|

Crankshaft, Remove and Install - Diesel engine

Remove Remove

| 2. |

Place collecting basin underneath.

|

| 4. |

Remove right engine damping block bracket

|

| 5. |

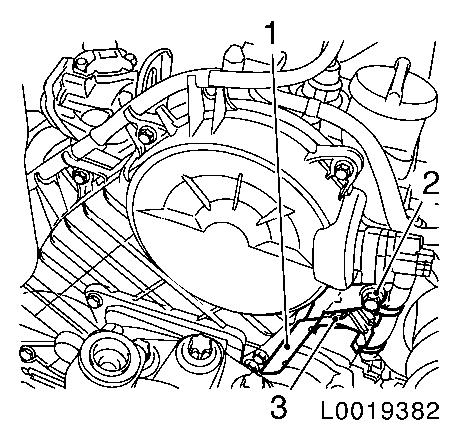

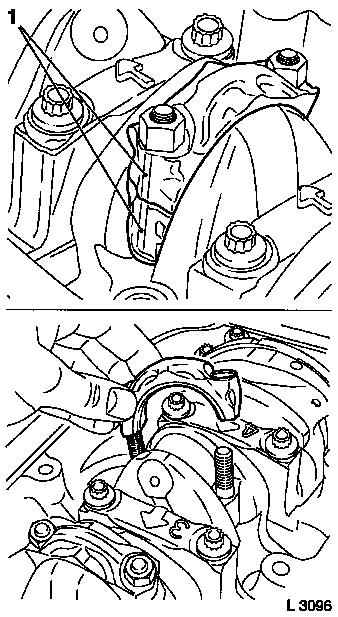

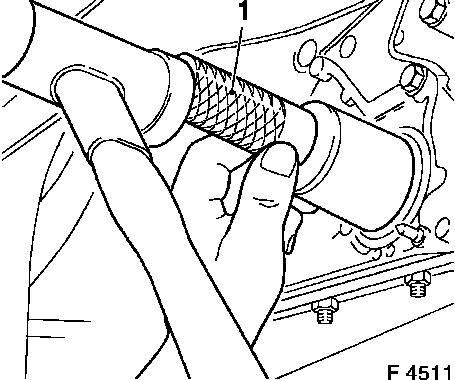

Remove injector wiring harness retaining plate (1)

| • |

Set retaining plate aside

|

|

|

|

| 6. |

Detach camshaft sensor (1)

| • |

Disconnect wiring harness connector.

|

|

|

|

| 7. |

Detach toothed belt cover (top)

| • |

Unscrew 8x bolts

Note: Note different

bolt lengths

|

| • |

Unclip 4x fuel return line

|

|

| 8. |

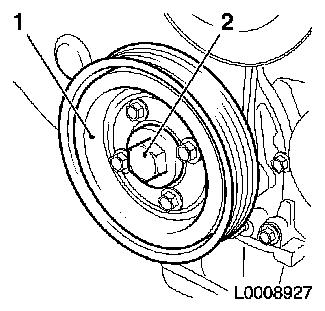

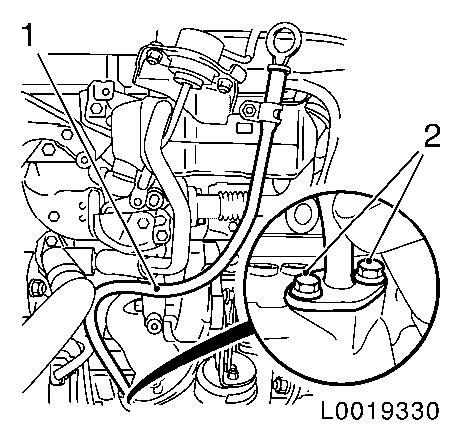

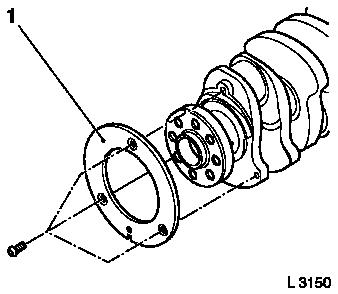

Remove torsional vibration damper (1)

| • |

Unscrew 4x bolts

Note: Counterhold at

bolt (2)

|

|

|

|

| 9. |

Remove lower toothed belt cover (1)

| • |

Remove engine damping block adapter

|

|

|

|

| 10. |

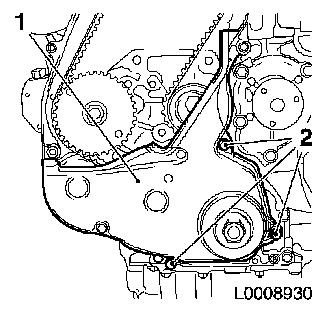

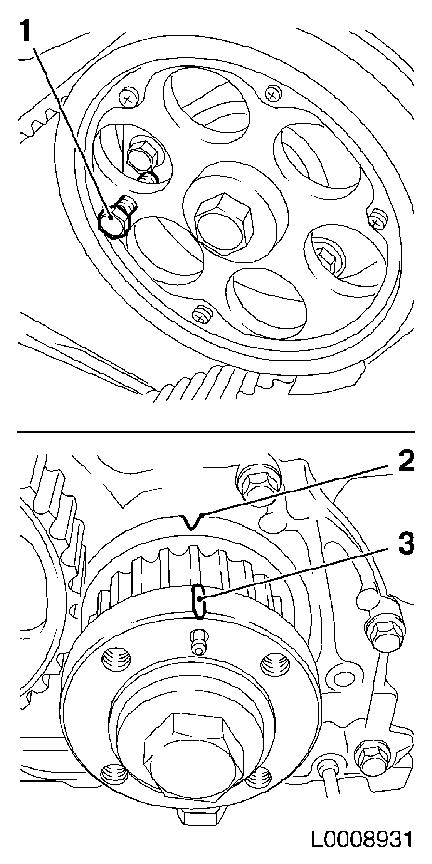

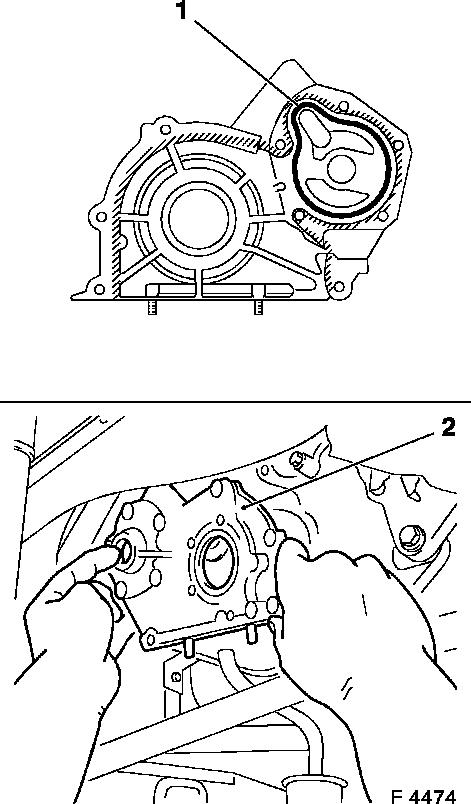

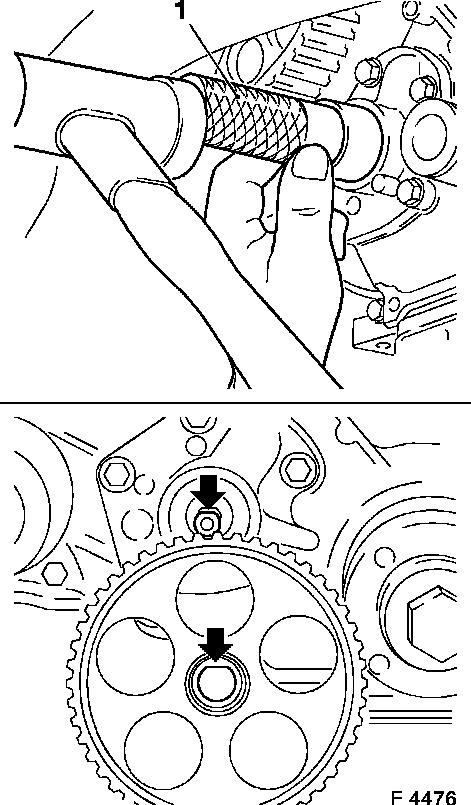

Set cylinder 1 to TDC of combustion stroke

| • |

Fix camshaft sprocket in position using TDC locking bolt

(M6x25) (1)

|

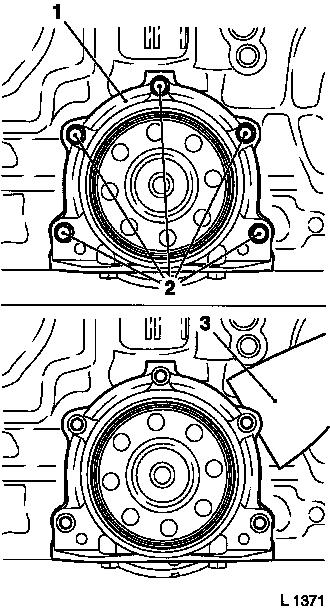

| • |

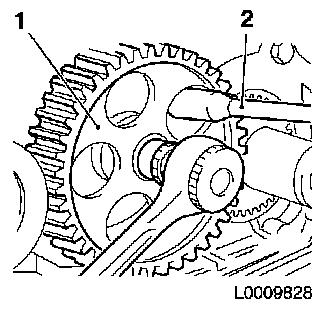

Turn crankshaft evenly in direction of engine rotation, until

mark (3) of toothed belt drive gear is in line with mark (2) on oil

pump cover

|

|

|

|

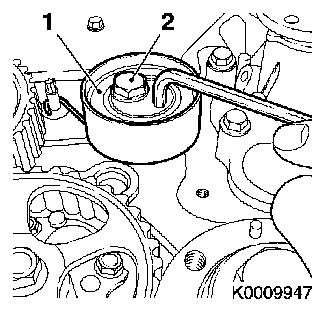

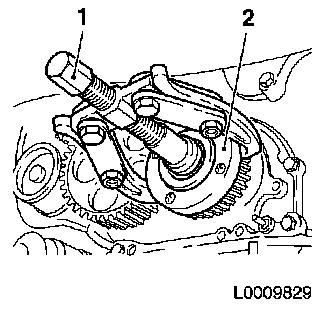

| 11. |

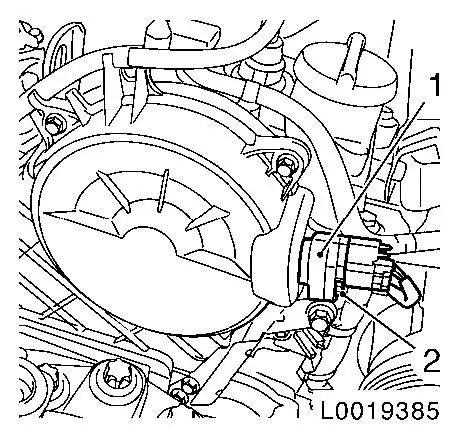

Release toothed belt tension roller (1)

| • |

Slacken bolt of toothed belt tension roller (2)

|

| • |

Turn toothed belt tension roller approx. 90°

anticlockwise

|

| • |

Tighten bolt - toothed belt tension roller

|

|

|

|

| 12. |

Remove toothed belt

| • |

Mark direction of rotation

|

|

| 13. |

Lock flywheel with KM-652

|

| 14. |

Remove thrust plate and clutch disk

|

| 16. |

Remove locking tool KM-652

|

| 17. |

Using KM-412-A , turn engine through

180°

|

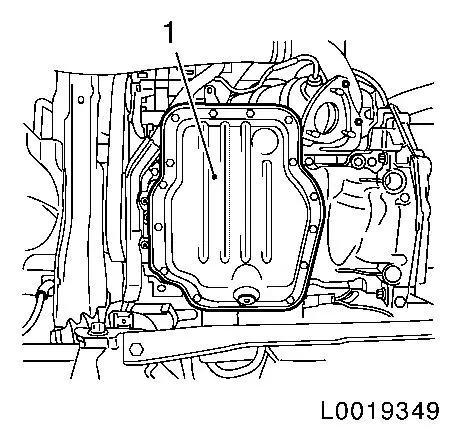

| 18. |

Remove lower part of oil pan

| • |

Detach lower part of oil pan with KM-J-37228

|

|

|

|

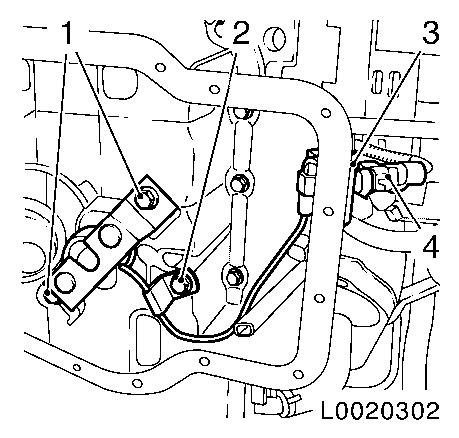

| 19. |

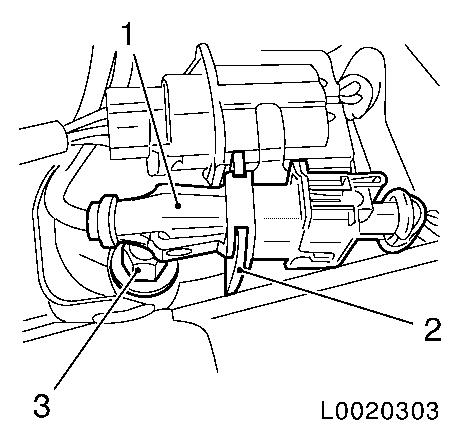

Remove residual oil quantity sensor

| • |

Disconnect wiring harness plug (4)

|

| • |

Release retaining clamp (3)

|

| • |

Unscrew 2x bolt (1 and 2)

|

|

|

|

| 20. |

Detach oil dipstick guide tube (1)

| • |

From cooler, exhaust gas recirculation

|

|

|

|

| 21. |

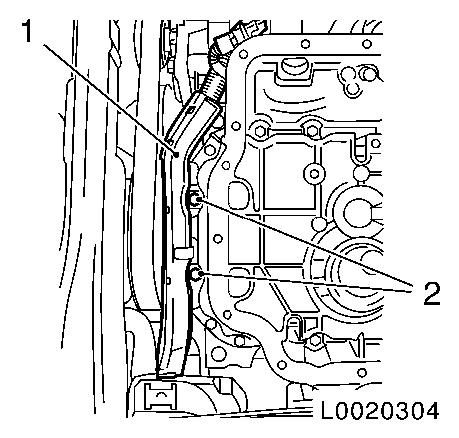

Detach bracket for wiring harness plug (2)

| • |

Unclip wiring harness plug (1)

|

|

|

|

| 22. |

Release wiring trough (1)

|

|

|

| 23. |

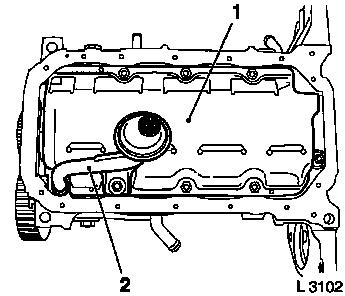

Remove upper part of oil pan

|

| 24. |

Detach oil intake pipe (2)

|

| 25. |

Detach oil baffle plate (1)

|

|

|

| 26. |

Detach toothed belt drive gear (1)

| • |

Unscrew bolt

| – |

Counterhold with KM-662-C

|

|

| • |

Remove with KM-161-B (1)

|

|

|

|

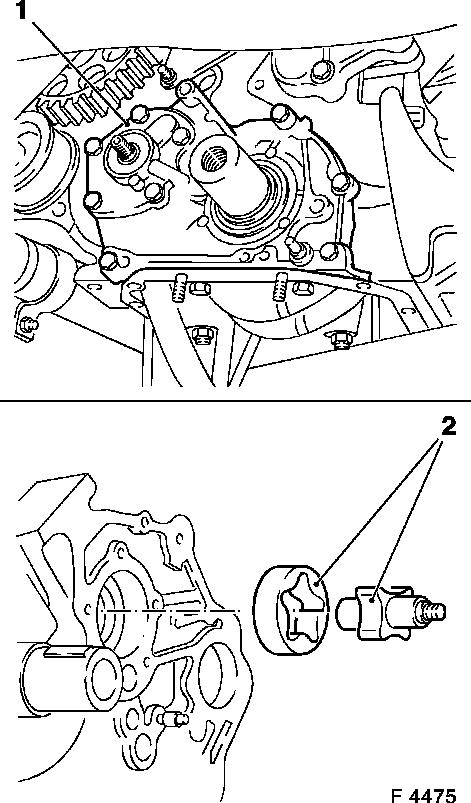

| 27. |

Detach oil pump gear (1)

| • |

Unscrew nut

Note: Counterhold with

socket wrench (2)

|

|

|

|

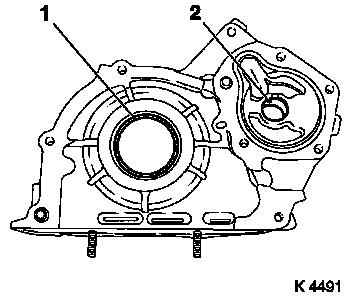

| 28. |

Remove oil pump cover (1)

| • |

Unscrew 9x bolts

Note: Note different

bolt lengths

|

| • |

Remove inner rotor and outer rotor (2)

|

|

|

|

| 29. |

Remove crankshaft seal ring (1)

Important: Do not damage sealing

surfaces

|

| • |

Prise out seal ring

|

|

| 30. |

Install oil pump seal ring (2)

Important: Do not damage sealing

surfaces

|

| • |

Prise out seal ring

|

|

|

|

| 31. |

Detach bracket for crankshaft seal ring (1) from cylinder

block

| • |

Separate crankshaft rear seal ring bracket (1) from cylinder

block using a suitable tool (3)

|

|

|

|

Important: The fracture surfaces

of the con-rods and the con-rod bearing caps build an individual

fit and must not at any time be confused or damaged. To prevent

damage, do not not place the con-rods or con-rod bearing caps on

the fracture surfaces.

|

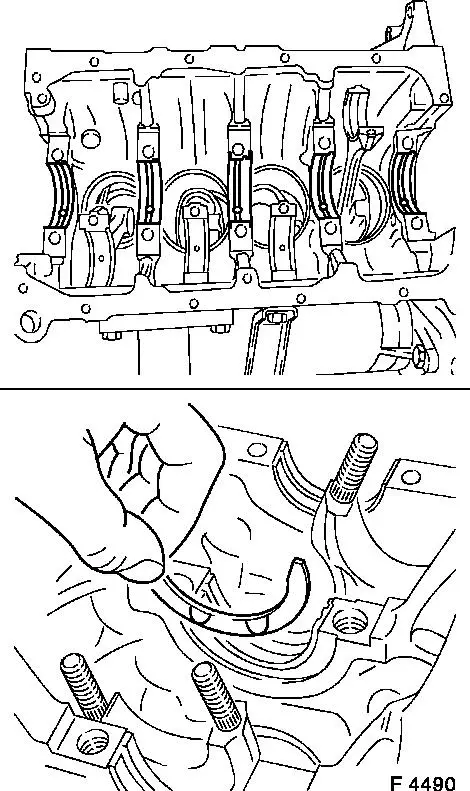

| 32. |

Remove 4x con-rod bearing cap

|

| 33. |

Take off 8x con-rod bearing shell

Note: Note

identification mark on con-rod bearing cap and con-rod. Apply

identification mark if not present

|

|

|

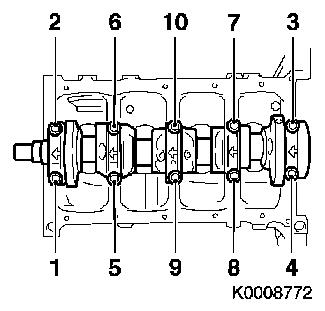

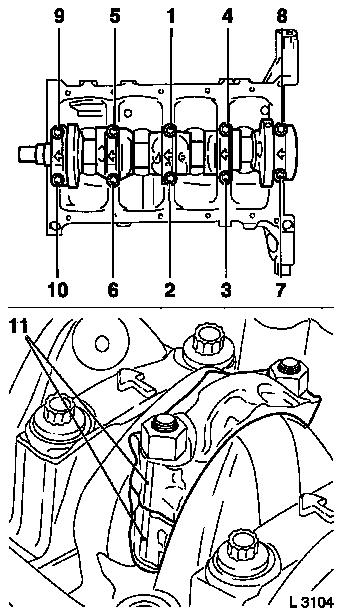

| 34. |

Remove crankshaft

| • |

Remove 5x crankshaft bearing cap

| – |

Release 10x bolt in the order shown (1 - 10)

|

|

| • |

Place crankshaft on wooden blocks

|

|

|

|

| 35. |

Take out 10x crankshaft bearing shell

| • |

Identify crankshaft bearing shells

Note: Note

identification on crankshaft bearing cap

|

|

|

|

| 37. |

Detach crankshaft pulse pick-up disc (1)

|

|

|

Install

Install

| 38. |

Clean the components

| • |

Lower part of oil pan, upper part of oil pan, cylinder

block

|

|

| 39. |

Visually check components

|

| 40. |

Attach crankshaft pulse pick-up disc

| • |

Tighten 3x new bolts 12 Nm

|

|

Important: Note mark and

allocation

|

| 41. |

Insert 8x con-rod bearing shell

| • |

In con-rod, con-rod bearing cap

|

|

Important: Note mark and

allocation

|

| 42. |

Insert 10 crankshaft bearing shells

| • |

In cylinder block, crankshaft bearing cap

|

|

Important: Oil grooves point

outwards

|

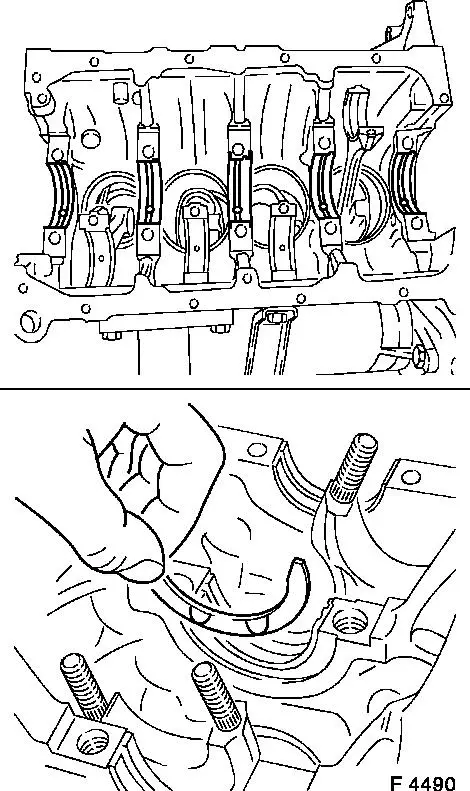

| 43. |

Replace wearing rings

| • |

Coat with engine oil [77.5x155 F4490)

|

|

|

|

|

| 44. |

Insert crankshaft

| • |

Coat crankshaft journal with engine oil

Note: Pay attention to

wearing rings

|

|

| 45. |

Attach 5x crankshaft bearing cap

Note: Note installation

position. arrows point to engine timing side

| • |

Tighten 10x new bolts in the specified tightening sequence

39 Nm + 60°

|

|

Important: Note marking (11) and

cylinder sequence on con-rod bearing cap and con-rod. Narrow bead

is toward engine timing side

|

| 46. |

Attach 4x con-rod bearing cap

| • |

Tighten 8x new nuts 25 Nm + 100° +

15°

|

|

|

| 47. |

Clean sealing surfaces.

|

| 48. |

Attach bracket for rear crankshaft seal ring to cylinder

block

| • |

Apply a bead of adhesive sealing compound to sealing surfaces

of crankshaft rear seal ring bracket (arrow)

Note: Select a suitable

sealing compound from the replacement parts catalogue

|

| • |

Tighten 5x bolts in the stated order (1 - 5) 10 Nm

|

|

| 49. |

Clean sealing surfaces.

|

| 50. |

Fit oil pump cover (2)

Important: The application of

adhesive sealing compound and installation of oil pump cover,

including torque test, must be completed within 10 minutes

|

| • |

Apply a bead of adhesive sealing compound (black) to the

sealing surface (cross-hatching) of the oil pump cover

|

| • |

insert inner and outer rotor in cylinder block

|

|

|

|

| 51. |

Fit toothed belt drive gear seal ring

| • |

Insert seal ring in oil pump cover

|

| • |

Drive in as far as the stop with KM-656 (1)

|

|

|

|

| 52. |

Remove oil pump seal ring

| • |

Insert new seal ring in oil pump cover. Do not forget to apply

silicone grease to the sealing lip of the ring.

|

| • |

Drive in as far as the stop with KM-657 (1)

|

|

| 53. |

Fit oil pump drive gear

Note: Note installation

position

| • |

Tighten nut

| – |

Counterhold with socket wrench

|

|

|

|

|

| 54. |

Replace toothed belt drive gear

| • |

Attach to crankshaft

Note: Note spring

washer

|

| • |

Tighten bolt 196 Nm

| – |

Counterhold with KM-662-C

|

|

|

| 55. |

Attach oil baffle plate

|

| 56. |

Attach oil intake pipe

|

| 57. |

Clean sealing surfaces.

| • |

Upper part of oil pan and engine block

|

|

| 58. |

Fit upper part of oil pan

| • |

Apply a bead of silicone sealant to the sealing surface of the

upper part of the oil pan

|

| • |

Tighten 14x bolts and 2x nuts 10

Nm

Note: Note different

bolt lengths

|

|

| 60. |

Attach wiring harness plug bracket

| • |

Clip in wiring harness plug

|

|

| 61. |

Attach dipstick guide tube

|

| 62. |

Install residual oil quantity sensor

| • |

Fix wiring harness plug

|

|

| 63. |

Clean sealing surfaces.

|

| 64. |

Install lower part of oil pan

| • |

Apply a bead of silicone sealing compound to sealing surfaces

of lower part of oil pan

|

| • |

Tighten 15x bolts 10 Nm

|

|

| 65. |

Using KM-412-A, turn engine through 180°

|

| 66. |

Insert locking tool KM-652

|

| 67. |

Fit flywheel

| • |

Tighten 8x new bolts 85 Nm + 30° +

15°

|

|

| 68. |

Install thrust plate and clutch disc

|

| 69. |

Remove locking tool KM-652

|

| 70. |

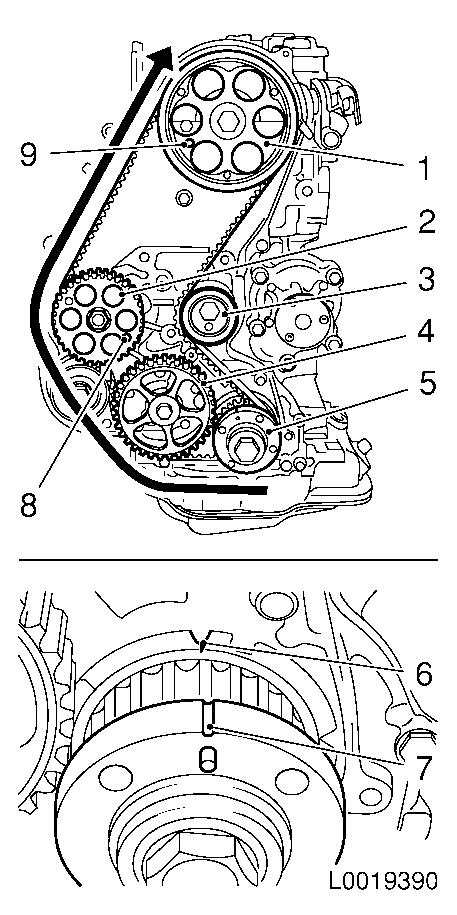

Install toothed belt

Note: TDC locking bolt

must be installed in camshaft sprocket (9) and high-pressure pump

gear (8) and marks (6) and (7) must align

| • |

Position toothed belt

| – |

Observe direction of rotation

|

| – |

Toothed belt must be tensioned in the direction of the arrow

from the toothed belt drive gear (5), through the oil pump drive

gear (4) and the high-pressure pump drive gear (2) to the camshaft

sprocket (1)

|

|

| • |

Slacken the toothed belt tension roller (3)

|

| • |

Tighten toothed belt tension roller 49

Nm

|

|

|

|

| 71. |

Timing, Check

| • |

Remove 2x TDC fixing bolt

|

| • |

Turn crankshaft approx. 720° in the direction of rotation

of the engine

| – |

To toothed belt drive gear

|

|

| • |

Mark (3) on toothed belt drive gear must be in line with the

lug (2) on the oil pump cover

|

| • |

Screw in 2x TDC locking bolts

Note: If it is not

possible to screw in a TDC locking bolt, the basic setting must be

carried out again.

|

| • |

Unscrew 2x TDC fixing bolt

|

|

| 72. |

Attach toothed belt cover at the bottom

| • |

Insert engine damping block adapter

|

|

| 73. |

Fit torsional vibration balancer

| • |

Tighten 4x bolt 20 Nm

Note: Counterhold

toothed belt drive gear at bolt

|

|

| 74. |

Fit upper toothed belt cover

| • |

Tighten 8x bolts 10 Nm

Note: Note different

bolt lengths

|

| • |

Clip in 4x fuel return line

|

|

| 75. |

Replace camshaft sensor

| • |

Fix wiring harness plug

|

|

| 76. |

Fit injector wiring harness retaining plate

|

| 77. |

Attach right engine damping block bracket

|

|