|

Balancer Shaft Unit, Remove and Install

Remove Remove

| 1. |

Remove lower engine splash guard

|

| 2. |

Disconnect catalytic converter control oxygen sensor wiring

harness plug

|

| 3. |

Remove front exhaust pipe

|

| 4. |

Remove oil drain bolt

Note: Collect engine

oil

|

| 5. |

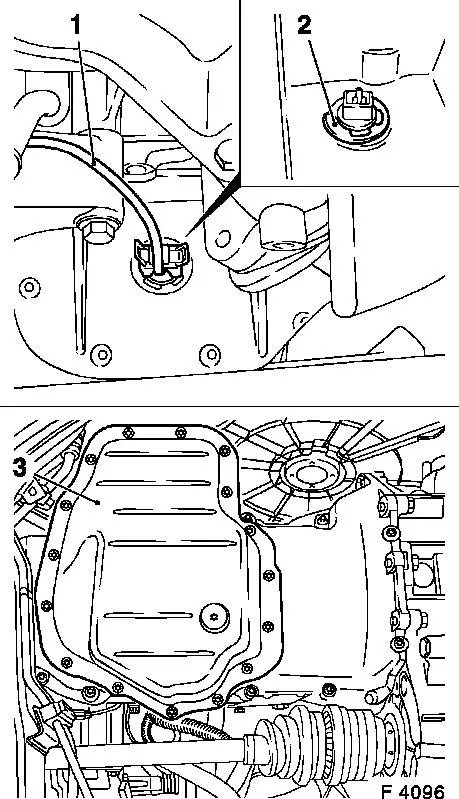

Disconnect wiring harness plug (1) for dynamic oil level

control and remove retaining ring (2)

|

| 6. |

Detach lower part of oil pan (3) from upper part of oil pan

|

|

|

| 7. |

Clean sealing surfaces and remove gasket remnants.

|

| 8. |

Remove oil filter from oil pump with KM-726-A

|

| 9. |

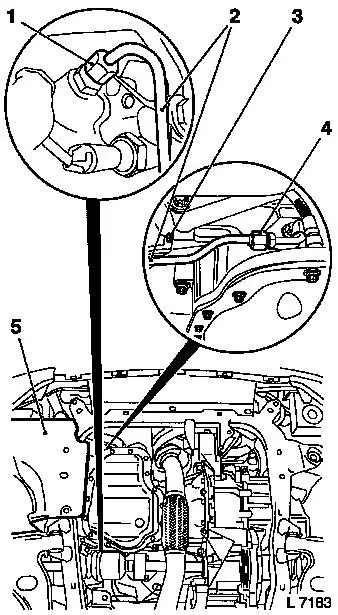

Detach union nut (4) from turbocharger oil feed line

(turbocharger)

Note: Place collecting

basin underneath.

|

| 10. |

Detach bracket (3) from cylinder block

|

| 11. |

Detach union nut (1) from cylinder block flange and remove

turbocharger oil feed line (cylinder block) (2)

|

|

|

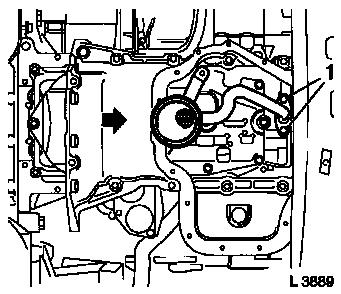

| 12. |

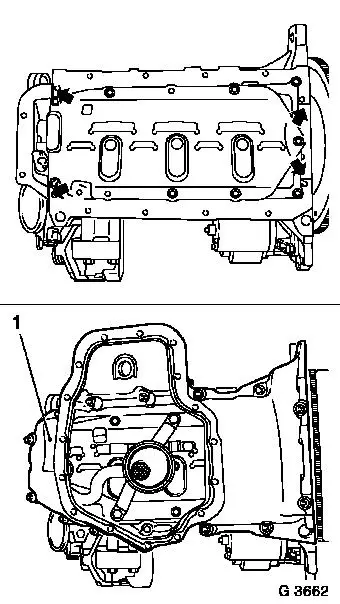

Detach oil pan top bolts (1) from transmission housing

|

| 13. |

Detach upper part of oil pan (2) from cylinder block and remove

oil pump

|

|

|

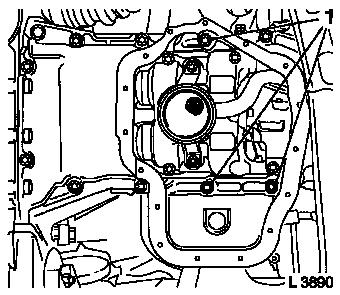

| 14. |

Detach 2x oil intake pipe bolts (1) from balancer shaft

unit

|

|

|

| 15. |

Move upper part of oil pan in direction of arrow and detach 2x

oil intake pipe bolts (1) from oil pump

|

| 16. |

Remove upper part of oil pan with oil intake pipe

|

|

|

| 17. |

Clean sealing surfaces and remove gasket remnants.

|

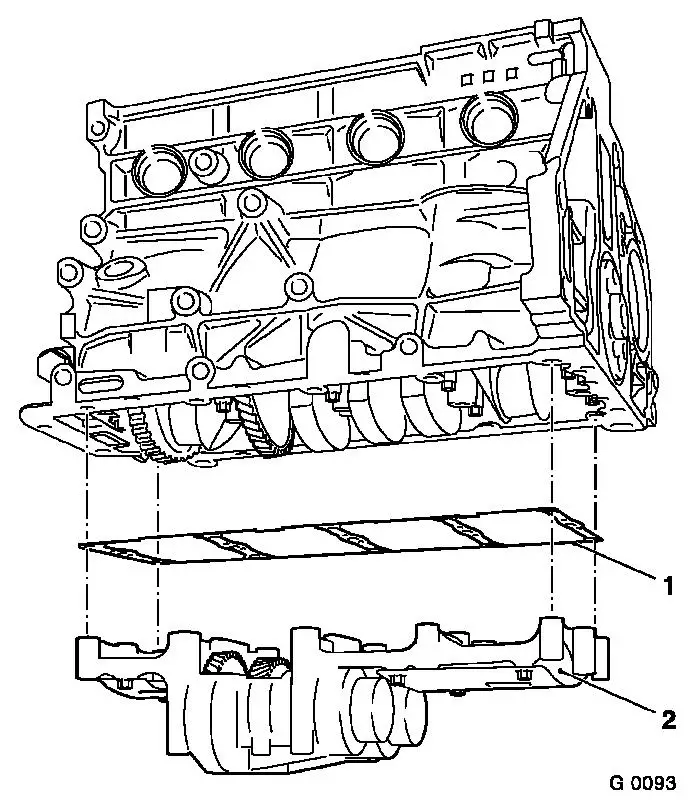

| 18. |

Remove oil baffle plate from balancer shaft unit

|

| 19. |

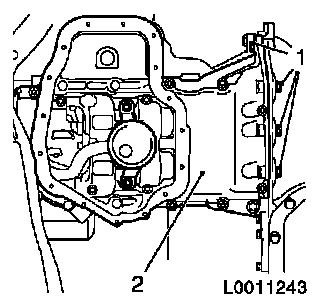

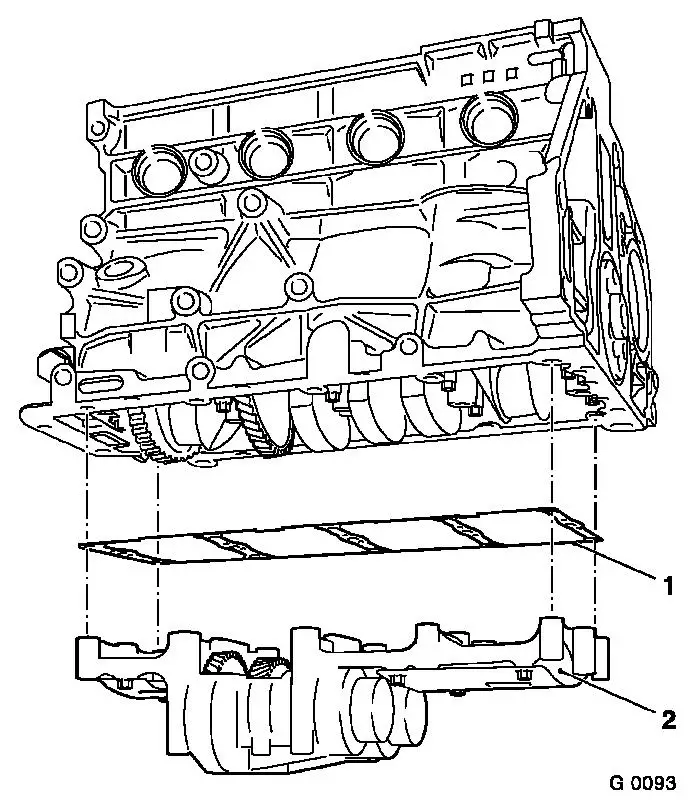

Detach balancer shaft unit (1) from cylinder block and

crankshaft bearing cap

| • |

Remove with balancer piece

|

|

|

|

Install

Install

| 20. |

Turn the crankshaft in the direction of engine rotation to the

mark "1st Cylinder TDC" using the fastening bolt for the toothed

belt drive gear.

|

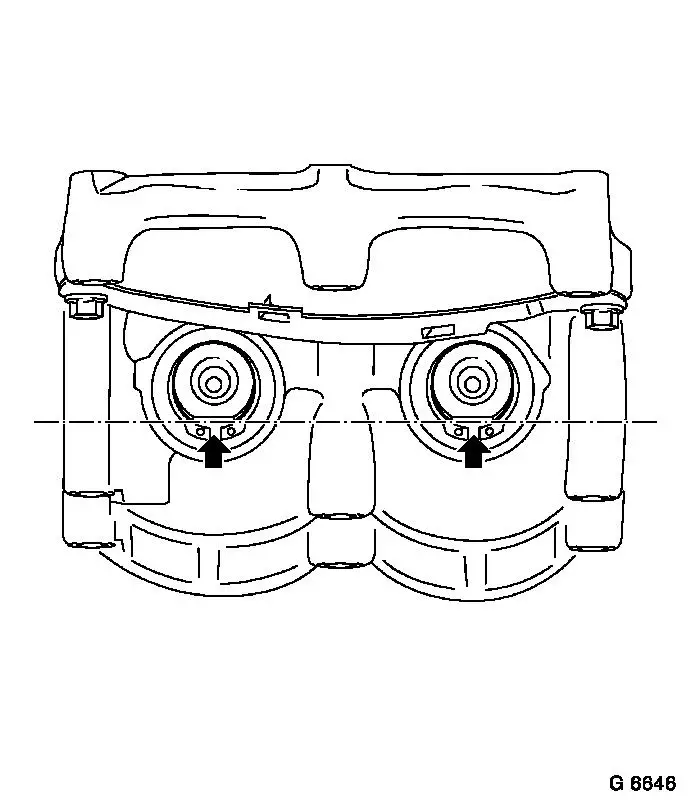

| 21. |

Turn balancer shafts so that both flattened sides (arrows)

point downward and form a horizontal line.

Note: If operations

have been performed on the crank drive that could affect the tooth

backlash between the balancer shafts and the crankshaft (e.g.

replacing the crankshaft, crankshaft bearing cap or balancer shaft

unit), the tooth backlash between balancer shafts and crankshaft

must be adjusted – see operation "Checking and adjusting

balancer shaft unit/crankshaft tooth backlash".

|

|

|

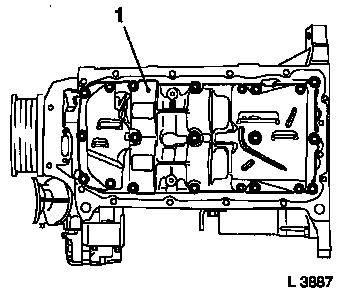

| 22. |

If no operations have been performed on crank drive that could

affect the tooth backlash between balancer shaft unit (2) and

crankshaft (e.g. removal and installation of con-rod bearing or

piston with con-rod), the same balancer piece (1) can be re-used

when installing.

|

|

|

| 23. |

Attach balancer shaft unit (2) with balancer piece (1) to

cylinder head and crankshaft bearing cap

| • |

Tighten all bolts uniformly 20 Nm +

45°

|

|

| 24. |

Attach oil baffle plate to balancer shaft unit 8 Nm

|

|

|

| 25. |

Apply a bead of adhesive sealing compound (black) to joints

(arrows) of oil pump and rear crankshaft bearing cap

|

| 26. |

Insert upper part of oil pan (1) with new gasket and oil intake

pipe

|

| 27. |

Attach oil intake pipe to oil pump with new seal ring 8 Nm

1)

|

| 28. |

Attach oil intake pipe to balancer shaft unit 10 Nm

|

|

|

| 29. |

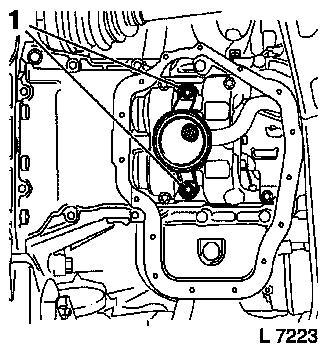

Attach upper part of oil pan to cylinder block, oil pump and

transmission housing with new gasket

|

| 30. |

Insert contact surfaces of bolts (1) coated with surface

sealant (green)

Installation sequence:

| 1. |

Tighten all bolts loosely. |

| 2. |

Tighten bolts at cylinder block and oil pump 20 Nm |

| 3. |

Tighten bolts at transmission housing 40 Nm . |

|

|

|

| 31. |

Insert turbocharger oil feed line (cylinder block) and attach

to cylinder block flange with union nut 20

Nm

|

| 32. |

Attach turbocharger oil feed line union nut (cylinder block) to

turbocharger oil feed line (turbocharger) 20 Nm

|

| 33. |

Attach turbocharger oil feed line bracket to cylinder block

35 Nm

|

| 34. |

Coat oil filter seal ring with a thin layer of engine oil and

attach to oil pump 15 Nm

|

| 35. |

Insert dynamic oil level control plug-in connection into upper

section of oil pan with new seal ring and fix in position with

retaining ring

|

| 36. |

Attach lower section of oil pan to upper section of oil pan

with new gasket and new bolts 8 Nm +

30°

|

| 37. |

Attach oil drain bolt to lower section of oil pan with new

gasket 10 Nm

|

| 38. |

Connect wiring harness plug for dynamic oil level control

|

| 39. |

Install front exhaust pipe with new gasket 35 Nm

|

| 40. |

Connect wiring harness plug for catalytic converter control

oxygen sensor

|

| 41. |

Route wiring harness

Note: Note routing of

wires

|

| 42. |

Install lower engine splash guard

|

| 43. |

Top up engine oil quantity to "MAX" mark on oil dipstick

|

1 ) Recut thread before use and insert bolts with

bolt locking compound (red). Installation time including torque

check should not exceed 10 minutes.

|