|

Valve Stem Seals, Replace

Remove Remove

| 1. |

Remove camshaft housing

|

|

Important: Pay attention to

assignment

|

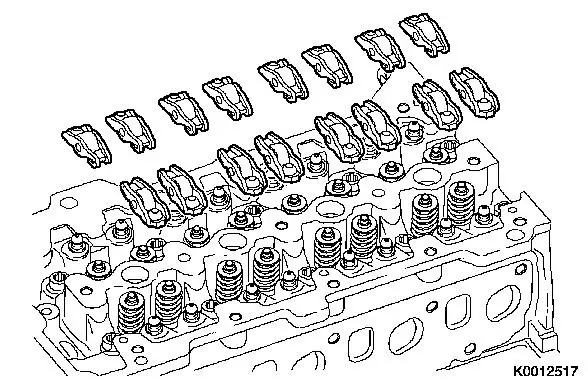

| 2. |

Remove 16x roller cam followers with hydraulic valve

lifters

|

|

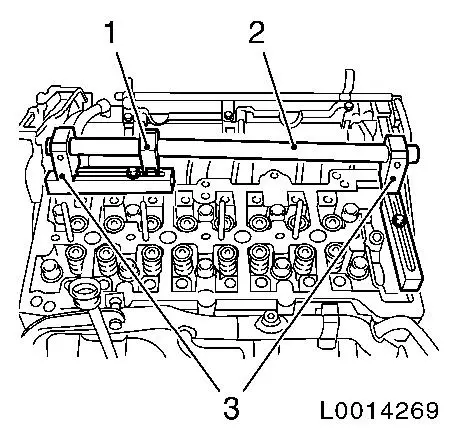

| 3. |

Insert MKM-6086

| • |

Attach 2x support MKM-6086-6 (3)

together with joint MKM-6086-8 (1) and

assembly shaft MKM-6086-4 (2) as depicted

in L0014269

|

|

|

|

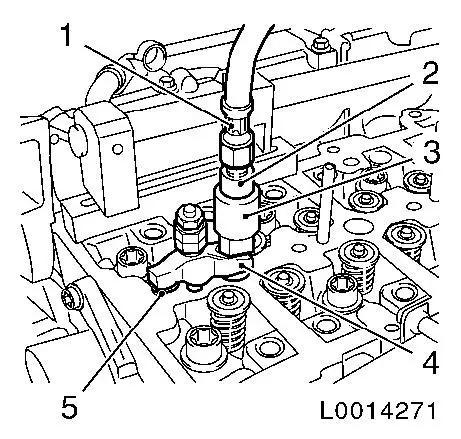

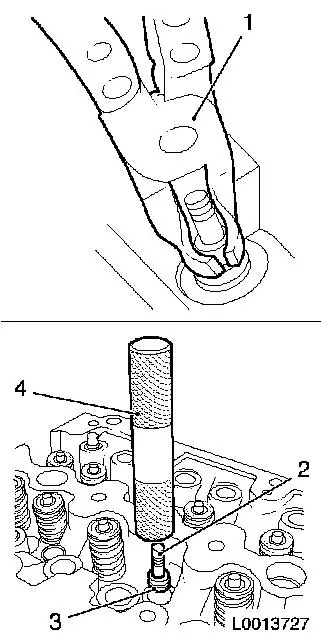

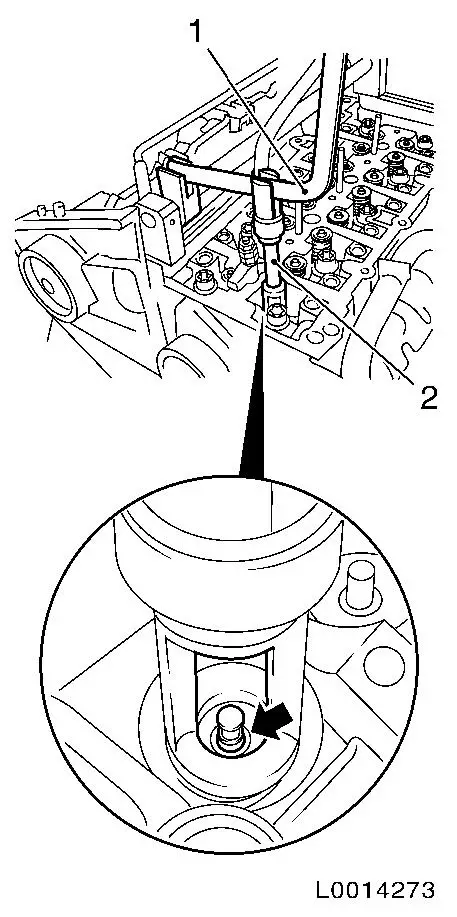

| 4. |

Attach EN-46782 (3) together with

EN-46783 (2) and MKM-6086-17 (1) to cylinder 1

| • |

Screw in bolt M8x25 (5)

|

| • |

Insert EN-46782 with bracket (4) in

injector bore

|

| • |

Fasten bracket

| – |

Tighten nut 20 Nm

Note: Compare stud bolt

lengths with suitable means

|

|

| • |

Apply compressed air to cylinder no. 1

|

|

|

|

| 5. |

Attach lever arm

| • |

Attach lever arm MKM-6086-7 (2)

together with adapter MKM-6086-12 and

dismantling head MKM-6086-11 (1) to joint

MKM-6086-8

|

|

Important: Ensure application of

compressed air

|

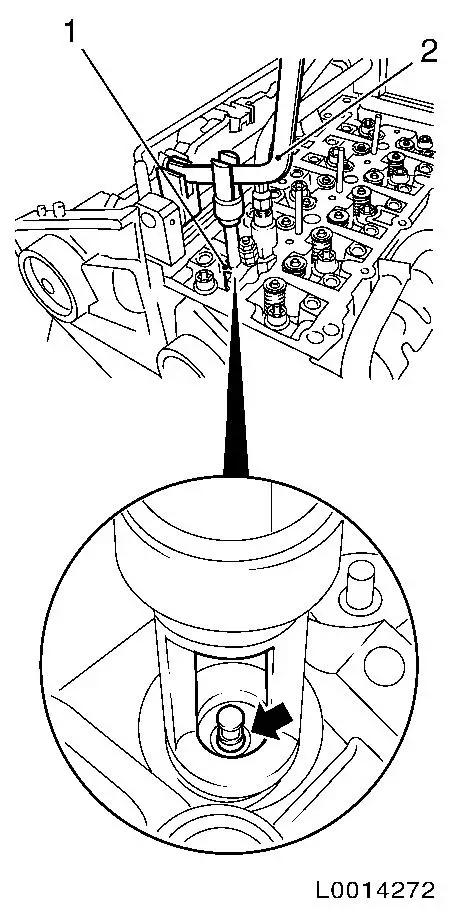

| 6. |

Remove 2x intake valve springs, cylinder 1

Important: Dismantling head must

be positioned vertically over the valve stem

|

| • |

Carefully push valve spring down using lever arm MKM-6086-7

|

| • |

Remove 2x valve cotter (arrow)

|

| • |

Remove valve head and valve springs

|

|

|

|

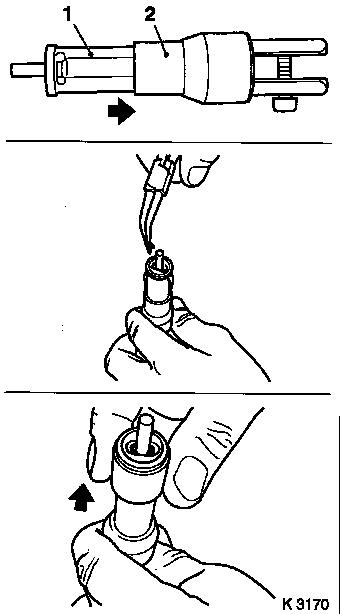

| 7. |

Renew 2x valve stem seals

| • |

Place new valve stem seal (3) on to valve stem (2)

Note: Coat new valve

stem seals with oil

|

| • |

Drive in as far as stop with EN-46779

(4)

|

|

|

|

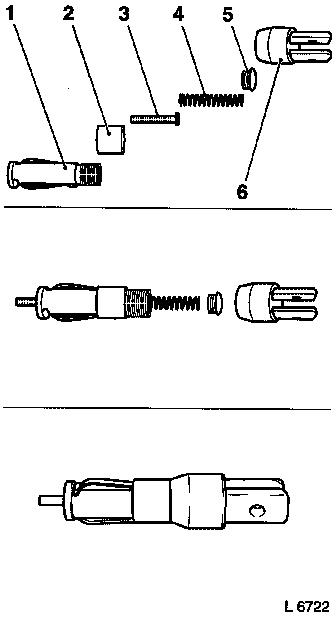

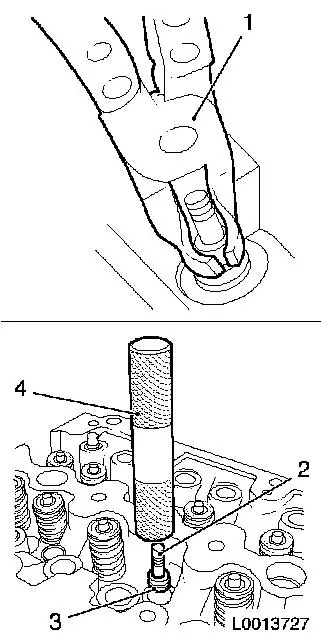

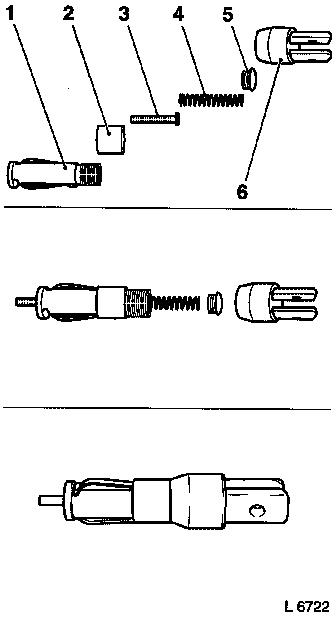

| 8. |

Complete Assembly Head MKM-6086-100-1

Note: Note

manufacturer's provisions!

| • |

Put together assembly head consisting of mount (1), fixing

sleeve (2), Thrust Piece MKM-6086-100-17

(3), spring (4), screw connection (5) and Lever Mount MKM-6086-12 (6)

|

|

|

|

| 9. |

Install 2x intake valve spring in cylinder 1

| • |

Insert valve springs and valve heads

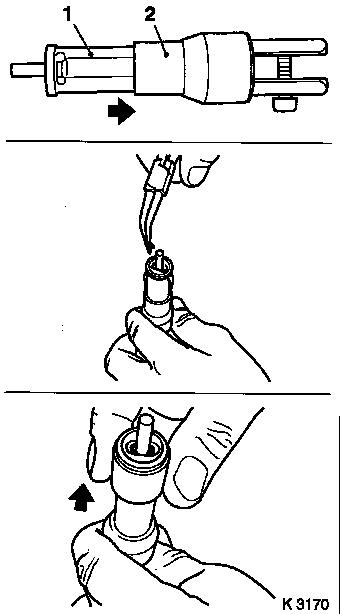

|

| • |

Insert valve cotters in Assembly Head MKM-6086-100-1 (1)

Important: Insert valve cotters

with tapered end towards valve.

|

| – |

Push clamping sleeve (2) towards the lever arm holder

|

| – |

Push clamping sleeve towards the valve

|

|

| • |

Attach assembly head to lever arm

|

|

|

|

Important: Ensure application of

compressed air

|

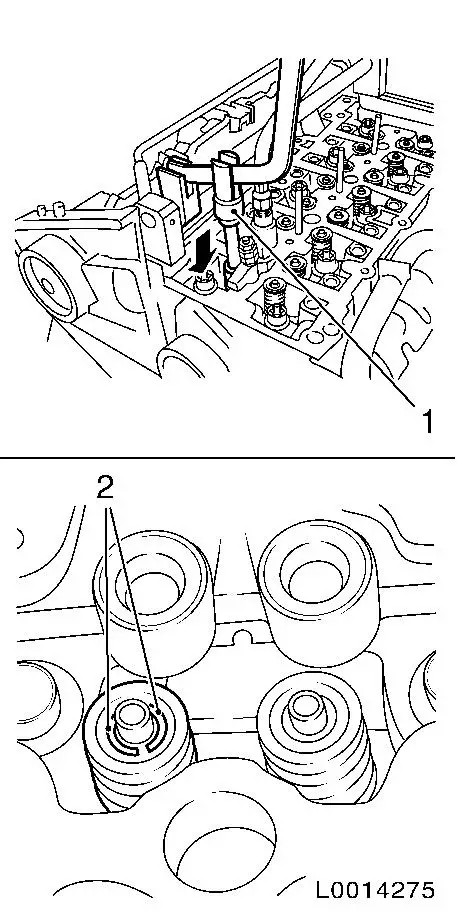

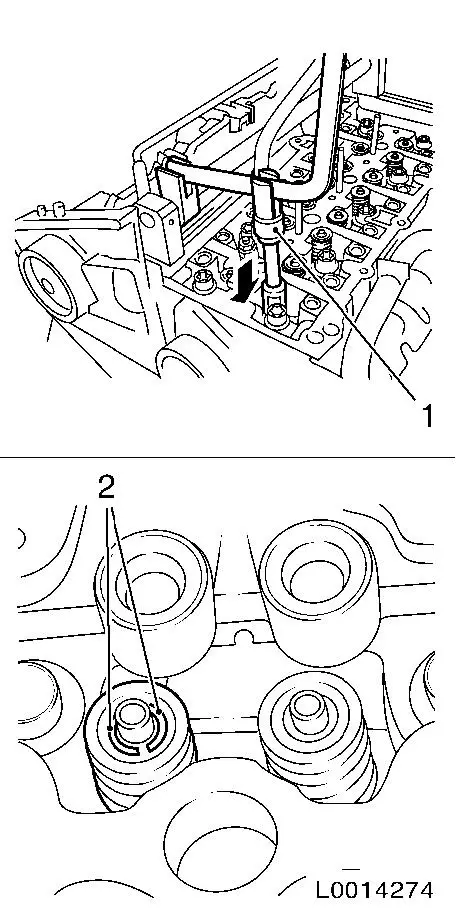

| 10. |

Install valve cotters

Important: Assembly head (1) must

stand vertically above valve stem. Valve cotters (2) must engage

audibly.

|

| • |

Carefully push valve springs downwards (arrow)

|

Important: Do not make 2nd

attempt without checking that both valve cotters are seated in the

assembly head.

|

| • |

Check seating of valve cotters

|

|

|

|

| 11. |

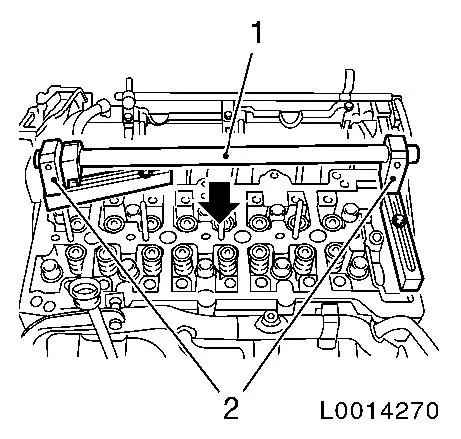

Transfer MKM-6086

| • |

Slide on MKM-6086-6 (2) together with

MKM-6086-4 (1) in direction of arrow as

depicted in L0014270

|

|

|

|

Important: Ensure application of

compressed air

|

| 12. |

Remove 2 exhaust valve springs cylinder 1

Important: Dismantling head must

be positioned vertically over the valve stem

|

| • |

Carefully push valve spring down using lever arm MKM-6086-7

|

| • |

Remove 2x valve cotter (arrow)

|

| • |

Remove valve head and valve springs

|

|

|

|

| 13. |

Renew 2x valve stem seals

| • |

Place new valve stem seal (3) on to valve stem (2)

Note: Coat new valve

stem seals with oil

|

| • |

Drive in as far as stop with EN-46779

(4)

|

|

|

|

| 14. |

Complete Assembly Head MKM-6086-100-1

Note: Note

manufacturer's provisions!

| • |

Put together assembly head consisting of mount (1), fixing

sleeve (2), Thrust Piece MKM-6086-100-18

(3), spring (4), screw connection (5) and Lever Mount MKM-6086-12 (6)

|

|

|

|

| 15. |

Install 2x exhaust valve spring of cylinder 1

| • |

Insert valve springs and valve heads

|

| • |

Insert valve cotters in Assembly Head MKM-6086-100-1 (1)

Important: Insert valve cotters

with tapered end towards valve.

|

| – |

Push clamping sleeve (2) towards the lever arm holder

|

| – |

Push clamping sleeve towards the valve

|

|

| • |

Attach assembly head to lever arm

|

|

|

|

Important: Ensure application of

compressed air

|

| 16. |

Install valve cotters

Important: Assembly head (1) must

stand vertically above valve stem. Valve cotters (2) must engage

audibly.

|

| • |

Carefully push valve springs downwards (arrow)

|

Important: Do not make 2nd

attempt without checking that both valve cotters are seated in the

assembly head.

|

| • |

Check seating of valve cotters

|

|

|

|

| 17. |

Repeat the procedure for cylinders 2 to 4

|

Install

Install

| 18. |

Insert 16 x roller cam follower with hydraulic valve lifter

Note: Pay attention to

assignment

|

| 19. |

Install camshaft housing

|

|