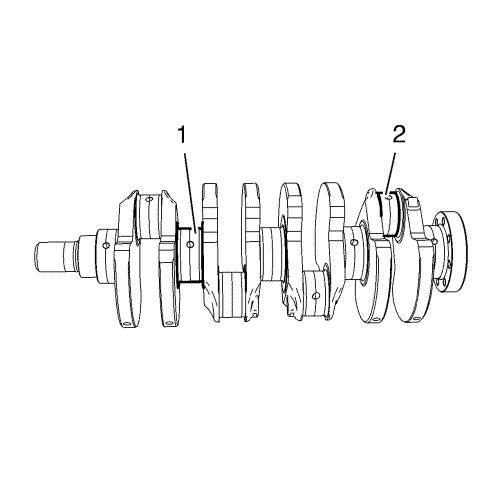

Crankshaft and Bearing Cleaning and Inspection

Cleaning Procedure

| 1. |

Clean the crankshaft with

solvent. |

| 2. |

Thoroughly clean all oil

passages and inspect for restrictions or burrs. |

| 3. |

Dry the crankshaft with

compressed air. |

Visual Inspection

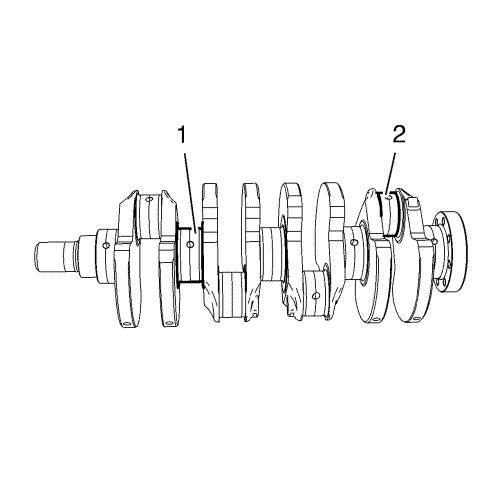

| 1. |

Inspect the 5 crankshaft

bearing journals (1) and 4 connecting rod bearing journals (2) for

wear: |

| |

• |

pitting or imbedded bearing

material |

| 2. |

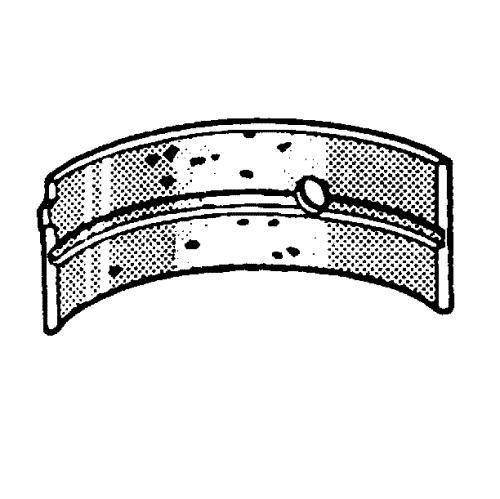

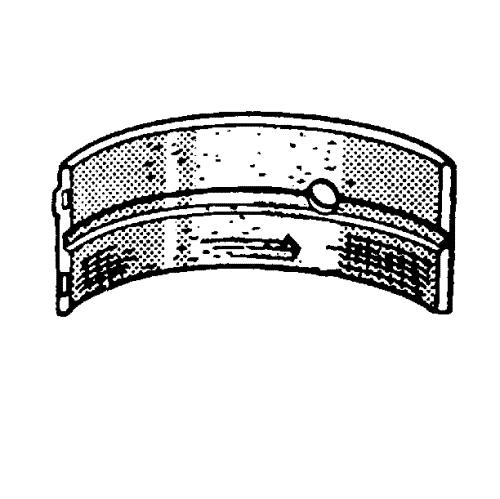

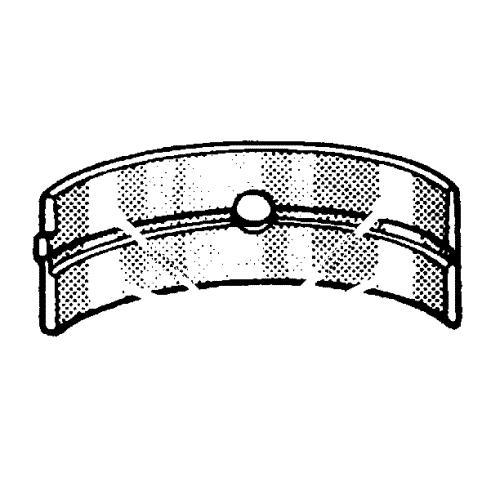

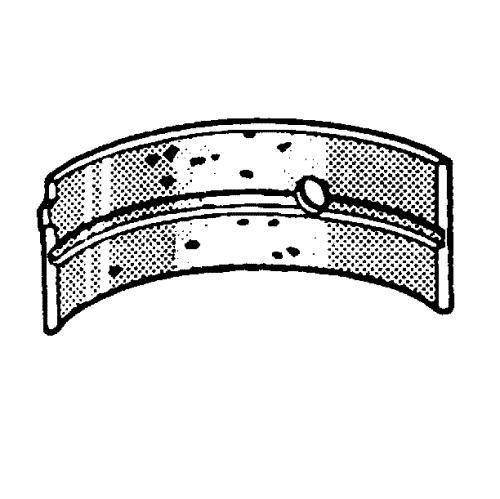

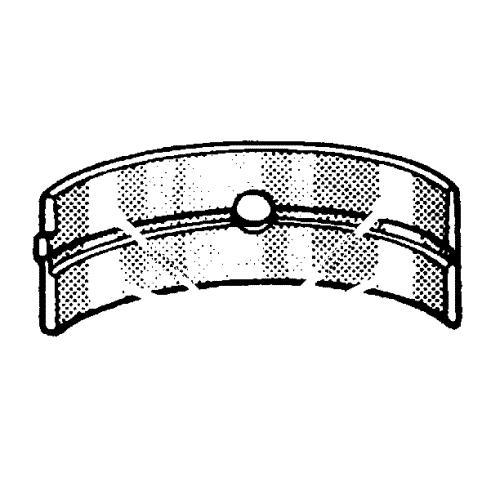

Inspect crankshaft bearings

for craters or pockets. Flattened sections on the bearing halves

also indicate fatigue. |

| 3. |

Inspect the crankshaft

bearings for excessive scoring or discoloration. |

| 4. |

Inspect the crankshaft

bearings for dirt or debris imbedded into the bearing

material. |

|

Note: If the lower

half of the bearing is worn or damaged, both upper and lower halves

should be replaced.

Generally, if the lower half is suitable for use, the upper

half should also be suitable for use.

|

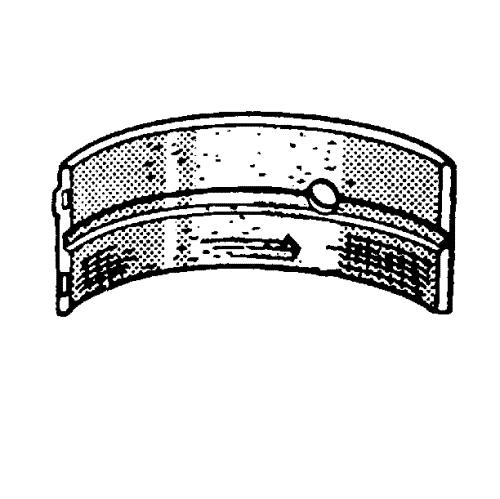

| 5. |

Inspect the crankshaft

bearings for improper seating indicated by bright, polished

sections of the bearing. |

Check Crankshaft Bearing Clearance (With Micrometer Gage

Internal Measuring Device)

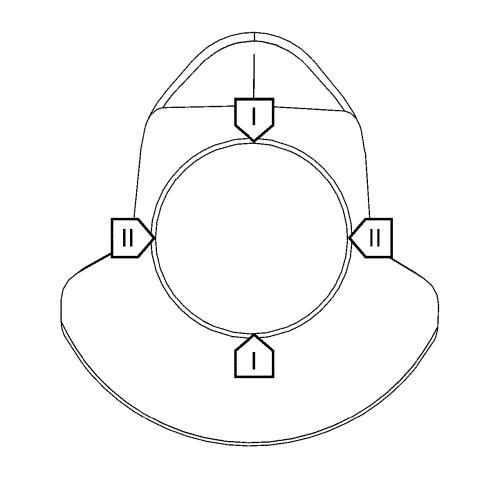

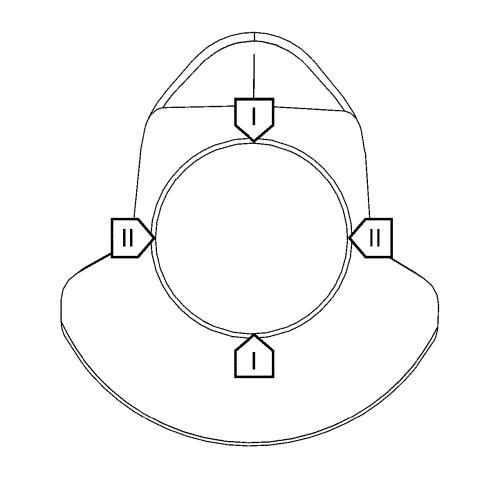

| 1. |

Measurement the crankshaft

bearing journal diameter with a micrometer gauge at the measuring

points (I) and (II). |

| 2. |

Calculate the average

crankshaft bearing journal diameter. Formula: 1. result + 2. result

/ 2. |

|

Note: Different

classes of bearing shells can be used for a crankshaft bearing to

reduce bearing clearance. The stronger of the two bearing shells

must be inserted in the crankcase.

|

| 3. |

Crankshaft bearing clearance

is calculated by using: |

| |

• |

Crankshaft bearing journal

diameter |

| |

• |

Crankshaft bearing shell

thickness |

| 4. |

Determine the crankshaft

bearing clearance. |

| |

Calculation formula: average crankshaft bearing bore diameter

minus average crankshaft bearing journal diameter minus crankshaft

bearing shell thickness from lower crankcase minus crankshaft

bearing shell thickness from engine block. |

Check Crankshaft Bearing Clearance (With Plastigage)

| 1. |

Install crankshaft with the 5

upper crankshaft bearing shells at the engine block. |

|

Note: Do not rotate

the crankshaft.

|

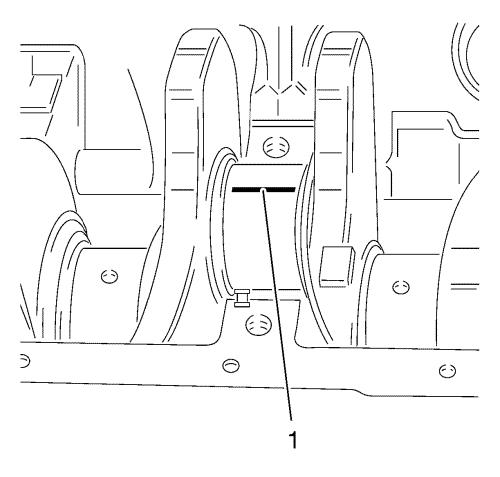

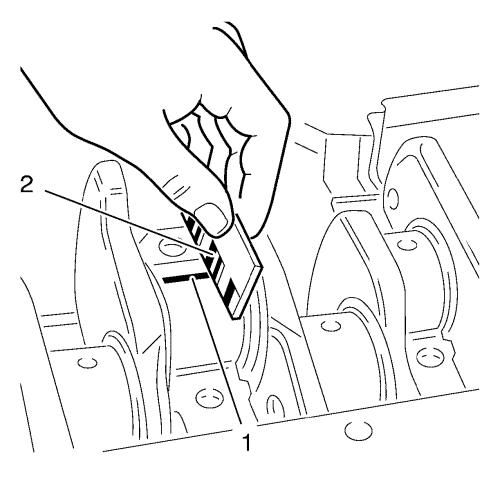

| 2. |

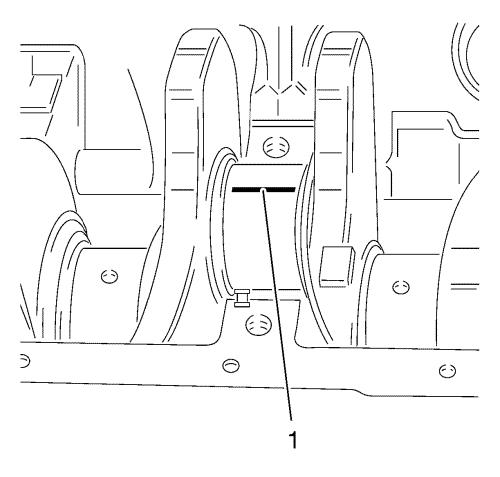

Lay on 5 times plastigage

(flexible plastic thread) axially over the entire width of the

crankshaft bearing journal (1). |

| 3. |

Install the 5 lower crankshaft

bearing shells. |

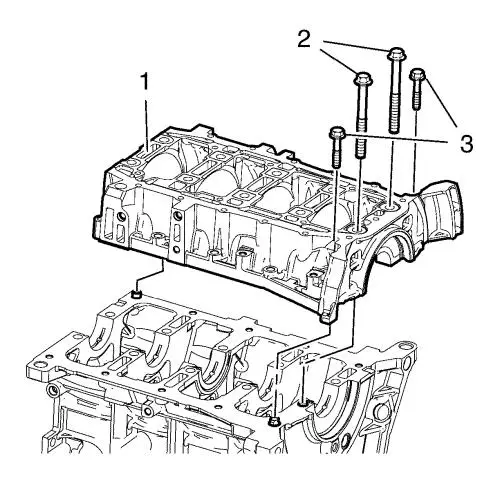

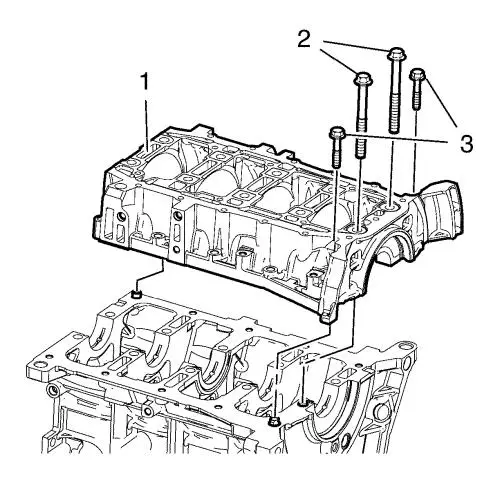

| 4. |

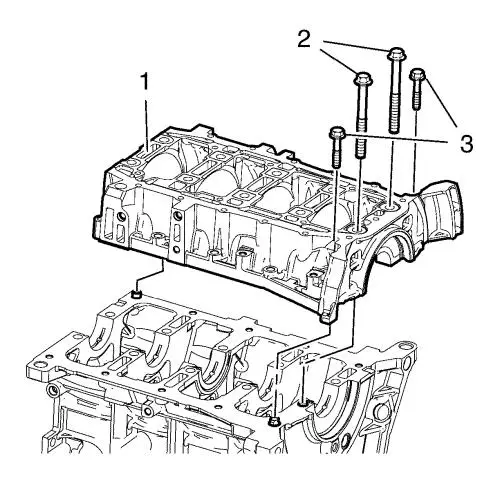

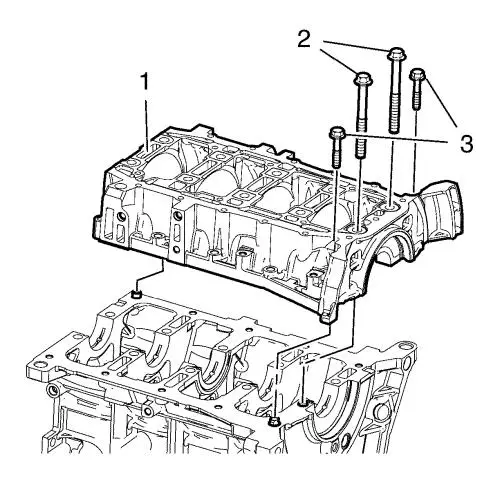

Install the lower crankcase

(1). |

| 5. |

Loosely install the 10 lower

crankcase inner bolts (2). |

| 6. |

Loosely install the 10 lower

crankcase outer bolts (3). |

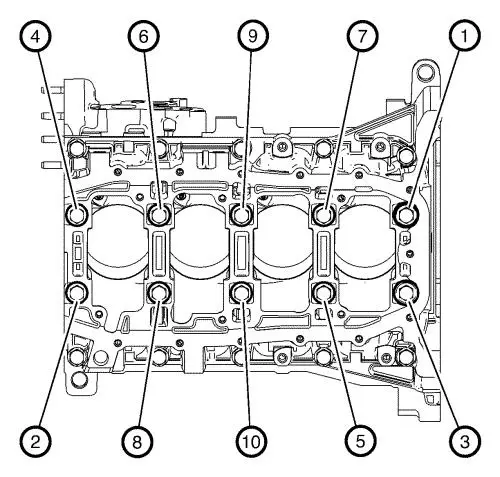

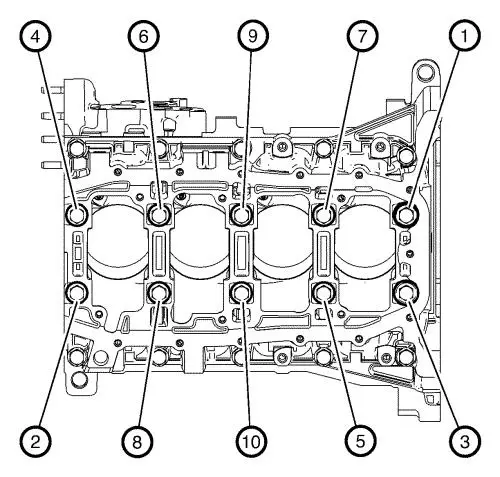

| 7. |

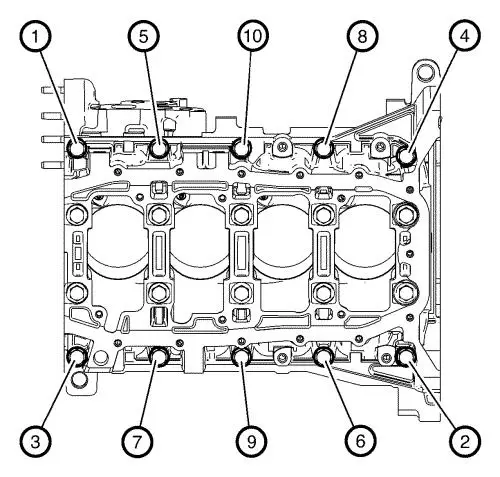

Tighten the 10 lower crankcase

inner bolts in sequence as shown and in the following order:

|

| |

• |

Tighten the bolts in sequence

as shown to 20 N·m (15 lb ft) .

|

| |

• |

Tighten in sequence as shown

to an additional 80° . |

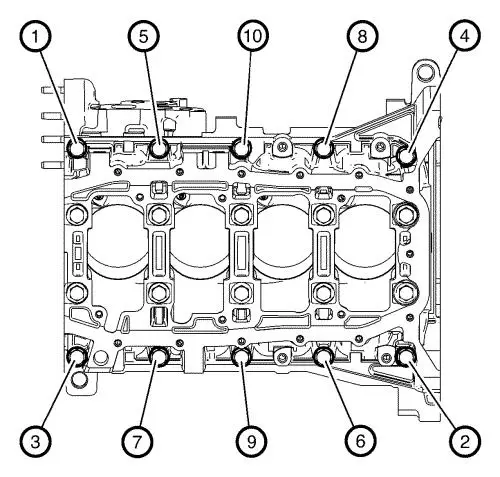

| 8. |

Tighten the 10 lower crankcase

outer bolts in sequence as shown to 30 N·m (22 lb

ft) . |

| 10. |

Remove the 10 lower crankcase

outer bolts (3). |

| 11. |

Remove the 10 lower crankcase

inner bolts (2). |

| 12. |

Remove the lower crankcase

(1). |

|

Note: When reading

the value, do not confuse millimeters and inches on the measuring

scale.

|

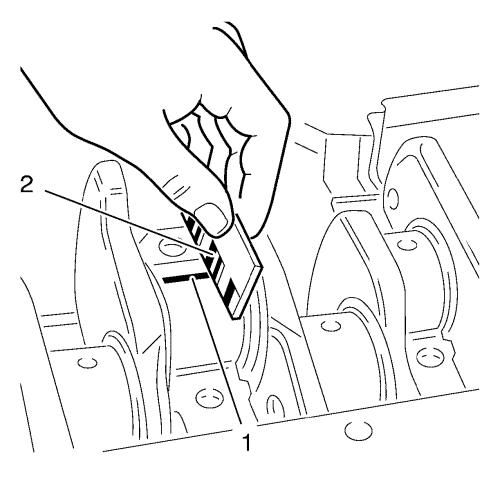

| 13. |

Measure the crankshaft bearing

play. |

| |

• |

Compare the width of the

flattened plastic thread (1) to the measuring scale (2).

|

|