|

Check and adjust balancer shaft unit/crankshaft

tooth backlash

Remove Remove

| 1. |

Remove lower engine splash guard

|

| 2. |

Disconnect catalytic converter control oxygen sensor wiring

harness plug

|

| 3. |

Remove front exhaust pipe

|

| 4. |

Remove oil drain bolt

Note: Collect engine

oil

|

| 5. |

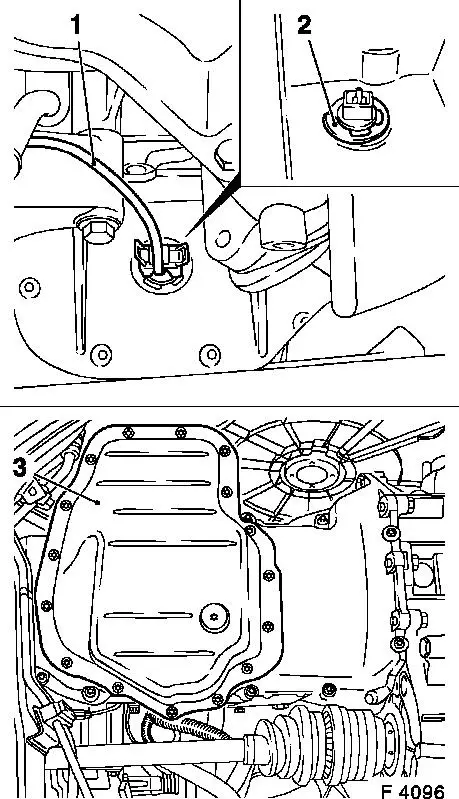

Disconnect wiring harness plug (1) for dynamic oil level

control and remove retaining ring (2)

|

| 6. |

Detach lower part of oil pan (3) from upper part of oil pan

|

|

|

| 7. |

Clean sealing surfaces and remove gasket remnants.

|

| 8. |

Remove oil filter from oil pump with KM-726-A

|

| 9. |

Detach union nut (4) from turbocharger oil feed line

(turbocharger)

Note: Place collecting

basin underneath.

|

| 10. |

Detach bracket (3) from cylinder block

|

| 11. |

Detach union nut (1) from cylinder block flange and remove

turbocharger oil feed line (cylinder block) (2)

|

|

|

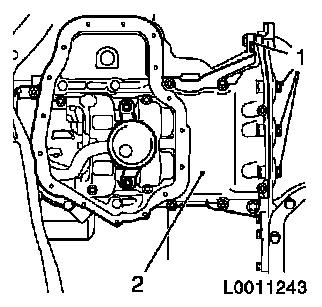

| 12. |

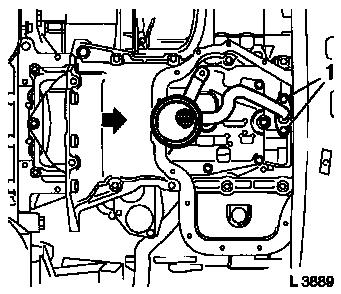

Detach oil pan top bolts (1) from transmission housing

|

| 13. |

Detach upper part of oil pan (2) from cylinder block and remove

oil pump

|

|

|

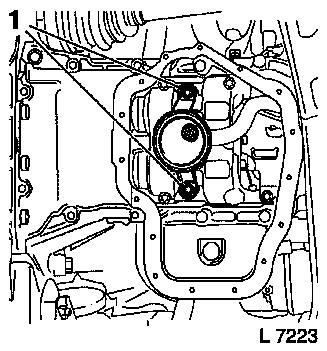

| 14. |

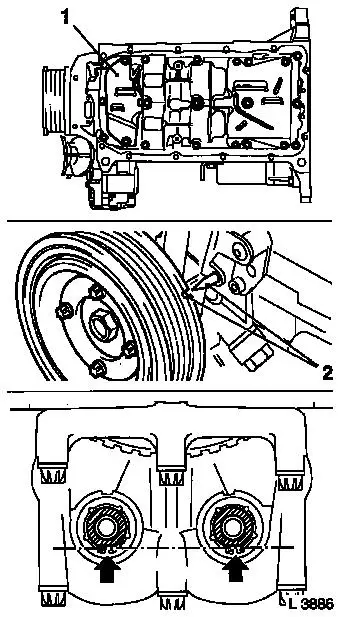

Detach 2x oil intake pipe bolts (1) from balancer shaft

unit

|

|

|

| 15. |

Move upper part of oil pan in direction of arrow and detach 2x

oil intake pipe bolts (1) from oil pump

|

| 16. |

Remove upper part of oil pan with oil intake pipe

|

|

|

| 17. |

Clean sealing surfaces and remove gasket remnants.

|

| 18. |

Remove oil baffle plate (1) from balancer shaft unit.

|

| 19. |

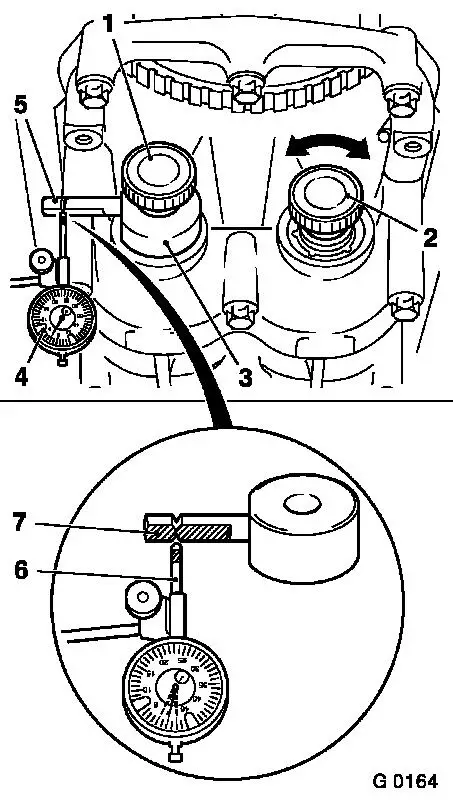

At toothed belt drive gear fastening bolt, turn crankshaft in

direction of engine rotation to "Cylinder no.1 TDC " (mark 2).

|

| 20. |

In this crankshaft position, the flattened sides (arrows) of

both balancer shafts must point down and form a horizontal

line.

|

|

|

Install

Install

| 21. |

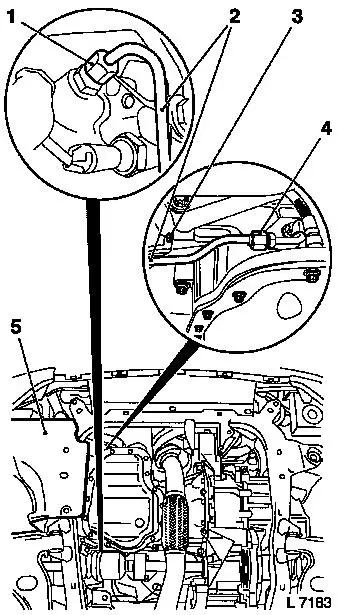

Screw measuring device KM-949 (3)

into 1st balancer shaft (intake side) using long knurled bolt (1)

and hand-tighten

Note: Measuring arm (5)

must point in "9 o'clock" direction

|

| 22. |

Screw short knurled bolt (2) into 2nd balancer shaft (exhaust

side) and also hand-tighten

|

| 23. |

Fit dial gauge bracket with dial gauge KM-798 (4) to cylinder block and place dial gauge

plunger (6) against measuring arm of measuring device KM-949 under pre-tension

Note: The plunger must

be placed exactly between the notch marks, vertically to the flat

plane (7)

|

| 24. |

Determine left and right stop positions by turning knurled bolt

(2) backwards and forwards. Set dial of dial gauge to zero.

|

|

|

| 25. |

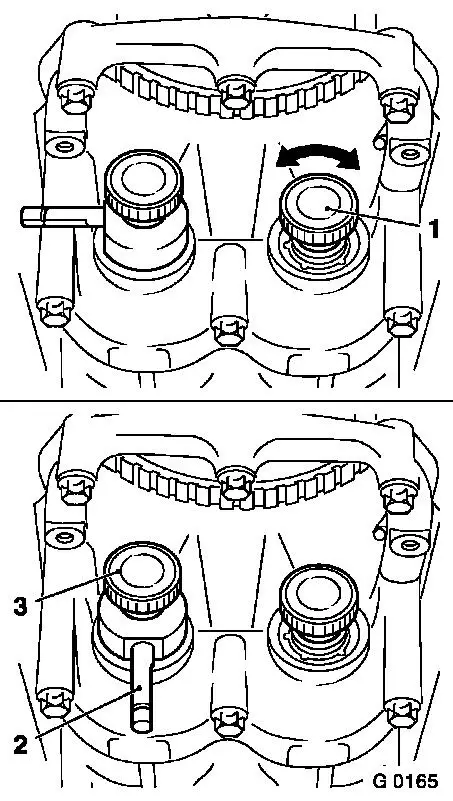

Move 2nd balancer shaft (exhaust side) forwards and backwards

again at knurled bolt (1) - read off tooth backlash from dial gauge

at same time.

|

| 26. |

Permissible backlash is: 0.02 mm to 0.06 mm.

|

| 27. |

The tooth backlash must be measured in 4 different positions -

to do this, continue rotating crankshaft at toothed belt drive gear

fastening bolt in steps of 90° in direction of engine rotation

until measuring arm (2) is in the "6 o'clock" position.

|

| 28. |

Then loosen the knurled bolt (3), move measuring arm to "9

o'clock" again and repeat measurement.

|

| 29. |

If any of the 4 measurements is out of tolerance (0.02 mm to

0.06 mm) the tooth backlash must be adjusted.

|

|

|

|