Cylinder Head Installation

Special Tools

| • |

EN-301

Measuring Bridge |

| • |

EN-470-B

Torque Angle Sensor |

| • |

EN-46778

Fixing Tool Crankshaft |

For equivalent regional tools, refer to

Special Tools .

|

Note: Ensure that the

cylinder head and the cylinder block sealing surfaces are clear of

oil, grease and old gasket material.

|

| 1. |

Clean the sealing

surfaces |

| 2. |

Inspect the flatness of

cylinder head and cylinder block sealing surfaces |

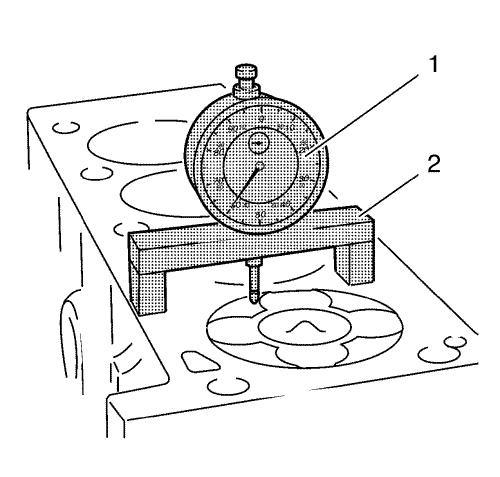

| 3. |

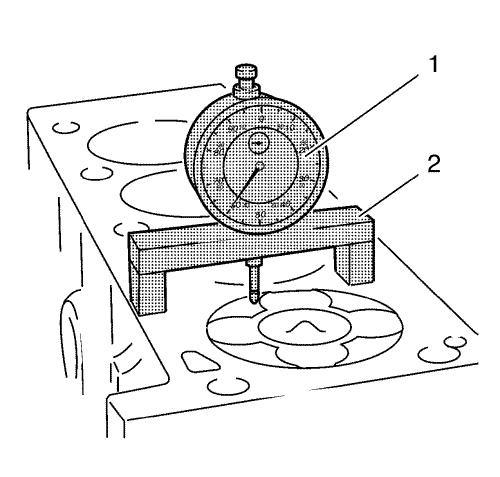

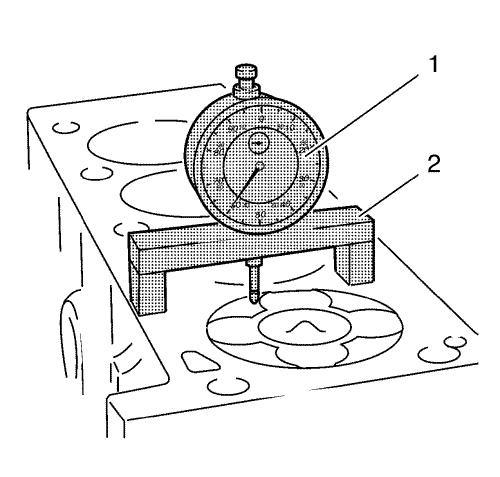

Install the EN-301

bridge (2) in compound with the GE-571-B

gauge (1). |

|

Note: The largest

piston projection is decisive for the selection of the cylinder

head gasket with the corresponding marking.

|

| 4. |

Measure the piston projection

dimensions at all pistons. |

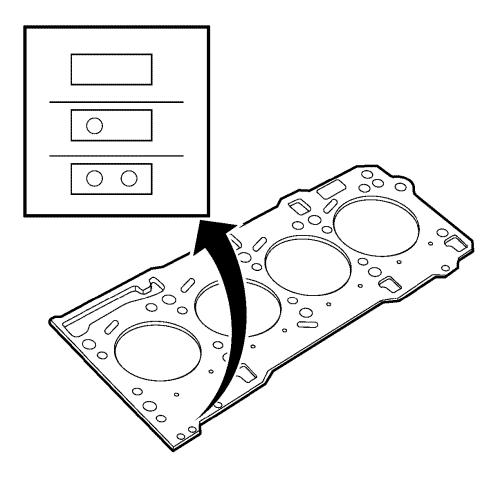

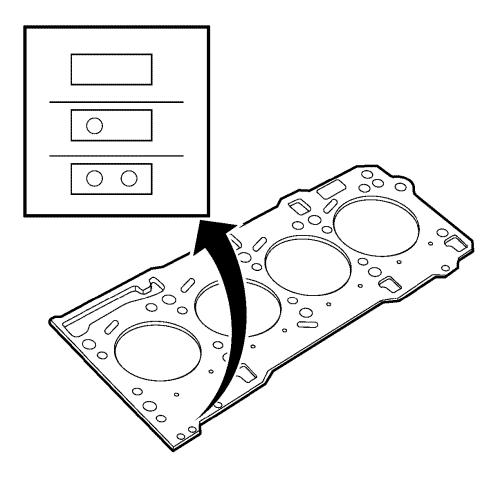

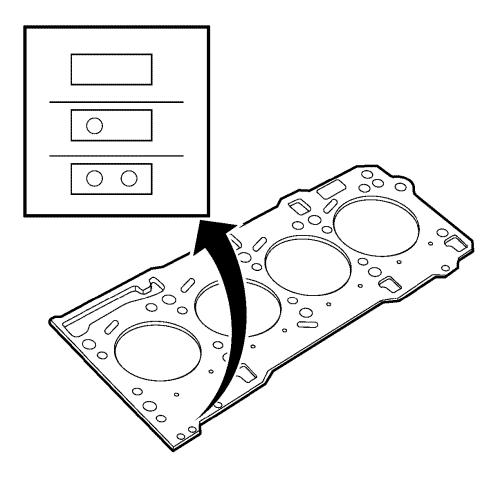

| 5. |

Select the cylinder head

gasket with the correct identification marks: |

| |

5.1 |

Piston projection

0.028 - 0.127 mm (0.0011 - 0.005) , choose the

cylinder head gasket with identification mark - without

holes. |

| |

5.2 |

Piston projection

0.128 - 0.227 mm (0.005 - 0.00894) , choose the

cylinder head gasket with identification mark - 1 hole.

|

| |

5.3 |

Piston projection

0.228 - 0.327 mm (0.00898- 0.01287) , choose the

cylinder head gasket with identification mark - 2 holes.

|

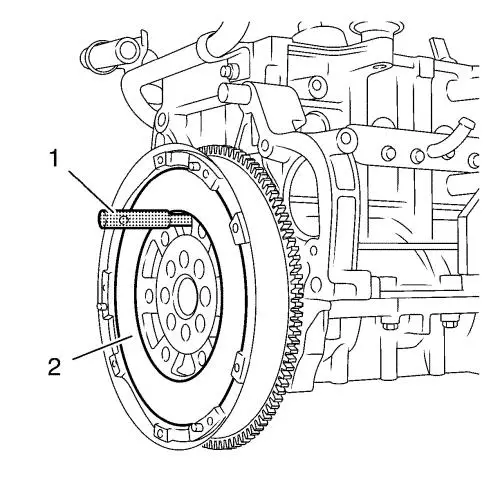

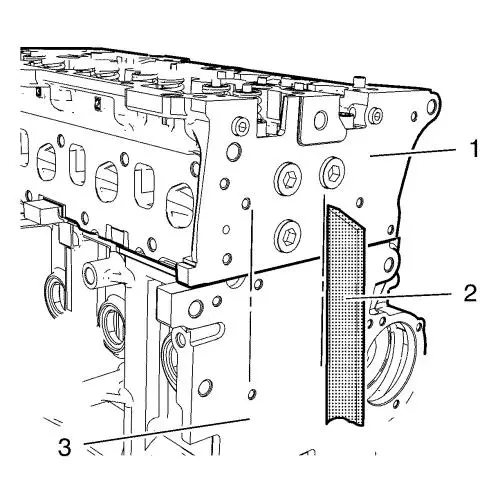

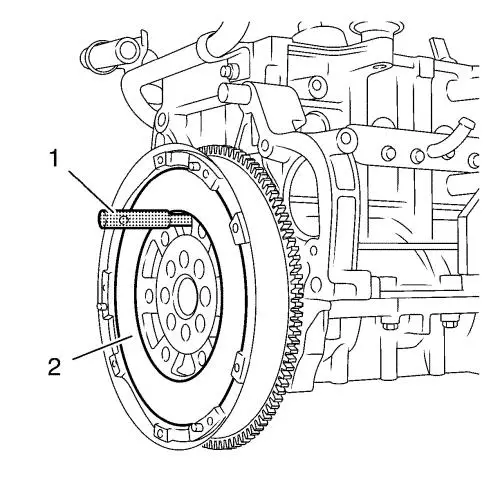

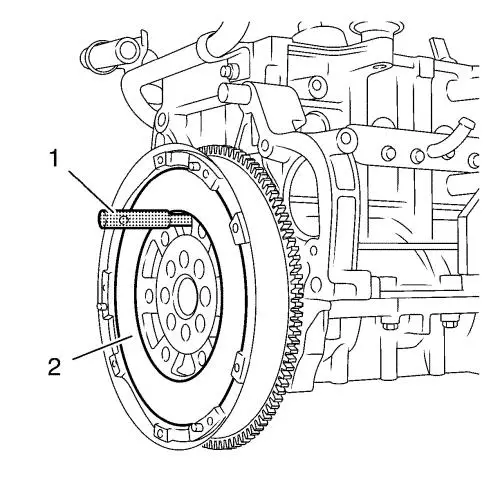

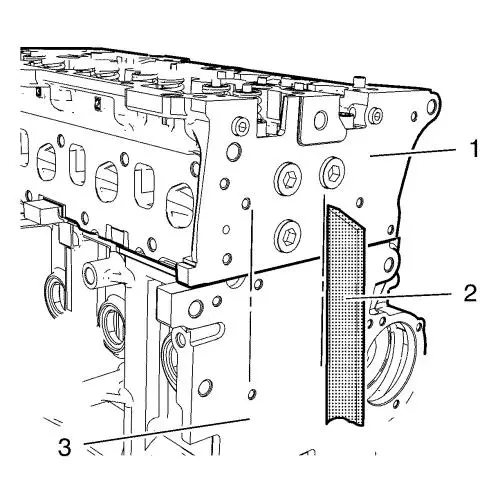

| 6. |

Turn the crankshaft in the

engine direction of rotation until the EN-46778

fixing tool (1) to engage with the drilling at flywheel (2) and

cylinder block. |

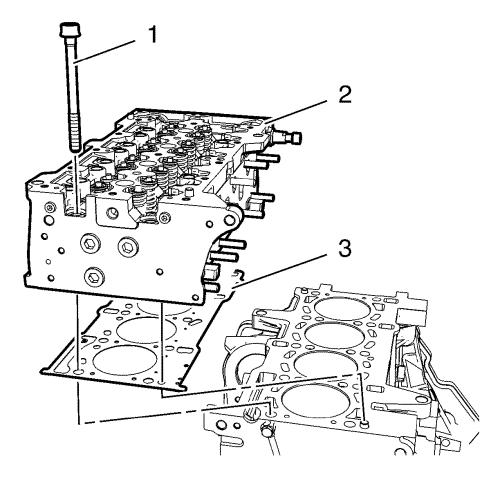

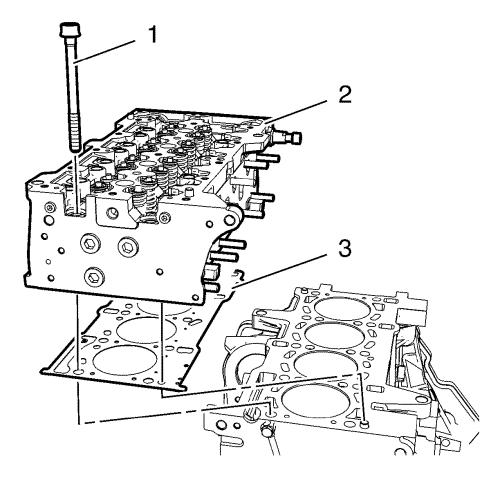

| 7. |

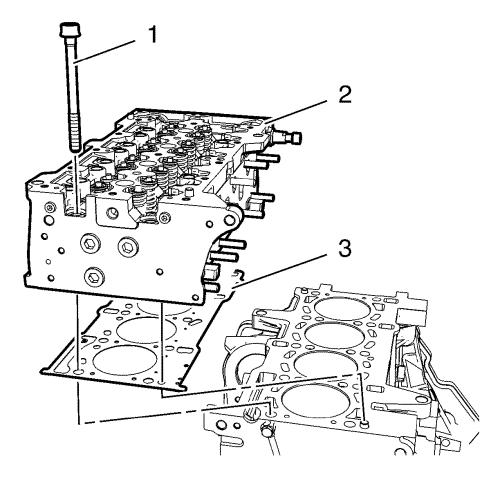

Install the cylinder head

gasket (3). |

| 8. |

Install the cylinder head

(2). |

| 9. |

Loosely install 10 NEW

cylinder head bolts (1). |

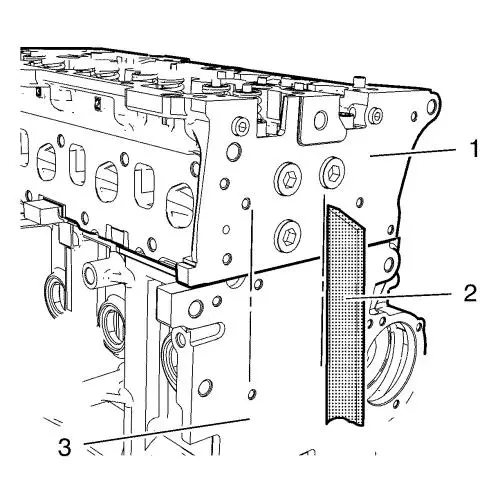

|

Note: Use a rubber

mallet to adjust the cylinder head. The overhang of the timing side

should be under 0.1 mm (0.00394 in) .

|

| 10. |

Align the cylinder head (1) to

the engine block (3) with a straightedge (2). |

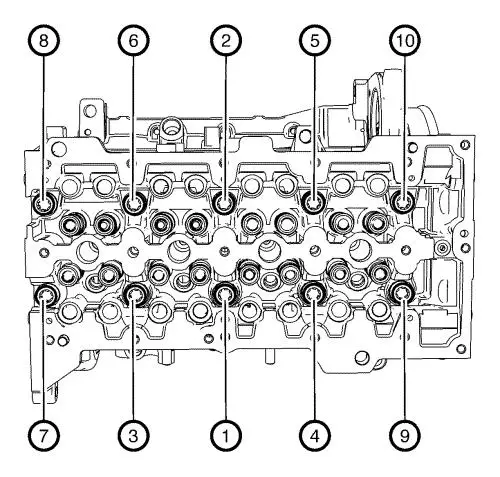

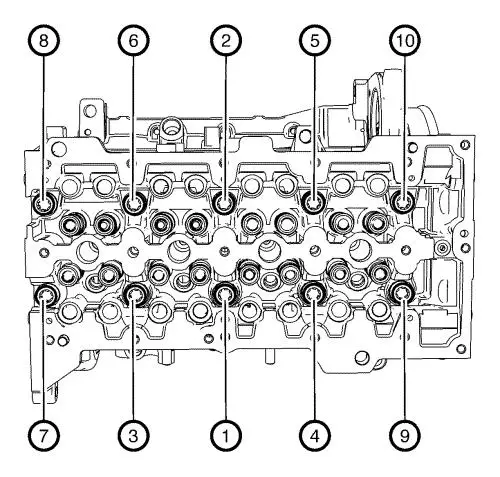

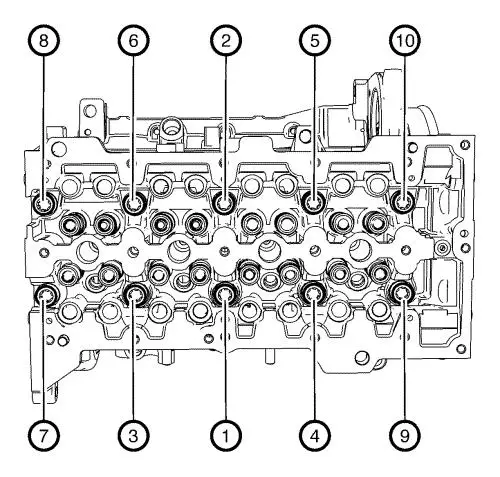

| 11. |

Tighten the 10 cylinder head

bolts in sequence as shown and in the following order: |

| |

• |

Tighten the bolts in sequence

as shown to 40N·m (30 lb ft) . |

| |

• |

Tighten in sequence as shown

to an additional 90° . Use EN-470-B

anglemeter . |

| |

• |

Tighten in sequence as shown

to an additional 90° . Use EN-470-B

anglemeter . |

|