|

End Shield Gasket, Replace (F13/F13+/F13

MTA/F17+/F17+ MTA)

Note: Transmission

remains installed.

Remove Remove

| 1. |

Remove battery support

|

| 2. |

Detach upper engine cover

Note: If present.

|

| 3. |

Remove gearbox cover

Note: F13/F17+ only

|

| 4. |

Remove gearshift module

|

| 5. |

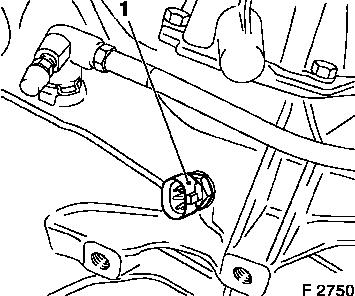

Unscrew reversing lamps switch (1)

Note: F13/F17+ only

| • |

Disconnect wiring harness plug, reversing lamp switch

|

|

|

|

| 6. |

Detach lower engine cover

Note: If present.

|

|

| 7. |

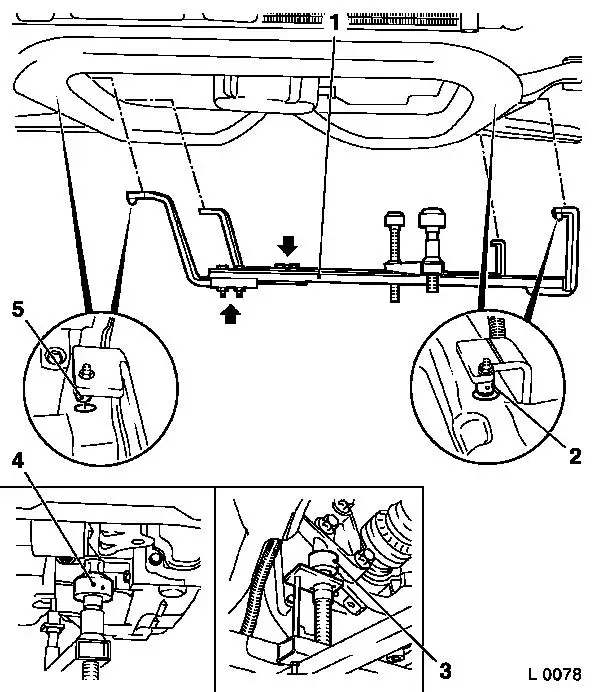

Attach KM-6001-B to front axle

body

Note: The guide pins

must sit in the support bearing with no play.

| • |

Release 2x bolt (arrows) for adjustment rails on KM-6001-B (1)

|

| • |

Insert KM-6001-B as shown

Note: 2x journals (2)

and (5) must sit flush in the guide holes of the front axle

body.

|

| • |

Tighten 2x bolt for adjustment rails

|

| • |

Twist up front support bearing (4)

| – |

until the guide pin is in contact with the front of the engine

damping block

|

|

| • |

Twist up rear support bearing (3)

| – |

until the guide pin is in contact with the rear of the engine

damping block

|

|

|

|

| 8. |

Remove front axle body

|

| 9. |

Detach left engine damping block

| • |

Detach from left engine damping block bracket

|

|

|

|

Important: Do not damage wiring

harnesses and attaching parts

|

| 10. |

Lower engine and transmission with MKM-883-1-A approx. 5 cm

|

| 11. |

Remove front left wheel

|

| 12. |

Remove end shield cover

|

|

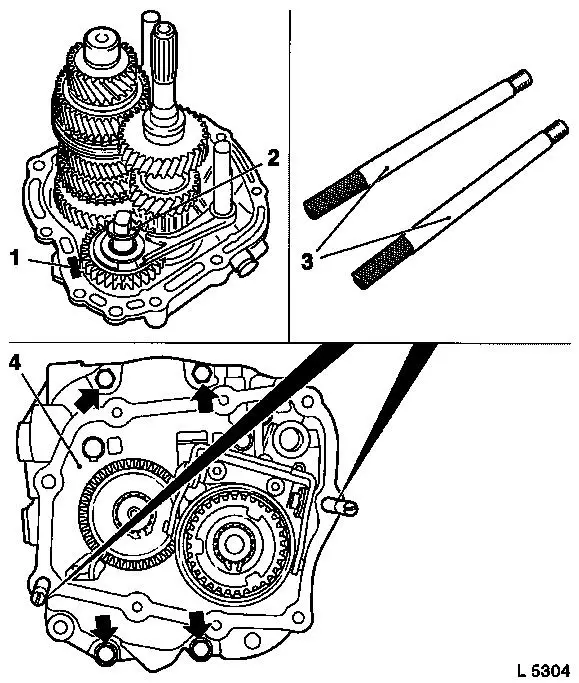

Important: When dismantling the

end shield it is essential to use KM-6155

(2) as otherwise the shaft seal ring of the central release will be

damaged.

|

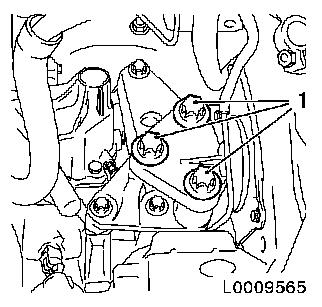

| 13. |

Screw KM-6155 into threaded bores

|

Important: Be careful of guide

sleeves, magnet (3) and spacer washer (4) for axle reverse idler

gear

|

| 14. |

Detach end shield

| • |

Unscrew 4x bolt (arrows)

|

|

|

| 15. |

Check all parts for damage

Note: Replace damaged

components.

|

| 16. |

Clean sealing surfaces

|

Install

Install

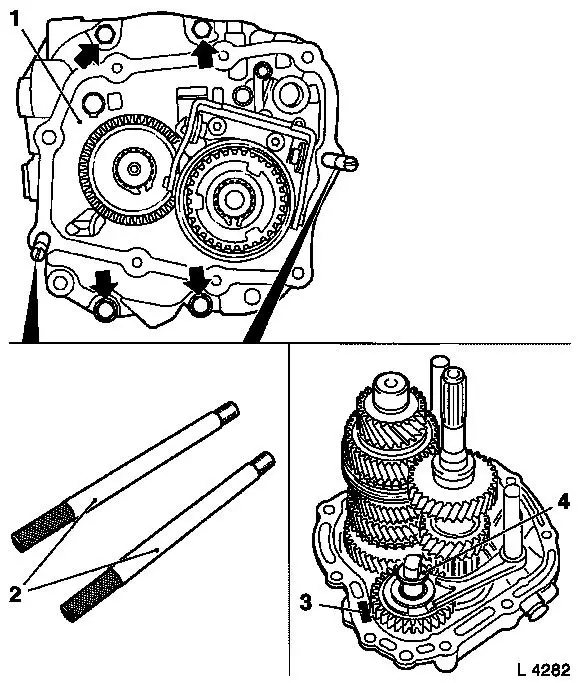

| 17. |

Stick new end shield gasket to transmission with roller bearing

grease

|

|

Important: Check that magnet (1)

and friction washer (2) are correctly seated.

|

| 18. |

Install end shield (4)

| • |

Carefully insert end shield into transmission housing

|

| • |

Tighten 4x bolt (arrows) 22 Nm

Note: Use new

bolts.

|

|

|

| 20. |

Attach end shield cover

|

| 21. |

Fit left front wheel 110 Nm

|

| 22. |

Lift engine and transmission with MKM-883-1-A

|

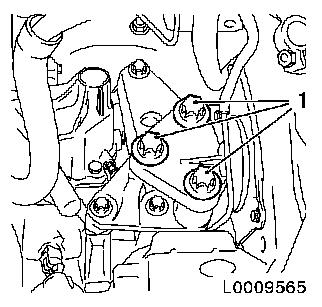

| 23. |

Install left engine damping block

| • |

Attach to left support for engine damping block

|

| • |

Tighten 3x bolt (1) 55 Nm

|

|

|

|

| 24. |

Install front axle body

|

| 25. |

Detach KM-6001-B from front axle

body

|

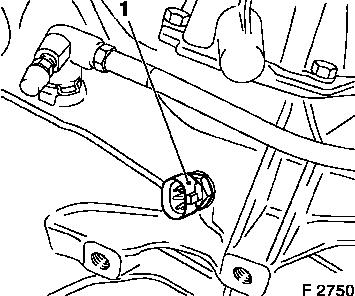

| 26. |

Tighten reversing lamp switch (1) 20

Nm

Note: F13/F17+ only

| • |

Connect wiring harness plug for reversing lamp switch

|

|

|

|

| 27. |

Attach gearbox cover to transmission

Note: F13/F17+ only

|

| 28. |

Install gearshift module

|

| 29. |

Install upper engine cover 7 Nm

Note: If present.

|

| 30. |

Install battery support

|

| 31. |

Check transmission fluid level

|

| 32. |

Attach lower engine cover

Note: If present.

|

| 33. |

Program volatile memories

|

| 34. |

Set transmission parameters

Note: F13 MTA/F17+ MTA

only

|

| 35. |

Comply with the start-up routines required

|

|