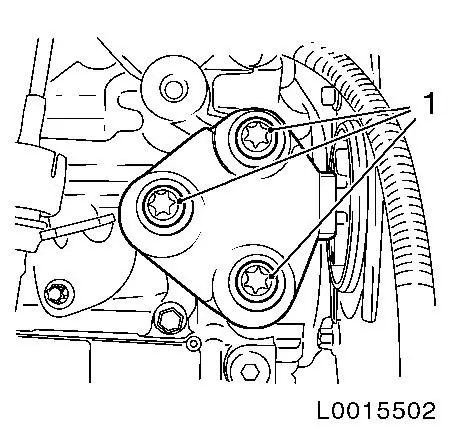

| 34. |

Detach right engine damping block from engine damping block

adapter

|

|

|

| 35. |

Detach left engine damping block from transmission

|

|

|

| 36. |

Raise vehicle by half its height

|

| 37. |

Detach AC high pressure line (1) from pressure sensor

|

|

|

| 38. |

Disconnect turbocharger solenoid valve (2)

| • |

Disconnect 2x vacuum lines (3)

Note: Mark vacuum

line

|

| • |

Disconnect wiring harness plug (1)

|

|

|

|

| 39. |

Detach cooling module wiring harness

| • |

Disconnect wiring harness plug (2)

|

|

|

|

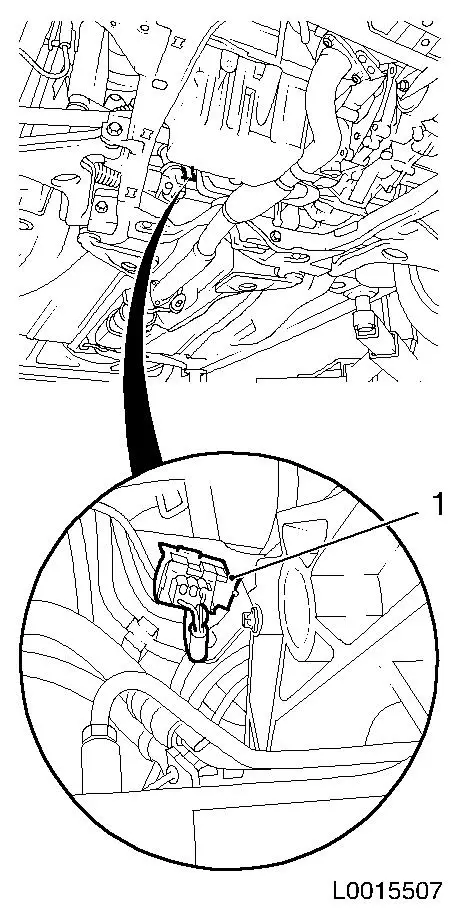

| 40. |

Detach wiring harness from engine control unit

| • |

Release and unplug wiring harness plug (1) from engine control

unit

|

| • |

Unclip wiring harness from bracket

|

| • |

Unclip 2x wiring harness from body

|

|

|

|

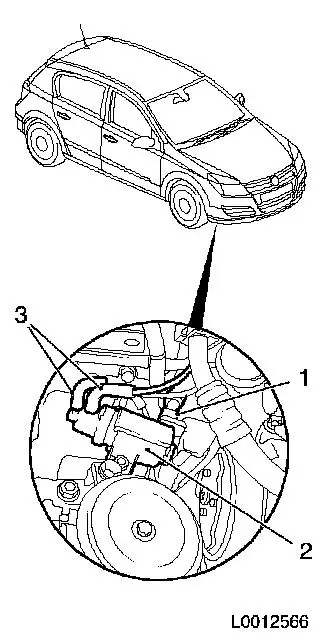

| 41. |

Detach 2x swing arms (2)

| • |

Unscrew 2x nuts

| – |

Use spanner (1) to hold against flat surface

|

|

|

| 42. |

Detach 2x tie rods

| • |

2x nuts

| – |

Use KM-161-B (3) to press out of

steering knuckle

|

|

|

| 43. |

Detach 2x steering knuckle pins

| • |

Detach 2x screw connections

|

| • |

Spread steering knuckle pins with KM-915 (4) and draw guiding joint out of steering

knuckle

|

|

|

|

| 44. |

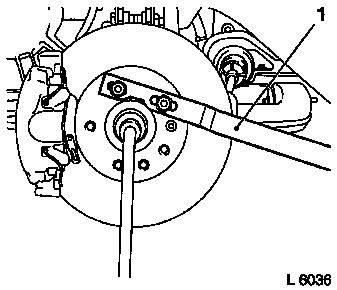

Detach 2x axle shafts

| • |

Unscrew 2x nuts

| – |

Counterhold at wheel hub with KM-468-B (1)

|

|

|

|

|

| 45. |

Raise vehicle by half its height

|

| 46. |

Unplug wiring harness plug of particle filter temperature

sensor (1)

| • |

Unclip wiring harness plug from bracket

|

| • |

Unclip wiring harness from front axle body bracket

|

|

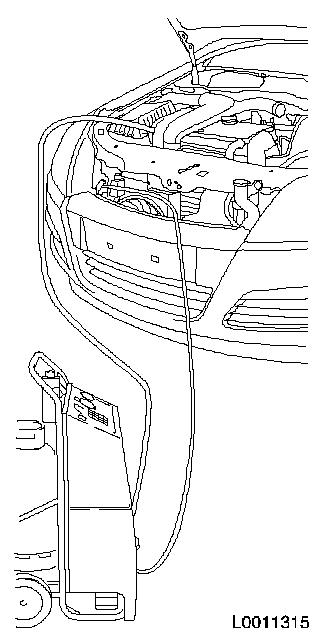

|

|

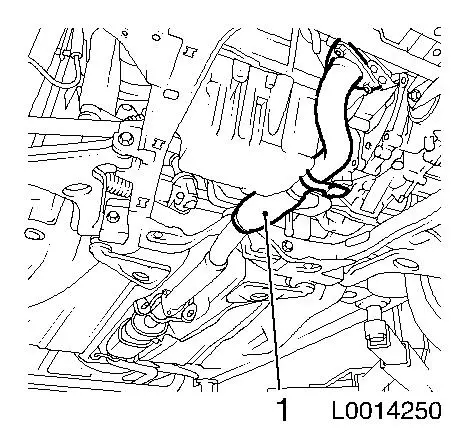

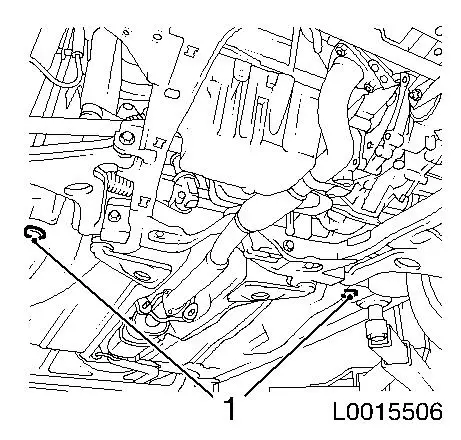

| 47. |

Release and unplug bulkhead wiring harness plug (1)

|

|

|

| 48. |

Remove 2x underbody closure plug (1)

|

|

|

|

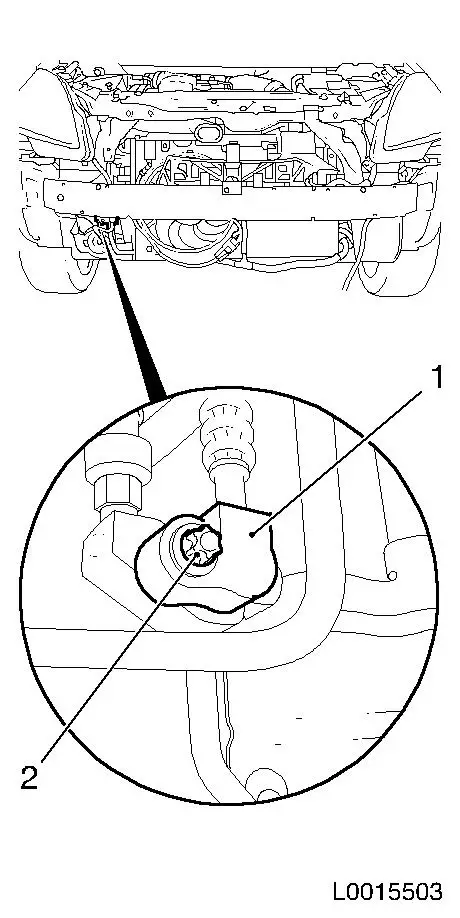

| 49. |

Fit KM-904 in conjunction with KM-6390

| • |

Attach to hydraulic lifter

Note: Use hydraulic

jack that can be lowered to a height of at least 100 cm

|

| • |

Lower centring pins (1)

|

| • |

Place under front axle body, ensure there is no play

| – |

Centring pins (2) must engage in the relevant holes in the

front axle body

|

|

|

|

|

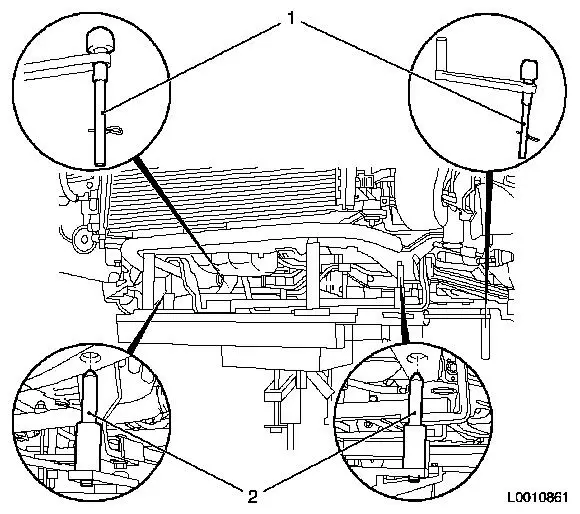

Important: Do not use an impact

screwdriver!

|

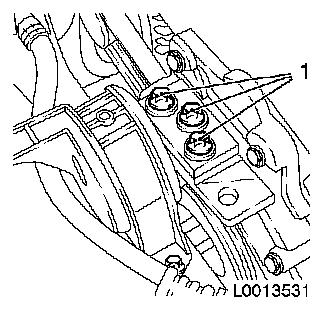

| 50. |

Remove front axle body

| • |

Unscrew 10x bolts (1...4)

Note: Note different

bolt lengths

|

|

|

Important: Ensure that no

attached parts are damaged.

|

| 51. |

Move out front axle body with engine

Note: Use a second

person

|

| 52. |

Check thread

| • |

Check ease of movement of 10x cage nuts, replacing if

necessary

|

|

Important: Ensure that no

attached parts are damaged.

|

| 53. |

Raise and align front axle body

Note: Use a second

person

| • |

Insert centring pins in underbody

|

|

Install

Install

Important: Do not use an impact

screwdriver!

|

| 54. |

Fit front axle body

| • |

Tighten 10x new bolt 90 Nm + 45° +

15°

Note: Note different

bolt lengths

|

|

| 55. |

Detach KM-904 together with KM-6390

|

| 56. |

Install 2x underbody closure plug

|

| 57. |

Lower vehicle by its full height

|

| 58. |

Attach right engine damping block to engine damping block

adapter

|

| 59. |

Attach left engine damping block to transmission

|

| 60. |

Connect air conditioning low pressure line

| • |

Clip wiring harness of turbocharger solenoid valve to low

pressure line

|

|

| 61. |

Install air cleaner housing

|

| 62. |

Attach 2x fuel line to fuel return damping case

| • |

Attach fuel return line to high-pressure pump

|

| • |

Attach fuel supply line

|

|

Warning: Connection must audibly

engage

|

| 63. |

Connect brake servo vacuum line

|

| 64. |

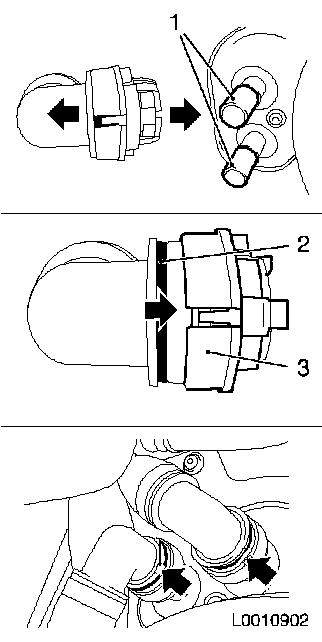

Attach 2x coolant hoses to heater core

| • |

Slide 2x quick release fitting locking mechanisms in direction

of arrow as far as they will go

| – |

The plastic rings (blue) are hidden

|

|

| • |

Fit 2x quick release fittings onto heater core connecting piece

(1) as far as they will go

Note: Pay attention to

coloured markings!

|

| • |

Slide 2x quick release fitting locking mechanisms (3) in

direction of arrow as far as they will go

| – |

The plastic rings (blue) must be visible

|

|

| • |

Check that quick release fittings are correctly seated and that

plastic rings (arrows) are visible

|

|

|

|

Important: Shift cables must not

be stretched, twisted or kinked.

|

| 65. |

Attach selector lever actuation cable

| • |

Clip in cable from above

|

| • |

Clip head into selector lever

|

|

| 66. |

Connect starter wiring harness

| • |

Connect and lock wiring harness plug

|

| • |

Attach earth connection wiring harness to body

|

| • |

Attach wiring harness to positive terminal

|

|

| 67. |

Connect engine timing wiring harness (top)

| • |

Attach positive cable to fuse carrier

Note: Pay attention to

installation position.

|

| • |

Connect and lock wiring harness plug

|

|

| 68. |

Connect steering wiring harness

| • |

Fix wiring harness plug

|

| • |

Attach positive cable to fuse carrier

Note: Pay attention to

installation position

|

| • |

Attach earth cable to negative battery terminal

|

| • |

Install fuse carrier cover

|

|

| 69. |

Install coolant expansion tank

|

| 70. |

Attach 3x coolant hose to coolant expansion tank

|

| 71. |

Raise vehicle by half its height

|

| 72. |

Install 2x axle shafts into wheel hub

| • |

Insert guiding joint into steering knuckle

|

| • |

Tighten 2x nut 150 Nm , slacken

45° , then tighten to 250 Nm

|

| • |

Counterhold at wheel hub with KM-468-B

|

|

| 73. |

Attach 2x guide joints to steering knuckle

| • |

Tighten 2x new screwed joint 50

Nm

|

|

| 74. |

Attach 2x tie rods to steering knuckle

| • |

Tighten 2x new nut 30 Nm + 90° +

15°

|

|

| 75. |

Attach 2x swing arms to spring strut support tube

Note: Use spanner to

counterhold against flat surface

| • |

Tighten 2x new nut 55 Nm

|

|

| 76. |

Attach wiring harness to engine control unit

| • |

Connect wiring harness plug to control unit

|

| • |

Clip wiring harness into bracket

|

| • |

Clip in 2x wiring harness to body

|

|

| 77. |

Attach cooling module wiring harness

| • |

Connect and lock wiring harness plug

|

| • |

Clip in 3x wiring harness brackets

|

|

| 78. |

Connect charge air control solenoid valve

| • |

Connect 2x vacuum lines

Note: Pay attention to

marks.

|

| • |

Fix wiring harness plug

|

|

| 79. |

Attach AC high pressure line to pressure sensor

|

| 80. |

Raise vehicle by half its height

|

| 83. |

Connect wiring harness plug of particle filter temperature

sensor

| • |

Clip wiring harness plug into bracket

|

| • |

Clip wiring harness into front axle body bracket

|

|

| 84. |

Connect and lock bulkhead wiring harness plug

|

| 85. |

Install front exhaust pipe

Important: Prevent exhaust system

from sagging in an uncontrolled manner. Even flex pipe bending of 5

- 10 degrees from intended installation position can cause damage

that may result in total failure of the flex pipe

|

| • |

Replace 2x seals

|

| • |

Attach to particle filter flange

| – |

Tighten 3x new nut 20 Nm

|

|

| • |

Attach to pre-catalytic converter

| – |

Tighten 3x new nut 20 Nm

|

|

| • |

Attach to oil pan

| – |

Apply assembly paste (white)

|

|

|

| 86. |

Install lower engine cover and right engine splash guard

|

| 87. |

Lower vehicle by half its height

|

| 88. |

Install front panelling

Note: Use a second

person

| • |

Clip in outside temperature sensor

|

| • |

Attach front panelling to bracket

|

| • |

Clip in the front panelling on the side

|

|

| 89. |

Attach front panelling at bottom

| • |

Install 6x body-bound rivets

|

|

| 90. |

Fit 2x front wheels

| • |

Screw in 10x wheel bolts

|

|

| 91. |

Lower vehicle by half its height

|

| 92. |

Fasten 2x front wheels

| • |

Tighten 10x wheel bolt 110 Nm

|

|

| 93. |

Attach front panelling at top

| • |

Fasten 2x body-bound rivets

|

|

| 94. |

Install battery holder

| • |

Attach pre-glow system control device

|

| • |

Clip on coolant hose bracket

|

|

| 95. |

Install battery

| • |

Insert battery insulation

|

| • |

Attach positive connection to positive terminal

|

|

| 96. |

Evacuate and charge air conditioning system

| • |

Connect service station

|

| • |

Connect blue hose to low pressure service connection with small

diameter

|

| • |

Connect red hose to high pressure service connection with large

diameter

Note: Read Service

Station operating instructions carefully.

|

| • |

Use the Service Station to insert the quantity of new

compressor lubricant into the climate control system that was

extracted when it was emptied.

| – |

Fill air conditioning system with R 134a refrigerant

|

|

|

|

|

| 97. |

Connect battery

| • |

Attach ground connection to ground terminal

|

|

| 99. |

Install radiator grille

| • |

6x clip in front panelling

|

| • |

Install 4x body-bound rivets

|

|

| 100. |

Install steering column intermediate shaft clamp bolt

| • |

Tighten new bolt 22 Nm

Note: Clean thread

before re-using and insert bolt with locking compound (blue). The

maximum installation time including torque check is 10 minutes.

|

|

| 101. |

Top up coolant or ensure correct quantity is present.

|

| 102. |

Program volatile memories

|

|