|

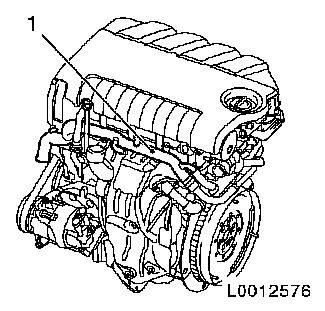

Repair engine using a short block

Important: When

working on the fuel system it is essential to pay attention to

cleanliness as even the smallest dirt particles can lead to faults

in engine operation or in the fuel system. Open fuel connections

must be sealed with appropriate plugs from the Opel Parts Catalogue

(catalogue number: 45 06 154 / part number: 9201697). Sealing plugs

are only intended to be used once.

Remove Remove

| 1. |

Detach transmission from engine

|

| 3. |

Remove KM-6263

| • |

Turn rotating spindle back to initial position

|

|

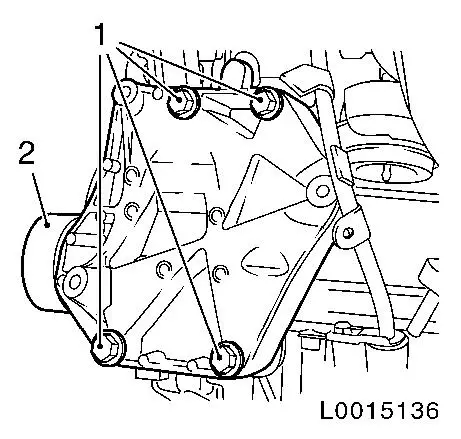

| 7. |

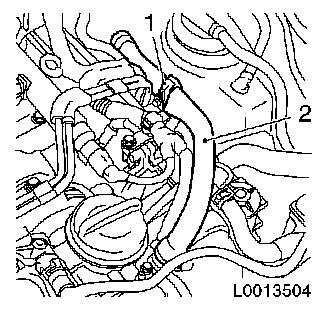

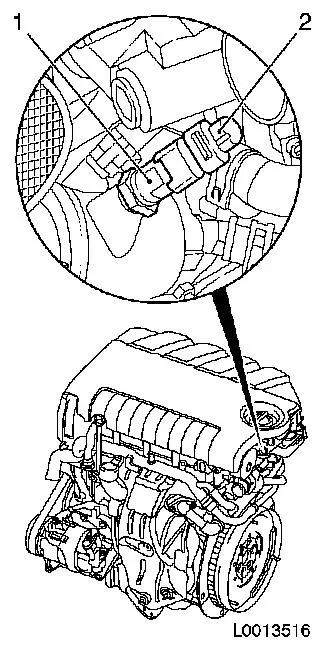

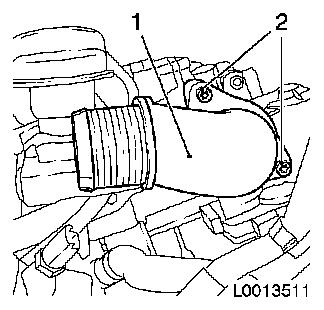

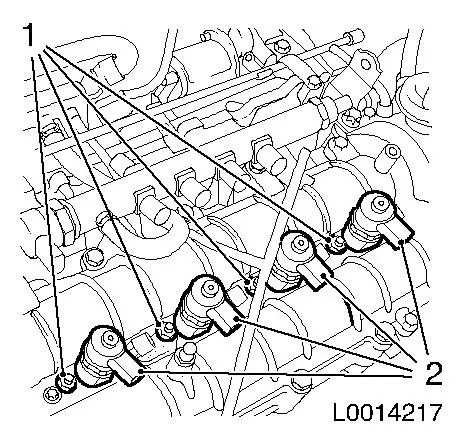

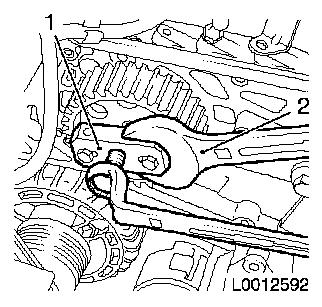

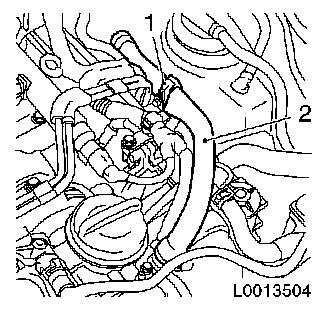

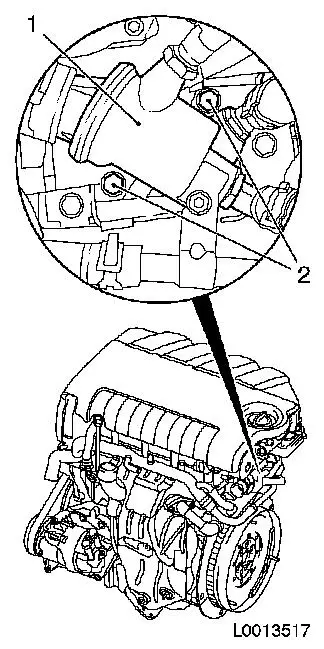

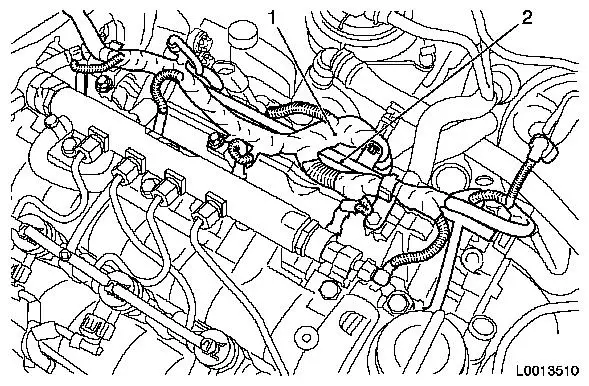

Detach engine vent hose (2)

| • |

Unclip from bracket (1)

|

|

|

|

| 8. |

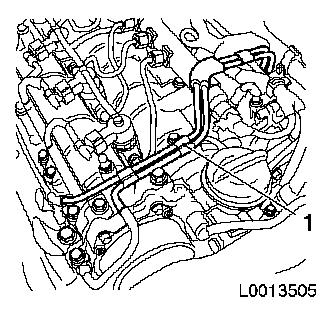

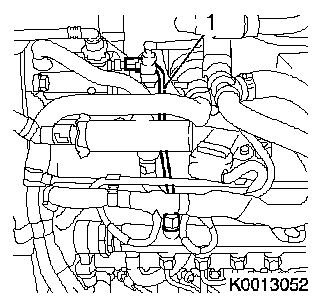

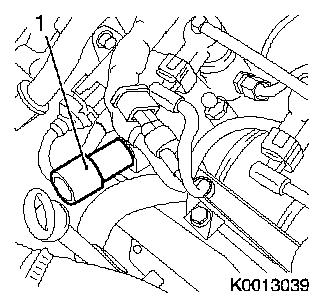

Remove vacuum line (1)

| • |

Detach 4x vacuum hoses

Note: Mark vacuum

hoses

|

|

|

|

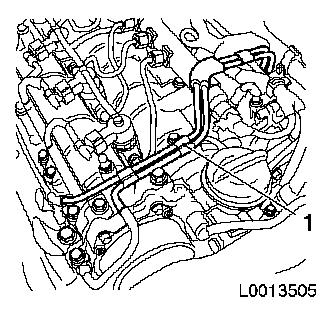

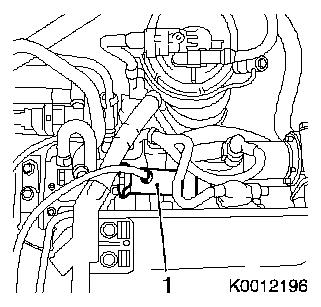

| 9. |

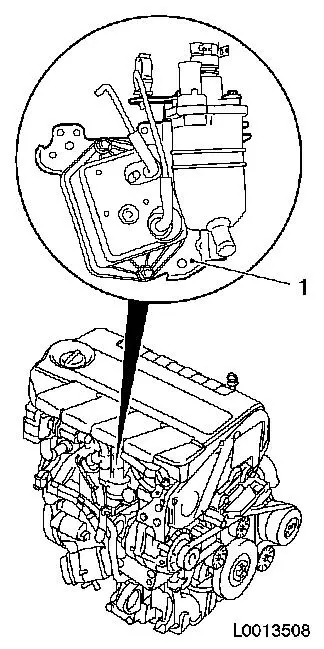

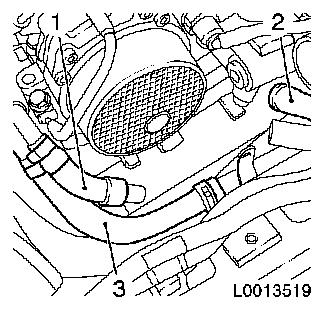

Remove oil separator/vacuum reservoir bracket (1)

| • |

Detach engine vent hose

| – |

Disconnect quick-release fitting

|

|

| • |

Unclip wiring harness bracket

|

|

|

|

| 10. |

Disconnect wiring harness plug (2) from coolant temperature

sensor (1)

|

|

|

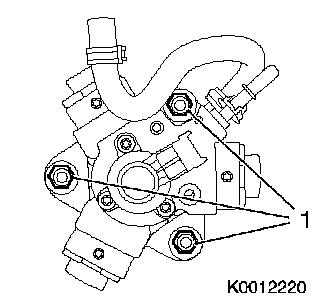

| 11. |

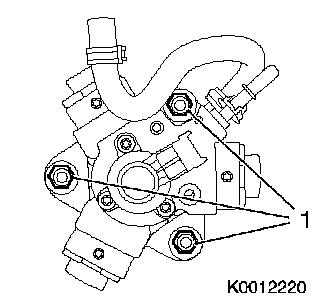

Remove thermostat housing (1)

| • |

Detach 4x coolant hoses

|

|

|

|

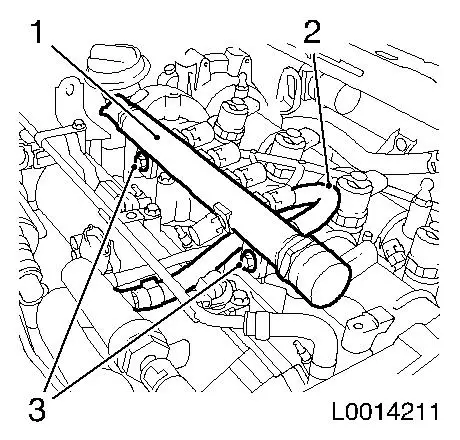

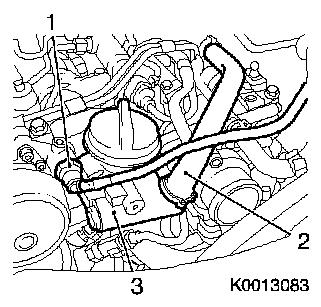

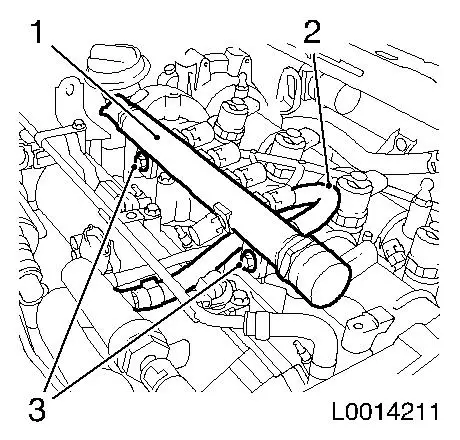

| 12. |

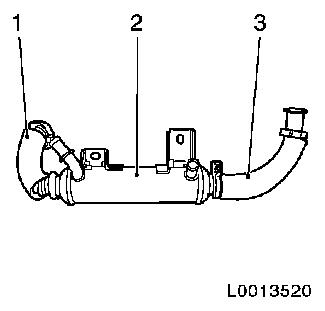

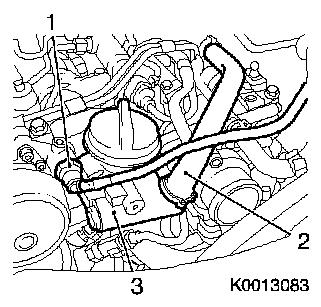

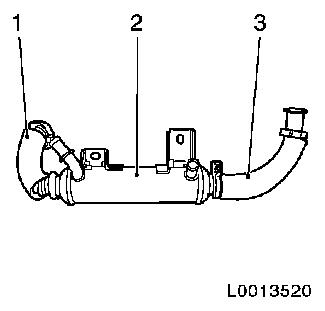

Detach 3x coolant hoses

| • |

Detach coolant hose (1) from top coolant pipe

|

| • |

Detach coolant hose (3) from bottom coolant pipe

|

| • |

Detach coolant hose (2) from EGR cooler

|

|

|

|

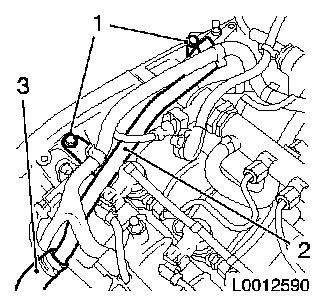

| 13. |

Release EGR metal tube (3) from EGR valve

|

|

|

| 15. |

Detach intake connection piece (1) from throttle valve

module

|

|

|

| 16. |

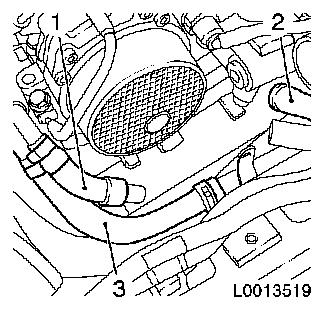

Remove engine oil filling nozzle (3)

|

|

|

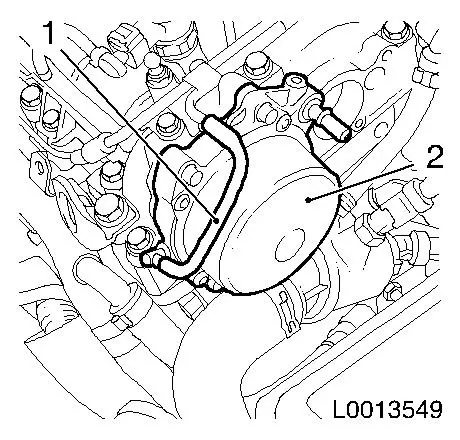

| 17. |

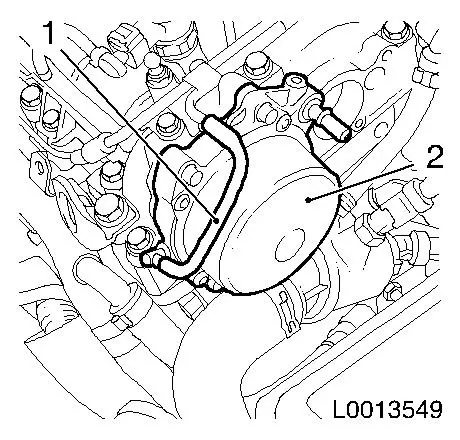

Remove vacuum pump (2)

|

|

|

| 18. |

Remove compressor

| • |

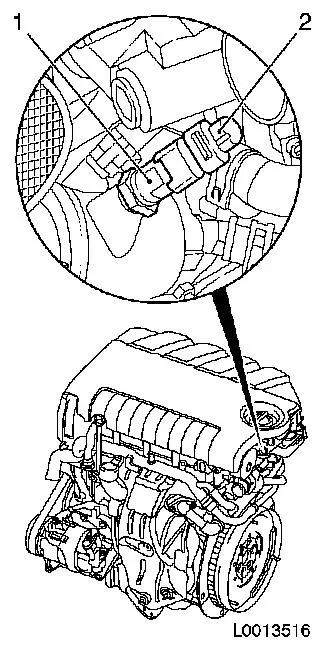

Disconnect wiring harness plug (2)

|

|

|

|

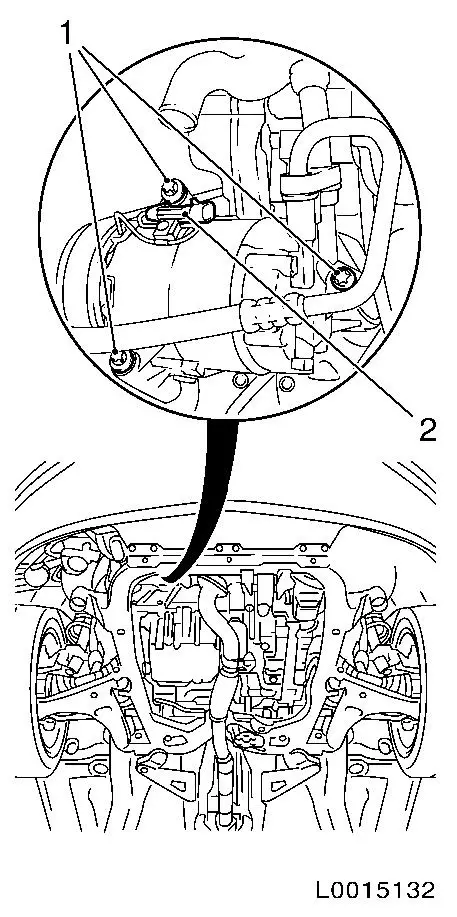

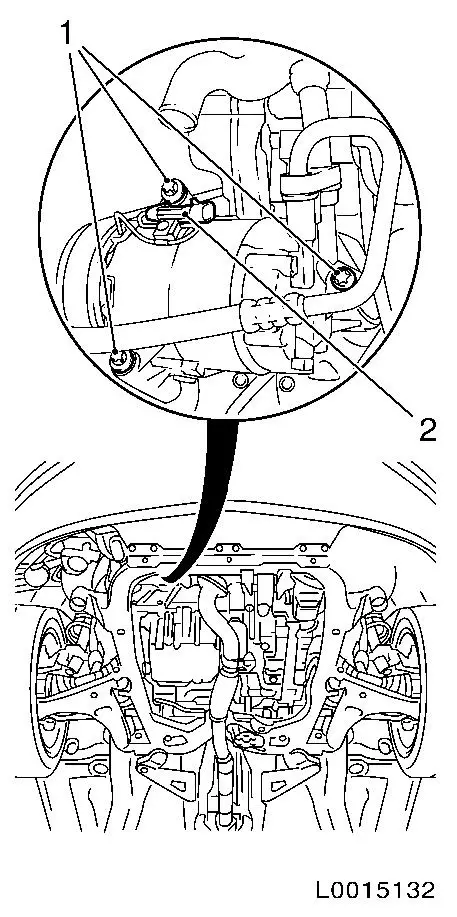

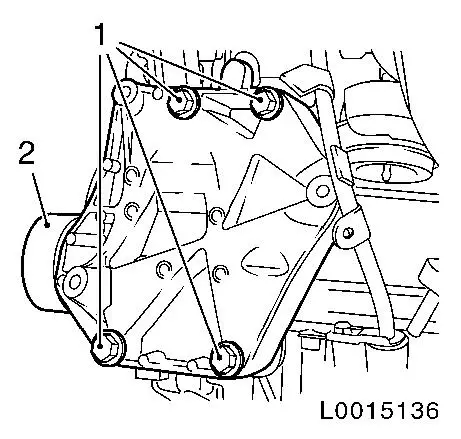

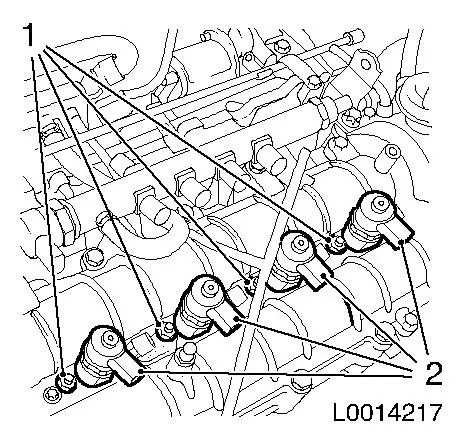

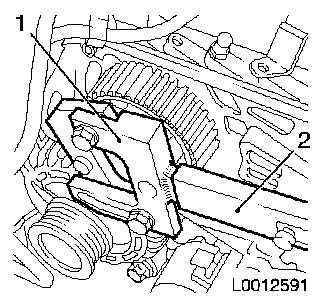

| 19. |

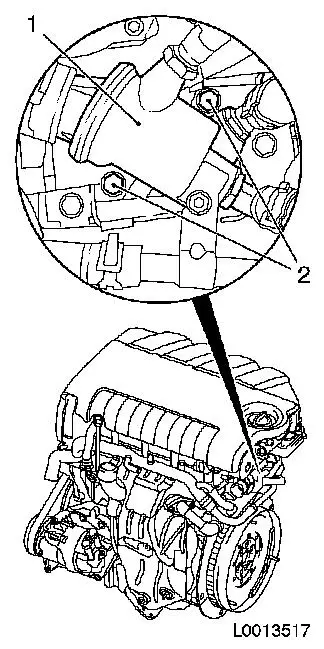

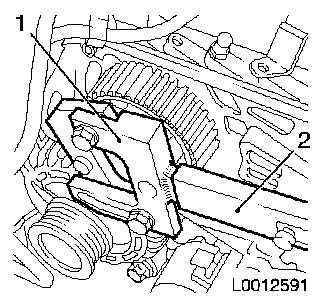

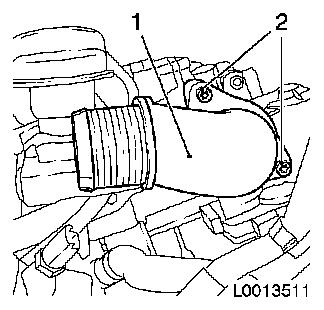

Detach compressor support from engine block

Note: Note guide

sleeves

| • |

Unscrew 4x bolts (1)

Note: Remove with

ribbed V-belt guide roller (2)

|

|

|

|

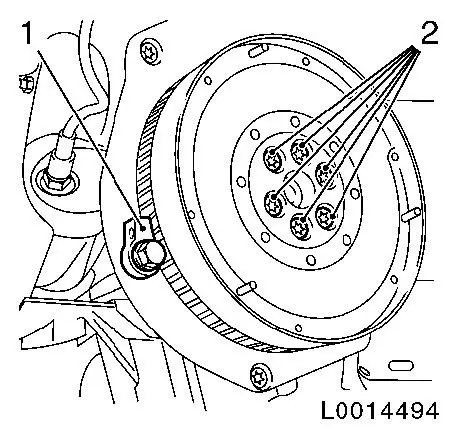

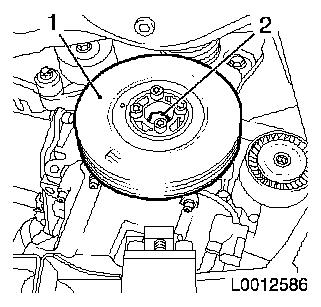

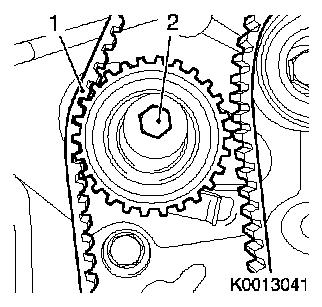

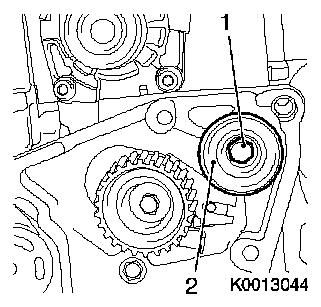

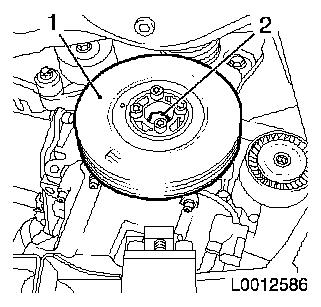

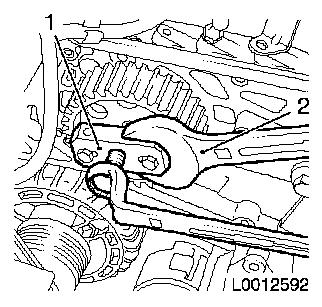

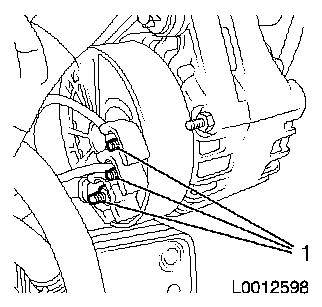

| 20. |

Remove torsional vibration damper (1)

| • |

Unscrew 4x bolts

Note: Counterhold

toothed belt drive gear at bolt (2)

|

|

|

|

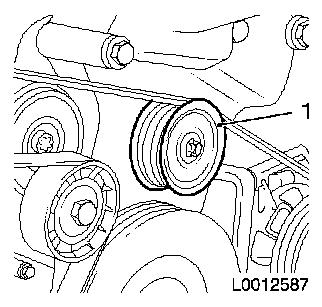

| 21. |

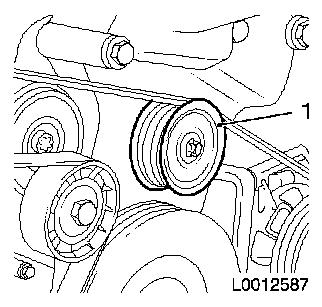

Remove upper ribbed V-belt guide roller (1)

|

|

|

| 22. |

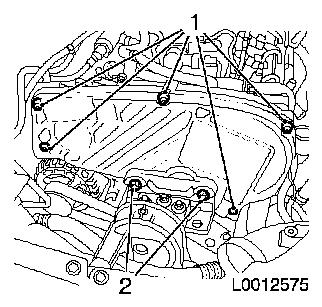

Remove upper toothed belt cover

| • |

Unscrew 5x bolts (1) with EN-47631

|

|

|

|

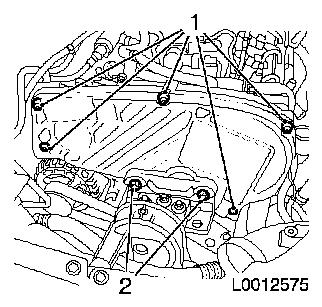

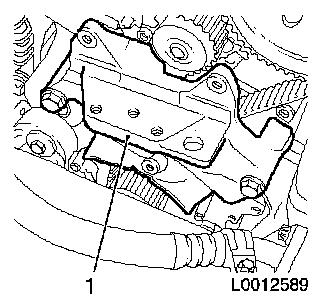

| 23. |

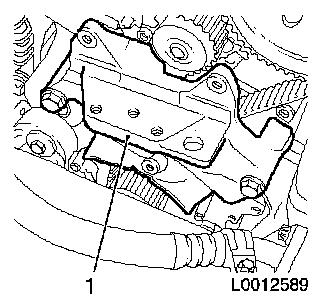

Remove engine damping block support (1)

| • |

Unscrew 5x bolts

Note: Note different

bolt lengths

|

|

|

|

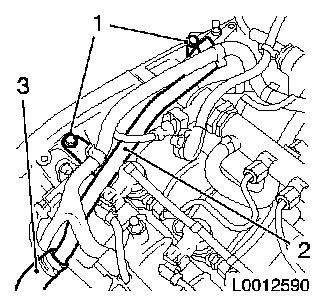

| 24. |

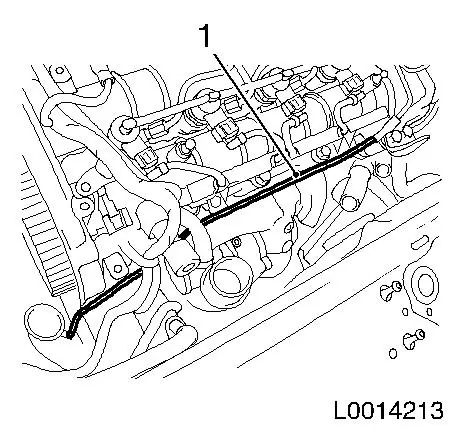

Detach engine venting pipe (2)

| • |

Detach engine venting hose (3) from engine venting pipe

|

|

|

|

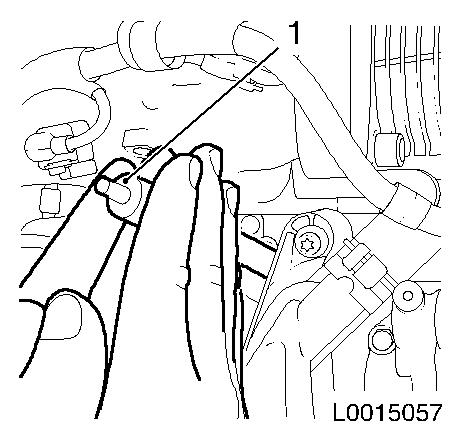

| 25. |

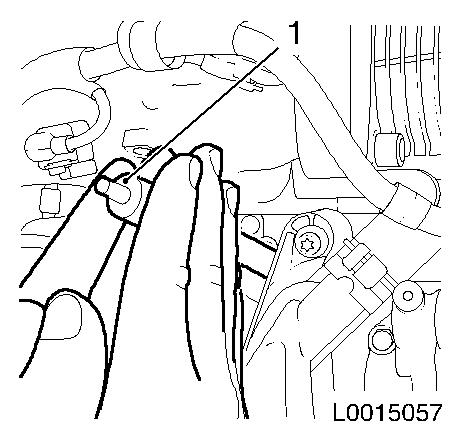

Install EN-46789 (1) in camshaft

housing

| • |

Unscrew exhaust camshaft closure bolt

|

|

| 26. |

Set cylinder no. 1 to TDC of combustion stroke

| • |

Rotate crankshaft in direction of engine rotation until

reference drift EN-46789 audibly engages

in exhaust camshaft

|

|

|

|

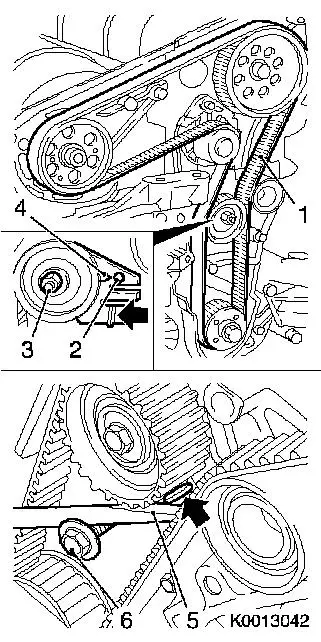

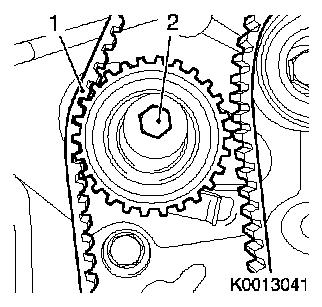

| 27. |

Remove toothed belt (1)

| • |

Slacken the toothed belt tension roller

|

|

|

|

| 28. |

Remove toothed belt tension roller

|

| 29. |

Remove toothed belt guide roller (2)

|

|

|

| 30. |

Detach vacuum line from cable conduit

|

|

|

| 31. |

Detach compressor wiring harness bracket

| • |

Set wiring harness aside

|

|

|

| 32. |

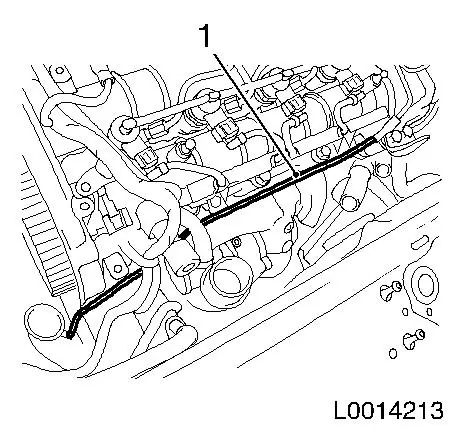

Detach engine management wiring harness (1)

| • |

Disconnect wiring harness connector.

| – |

Coolant temperature sensor

|

|

|

| 33. |

Detach coolant pipe (2) from intake manifold

| • |

Detach coolant hose from coolant pipe

|

|

|

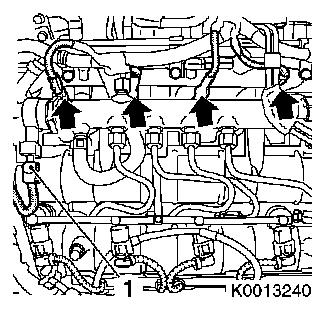

| 34. |

Detach leak oil line (1)

Note: The oil leak line

must not be detached from the fuel return damping case. It if is

detached, it must be replaced.

| • |

Release 4x retaining clamp (arrows)

|

|

|

|

Important: After detaching the

high pressure lines, seal off injector and pressure chamber

openings with protective caps

1)

|

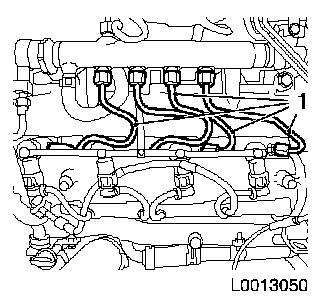

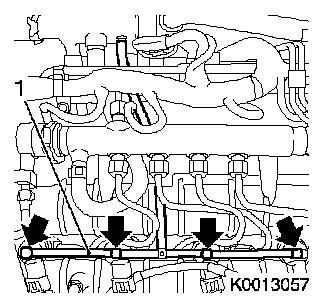

| 35. |

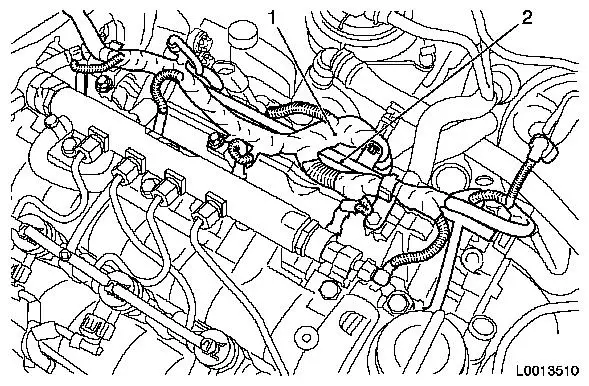

Detach 4x high pressure line (1), pressure chamber on

injector

Note: When releasing

the retaining nut, counterhold with open-ended wrench against the

injector.

| • |

Release 8x retaining nut

|

|

|

|

Important: After detaching the

high pressure lines, seal the apertures of the injectors and the

pressure chamber with protective caps

1)

|

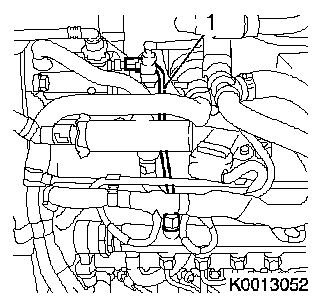

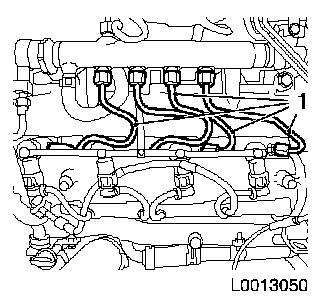

| 36. |

Detach high-pressure pump high-pressure line (1) from

accumulator

Note: When releasing

the retaining nut, counterhold with open-ended wrench against the

injector.

|

|

|

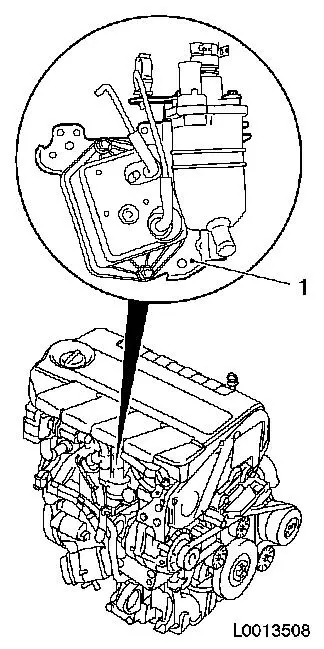

| 37. |

Remove accumulator (1)

|

|

|

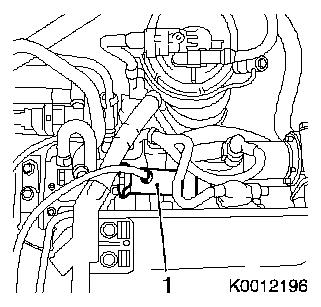

| 38. |

Remove fuel return damping case (1) with oil leak line

Note: Open fuel

connections must be sealed with appropriate plugs

|

|

|

| 39. |

Detach bracket (1) for toothed belt cover

|

|

|

| 40. |

Remove 4x injector (2)

Note: If injectors

cannot be removed by hand, use EN-46786

in conjunction with KM-328-B

| • |

Remove 4x injector with bracket

Note: After removal,

close the injector openings with protective caps

1)

|

|

|

|

| 41. |

Remove coolant pipe (1)

|

|

|

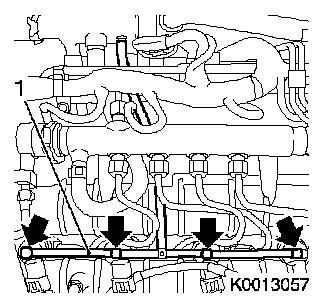

| 42. |

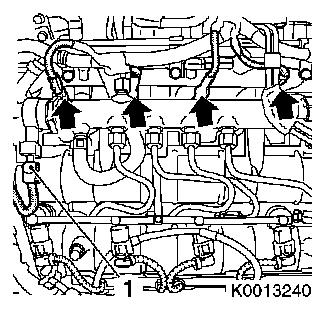

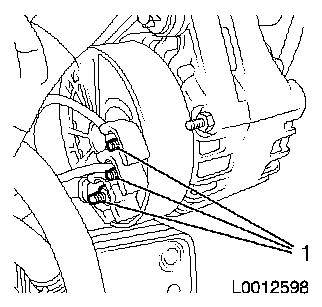

Remove 4x glow plugs with EN-48390

| • |

Disconnect 4x wiring harness plug, sheathed glow plug

(arrows)

|

|

|

|

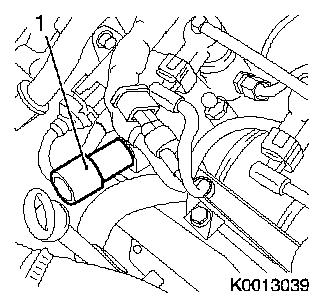

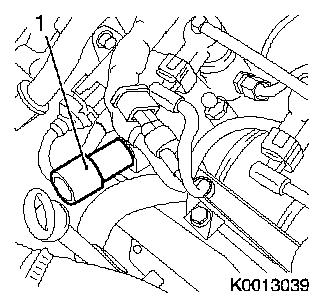

| 43. |

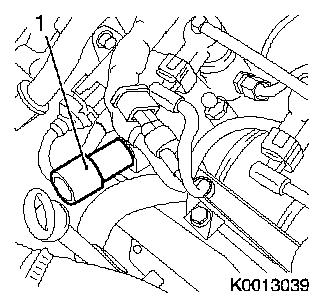

Release high-pressure pump gear

Note: Use a second

person

| • |

Counterhold with KM-6347 (1) in

combination with KM-956-1 (2)

|

|

|

|

| 44. |

Detach high-pressure pump gear

| • |

Pull off high-pressure pump drive gear

| – |

Counterhold with open-ended wrench (2)

|

|

|

|

|

| 45. |

Remove high pressure pump

|

|

|

| 46. |

Detach 3x alternator wiring harnesses

|

|

|

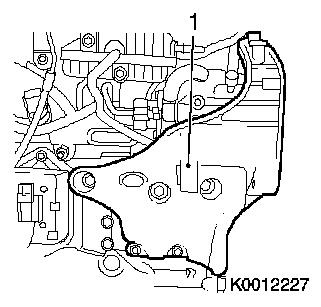

| 48. |

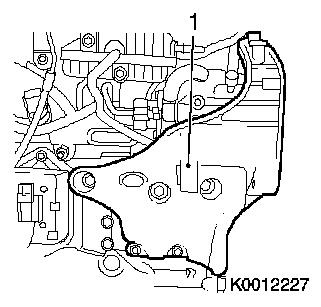

Detach high-pressure pump bracket (1)

| • |

Detach coolant pipe bracket from high-pressure pump bracket

|

| • |

Unscrew 6x bolts

Note: Note different

bolt lengths

|

|

|

|

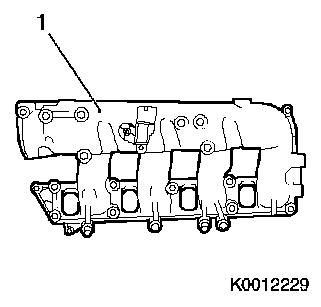

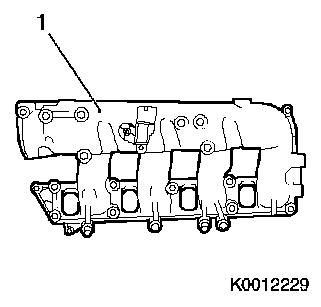

| 49. |

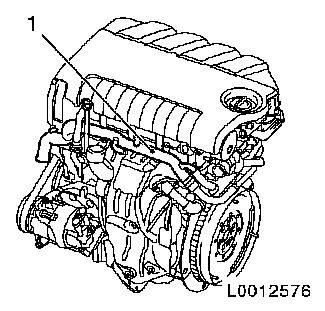

Remove intake manifold (1)

|

|

|

| 50. |

Detach alternator bracket

| • |

Unscrew 2x bolts

Note: Note different

bolt lengths

|

|

| 51. |

Fit engine transport shackle

|

| 52. |

Hitch engine up to workshop crane.

|

| 53. |

Detach engine from KM-412

|

| 54. |

Detach KM-412-36-1 and KM-412-36-2 from engine block

|

| 55. |

Unhitch engine from workshop crane.

|

| 56. |

Detach engine transport shackle

|

| 57. |

Attach engine transportation shackle to engine short block

|

Install

Install

| 58. |

Hitch engine short block up to workshop crane

|

| 59. |

Attach KM-412-36-1 an KM-412-36-2 to engine block

|

| 60. |

Attach engine short block to KM-412

|

| 61. |

Unhitch engine short block from workshop crane

|

Important: According to the

instruction provided by the engine preparer, all attaching parts to

be refitted must be cleaned of dirt particles and liquids.

|

| 62. |

Cleaning work for attaching parts

|

| 63. |

Detach engine transport shackle

|

| 64. |

Attach alternator bracket

| • |

Tighten 2x bolts

Note: Note different

bolt lengths

|

|

| 65. |

Install intake manifold

| • |

Tighten 9x new nut 25 Nm

|

|

| 66. |

Attach high-pressure pump bracket

| • |

Tighten 6x bolt 25 Nm

Note: Note different

bolt lengths

|

| • |

Attach coolant pipe bracket to high-pressure pump bracket

|

|

| 67. |

Attach alternator

| • |

Tighten lower bolt 70 Nm

|

|

| 68. |

Attach alternator wiring harness

| • |

Tighten 2x nut (M6) 5 Nm

|

|

| 69. |

Install high pressure pump

|

| 70. |

Fit high pressure pump wheel

|

| 71. |

Fasten high-pressure pump gear

Note: 2nd mechanic

| • |

Counterhold with KM-6347 in

conjunction with KM-956-1

|

|

| 72. |

Tighten 4x sheathed glow plugs to 8

Nm

|

| 73. |

Attach wiring harness of sheathed glow plugs

| • |

Connect 4x wiring harness plug, sheathed glow plug

|

|

| 75. |

Cleaning work

| • |

Use EN-47632 (1) to clean the

injector seats. Insert EN-47632 with

coarse fleece in the injector shaft and clean the injector seat by

turning. Finish by cleaning with the fine fleece.

|

|

|

|

| 77. |

Attach bracket, toothed belt cover

|

| 78. |

Install fuel return damping case with oil leak line

| • |

Tighten 2x bolts

| – |

Attach wiring harness bracket to fuel return damping case

|

|

|

Important: When tightening the

retaining nut on the counterhold on the connection for the fuel

high pressure pump with open-ended wrench

|

| 80. |

Attach new high-pressure pump high-pressure line to pressure

chamber

| • |

Tighten 2x union nuts 25 Nm

|

|

Important: When tightening the

retaining nut, counterhold against the injector with open-ended

wrench, Use new pressure lines

|

| 81. |

Attach 4x high pressure line for pressure chamber to

injector

| • |

Tighten 8x retaining nut

|

|

| 82. |

Attach oil leak line

| • |

Clip 4x oil leak line into injector

|

|

| 83. |

Attach coolant pipe to intake manifold

| • |

Attach coolant hose to coolant pipe

|

|

| 84. |

Attach engine management wiring harness

| • |

Connect 18x wiring harness plugs

|

| • |

Coolant temperature sensor

|

| • |

Pressure-regulating valve

|

| • |

Charge pressure control solenoid valve

|

|

| 85. |

Attach compressor wiring harness

|

| 86. |

Clip vacuum line into cable conduit

|

| 88. |

Install toothed belt guide roller

| • |

Tighten bolt 50 Nm

Note: Use screw locking

compound (red)

|

|

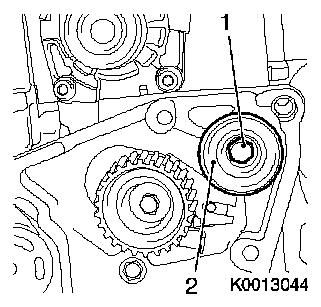

| 90. |

Fit toothed belt tightening roll

Note: Insert tension

roller in guide

| • |

Use screw locking compound (red)

|

|

| 91. |

Install EN-46789 (1) in camshaft

housing

| • |

Unscrew exhaust camshaft closure bolt

|

|

| 92. |

Check camshaft setting on cylinder 1 at TDC of combustion

stroke

| • |

Reference tool EN-46789 must be

engaged in exhaust camshaft

|

|

|

|

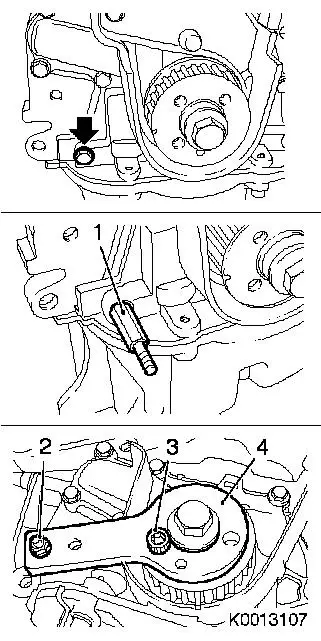

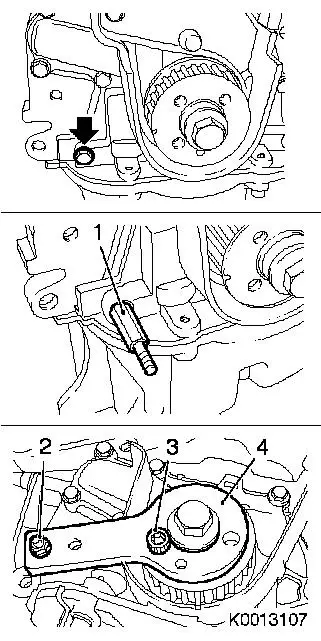

| 93. |

Check crankshaft setting with EN-46788

| • |

Unscrew oil pump bolt (arrow)

|

| • |

Tighten stud bolt (1) EN-46788

|

| • |

Attach positioning disk (4) EN-46788

|

| • |

Detach positioning disk EN-46788

|

|

|

|

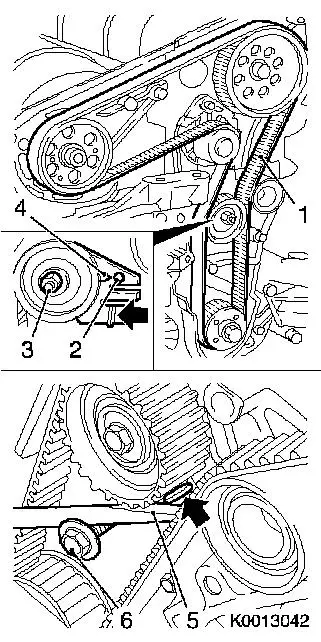

| 94. |

Install toothed belt

| • |

Observe prescribed direction of rotation

|

Important: Tightened end (1) must

be taut

|

| • |

Position toothed belt

|

|

| 95. |

Block crankshaft.

| • |

Attach positioning disk EN-46788

|

|

| 96. |

Tension the toothed belt

| • |

Tension toothed belt tension roller

Note: Push adjusting

lever in direction of arrow with a screwdriver (5) until pointer

(4) of toothed belt tension roller aligns with mark (2).

|

| • |

Tighten bolt, toothed belt tension roller (3) 25 Nm

|

| • |

Detach positioning disk EN-46788

|

|

|

|

| 97. |

Remove EN-46788

| • |

Remove positioning disk EN-46788

|

|

| 98. |

Turn crankshaft 720° in the direction of rotation of the

engine

| • |

Rotate crankshaft 720° in direction of engine rotation

until reference drift EN-46789 audibly

engages in exhaust camshaft

|

|

|

|

| 99. |

Check crankshaft setting with EN-46788

Note: If EN-46788 cannot be fitted, repeat the toothed belt

positioning procedure

| • |

Attach positioning disk EN-46788

|

| • |

Remove positioning disk and stud bolt EN-46788

|

| • |

Tighten oil pump bolt 9 Nm

|

|

| 100. |

Remove EN-46789 from camshaft

housing

|

| 101. |

Attach engine venting pipe

| • |

Attach engine venting hose to engine venting pipe

|

|

| 102. |

Install support for engine damping block

Note: Note different

bolt lengths

| • |

Tighten 4x bolt (M10) 50 Nm

|

| • |

Tighten bolt (M8) 25 Nm

|

|

| 103. |

Install upper toothed belt cover

| • |

Tighten 2x bolt (M8) 25 Nm

|

|

| 104. |

Install upper ribbed V-belt guide roller

|

| 105. |

Install torsional vibration damper

Note: Observe correct

fitting position

| • |

Tighten 4x bolt 25 Nm

Note: Counterhold

toothed belt drive gear at bolt

|

|

| 106. |

Attach compressor support to engine block

Note: Note guide

sleeves

|

| 107. |

Attach compressor to support

| • |

Fix wiring harness plug

|

|

| 108. |

Clean sealing surface

|

| 109. |

Install vacuum pump

| • |

Tighten 4x new bolt 5 Nm +

50°

|

|

| 110. |

Install engine oil filling nozzle

| • |

Tighten 3x bolts

Note: Recut thread

before re-using and insert bolt with locking compound (red). The

maximum installation time including torque check is 10 minutes

|

|

| 111. |

Attach intake port to throttle valve module

| • |

Replace gasket

Note: Coat with special

grease (white)

|

|

| 113. |

Attach EGR metal tube to EGR valve

|

| 114. |

Attach 3x coolant hoses

| • |

Attach coolant hose to top coolant pipe

|

| • |

Attach coolant hose to bottom coolant pipe

|

| • |

Attach coolant hose to EGR cooler

|

|

| 115. |

Clean sealing surface

|

| 117. |

Attach thermostat housing

| • |

Attach 4x coolant hoses to coolant pipe

|

|

| 118. |

Connect coolant temperature sensor wiring harness plug

|

| 119. |

Install oil separator/vacuum reservoir bracket

| • |

Attach engine venting hose

|

| • |

Clip in wiring harness cover

|

|

| 120. |

Install vacuum line

| • |

Connect 4x vacuum hoses

Note: Pay attention to

marks

|

|

| 123. |

Fit flywheel

| • |

Tighten 6x new bolt 160 Nm

|

|

| 124. |

Attach KM-6263

Important: Fasten KM-6263 but only to engine block, not to oil pan

|

| • |

Tighten 4x bolts

|

| • |

Insert clutch pin KM-6263-30 with

KM-6263-22

|

|

| 126. |

Attach transmission to engine

|

1 ) Protective caps are available from the Opel

parts catalogue under catalogue number 45 06 154 / part number:

9201697

|