|

Camshafts, Remove and Install

Remove Remove

| 1. |

Remove rear toothed belt cover

|

Important: Crankshaft must be

60° before TDC

|

| 2. |

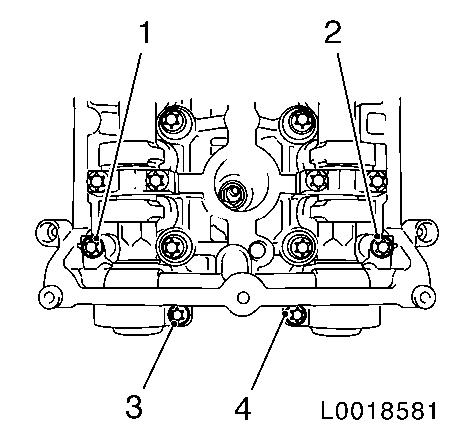

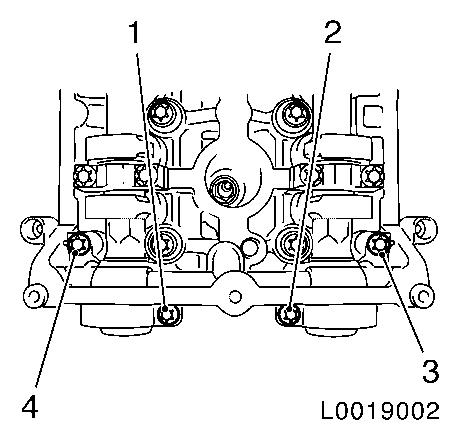

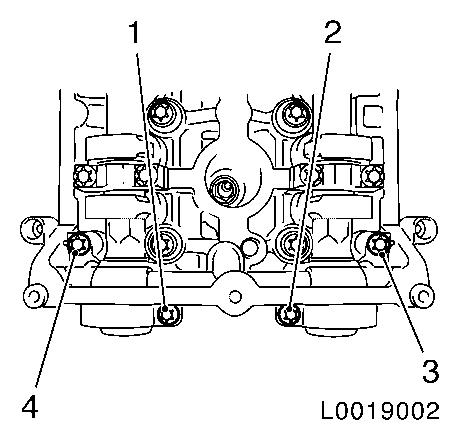

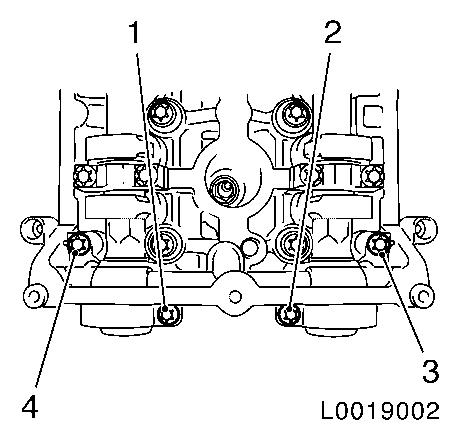

Remove camshaft sensor of intake camshaft (2)

| • |

Disconnect wiring harness plug (1)

|

|

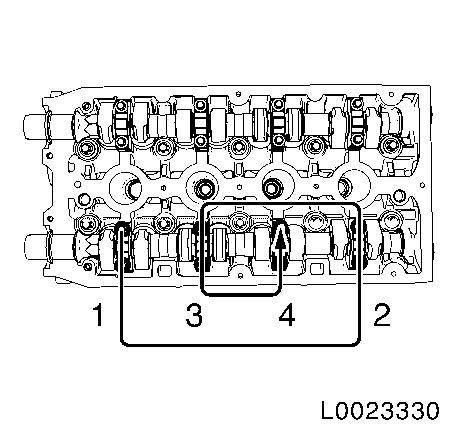

| 3. |

Remove camshaft sensor of exhaust camshaft (4)

| • |

Disconnect wiring harness connector (3)

|

| • |

Unclip wiring harness of mixture regulator oxygen sensor from

bracket

|

|

|

|

| 4. |

Remove KM-6628-A

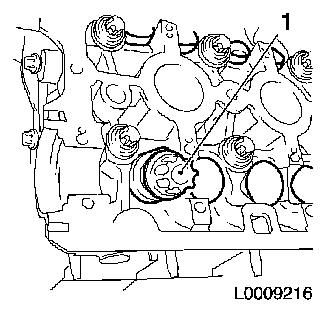

| • |

Counterhold at hexagon of camshafts

|

|

| 5. |

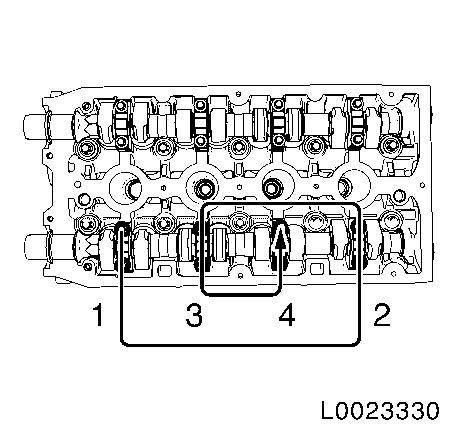

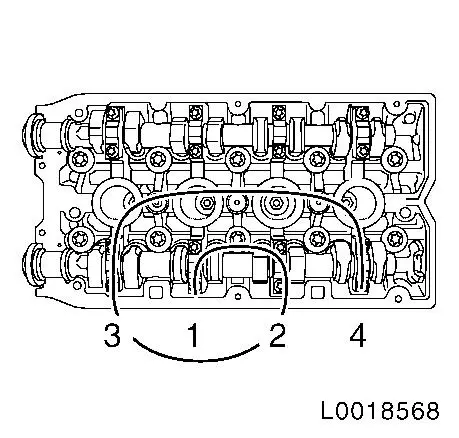

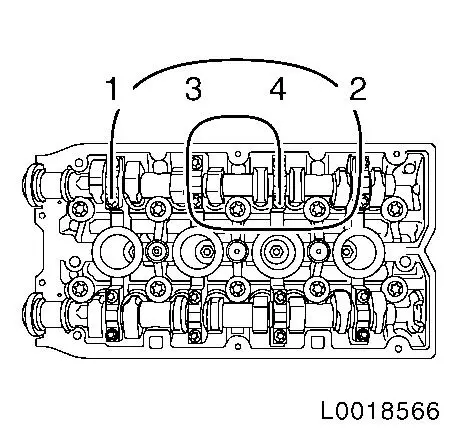

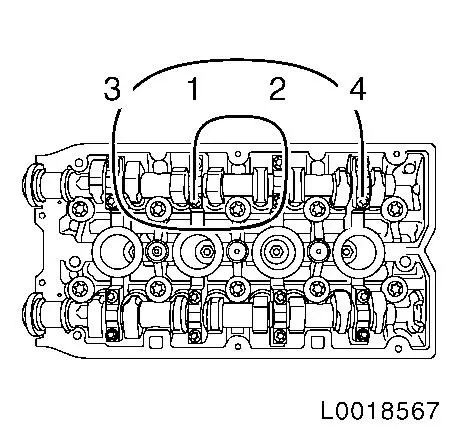

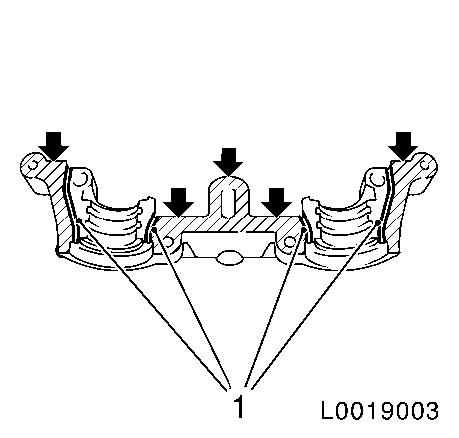

Remove camshaft bearing support

| • |

Unscrew 4x bolts

| – |

Note removal sequence 1 - 4

|

|

| • |

Release bearing support by striking it gently with a plastic

hammer

|

|

|

|

|

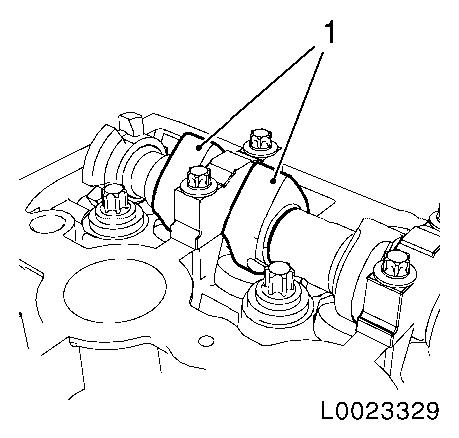

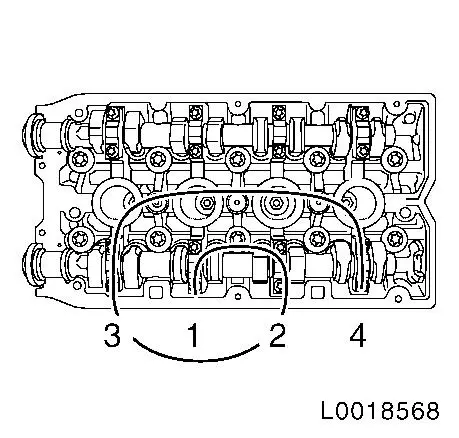

| 6. |

Remove exhaust camshaft

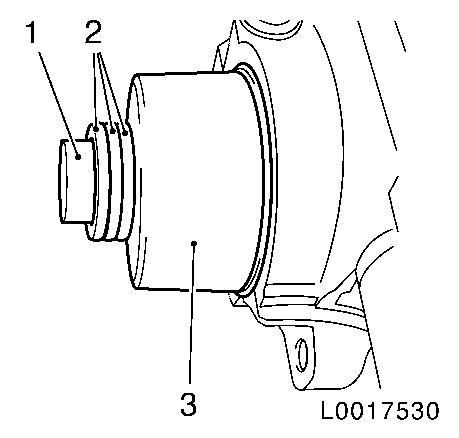

Note: Mark camshaft

bearing caps before removal

| • |

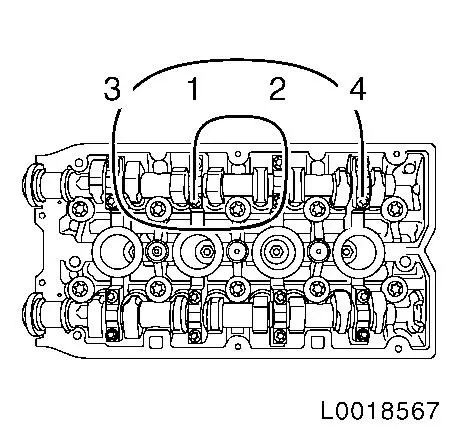

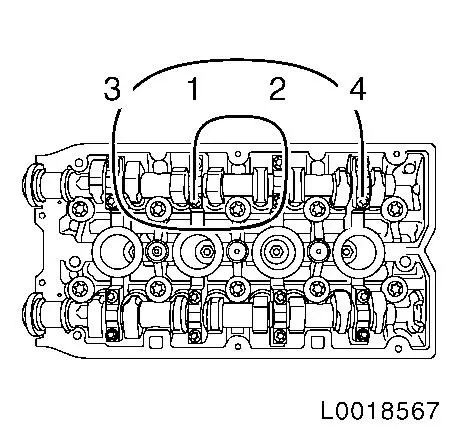

Slacken camshaft bearing caps 5 - 8 working in spiral from

outside to inside in steps of 1/2 up to 1 turn

|

| • |

Note removal sequence 1 - 4

|

| • |

Remove the camshaft bearing cover from the cylinder head and

take out the camshaft

|

|

|

| 7. |

Remove intake camshaft

Note: Mark camshaft

bearing caps before removal

| • |

Slacken camshaft bearing caps 1 - 4 working in spiral from

outside to inside in steps of 1/2 up to 1 turn

|

| • |

Note removal sequence 1 - 4

|

| • |

Remove the camshaft bearing cover from the cylinder head and

take out the camshaft

|

|

|

|

| 8. |

Detach seal rings from camshafts

|

Install

Install

| 9. |

Install intake camshaft

| • |

Coat with MoS 2 lubricating paste

|

| • |

Insert camshaft

Note: Note the

identification marking on the camshaft bearing cover

|

| • |

Install camshaft bearing cover

| – |

Note installation sequence 1 - 4

|

| – |

Tighten camshaft bearing caps 1 - 4 in a spiral from the inside

outward 8 Nm

|

|

|

|

|

| 10. |

Install exhaust camshaft

| • |

Coat with MoS 2 lubricating paste

|

| • |

Insert camshaft

Note: Note the

identification marking on the camshaft bearing cover

|

| • |

Install camshaft bearing cover

| – |

Note installation sequence 1 - 4

|

| – |

Tighten camshaft bearing caps 5 - 8 in a spiral from the inside

to the outside 8 Nm

|

|

|

|

|

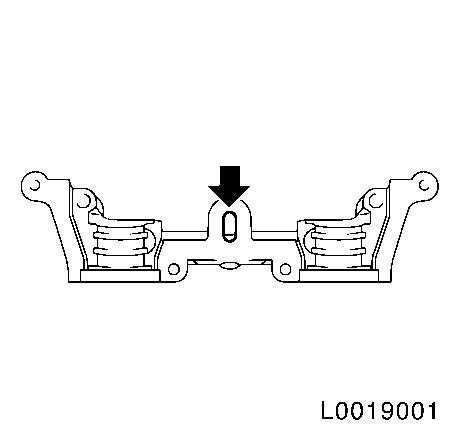

Important: Sealing surfaces must

be free from oil and grease

|

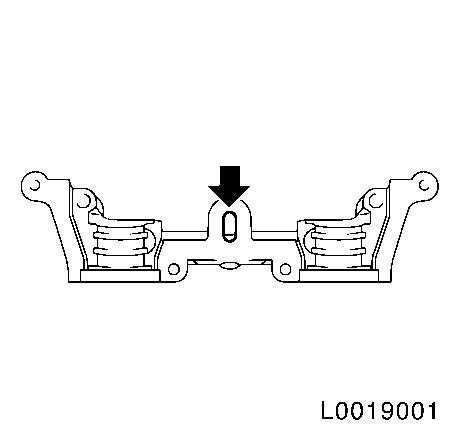

| 11. |

Clean sealing surfaces of the camshaft bearing support and the

cylinder head with a suitable tool, e.g. plastic wedge

| • |

Free oil duct (arrow) from any sealant residue

|

|

|

|

| 12. |

Place the camshaft bearing cap on the cylinder block without

sealant and hand-tighten the bolts (approx. 2 Nm )

Note: Note correct

tightening sequence 1-4.

|

|

|

| 13. |

Fit the camshaft adjuster for the intake camshaft to the intake

camshaft

|

| 14. |

Fit the camshaft adjuster for the exhaust camshaft to the

exhaust camshaft

|

Important: If the actual value

deviates from the required value, these values must be noted and

the adjustment procedure carried out

|

| 15. |

Check the valve clearance at both intake valves for cylinder

1

| • |

Turn the intake camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 1 are

located in test position (1)

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

intake side valve clearance: 0.25 mm

|

|

|

|

| 16. |

Check the valve clearance at both intake valves for cylinder

3

| • |

Turn the intake camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 3 are

located in test position

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

intake side valve clearance: 0.25 mm

.

|

|

| 17. |

Check the valve clearance at both intake valves for cylinder

4

| • |

Turn the intake camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 4 are

located in test position

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

intake side valve clearance: 0.25 mm

.

|

|

| 18. |

Check the valve clearance at both intake valves for cylinder

2

| • |

Turn the intake camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 2 are

located in test position

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

intake side valve clearance: 0.25 mm

.

|

|

Important: If the actual value

deviates from the required value, these values must be noted and

the adjustment procedure carried out

|

| 19. |

Check the valve clearance at both exhaust valves for cylinder

4

| • |

Turn the exhaust camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 4 are

located in test position (1)

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

exhaust side valve clearance: 0.30

mm

|

|

|

|

| 20. |

Check the valve clearance at both exhaust valves for cylinder

2

| • |

Turn the exhaust camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 2 are

located in test position

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

exhaust side valve clearance: 0.30

mm

|

|

| 21. |

Check the valve clearance at both exhaust valves for cylinder

1

| • |

Turn the exhaust camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 1 are

located in test position

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

exhaust side valve clearance: 0.30

mm

|

|

| 22. |

Check the valve clearance at both exhaust valves for cylinder

3

| • |

Turn the exhaust camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 3 are

located in test position

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

exhaust side valve clearance: 0.30

mm

|

|

| 23. |

Detach camshaft adjuster for intake camshaft

| • |

Counterhold against the intake camshaft hex

|

|

| 24. |

Detach camshaft adjuster for exhaust camshaft

| • |

Counterhold against the exhaust camshaft hex

|

|

| 25. |

Detach camshaft bearing support

|

Important: If the actual value

matches the required value, continue with step 49

|

| 26. |

If the actual values do not match the required values, set the

valve clearance as follows

|

| 27. |

Remove intake camshaft

Note: Mark the camshaft

bearing caps before removing them.

| • |

Slacken camshaft bearing caps 1 - 4, working in spiral from

outside to inside in steps of 1/2 up to 1 turn

|

| • |

Note removal sequence 1 - 4

|

| • |

Remove the camshaft bearing cover from the cylinder head and

take out the camshaft

Note: Note marking on

the camshaft bearing cap with stamped numbers from 1 to 8 (there is

a dot at bottom left before each number to avoid mistakes).

|

|

|

|

|

| 28. |

Remove exhaust camshaft

Note: Mark the camshaft

bearing caps before removing them.

| • |

Slacken camshaft bearing caps 5 - 8, working in spiral from

outside to inside in steps of 1/2 up to 1 turn

|

| • |

Note removal sequence 1 - 4

|

| • |

Remove the camshaft bearing cover from the cylinder head and

take out the camshaft

Note: Note marking on

the camshaft bearing cap with stamped numbers from 1 to 8 (there is

a dot at bottom left before each number to avoid mistakes).

|

|

|

| 29. |

Remove cup tappet with KM-845 (1)

|

|

|

| 30. |

Determine cup tappet size

|

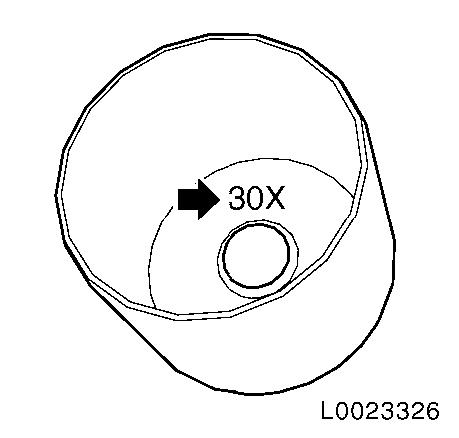

Example of determining the size of a cup tappet,

intake side:

|

|

Dimension of fitted cup tappet

|

|

3.20 mm

|

(Identification no. 20)

|

|

Valve clearance measurement between cams and cup tappets

|

+

|

0.35 mm

|

|

| |

=

|

3.55 mm

|

|

|

Required value, valve lash, intake side

|

-

|

0.25 mm

|

|

|

Nominal dimension of the new cup tappet

|

|

3.30 mm

|

(Identification number 30X)

|

Note: The identification

number (arrow) is on the inside of the cup tappet

| • |

Now use a cup tappet with this dimension or one that is nearest

to it

Currently available cup tappet sizes

|

|

|

|

| 31. |

Insert cup tappet with KM-845

| • |

Lightly coat sliding surfaces with oil

|

|

| 32. |

Install intake camshaft

| • |

Coat with MoS 2 lubricating paste

|

| • |

Insert camshaft

Note: Note the

identification marking on the camshaft bearing cover.

|

| • |

Install camshaft bearing cover

| – |

Tighten camshaft bearing caps 1 - 4 in a spiral from the inside

outward 8 Nm

Note: Note correct

tightening sequence 1 - 4.

|

|

|

|

|

| 33. |

Install exhaust camshaft

| • |

Coat with MoS 2 lubricating paste

|

| • |

Insert camshaft

Note: Note the

identification marking on the camshaft bearing cover.

|

| • |

Install camshaft bearing cover

| – |

Tighten camshaft bearing caps 5 - 8 in a spiral from the inside

to the outside 8 Nm

Note: Note correct

tightening sequence 1 - 4.

|

|

|

|

|

| 34. |

Clean sealing surfaces of the camshaft bearing support and the

cylinder head with a suitable tool, e.g. plastic wedge

| • |

Free oil duct (arrow) from any sealant residue

|

|

|

|

| 35. |

Place the camshaft bearing cap on the cylinder head without

sealant and hand-tighten the bolts (approx. 2 Nm )

Note: Note correct

tightening sequence 1-4.

|

|

|

| 36. |

Fit the camshaft adjuster for the intake camshaft to the intake

camshaft

|

| 37. |

Fit the camshaft adjuster for the exhaust camshaft to the

exhaust camshaft

|

Important: If the actual value

deviates from the required value, these values must be noted and

the adjustment procedure repeated

|

| 38. |

Check the valve clearance at both intake valves for cylinder

1

| • |

Turn the intake camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 1 are

located in test position (1)

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

intake side valve clearance: 0.25 mm

|

|

|

|

| 39. |

Check the valve clearance at both intake valves for cylinder

3

| • |

Turn the intake camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 3 are

located in test position

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

intake side valve clearance: 0.25 mm

.

|

|

| 40. |

Check the valve clearance at both intake valves for cylinder

4

| • |

Turn the intake camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 4 are

located in test position

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

intake side valve clearance: 0.25 mm

.

|

|

| 41. |

Check the valve clearance at both intake valves for cylinder

2

| • |

Turn the intake camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 2 are

located in test position

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

intake side valve clearance: 0.25 mm

.

|

|

Important: If the actual value

deviates from the required value, these values must be noted and

the adjustment procedure repeated

|

| 42. |

Check the valve clearance at both exhaust valves for cylinder

4

| • |

Turn the exhaust camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 4 are

located in test position (1)

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

exhaust side valve clearance: 0.30

mm

|

|

|

|

| 43. |

Check the valve clearance at both exhaust valves for cylinder

2

| • |

Turn the exhaust camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 2 are

located in test position

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

exhaust side valve clearance: 0.30

mm

|

|

| 44. |

Check the valve clearance at both exhaust valves for cylinder

1

| • |

Turn the exhaust camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 1 are

located in test position

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

exhaust side valve clearance: 0.30

mm

|

|

| 45. |

Check the valve clearance at both exhaust valves for cylinder

3

| • |

Turn the exhaust camshaft to the camshaft adjuster bolt in the

direction of engine rotation until the cams for cylinder 3 are

located in test position

|

| • |

Insert feeler gauge EN-6361 and check

valve clearance

Note: Required value,

exhaust side valve clearance: 0.30

mm

|

|

| 46. |

Detach camshaft adjuster for intake camshaft

| • |

Counterhold against the intake camshaft hex

|

|

| 47. |

Detach camshaft adjuster for exhaust camshaft

| • |

Counterhold against the exhaust camshaft hex

|

|

| 48. |

Detach camshaft bearing support

|

Important: It is necessary to

ensure that no sealant is applied outside the designated sealing

surfaces.

|

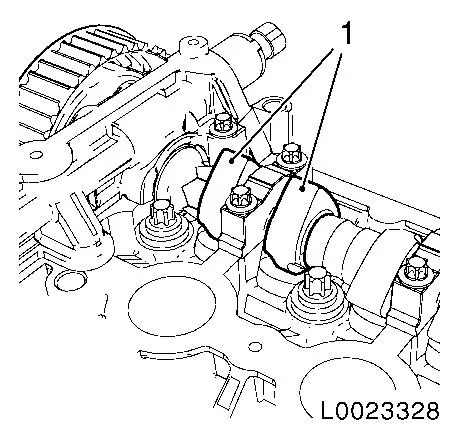

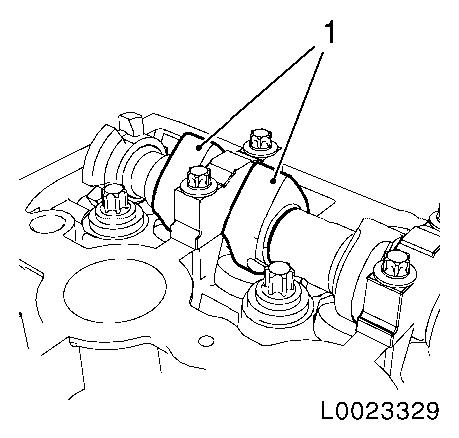

| 49. |

Apply surface sealant to sealing surfaces (arrows) of the

camshaft bearing support thinly and evenly

Note: The grooves (1)

adjacent to the sealing surfaces must remain free from sealant.

|

|

|

| 50. |

Place the camshaft bearing support on the cylinder head and

hand-tighten the bolts (approx. 2 Nm

)

|

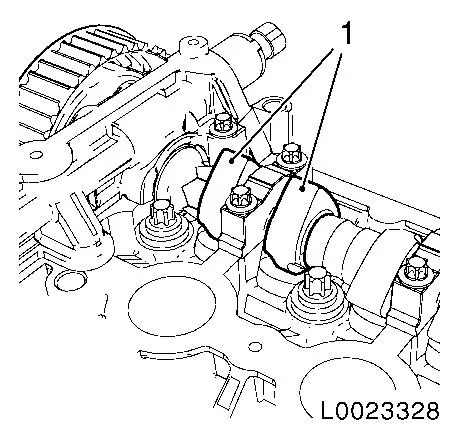

| 51. |

Install 2x camshaft seal ring

| • |

Attach seal ring with KM-422 (3)

until it lies on the cylinder head

| – |

To install, use camshaft sprocket bolt (1) in conjunction with

shims (2) with a total thickness of approx. 10 mm

|

|

|

|

|

Important: No sealant may reach

the camshafts

|

| 52. |

Tighten the camshaft bearing support

| • |

Tighten 4x bolt 8 Nm

| – |

Note installation sequence 1-4

|

|

|

|

|

| 53. |

Install camshaft sensor of exhaust camshaft

| • |

Clip on wiring harness of mixture regulator oxygen sensor to

bracket

|

| • |

Fix wiring harness plug

|

|

| 54. |

Install camshaft sensor, intake camshaft

| • |

Fix wiring harness plug

|

|

| 55. |

Rotate the crankshaft about 60° to TDC of cylinder 1

Note: In direction of

engine rotation.

|

| 56. |

Install rear toothed belt cover

|

|