|

Piston with Con-rod, Remove and Install

Remove Remove

| 3. |

Raise vehicle by its full height

|

| 4. |

Place collecting basin underneath.

|

| 5. |

Drain engine oil

| • |

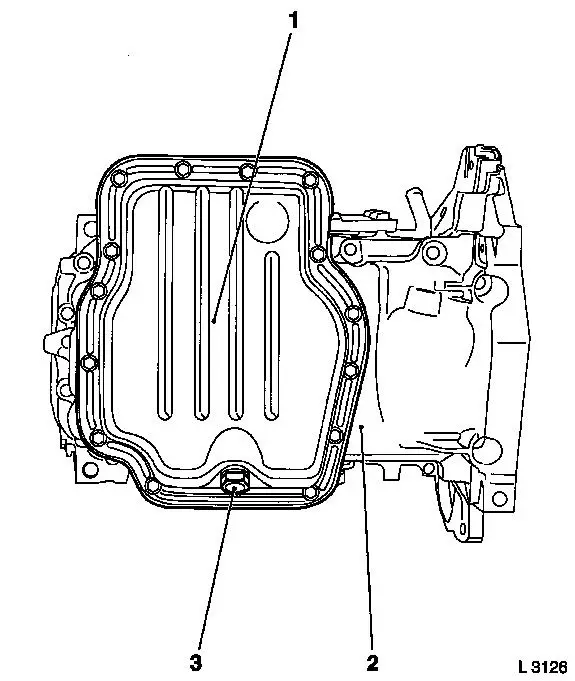

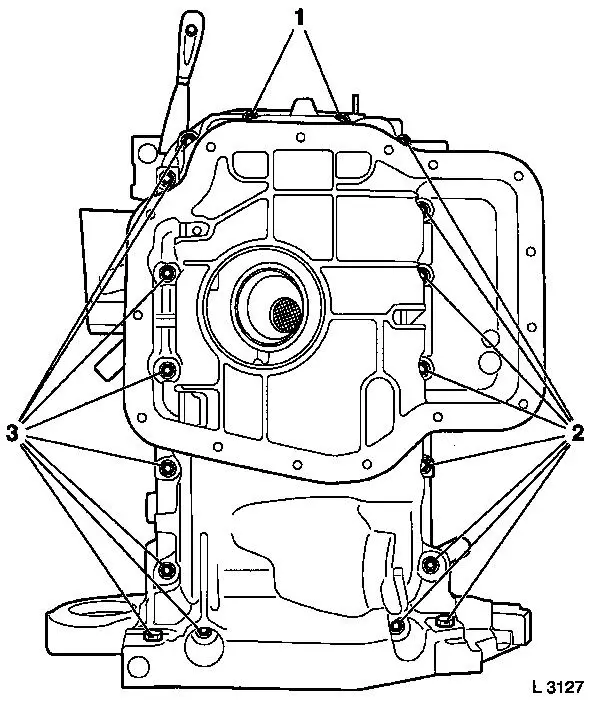

Unscrew oil drain bolt (3)

|

| • |

Tighten oil drain bolt 78.4 Nm

|

|

| 6. |

Detach lower part of oil pan (1) from upper part of oil pan (2)

with KM-J-37228

|

|

|

| 7. |

Remove front exhaust pipe

| • |

Detach from start-up catalytic converter

|

| • |

Detach from central silencer

|

|

|

|

| 8. |

Detach oil dipstick guide tube from upper part of oil pan

|

|

|

| 9. |

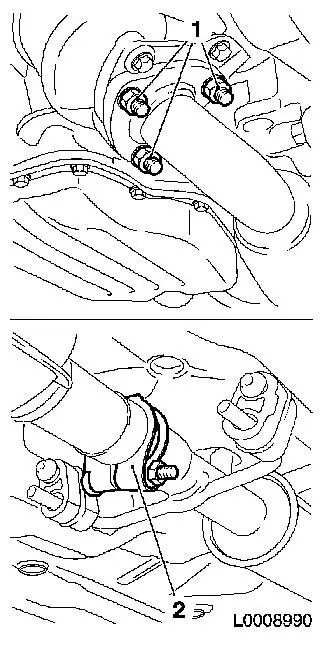

Disconnect engine oil level sensor wiring harness plug (1)

|

|

|

| 10. |

Detach upper part of oil pan from cylinder block

| • |

Unscrew bolt (2) and (3)

|

| • |

Separate upper part of oil pan from cylinder block with a broad

spatula

|

|

|

|

| 11. |

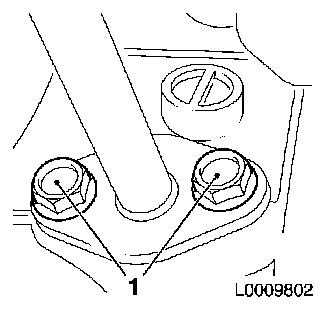

Remove con-rod bearing cap

| • |

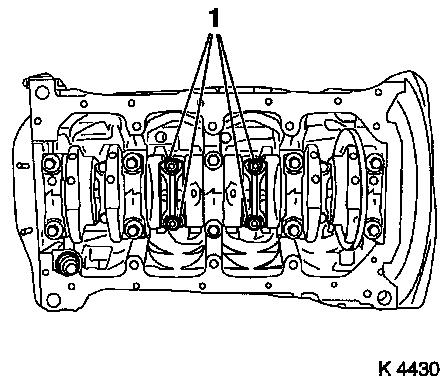

Cylinder 2 and 3

| – |

Detach 4x screw connections (1)

|

|

| • |

Remove con-rod bearing cap

Note: Note

identification mark on con-rod bearing cap and con-rod. Apply

identification mark if not present

|

|

|

|

| 12. |

Turn crankshaft

| • |

Turn (180°) in direction of engine rotation

|

|

| 13. |

Remove con-rod bearing cap

| • |

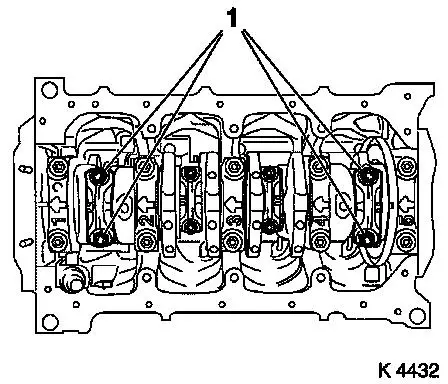

Cylinder 1 and 4

| – |

Detach 4x screw connections (1)

|

|

| • |

Remove con-rod bearing cap

Note: Note

identification mark on con-rod bearing cap and con-rod. Apply

identification mark if not present

|

|

|

|

| 14. |

Lower vehicle by its full height

|

| 15. |

Take out 4x piston

| • |

Remove combustion residue

|

|

| 16. |

Remove con-rod bearing shells from con-rod and con-rod bearing

cap

Note: Mark con-rod

bearing shells and set aside in order

|

| 17. |

Visually check components

| • |

Crank drive, valve control, cylinder head, cylinder block,

exhaust manifold, turbocharger, valve drive, ribbed V-belt

drive

|

|

Install

Install

| 18. |

Install con-rod bearing shells

Note: Note marking

|

| 19. |

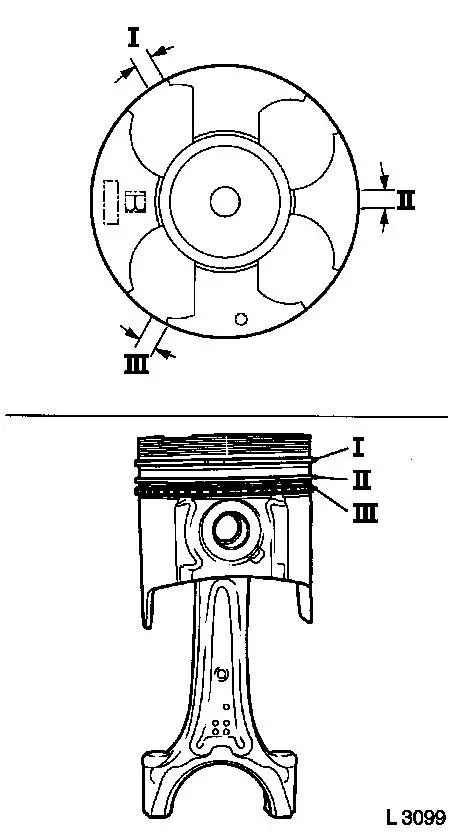

Adjust piston rings

| • |

Arrange joints of piston rings offset by 120°

| – |

I Rectangular compression ring (first compression ring)

|

| – |

II Tapered compression ring (second compression ring)

|

| – |

III bevelled cap ring (oil scraper ring)

|

|

|

|

|

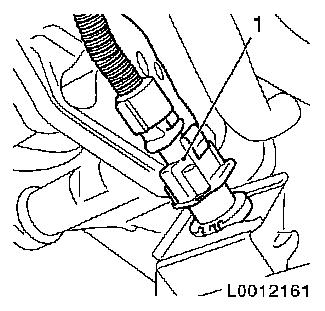

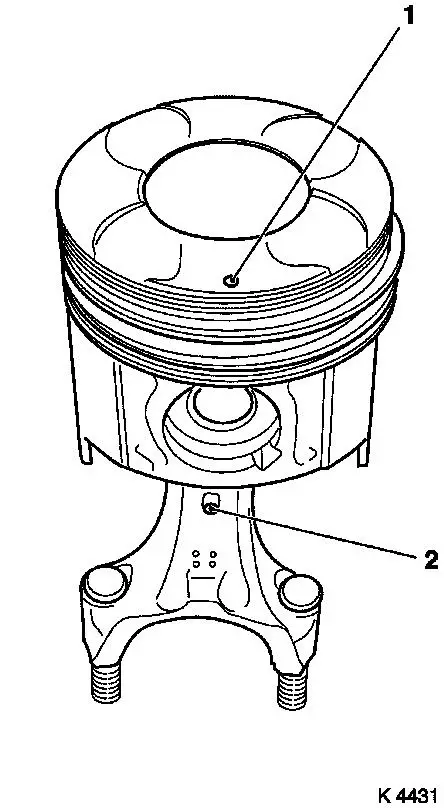

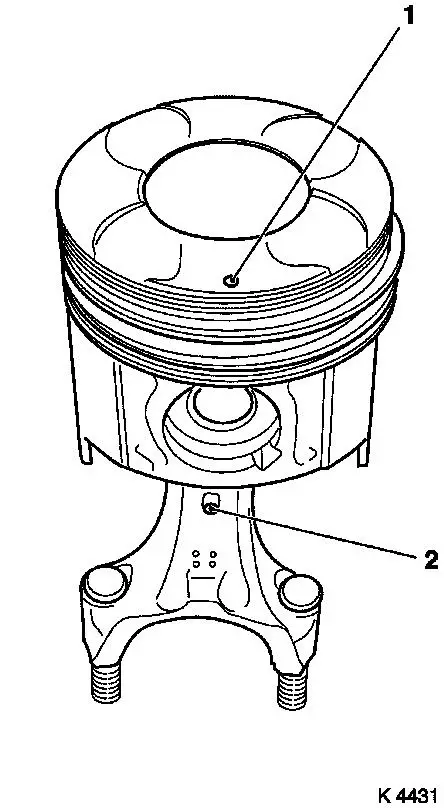

Important: Marking (1) on piston

head and marking (2) on con-rod point towards the engine timing

side

|

| 20. |

Install piston with con-rod in cylinder block

| • |

Force piston rings together with piston ring tensioning

belt

|

|

|

|

| 21. |

Raise vehicle by its full height

|

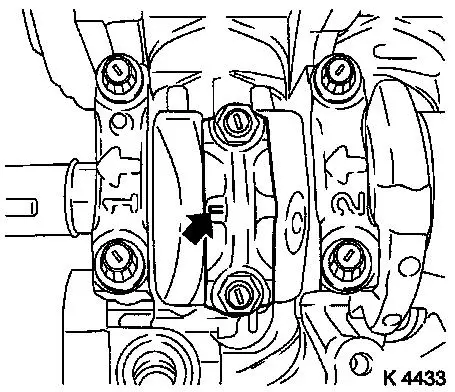

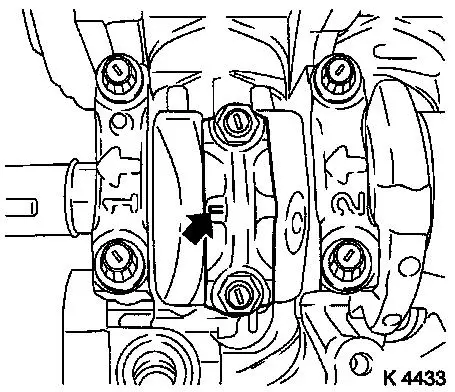

Important: Note cylinder sequence

marking on con-rod bearing cap and con-rod. Narrow bead (arrow)

points towards engine timing side

|

| 22. |

Install con-rod bearing cap

| • |

Tighten 2x new screwed joint 24.5 Nm +

100° + 15°

|

|

|

|

| 23. |

Turn crankshaft

| • |

Turn (180°) in direction of engine rotation

|

|

| 24. |

Lower vehicle by its full height

|

Important: Marking (1) on piston

head and marking (2) on con-rod point towards the engine timing

side

|

| 25. |

Install piston with con-rod in cylinder block

| • |

Force piston rings together with piston ring tensioning

belt

|

|

|

|

| 26. |

Raise vehicle by its full height

|

Important: Note cylinder sequence

marking on con-rod bearing cap and con-rod. Narrow bead (arrow)

points towards engine timing side

|

| 27. |

Install con-rod bearing cap

| • |

Attach 2x new screwed joint 24.5 Nm +

100° + 15°

|

|

|

|

| 28. |

Clean sealing surfaces.

|

| 29. |

Apply sealing compound

|

| 30. |

Install upper part of oil pan

| • |

Apply a bead of silicone sealant (grey) to the sealing surface

of the upper part of the oil pan

|

| • |

Tighten 18x bolt 9.8 Nm

|

|

| 31. |

Connect engine oil level wiring harness plug

|

| 32. |

Attach oil dipstick guide tube to upper part of oil pan

| • |

Tighten 2x bolts 9.8 Nm

|

|

| 33. |

Install front exhaust pipe

| • |

Attach to start-up catalytic converter

|

| • |

Attach to central silencer

|

|

| 34. |

Clean sealing surfaces.

|

| 35. |

Apply sealing compound

|

| 36. |

Remove lower part of oil pan

| • |

Apply a bead of silicone sealant (grey) to the sealing surfaces

of the lower part of the oil pan

|

| • |

Tighten 15x bolt 9.8 Nm

|

|

| 37. |

Lower vehicle by its full height

|

| 38. |

Install cylinder head

|

|