Camshaft Housing Cover Gasket Replacement (with Start/Stop

System)

Special Tools

| • |

GE-328-B

Sliding Hammer |

| • |

EN-48559

Protective Caps |

For equivalent regional tools, refer to

Special Tools .

Removal Procedure

Warning: Refer to

Gasoline/Gasoline Vapors Warning .

|

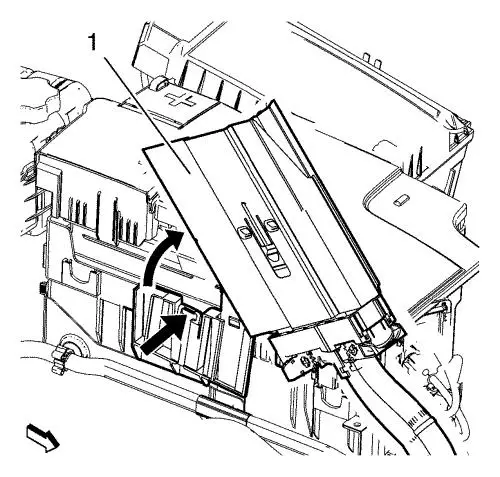

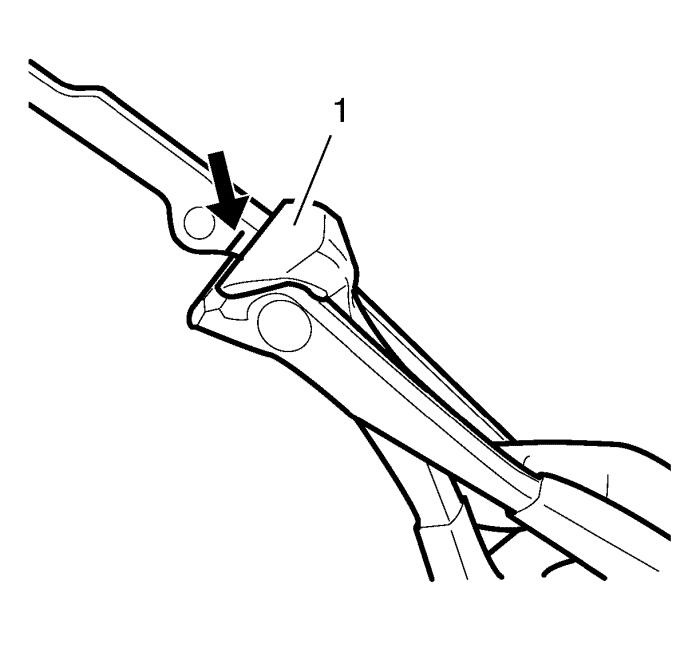

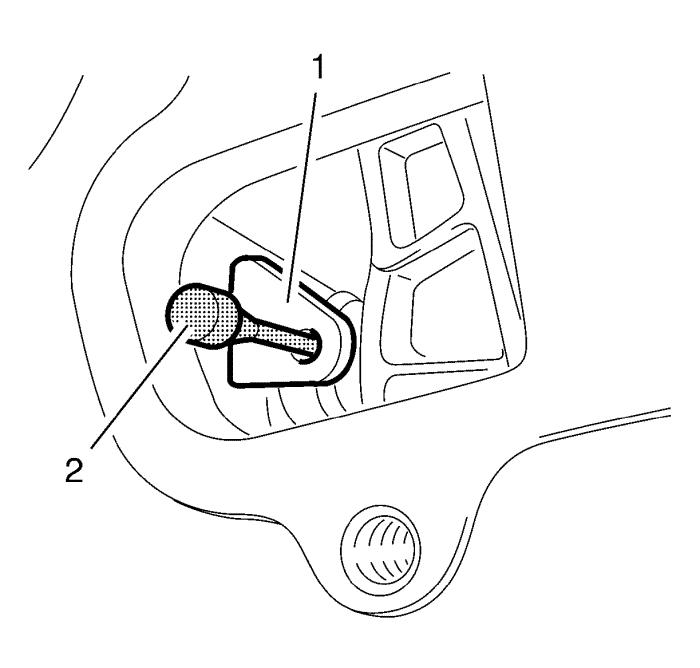

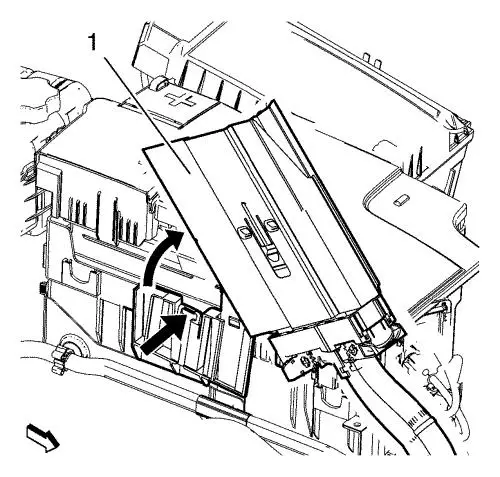

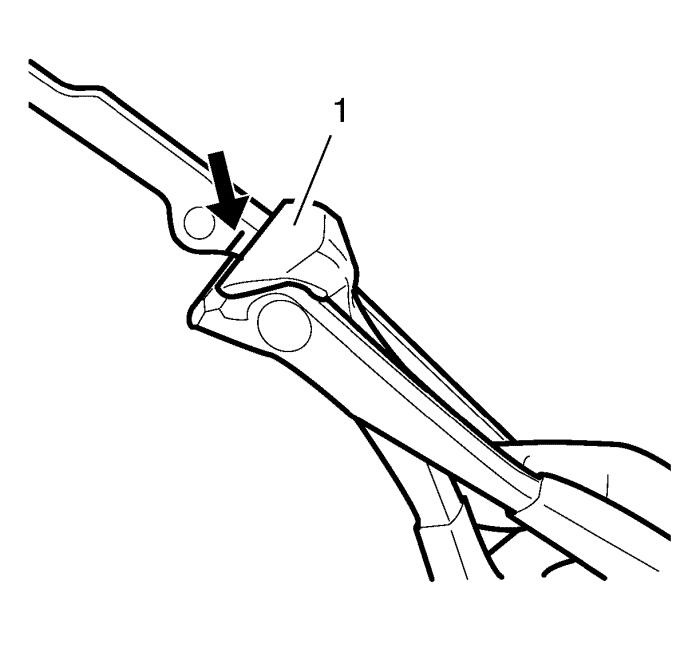

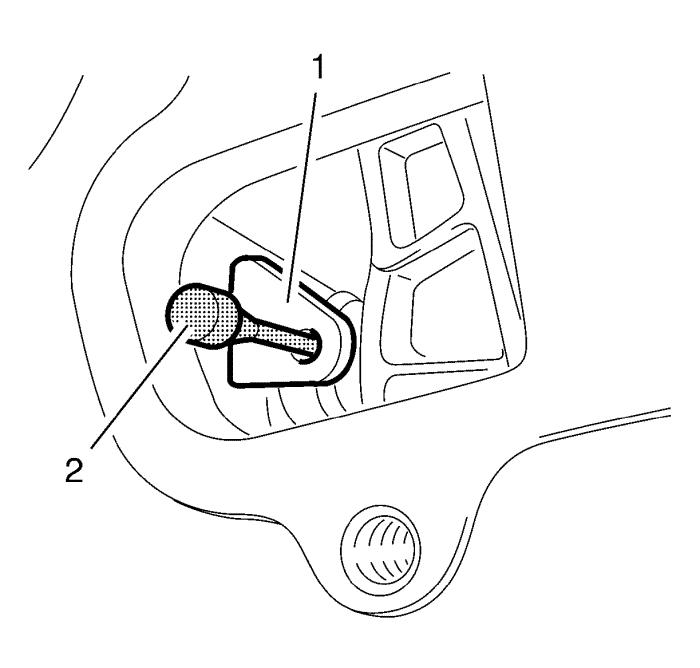

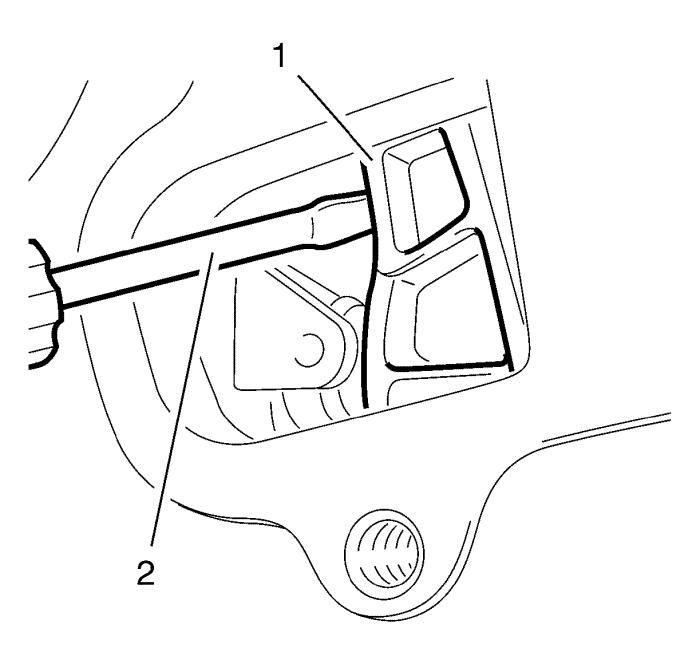

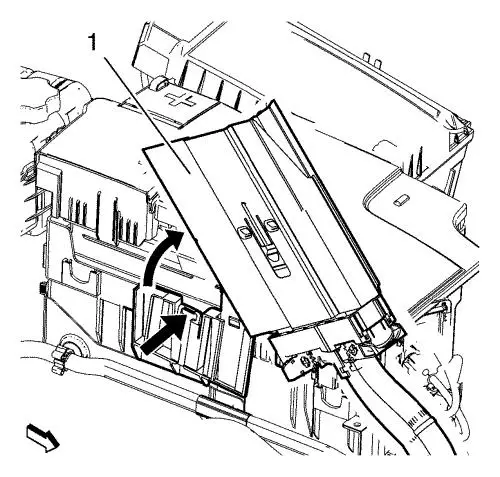

Note: Use a small

screwdriver to unclip the retainer clip (black arrow) and pull the

electronic control module out.

|

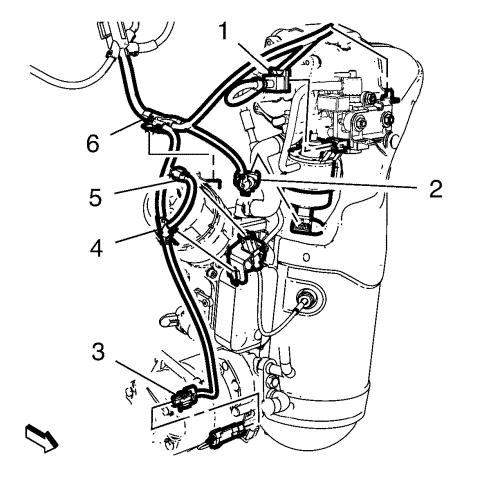

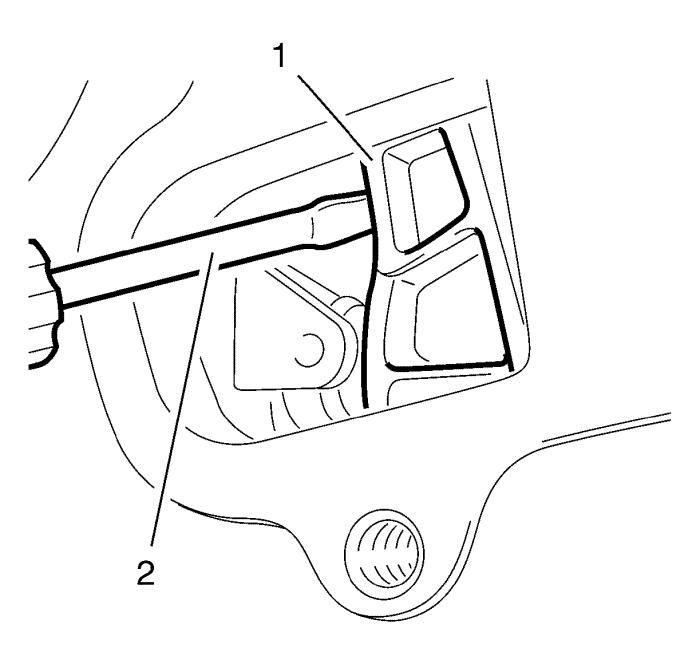

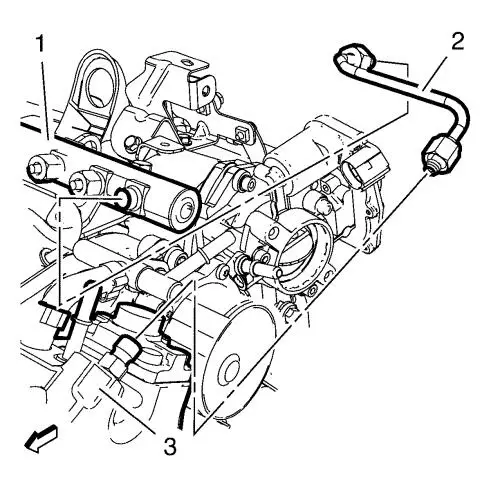

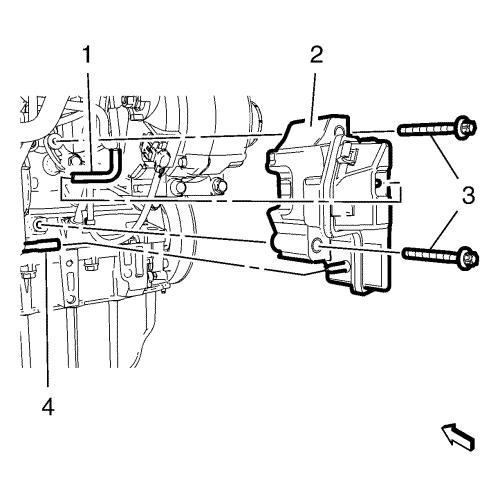

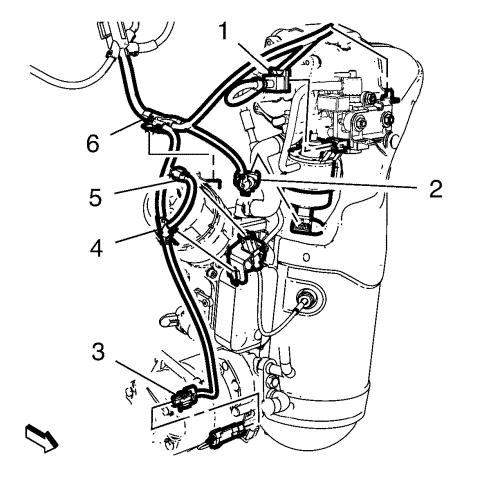

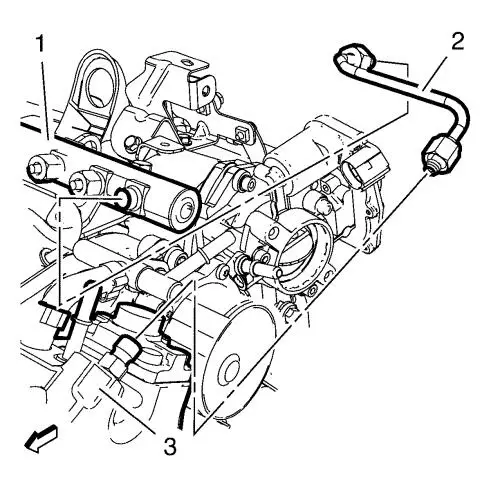

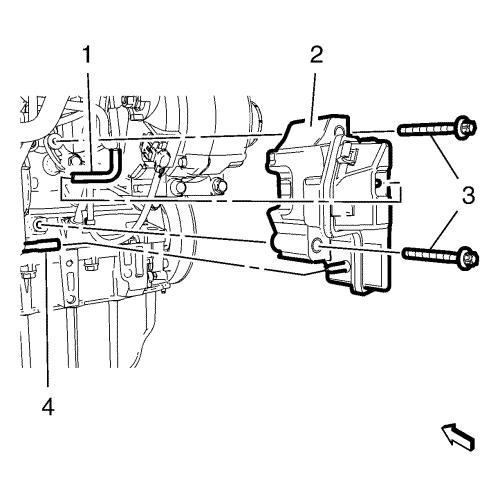

| 5. |

Remove the electronic control

module (1) from the battery tray. |

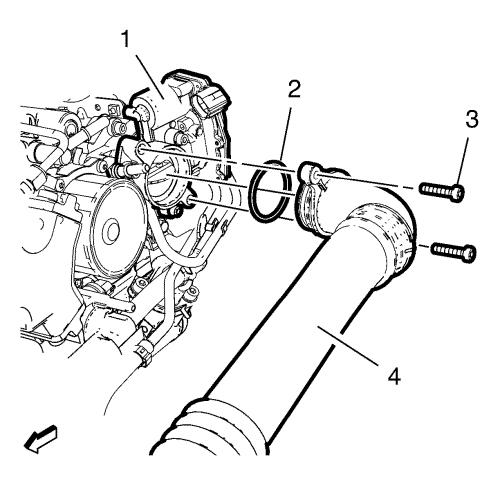

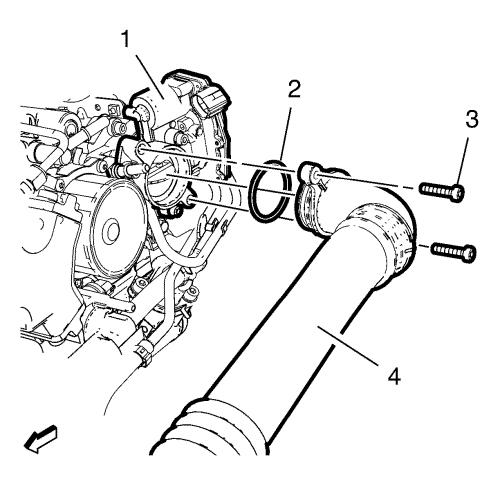

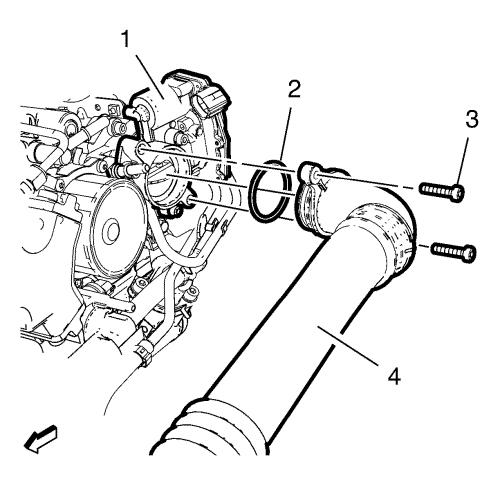

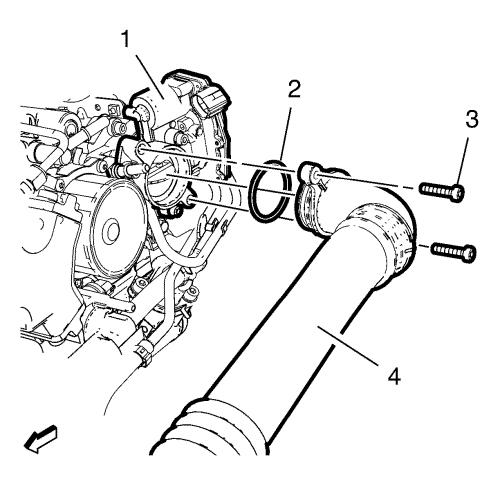

| 6. |

Remove the 2 charge air cooler

outlet air hose bolts (3). |

| 7. |

Remove the charge air cooler

outlet air hose bolt from the radiator inlet hose bracket.

|

| 8. |

Remove the charge air cooler

outlet air hose (4) from the throttle body (1) and hang

aside. |

| 9. |

Remove the charge air cooler

outlet air hose seal (2). |

| 10. |

Disconnect the positive

crankcase ventilation pipe connector (3) from the positive

crankcase ventilation oil separator. |

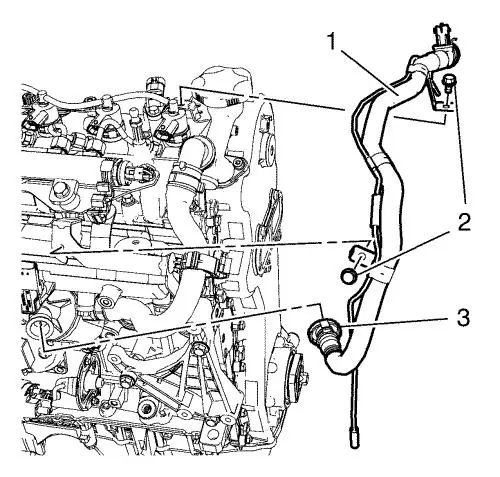

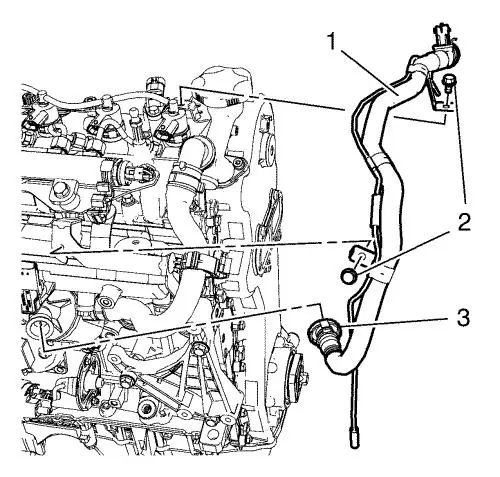

| 11. |

Disconnect the positive

crankcase ventilation pipe connector wiring harness plug.

|

| 12. |

Remove the vacuum hose from

the turbocharger wastegate actuator vacuum control solenoid

valve. |

| 13. |

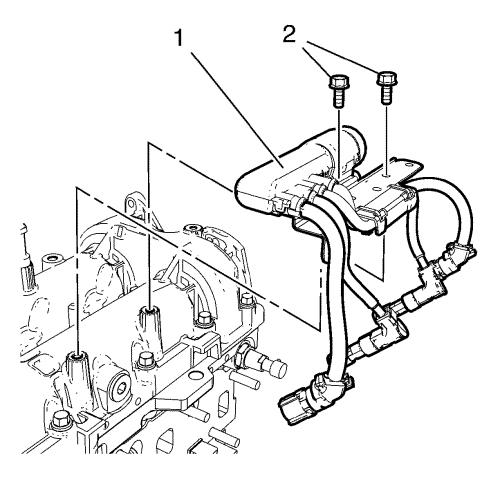

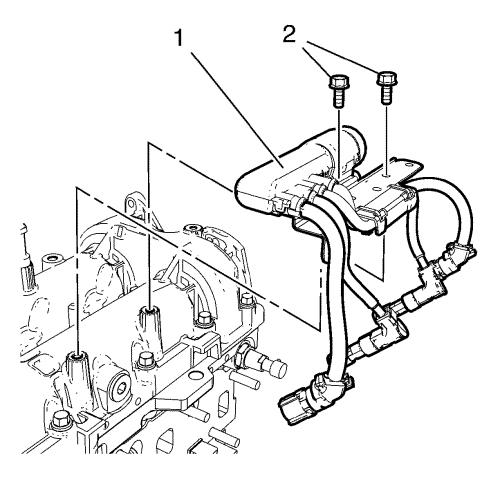

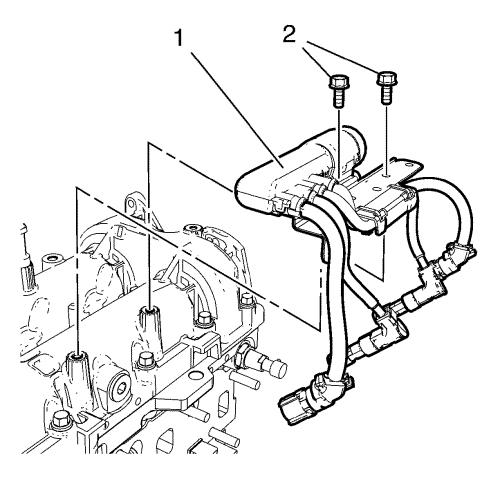

Remove the 2 positive

crankcase ventilation pipe bracket bolts (2). |

| 14. |

Remove the positive crankcase

ventilation pipe (1). |

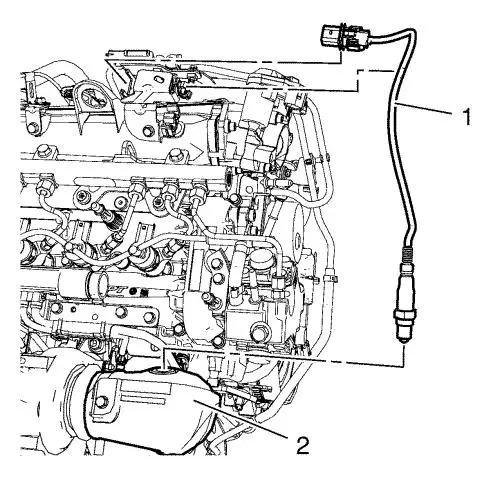

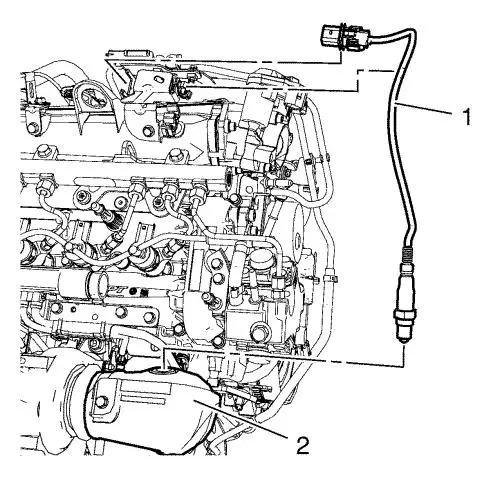

| 15. |

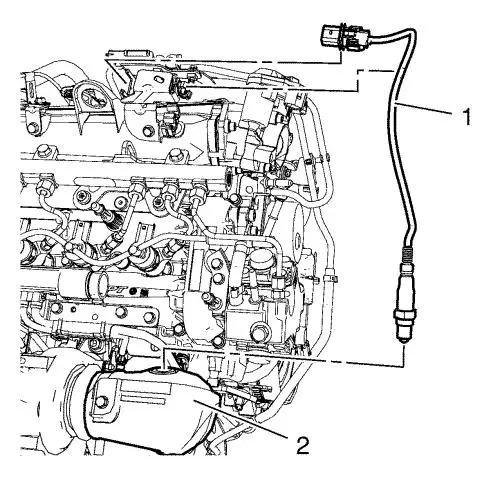

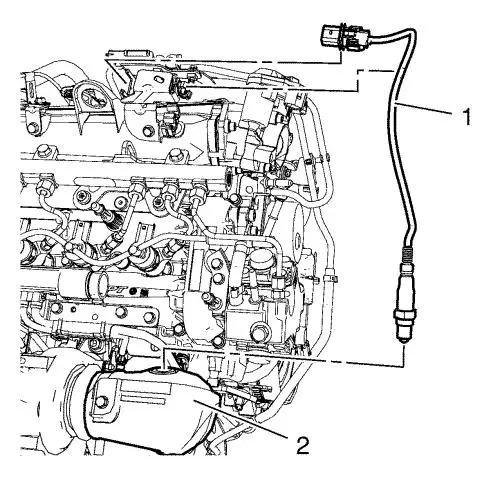

Unclip the oxygen sensor plug

from the exhaust pressure sensor bracket and the ECM wiring

harness. |

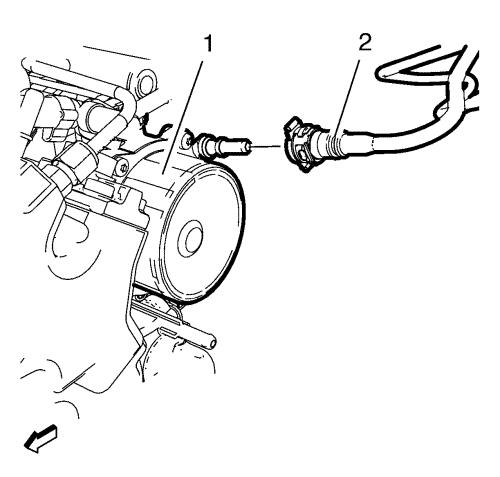

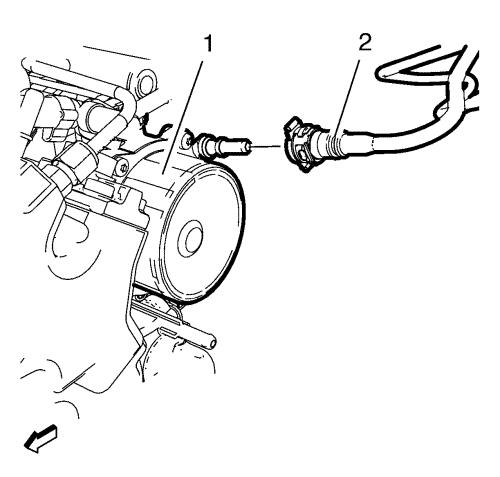

| 16. |

Remove the oxygen sensor (1)

from the catalytic converter (2). |

| 17. |

Disconnect the air

conditioning compressor wiring harness plug (3). |

| 18. |

Disconnect the exhaust

temperature sensor wiring harness plug (5). |

| 19. |

Unclip the retainer clip (4)

from the exhaust temperature sensor wiring harness bracket.

|

| 20. |

Disconnect the turbocharger

wastegate sensor wiring harness plug (2). |

| 21. |

Unclip the retainer clip (6)

from the oil filter housing. |

| 22. |

Disconnect the turbocharger

wastegate actuator vacuum control solenoid valve wiring harness

plug (1). |

| 23. |

Unclip the retainer clip from

the turbocharger wastegate actuator vacuum control solenoid valve

bracket. |

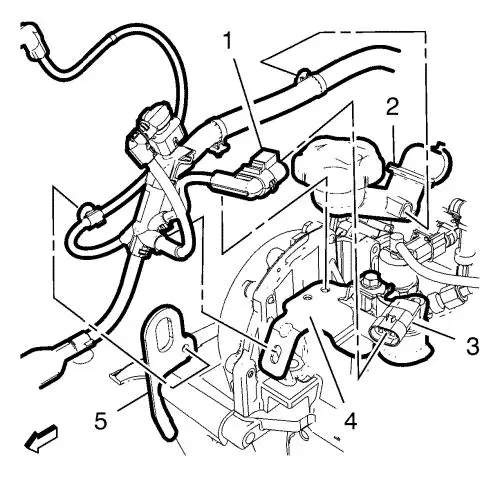

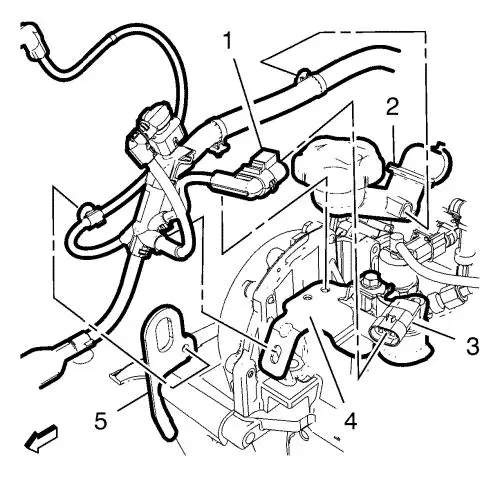

| 24. |

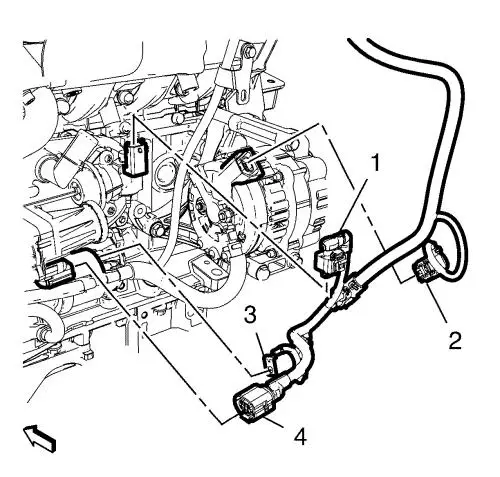

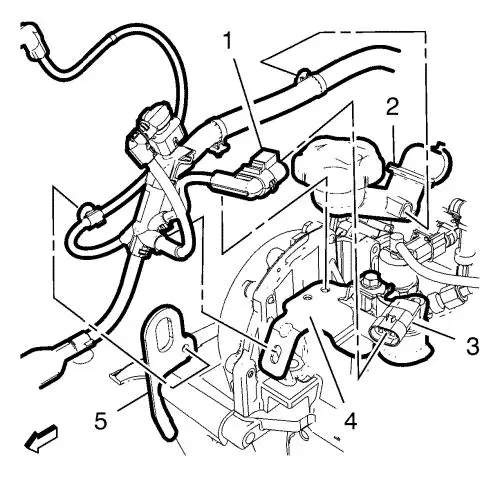

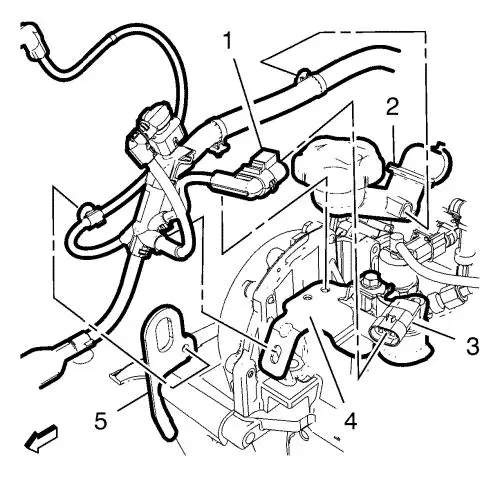

Disconnect the camshaft sensor

wiring harness plug (1) from the camshaft sensor (3). |

| 25. |

Unclip the 3 retainer clips

from: |

| |

• |

Engine lift bracket (5)

|

| |

• |

Engine sight shield stud

bracket (4) |

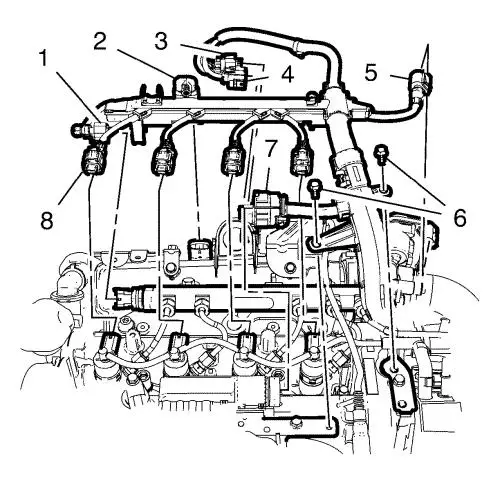

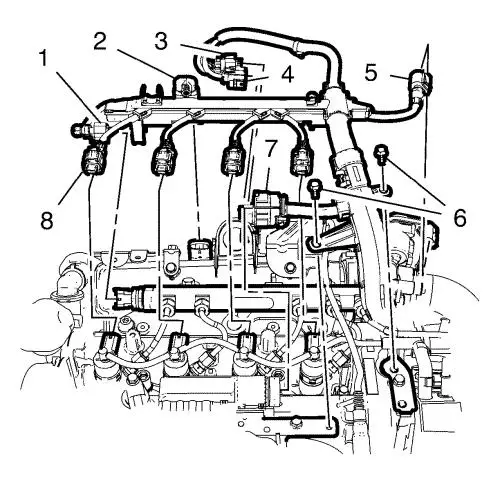

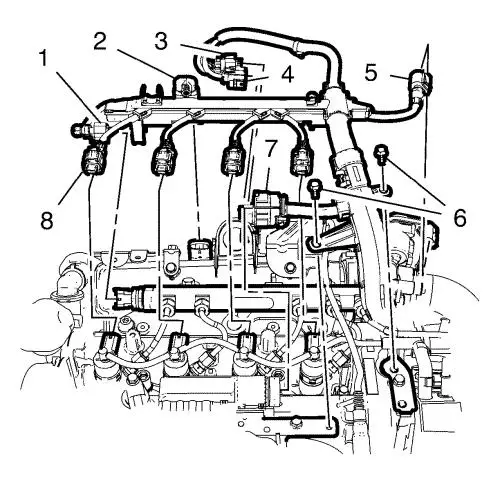

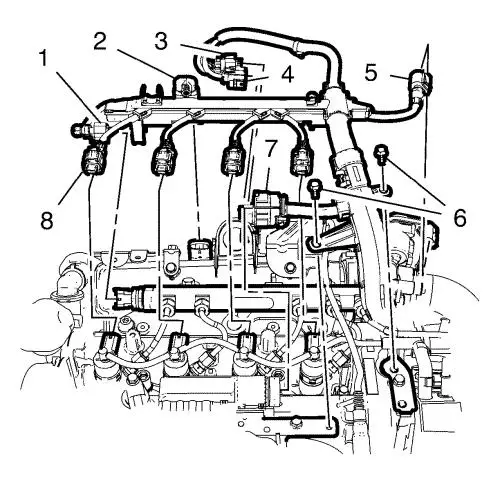

| 26. |

Disconnect the 4 fuel injector

wiring harness plugs (8). |

| 27. |

Disconnect the fuel rail

sensor wiring harness plug (1). |

| 28. |

Disconnect the manifold

absolute pressure sensor wiring harness plug (2). |

| 29. |

Disconnect the oxygen sensor

wiring harness plug (3). |

| 30. |

Disconnect the exhaust

pressure sensor wiring harness plug (4). |

| 31. |

Disconnect the throttle body

wiring harness plug (5). |

| 32. |

Remove the 2 wiring harness

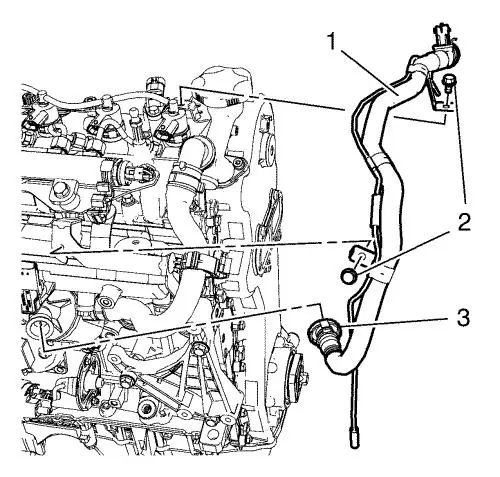

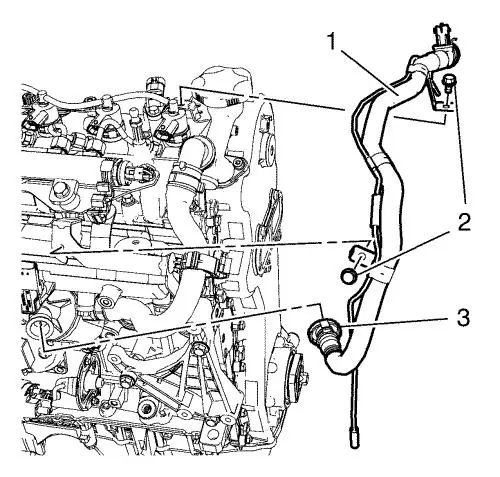

bracket bolts (6). |

| 33. |

Unclip the ECM wiring harness

from the radiator inlet hose bracket. |

| 34. |

Disconnect the glow plug

wiring harness connector (7). |

| 35. |

Disconnect the engine coolant

temperature sensor wiring harness plug from the thermostat

housing. |

| 36. |

Disconnect the oil temperature

sensor wiring harness plug from the oil temperature sensor.

|

| 37. |

Disconnect the crankshaft

position sensor wiring harness plug from the crankshaft position

sensor. |

| 38. |

Disconnect the fuel injection

fuel pump wiring harness plug from the fuel injection fuel

pump. |

| 39. |

Disconnect the backup lamp

switch wiring harness plug from the backup lamp switch.

|

| 40. |

Unclip the wiring harness

retainer clips. |

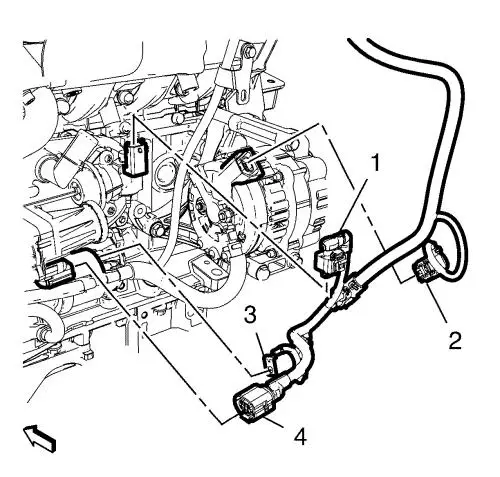

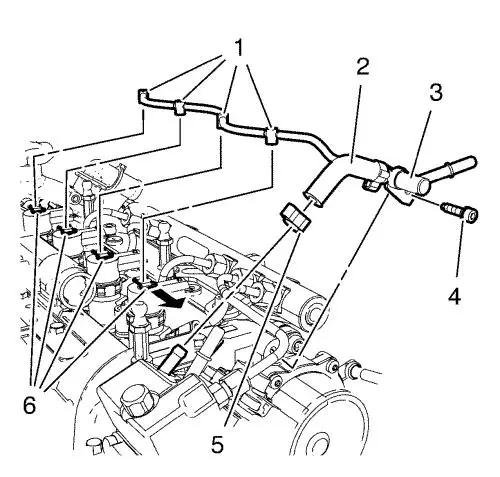

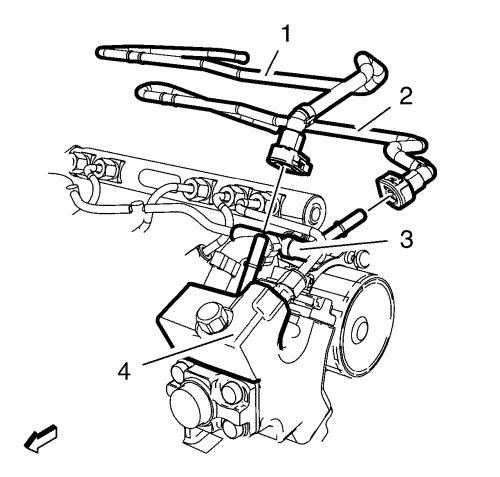

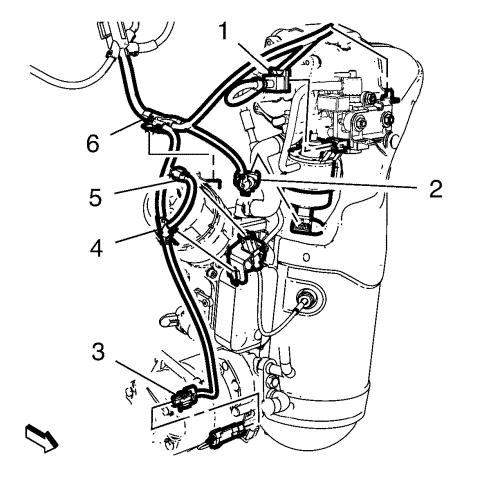

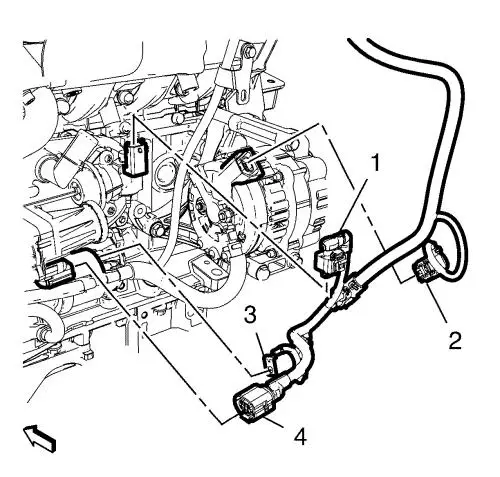

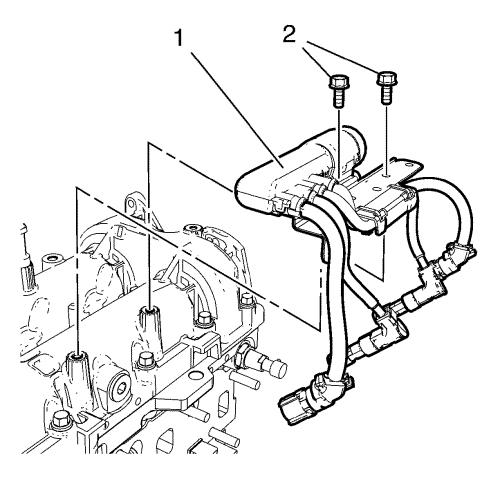

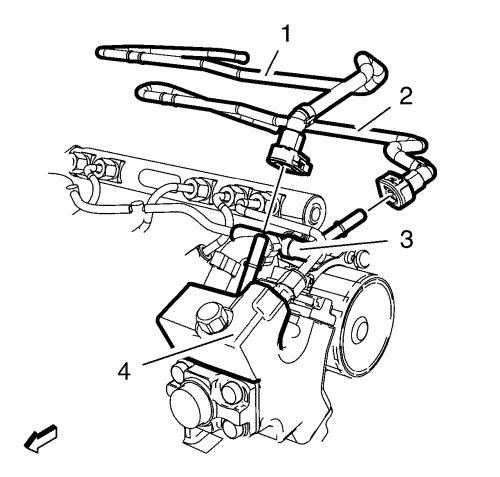

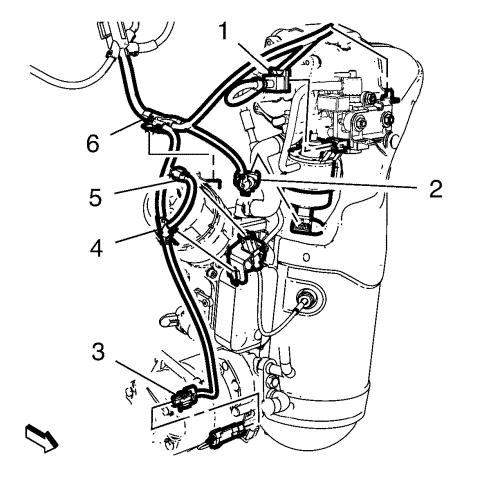

| 44. |

Unclip the generator wiring

harness clip from the exhaust gas recirculation valve vacuum tank

(2). |

| 45. |

Remove the turbocharger

wastegate actuator hose (1). |

| 46. |

Remove the turbocharger

wastegate actuator pipe (4). |

| 47. |

Remove the 2 exhaust gas

recirculation valve vacuum tank bolts (3). |

| 48. |

Remove the exhaust gas

recirculation valve vacuum tank (2). |

| 49. |

Disconnect the generator

wiring harness plug (2). |

| 50. |

Disconnect the exhaust gas

recirculation valve wiring harness plug (1). |

| 51. |

Disconnect the exhaust gas

recirculation cooler wiring harness plug (4). |

| 52. |

Remove the starter control

cable nut. |

| 53. |

Remove the starter control

cable (3). |

| 54. |

Unclip the wiring harness from

the oil level indicator tube. |

| 55. |

Unclip the wiring harness from

exhaust gas recirculation cooler. |

| 57. |

Hang the ECM wiring harness

aside. |

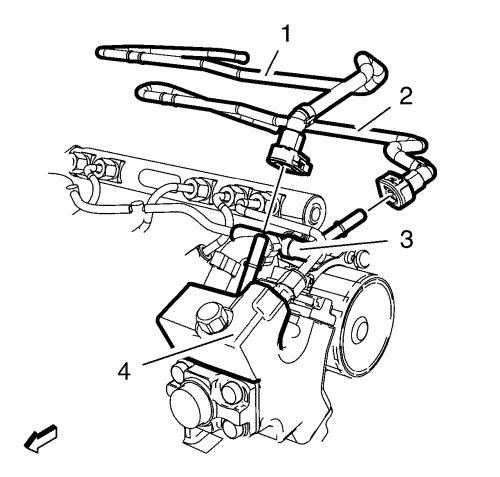

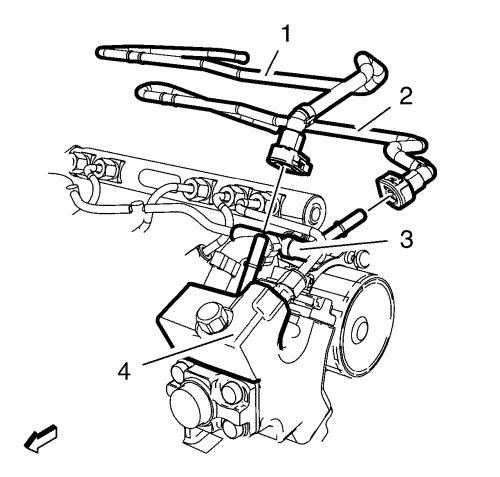

| 58. |

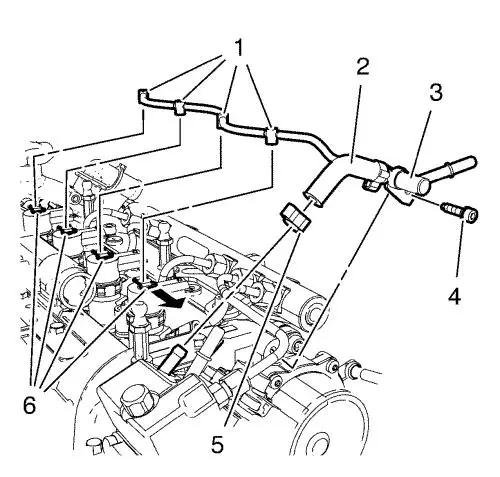

Remove the fuel feed pipe (1)

from the fuel injection pump (4). |

| 59. |

Remove the fuel return pipe

(2) from the fuel separator (3). |

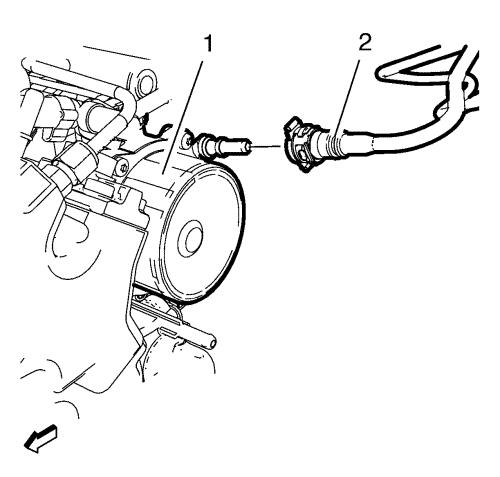

| 60. |

Remove the brake booster

vacuum pipe (2) from the vacuum pump (1). |

| 61. |

Remove the turbocharger

wastegate actuator vacuum hose from the vacuum pump. |

| 62. |

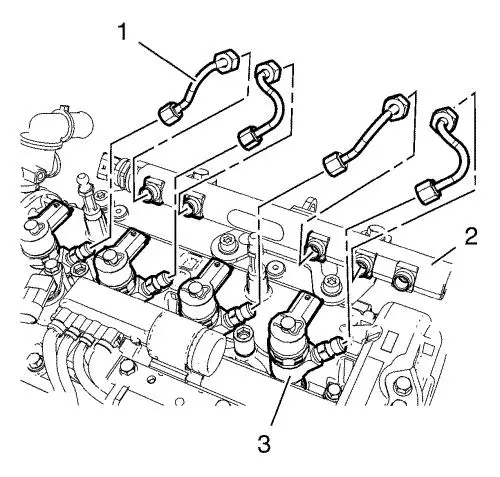

Remove the fuel feed pipe (2)

from the fuel injection fuel pump (3) and the fuel rail (1).

|

| |

• |

Remove the fuel feed pipe nut

from the fuel rail. |

| |

• |

Remove the fuel feed pipe nut

from the fuel injection fuel pump. |

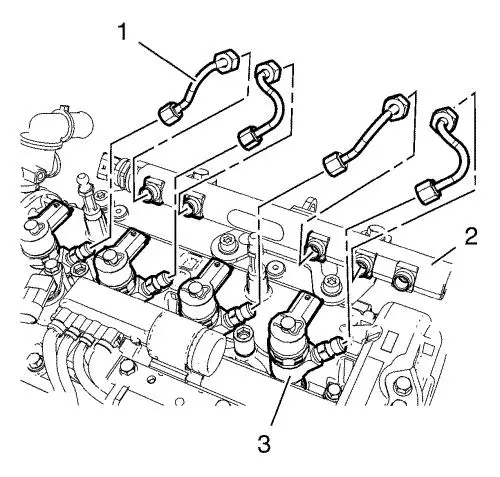

| 63. |

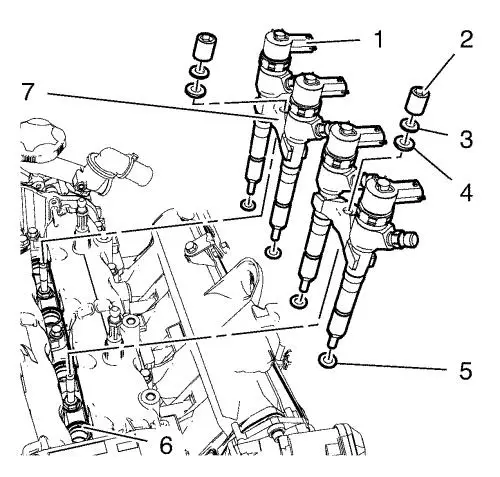

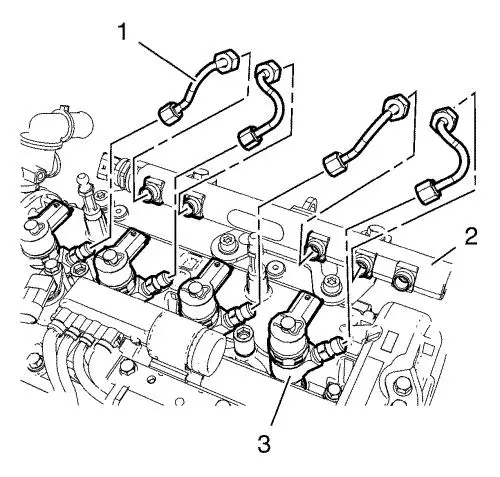

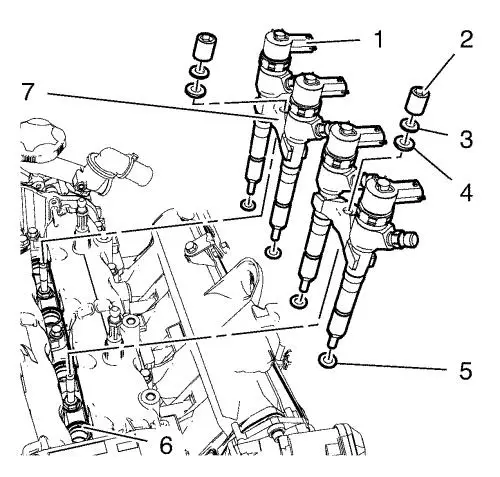

Unclip the 4 fuel injector

fuel return hose retainer springs (6). |

| 64. |

Remove the fuel injector fuel

return hose (1) from the 4 fuel injectors. |

| 65. |

Remove the fuel return hose

clamp (5). |

| 66. |

Remove the fuel return hose

(2) from the fuel injector pump. |

| 67. |

Remove the fuel separator bolt

(4). |

| 68. |

Remove the fuel injector fuel

return hose with the fuel separator (3). |

| 69. |

Loosen the 2 fuel rail

bolts. |

| 70. |

Remove the 4 fuel feed pipes

(1) from the 4 fuel injectors (3) and the fuel rail (2).

|

| |

• |

Remove the 4 fuel feed pipe

nut from the fuel rail. |

| |

• |

Remove the 4 fuel feed pipe

nut from the 4 fuel injectors. |

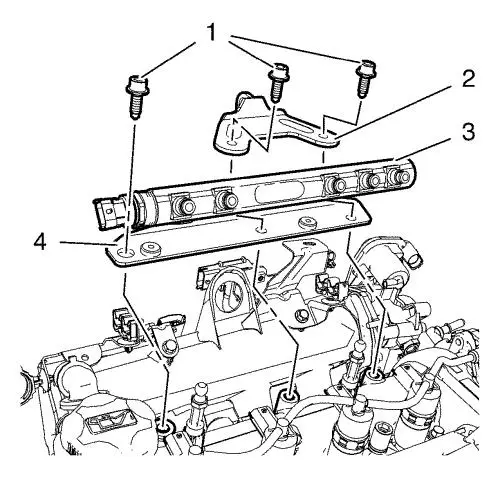

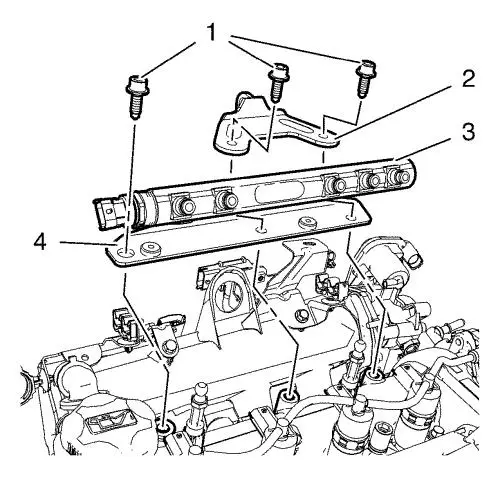

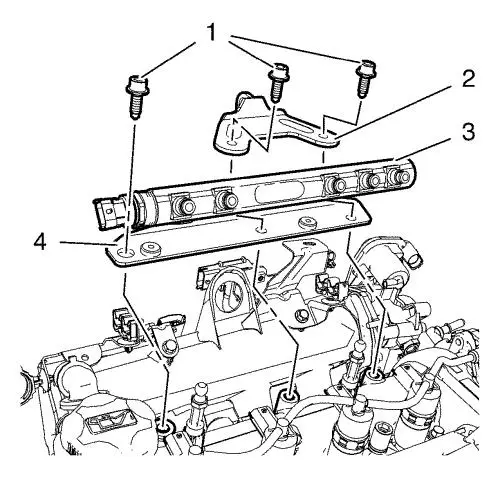

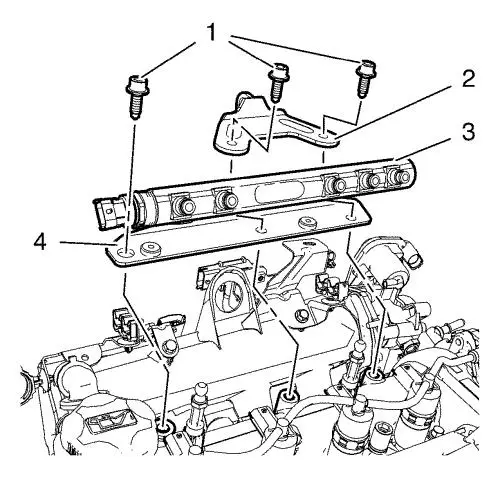

| 71. |

Remove the 3 fuel rail bracket

bolts (1). |

| 72. |

Remove the engine lift bracket

(2). |

| 73. |

Remove the fuel rail (3) with

the fuel rail bracket (4). |

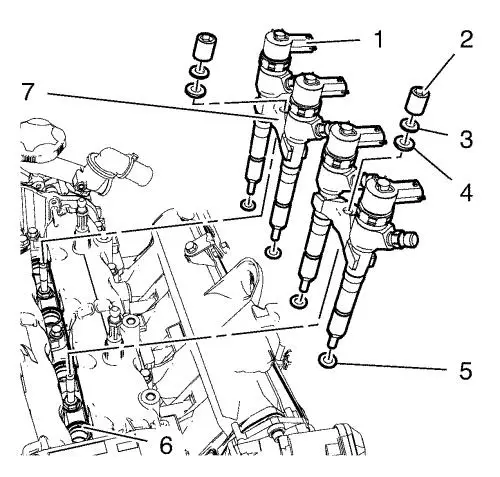

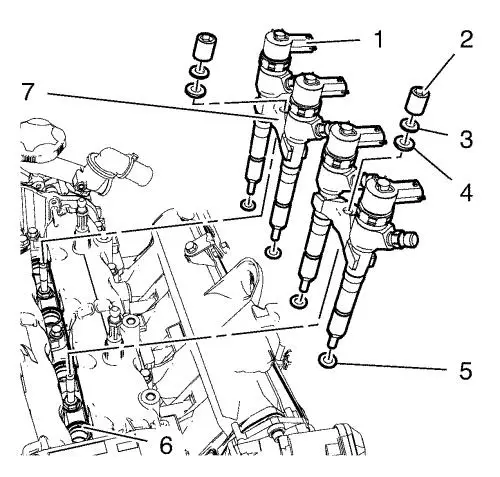

| 74. |

Remove the 2 fuel injector

bracket nuts (2). |

| 75. |

Remove the 2 fuel injector

conical washer (3). |

| 76. |

Remove the 2 fuel injector

spherical washers (4). |

|

Note: Injectors are

to be removed only in pairs. If the Injectors are not removed by

hand use the EN-46786 remover with

GE-328-B sliding hammer .

|

| 77. |

Remove the 4 fuel injectors

(1) with the 2 fuel injector brackets (7). |

| 78. |

Remove the 4 fuel injector

seals (5). |

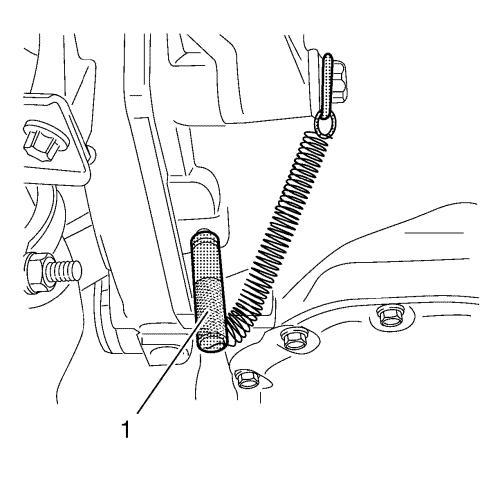

| 79. |

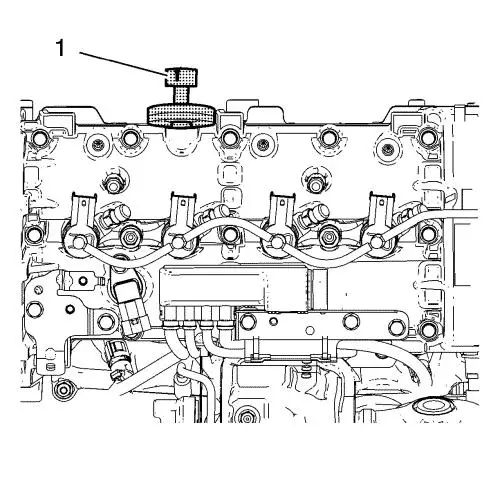

Close the injector nozzles

with the EN-48559 protective caps . |

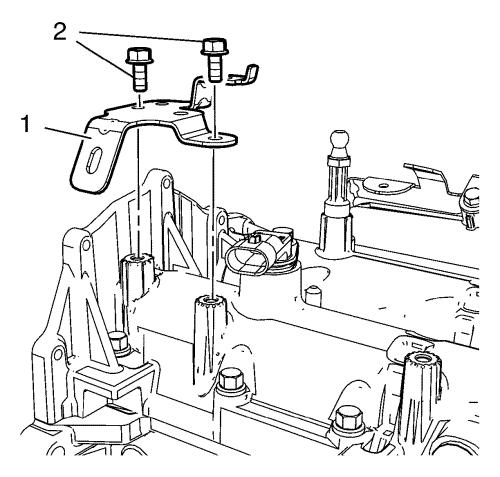

| 80. |

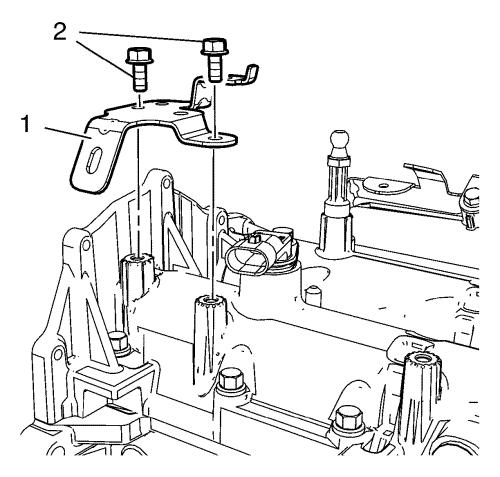

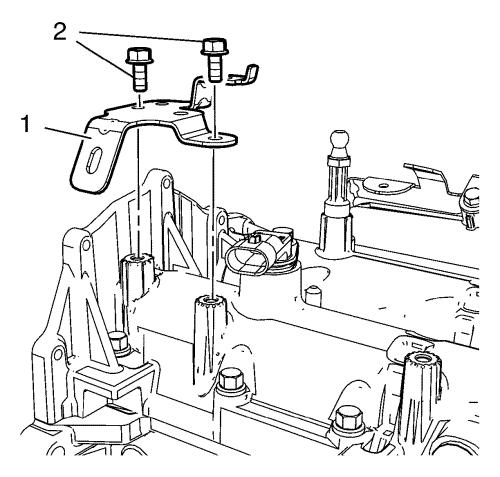

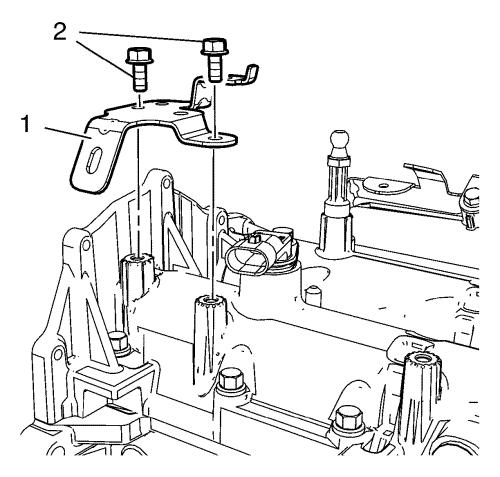

Remove the 2 glow plug wiring

harness bracket bolts (2). |

| 81. |

Remove the glow plug wiring

harness bracket (1). |

| 82. |

Remove the engine control

module wiring harness bracket bolt (2). |

| 83. |

Remove the engine control

module wiring harness bracket (1) left side. |

| 84. |

Remove the 2 engine control

module wiring harness bracket bolts (2). |

| 85. |

Remove the engine control

module wiring harness bracket (1) right side. |

| 86. |

Remove the 2 oil filler tube

bolts (2, 3). |

| 87. |

Remove the oil filler tube (1)

from the oil pump housing (4). |

|

Note: The SPX

installation manual is supplied with the special tool and is also

available online from SPX directly. Go to

www.spxtools-shop.com.

|

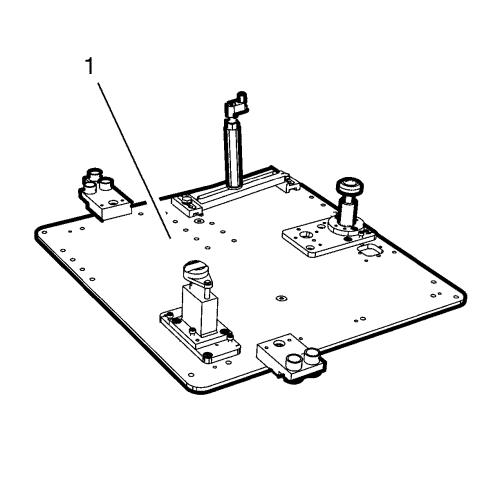

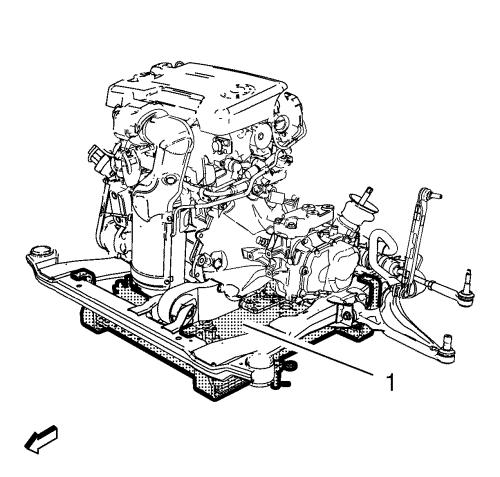

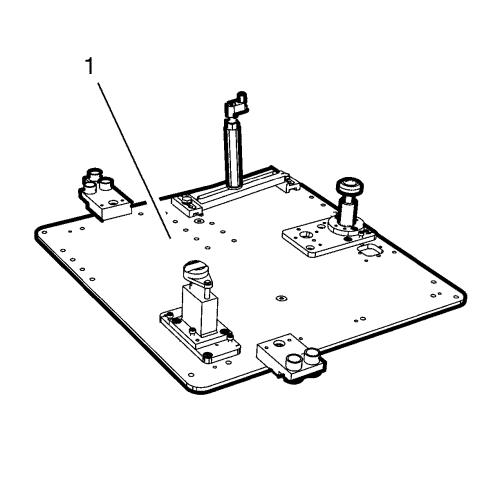

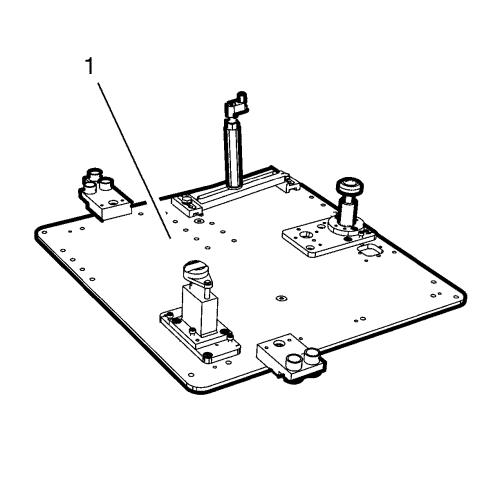

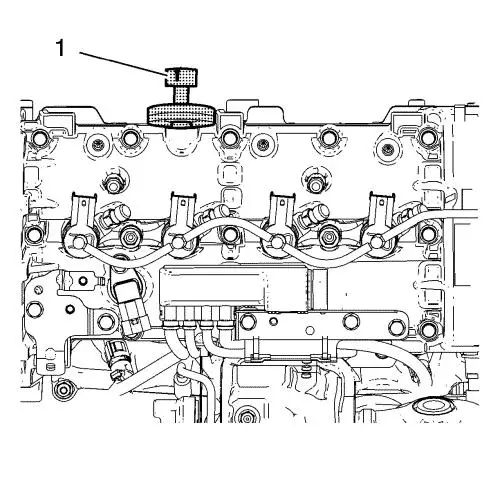

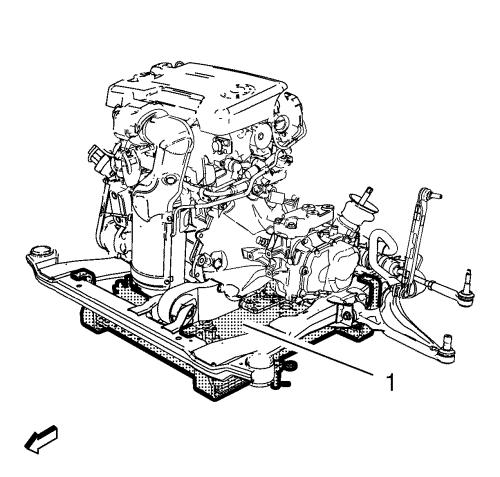

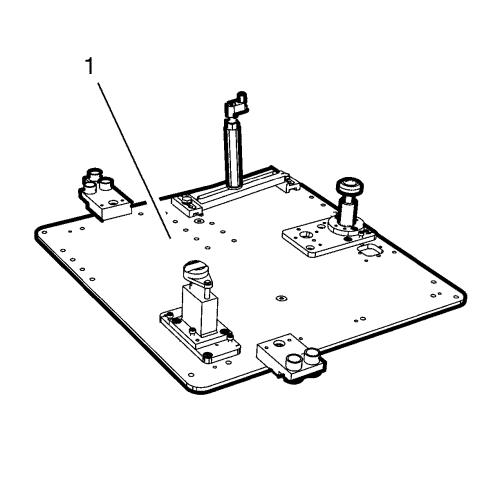

| 88. |

Assemble the CH-49290

engine support tool (1) according to the details provided in

the SPX installation manual. |

| 89. |

Support the CH-904

base frame on a jack. |

| 90. |

Support the CH-49290

engine support tool on the CH-904 base frame

. |

|

Note: The SPX

installation manual is supplied with the special tool and is also

available online from SPX directly. Go to

www.spxtools-shop.com.

|

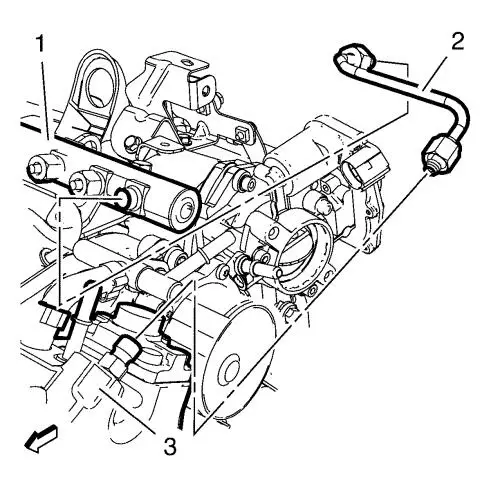

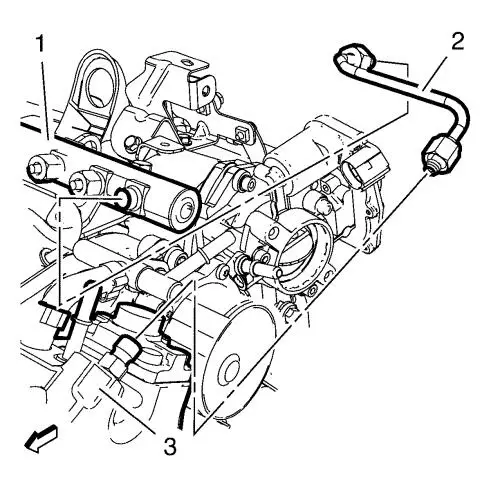

| 91. |

Install the CH-49290

engine support tool (1) according to the details provided in

the SPX installation manual. |

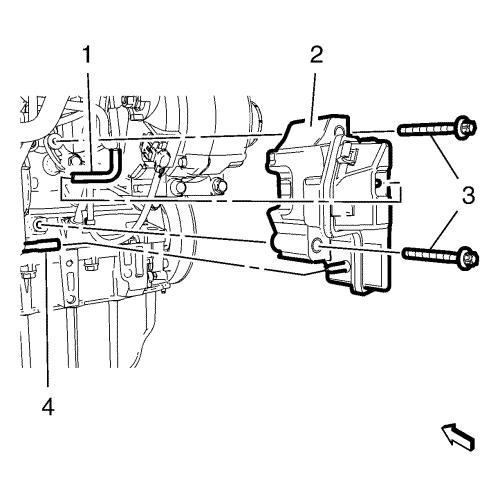

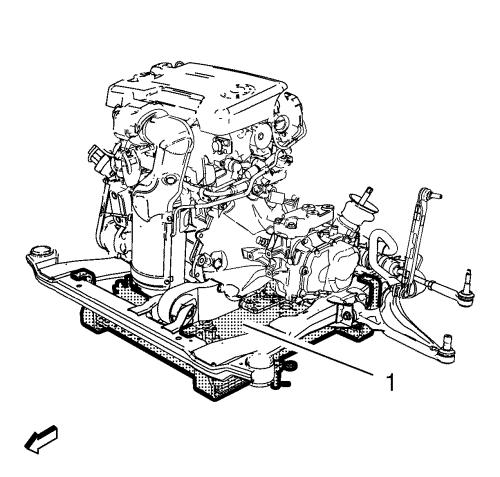

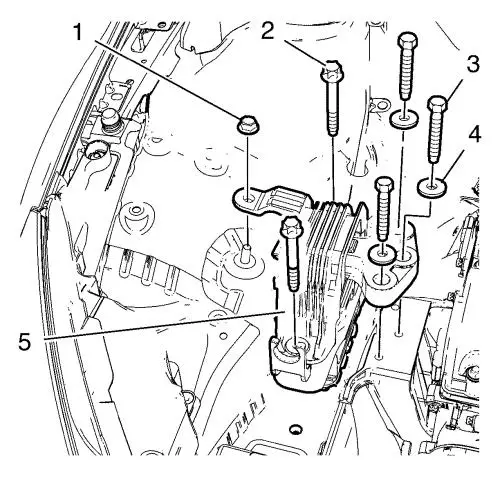

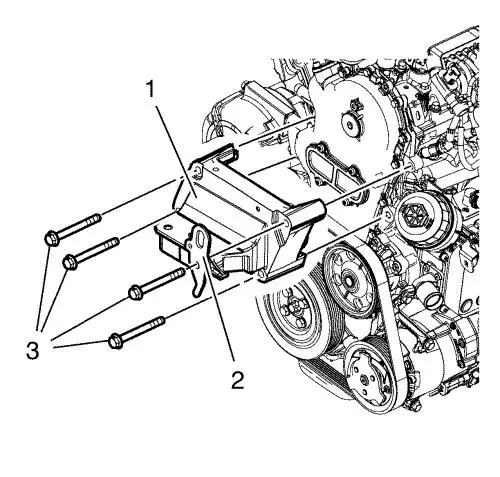

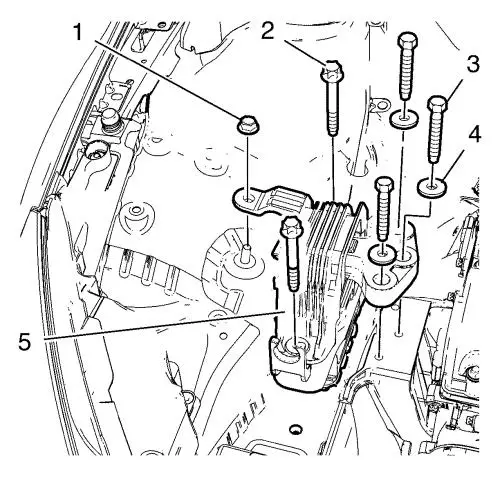

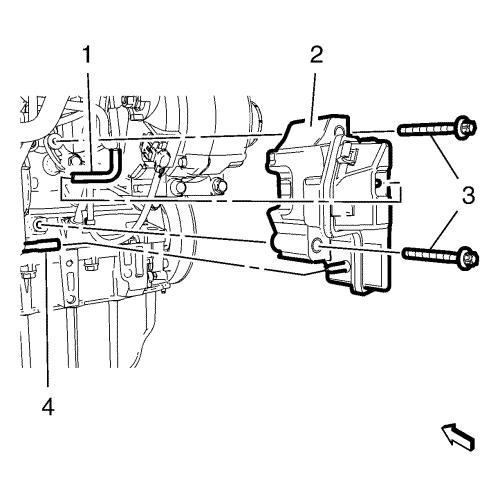

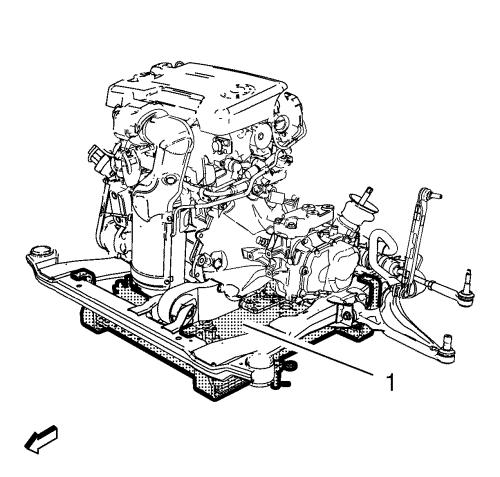

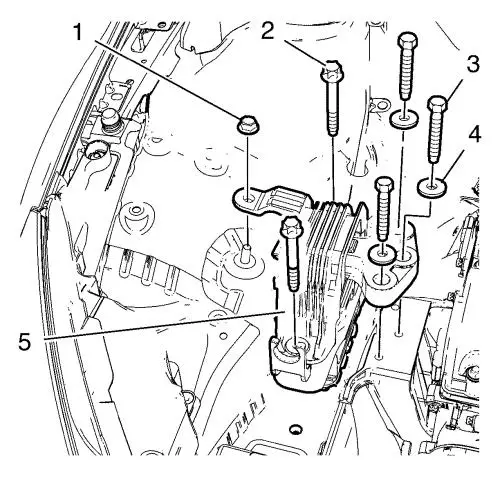

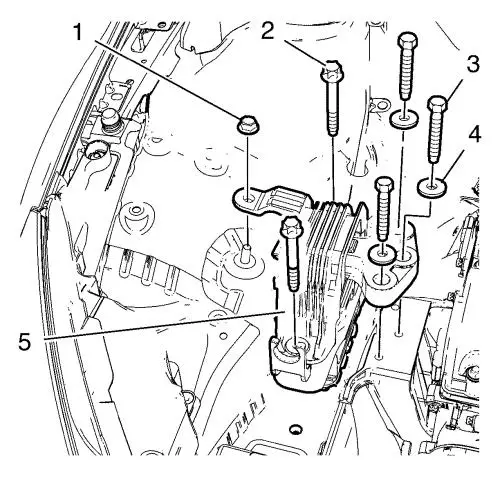

| 93. |

Remove the 3 engine mount to

engine mount bracket bolts (3) and the 3 washers (4). |

| 94. |

Remove the 2 engine mount to

body bolts (2) and the engine mount nut (1). |

| 95. |

Remove the engine mount

(5). |

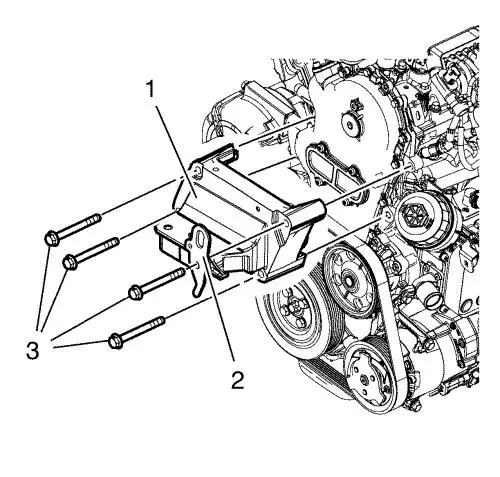

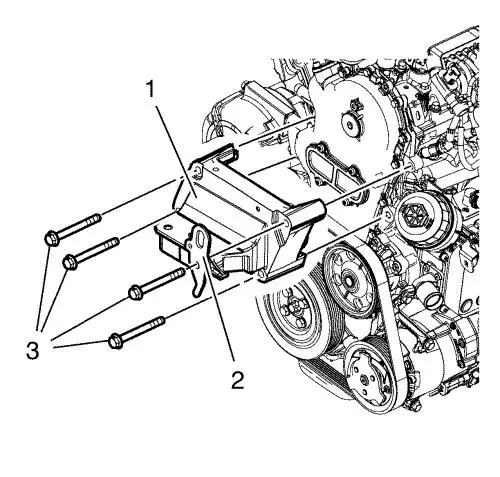

| 96. |

Remove 4 engine mount bracket

bolts (3). |

| 97. |

Remove engine lift bracket

(2). |

| 98. |

Remove engine mount bracket

(1). |

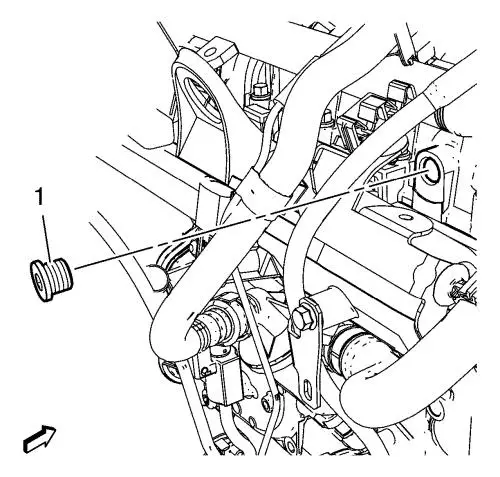

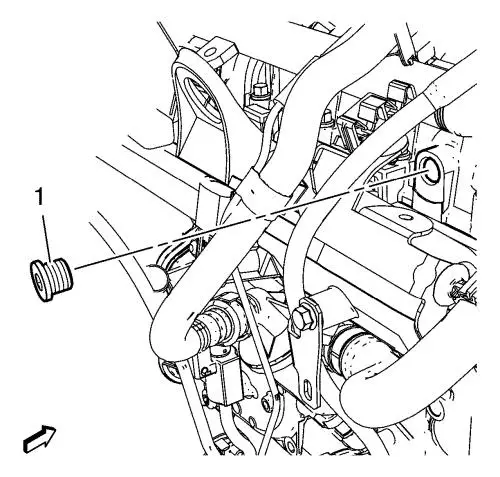

| 99. |

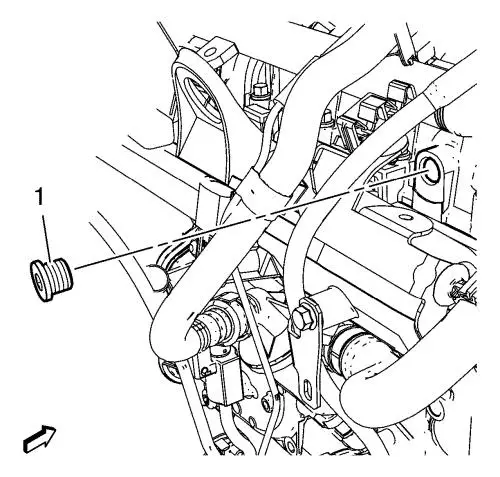

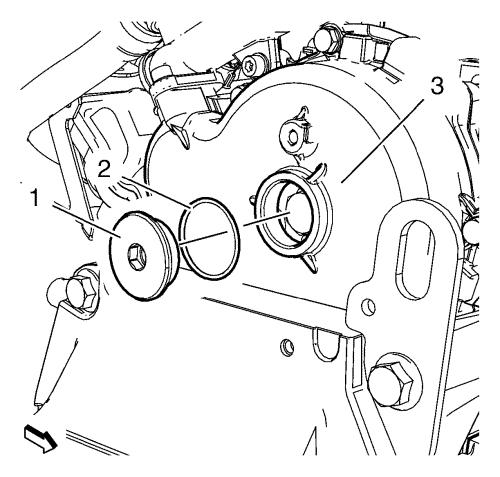

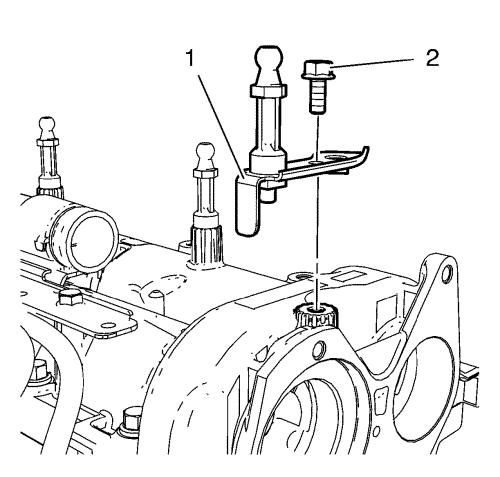

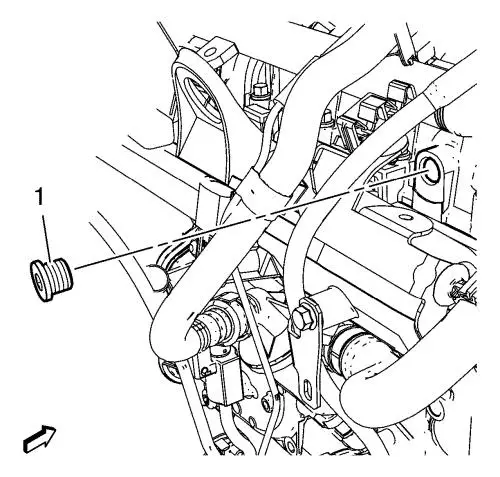

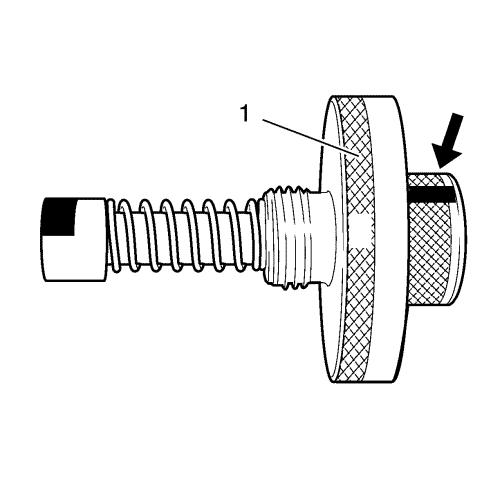

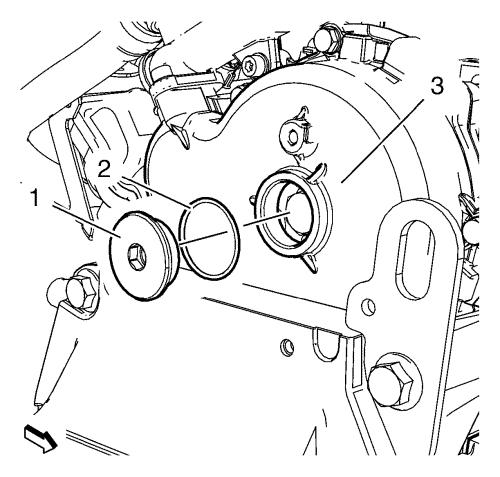

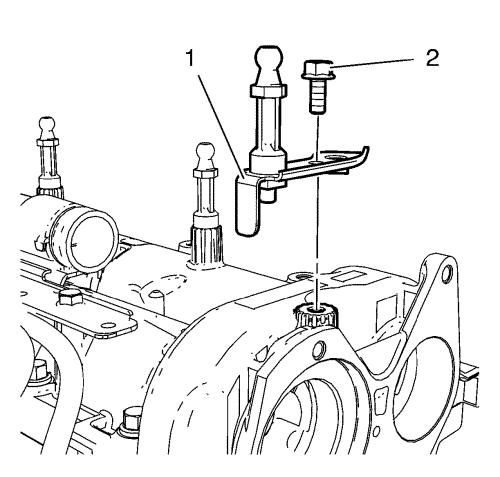

Remove the intake camshaft

housing core hole plug (1) from the camshaft housing. |

| 100. |

Clean the threads at the

camshaft housing and the camshaft housing core hole plug.

|

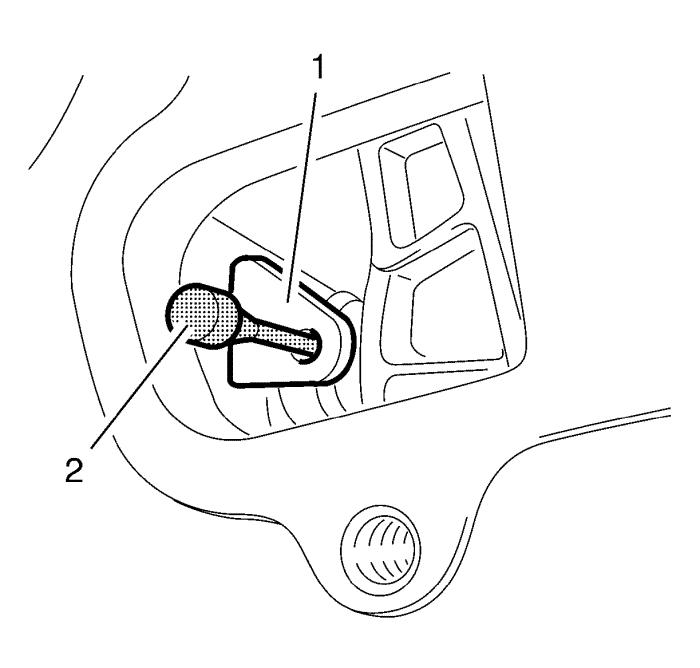

| 101. |

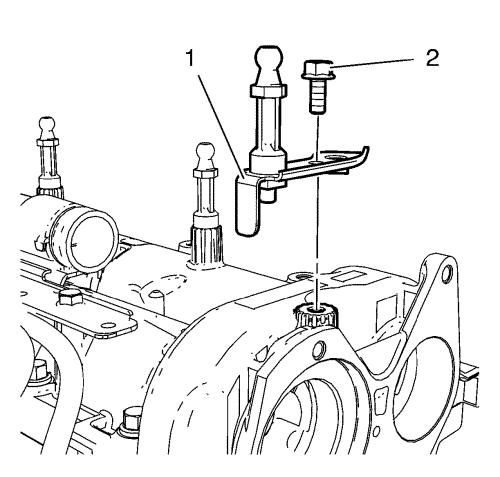

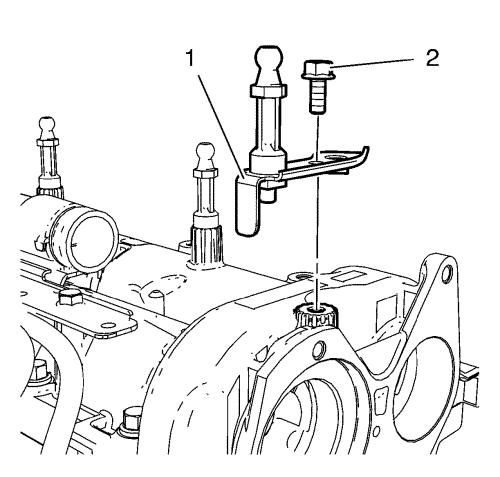

Mark (arrow) at the

EN-46781 fixing tool (1). |

|

Note: The

EN-46781 fixing tool (1) must be installed in

horizontal position.

|

| 102. |

Install the EN-46781

fixing tool (1) into the intake side. |

|

Note: If the

EN-46781 fixing tool does not rotate any longer,

the tool is correctly engaged.

|

| 103. |

Turn the crankshaft at the

crankshaft sprocket bolt carefully, until the EN-46781

fixing tool (1) engages at the intake camshaft. |

|

Note: Turn the

crankshaft carefully until EN-46785 fixing tool

engages in the flywheel.

|

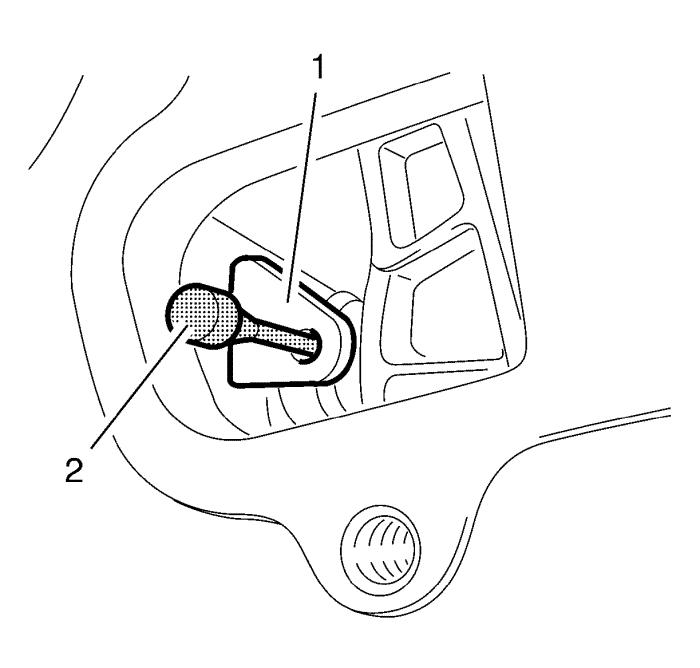

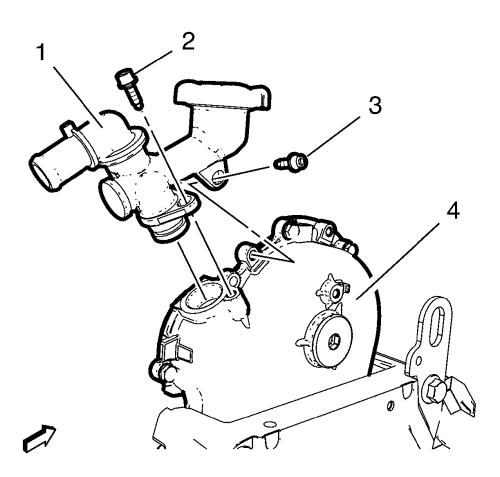

| 105. |

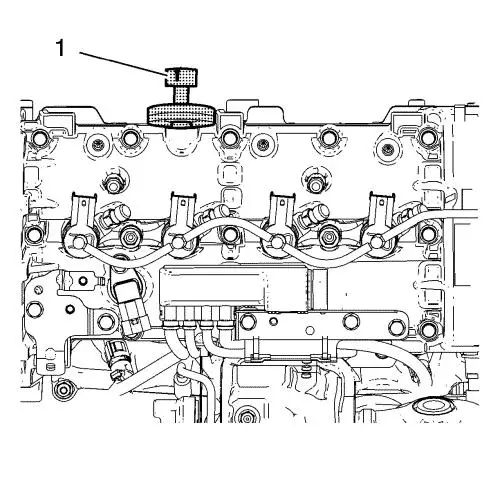

Install the EN-46785

fixing tool (1). |

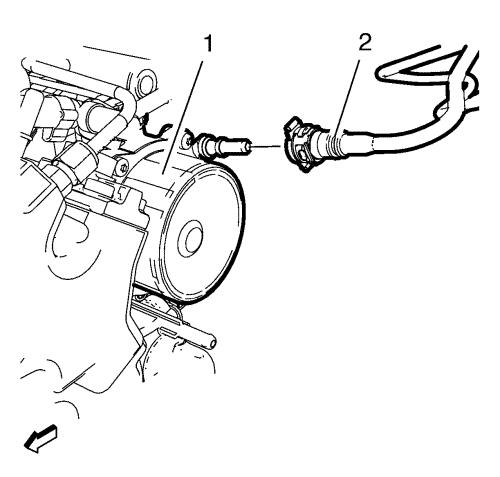

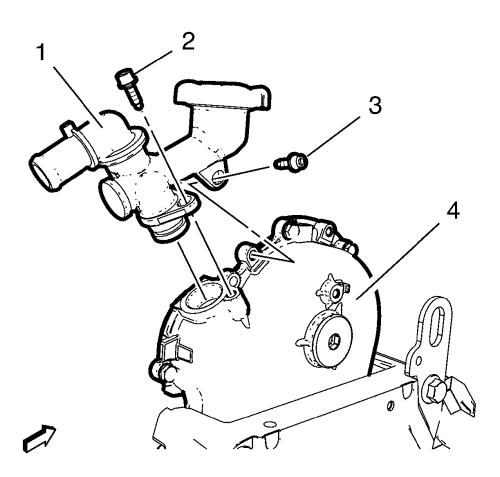

| 107. |

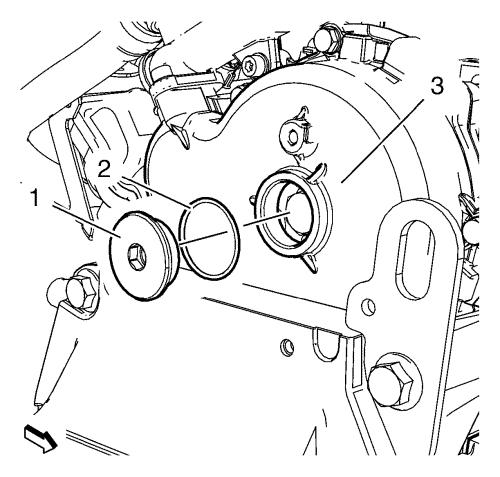

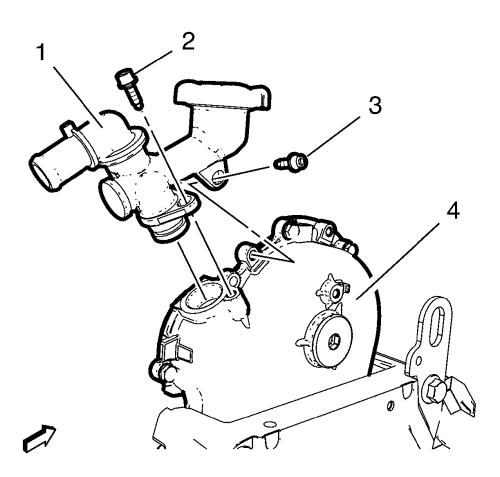

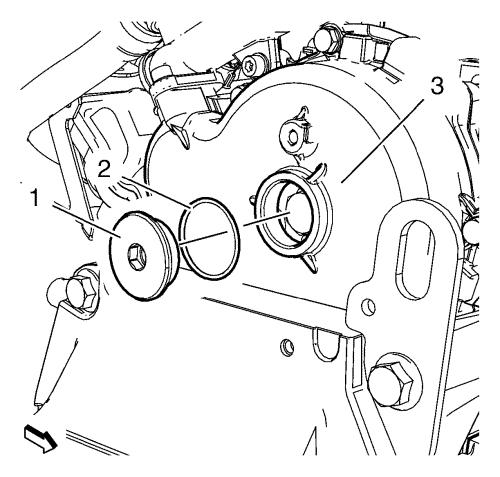

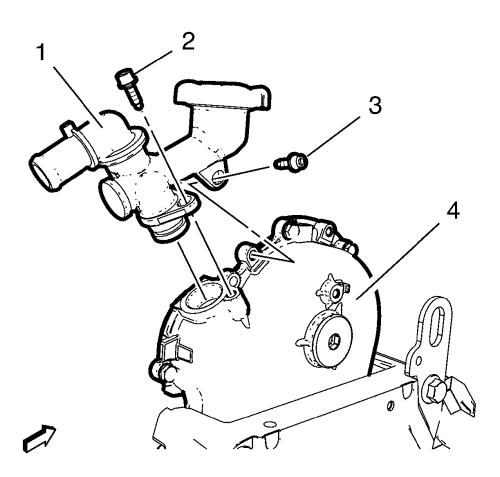

Remove the oil pump housing

plug (1) from the oil pump housing (3). |

| 108. |

Remove the oil pump housing

plug seal (2). |

| 109. |

Remove the 4 oil pump housing

closure cover bolts (4). |

| 110. |

Remove the oil pump housing

closure cover (1) from the oil pump housing (3). |

| 111. |

Remove the oil pump housing

closure cover gasket (2). |

|

Note: Do NOT remove

the camshaft sprocket bolt.

|

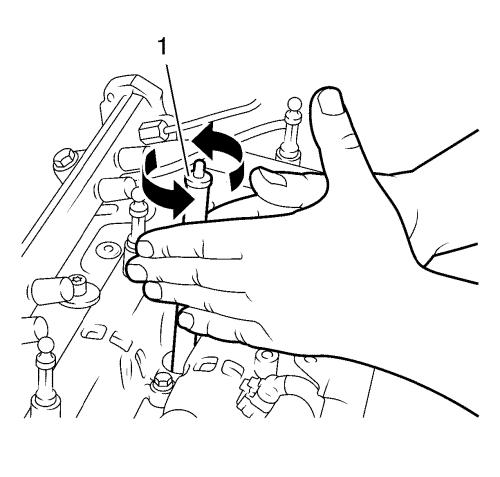

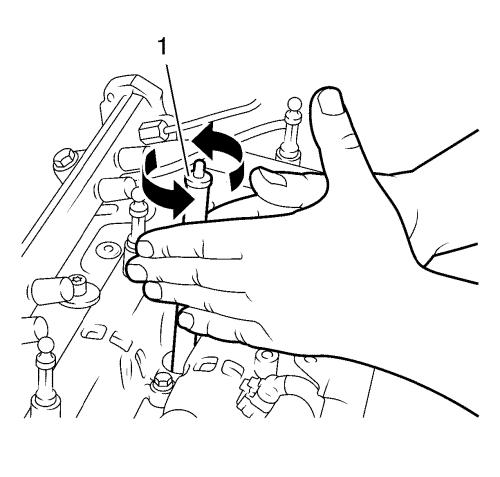

| 112. |

Loosen the camshaft sprocket

bolt. |

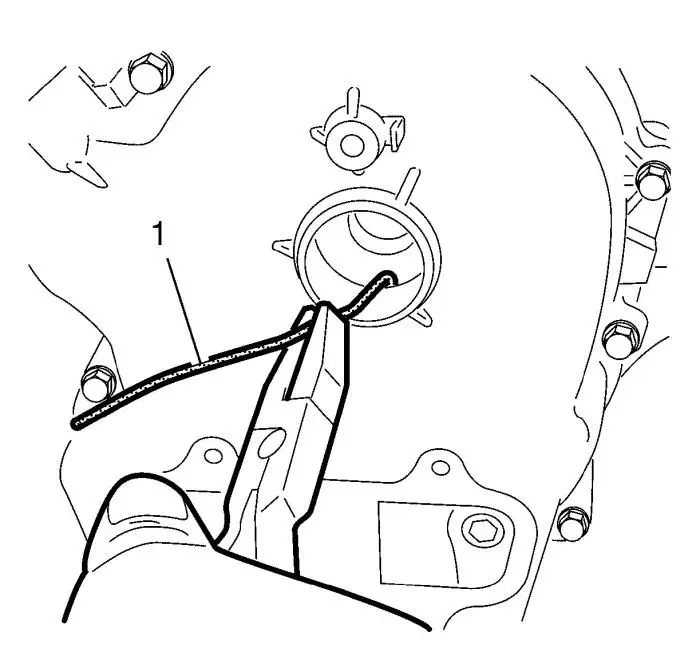

| 113. |

Tension the timing chain

tensioner (1). |

| 114. |

Fixing the timing chain

tensioner position with the EN-955-1 locking tool

(2). |

| 115. |

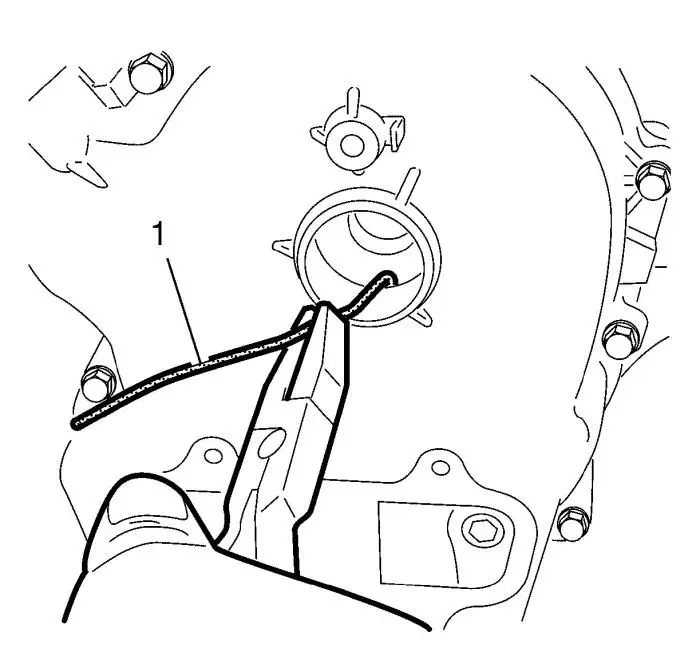

Remove the camshaft sprocket

bolt. |

| 116. |

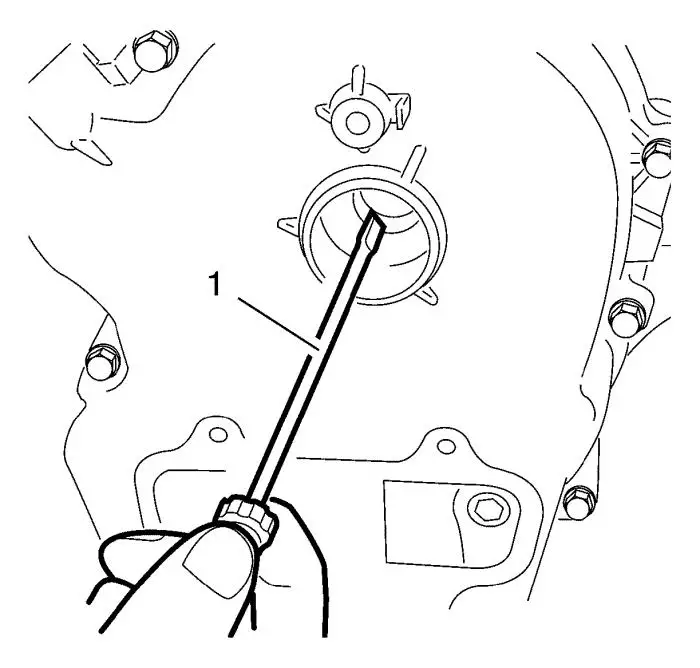

Remove the camshaft sprocket

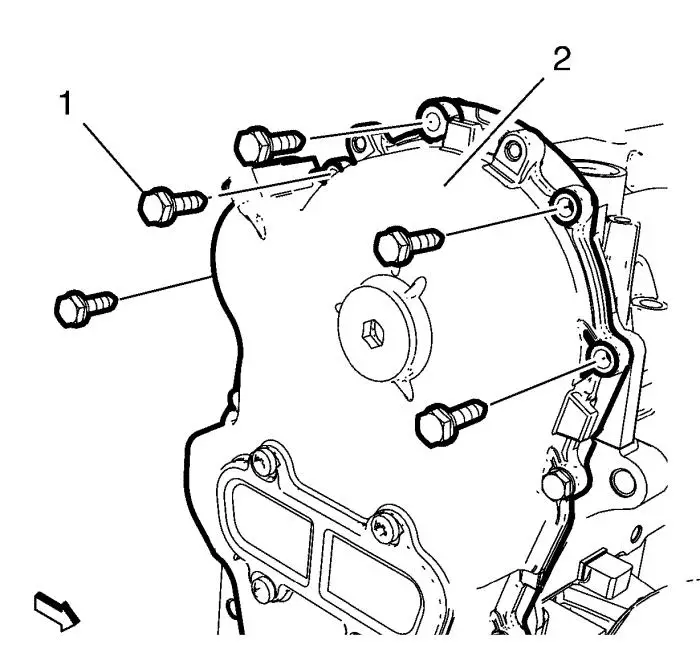

from the exhaust camshaft. Using a bent piece of rigid wire

(1). |

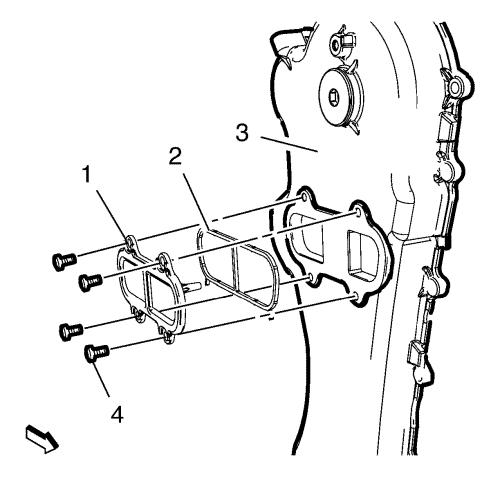

| 117. |

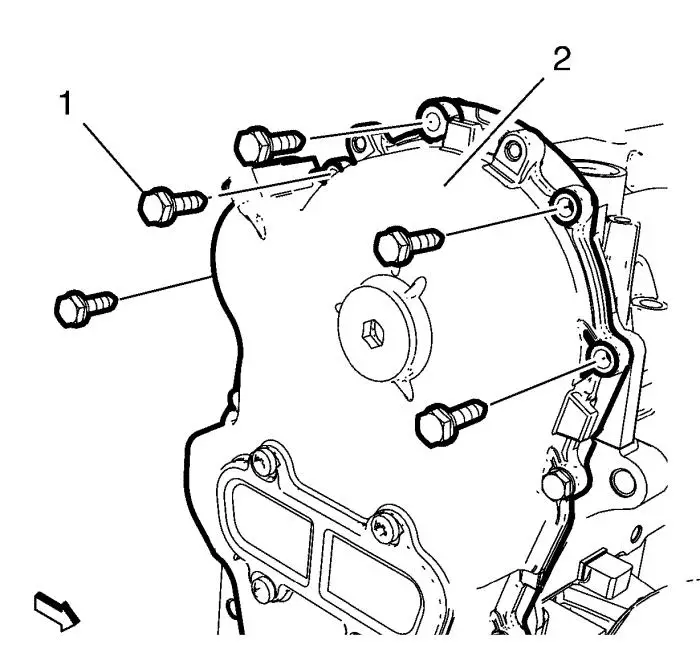

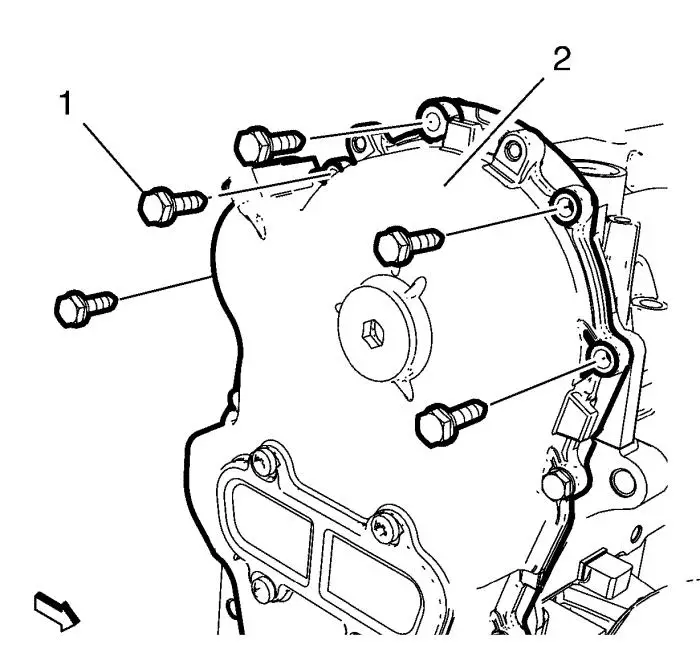

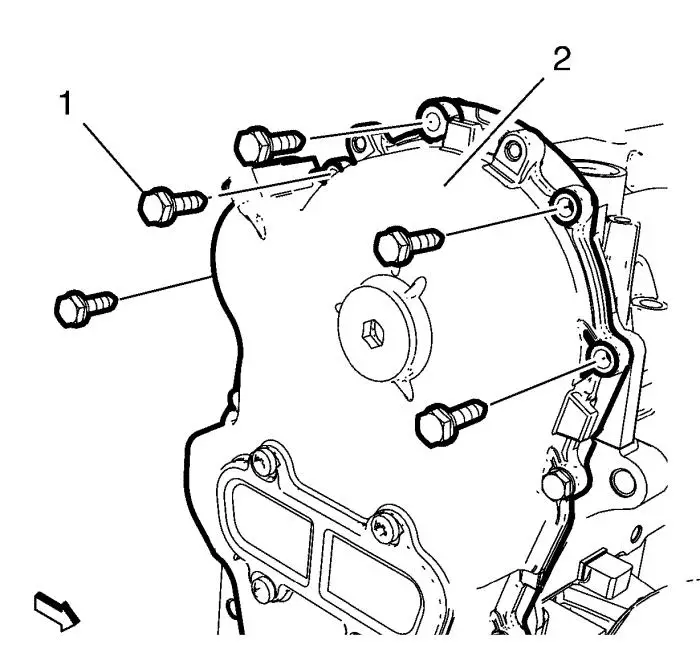

Remove the 5 oil pump housing

bolts from the oil pump housing (2) and camshaft housing.

|

|

Note: Take note that

there are different bolt lengths.

|

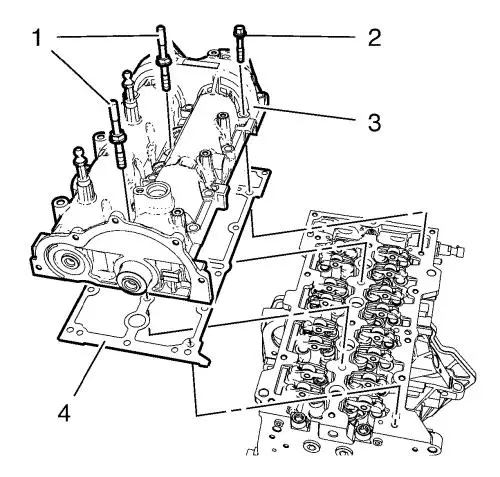

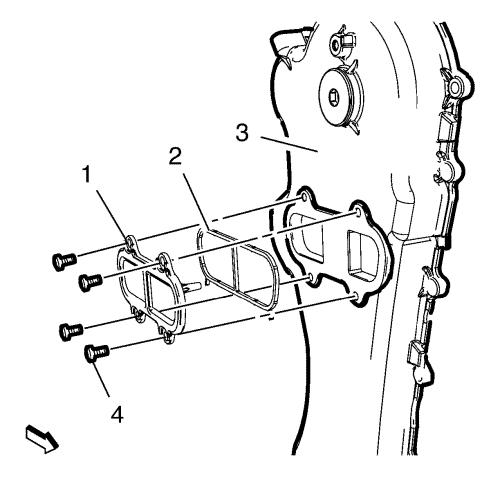

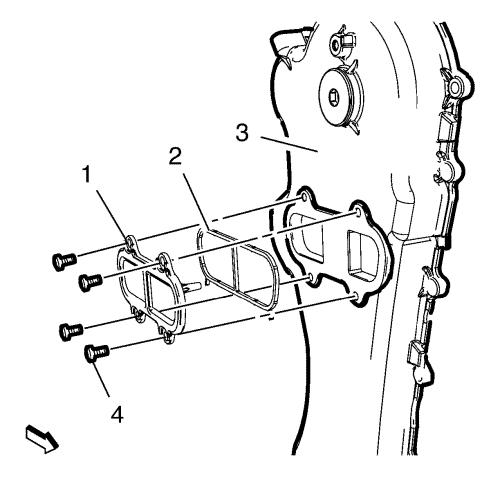

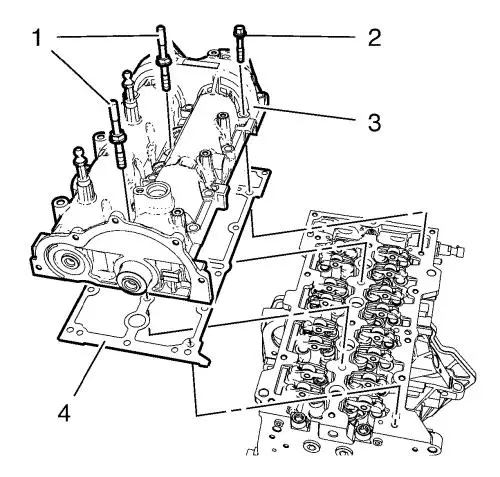

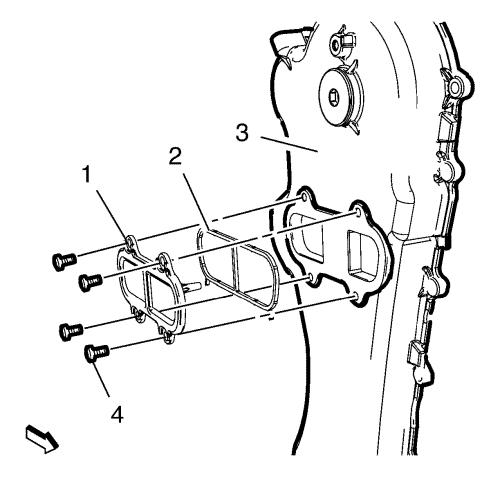

| 118. |

Remove the 16 camshaft housing

bolts (2). |

| 119. |

Remove the 2 camshaft housing

studs (1). |

|

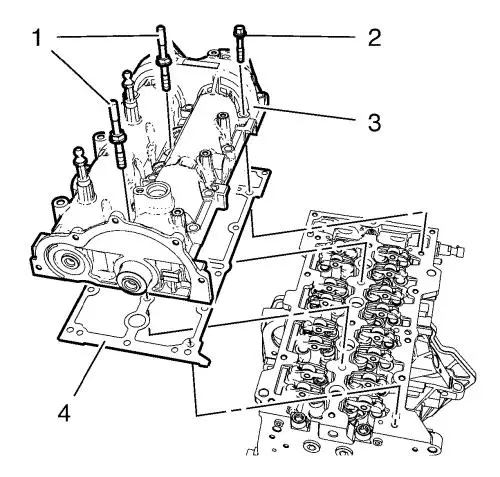

Note: Carefully lever

the camshaft housing off timing case gasket with plastic wedge and

use a rubber mallet to knock it off the timing case. Place the

camshaft housing on suitable support.

|

| 120. |

Remove the camshaft housing

(3). |

| 121. |

Remove the camshaft housing

gasket (4). |

Installation Procedure

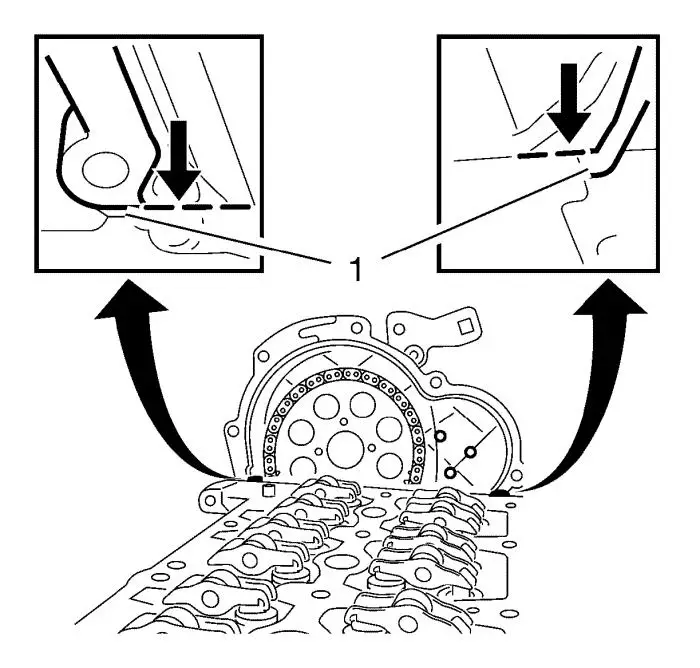

| 1. |

Remove the upper oil pump

housing gasket. |

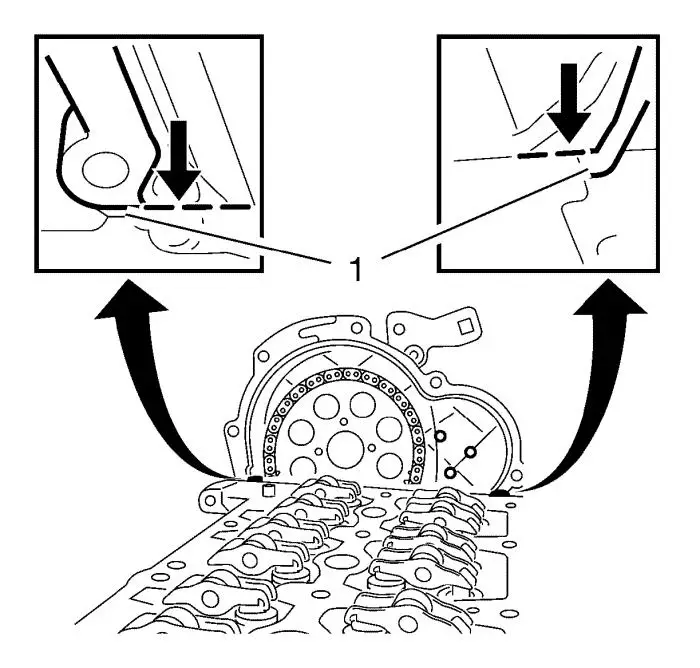

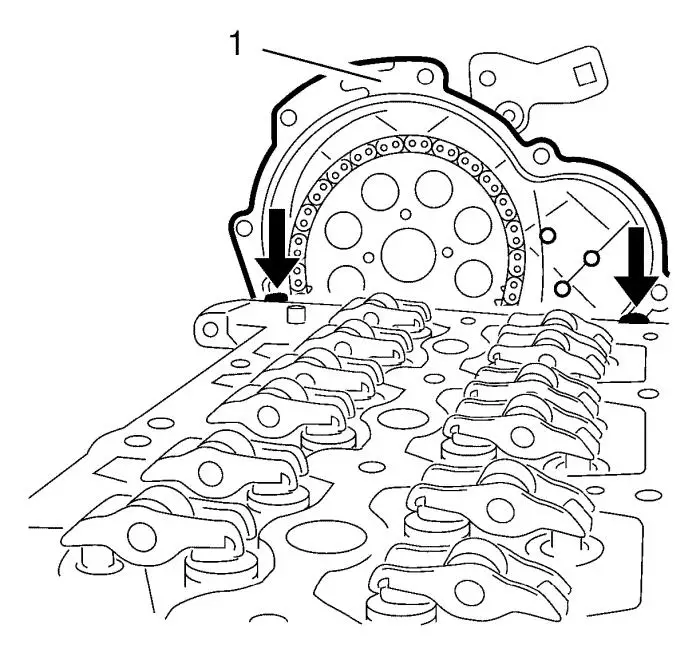

| |

• |

Cut into the elastomer sealing

lips (arrows) using a sharp knife pressed against the cylinder

head. |

| |

• |

With a plastic spatula, loosen

the seal from the timing case and carefully snap it off at the

designated point (1). |

| |

• |

Remove the upper oil pump

housing gasket. |

|

Note: Make sure that

no residues remain at the joint between the timing case and

cylinder head, and that no bits of the gasket fall into the timing

case.

|

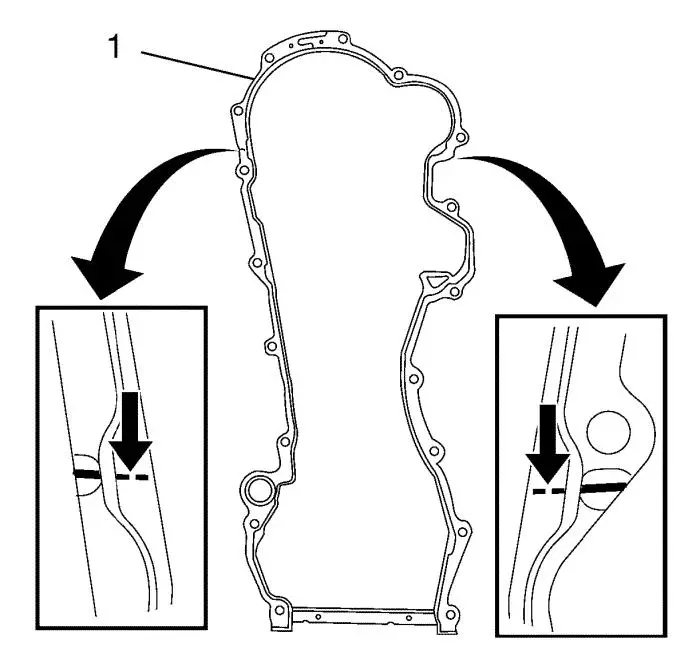

| 2. |

Remove any gasket residue and

clean all sealing surfaces thoroughly. |

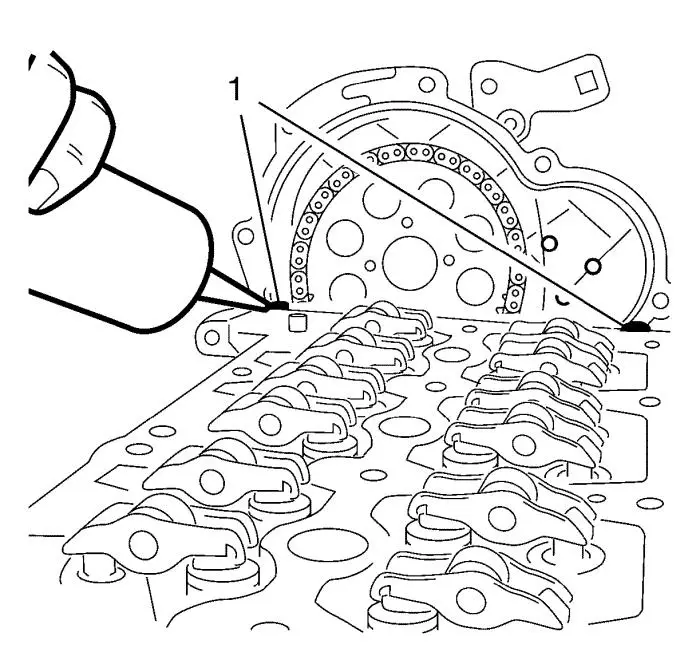

| 3. |

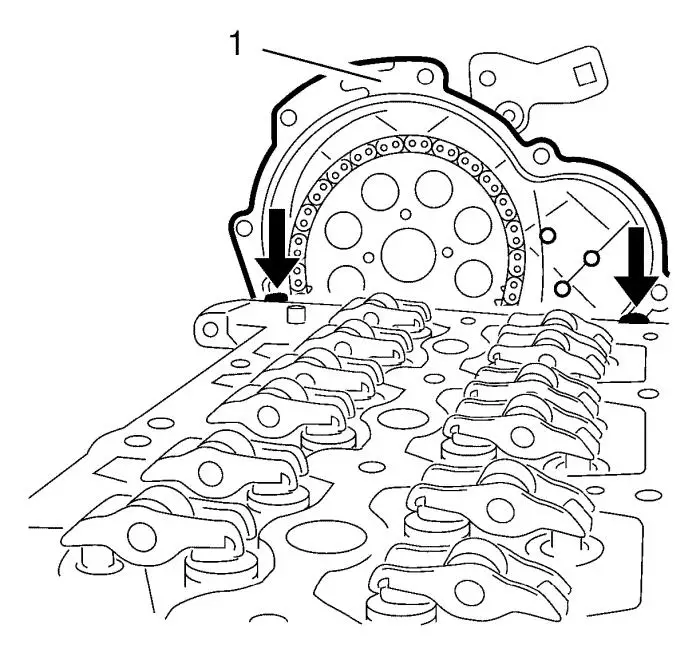

Fit the NEW oil pump housing

gasket. (1). |

| |

Using a sharp knife, cut into the elastomer sealing lips

(arrows) at the breaking points of the new gasket. |

|

Note: It is essential

for the cutting tool (1) to have a straight cutting surface.

|

| 4. |

Cut the NEW oil pump housing

gasket off at the breaking points (arrow). |

|

Note: The upper new

gasket and the old lower gasket must not be allowed to overlap.

|

| 5. |

Fit NEW oil pump housing

gasket (1) to the contact surface between the cylinder block and

the timing case until the seal lies flush on the cylinder head and

timing case (arrows) and the holes in the gasket and the timing

case match up. |

| 6. |

Clean any oil and grease of

the exhaust camshaft, camshaft sprocket, camshaft sprocket bolt and

thread in exhaust camshaft. |

| 7. |

Clean all sealing

surfaces. |

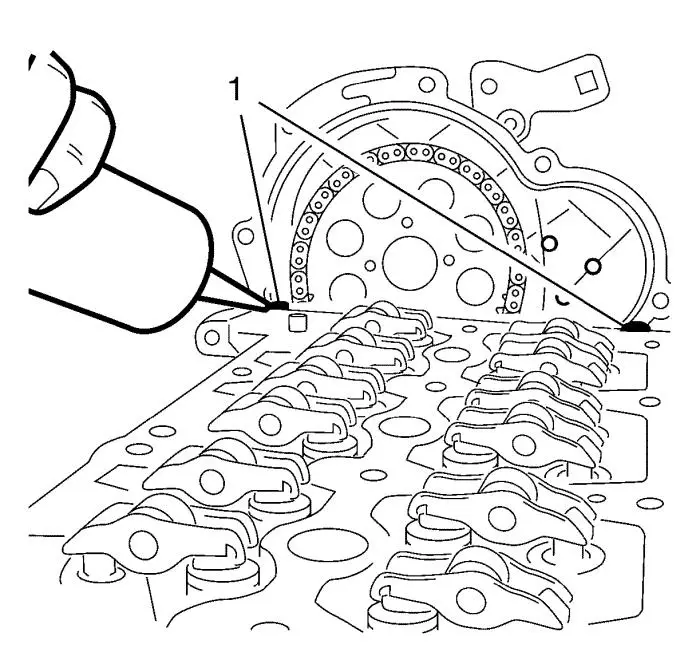

| 8. |

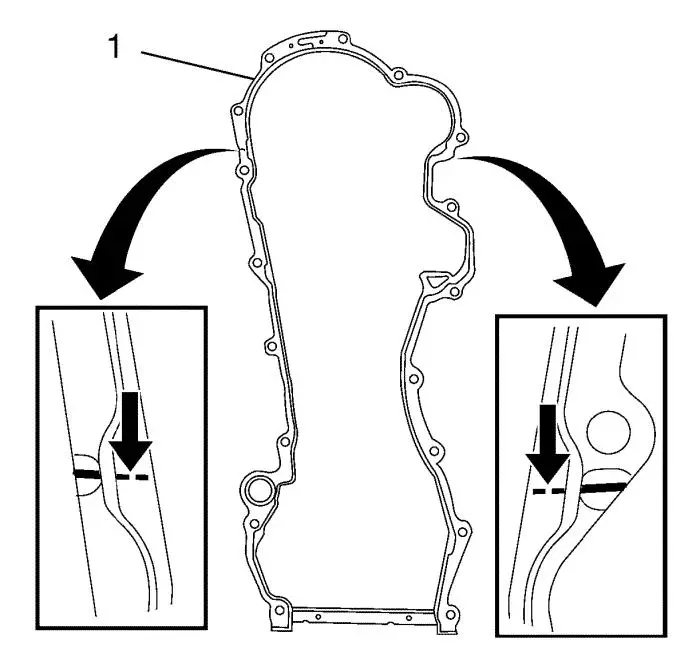

Apply silicone sealing

compound to the transitions between the cylinder head and oil pump

housing (1). |

| 9. |

Install NEW camshaft housing

gasket. |

| 10. |

Apply silicone sealing

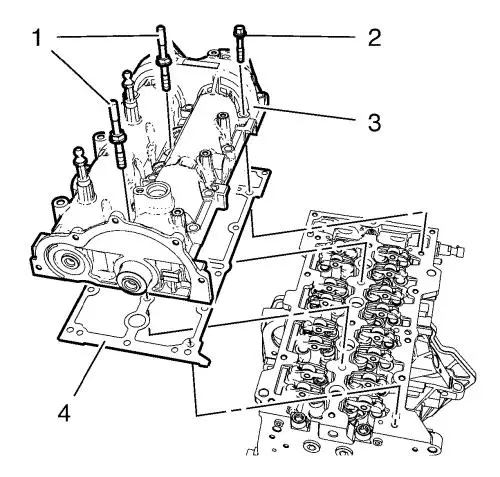

compound to the transitions between the camshaft housing gasket and

oil pump housing. |

| 11. |

Install the camshaft housing

(3). |

|

Note: Tightening the

2 camshaft housing studs in sequence until the camshaft housing is

lying evenly on the cylinder head.

|

| 12. |

Loosely install the 2 camshaft

housing studs (1). |

|

Note: Mind at

different bolt length.

|

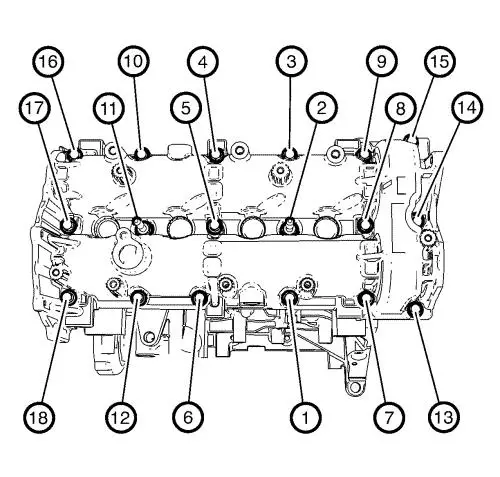

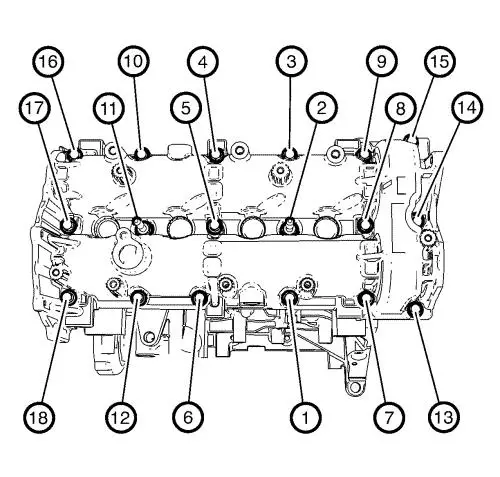

| 13. |

Loosely install the 16

camshaft housing bolts (2). |

| 14. |

Carefully align the camshaft

housing on the oil pump housing, using a rubber mallet.

|

| 15. |

Install the 5 oil pump housing

bolts (1) to the oil pump housing (2) and camshaft housing and

tighten the bolts carefully until the camshaft housing is in

contact with the oil pump housing. |

| 16. |

Tighten the 16 camshaft cover

bolts and the 2 camshaft cover studs in sequence as shown and first

step: |

| |

• |

For camshaft housing bolts M7

to 12 N·m (106 lb in) . |

| |

• |

For camshaft housing studs M8

to 15 N·m (11 lb ft) . |

| 17. |

Tighten the 16 camshaft cover

bolts and the 2 camshaft cover studs in sequence as shown and final

step: |

| |

• |

For camshaft housing bolts M7

to 18 N·m (13 lb ft) . |

| |

• |

For camshaft housing studs M8

to 25 N·m (18 lb ft) . |

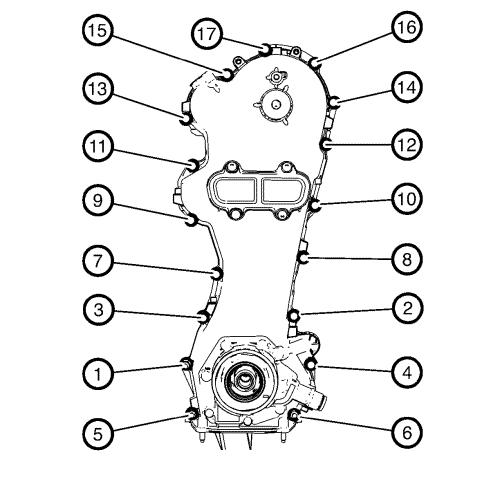

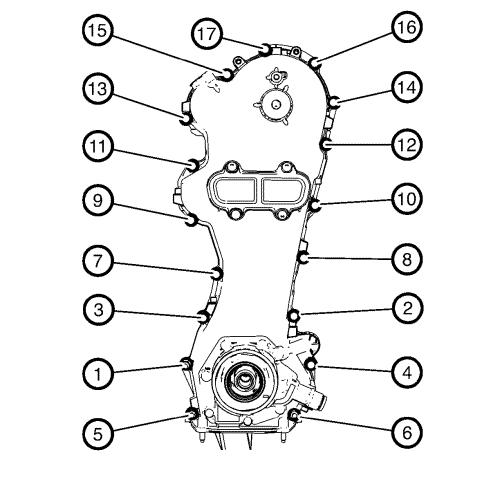

| 18. |

Tighten the 5 oil pump housing

bolts (13 - 17) in sequence as shown: |

| |

• |

In first step and in sequence

as shown, tighten to 4 N·m (35 lb in)

. |

| |

• |

In second step and in sequence

as shown, tighten to 9 N·m (80 lb in)

. |

| 19. |

Install the camshaft sprocket

to the exhaust camshaft. |

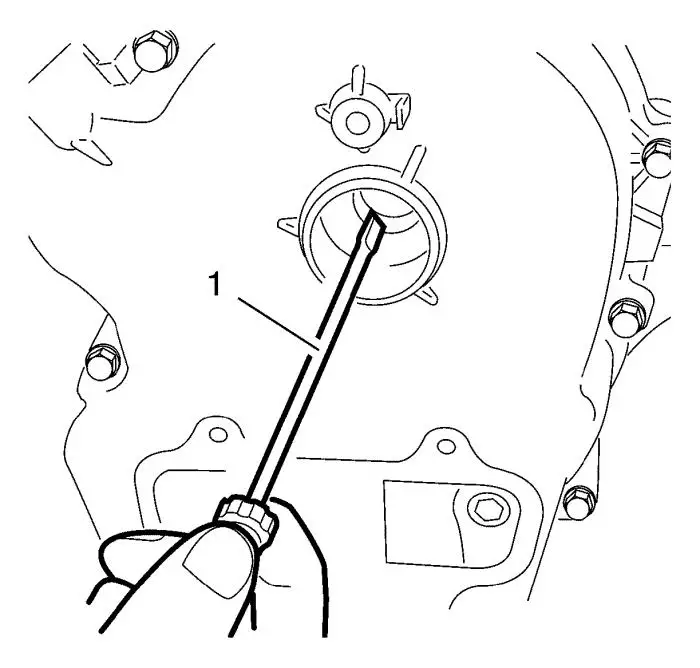

| |

• |

Using a suitable tool (1),

place the drive gear on the exhaust camshaft. |

| |

• |

Loosely install camshaft

sprocket bolt. |

| 20. |

Remove the EN-955-1

locking tool (2) from timing chain tensioner (1).

|

|

Note: A second

mechanical must tighten the timing chain tensioner (1) with a

suitable tool (2) while the timing chain is being tightened.

|

| 21. |

Tighten the camshaft sprocket

bolt to 150 N·m (111 lb ft) . |

| 22. |

Remove the EN-46785

fixing tool (1). |

| 23. |

Remove the EN-46781

fixing tool (1). |

| 24. |

Turn the crankshaft

720° (2 turns) in the direction of engine

rotation. |

| 26. |

Install the oil pump housing

closure cover gasket (2). |

| 27. |

Install the oil pump housing

closure cover (1) to the oil pump housing (3). |

| 28. |

Install the 4 oil pump housing

closure cover bolts (4) and tighten to 9 N·m (80 lb

in) . |

| 29. |

Install the oil pump housing

plug seal (2). |

| 30. |

Install the oil pump housing

plug (1) to the oil pump housing (3) and tighten to 9

N·m (80 lb in) . |

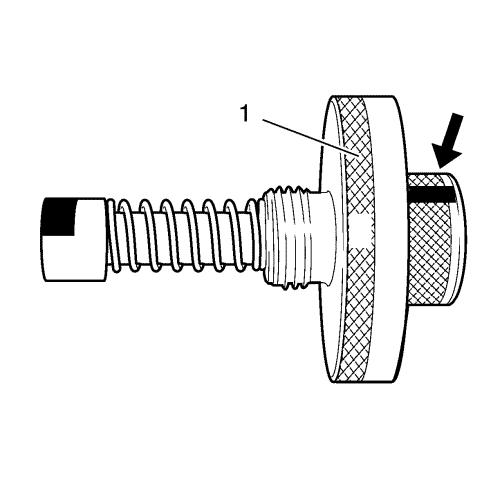

| 31. |

Install the intake camshaft

housing core hole plug (1) to the camshaft housing and tighten to

15 N·m (11 lb ft) . |

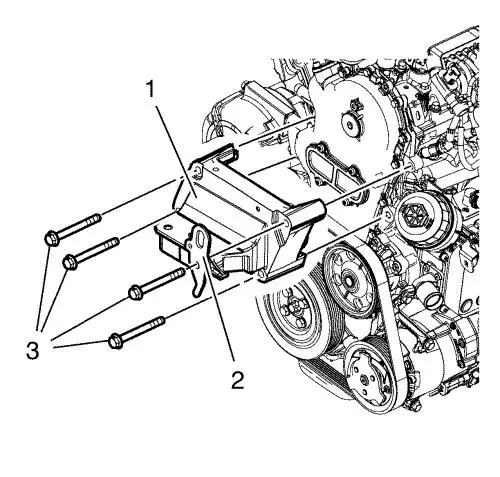

| 32. |

Install the engine mount

bracket (1). |

| 33. |

Install the engine lift

bracket (2). |

| 34. |

Install the 4 engine mount

bracket bolts (3) and tighten to 60 N·m (44 lb

ft) . |

| 35. |

Install the engine mount

(5). |

| 36. |

Install the 2 engine mount to

body bolts (2) and the engine mount nut (1) and tighten to

62 N·m (46 lb ft) . |

| 37. |

Install the 3 engine mount to

engine mount bracket bolts (3) and the 3 washers (4) and tighten to

62 N·m (46 lb ft) . |

| 39. |

Lower the CH-49290

engine support tool (1). |

| 40. |

Remove the CH-49290

engine support tool from CH-904 base frame

. |

|

Note: The SPX

installation manual is supplied with the special tool and is also

available online from SPX directly. Go to

www.spxtools-shop.com.

|

| 41. |

Disassemble the

CH-49290 engine support tool (1) according to the

details provided in the SPX installation manual. |

| 42. |

Install the oil filler tube

(1) to oil pump housing (4). |

| 43. |

Install the 2 oil filler tube

bolts (2, 3) and tighten to 9 N·m (80 lb

in) . |

| 44. |

Install the engine control

module wiring harness bracket (1) right side. |

| 45. |

Install the 2 engine control

module wiring harness bracket bolts (2) and tighten to 9

N·m (80 lb in) . |

| 46. |

Install the engine control

module wiring harness bracket (1) left side. |

| 47. |

Install the engine control

module wiring harness bracket bolt (2) and tighten to 9

N·m (80 lb in) . |

| 48. |

Install the glow plug wiring

harness bracket (1). |

| 49. |

Install the 2 glow plug wiring

harness bracket bolts (2) and tighten to 9 N·m (80

lb in) . |

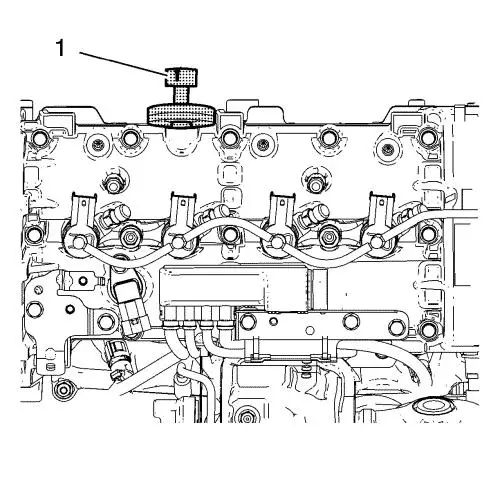

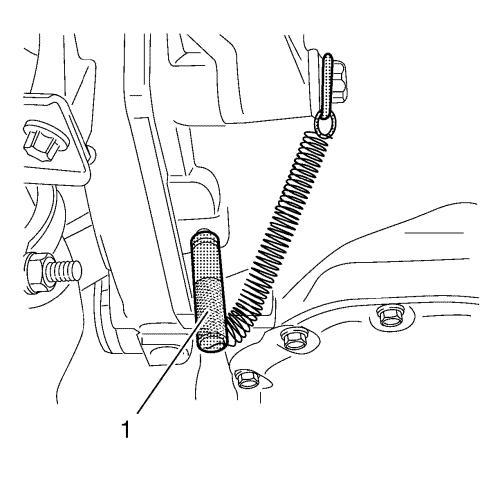

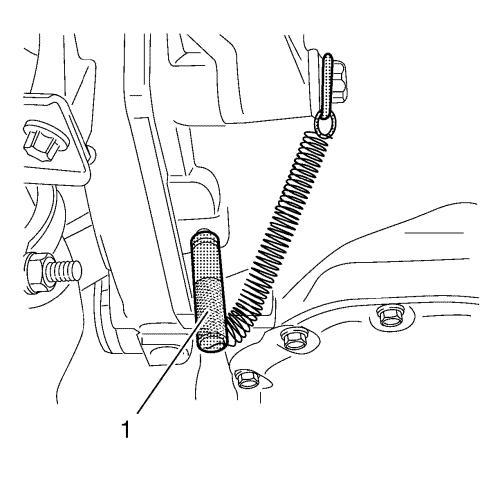

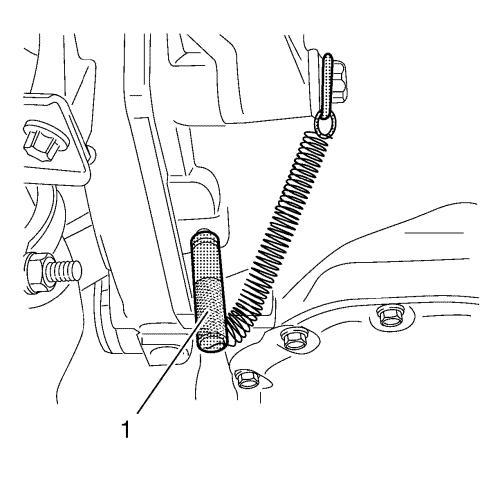

| 50. |

Clean the injector sealing

surfaces in the cylinder head using EN-47632

cleaning tool (1) in following procedure: |

| |

• |

First take the brush side to

loosen the dirt. |

| |

• |

Second take the sponge side to

remove the dirt. |

| 51. |

Install the 4 NEW fuel

injector gaskets (6) to the camshaft housing. |

| 52. |

Remove the EN-48559

protective caps from the injector nozzles. |

| 53. |

Install the 4 NEW fuel

injector seals (5) to the fuel injectors. |

| 54. |

Install the 4 fuel injectors

(1) with the 2 fuel injector brackets (7). |

| 55. |

Install the 2 fuel injector

spherical washers (4). |

| 56. |

Install the 2 fuel injector

conical washer (3). |

| 57. |

Install the 2 fuel injector

bracket nuts (2) and tighten to 20 N·m (15 lb

ft) . |

| 58. |

Install the fuel rail (3) with

the fuel rail bracket (4). |

| 59. |

Install the engine lift

bracket (2). |

| 60. |

Install the 3 fuel rail

bracket bolts (1) and tighten to 25 N·m (18 lb

ft) . |

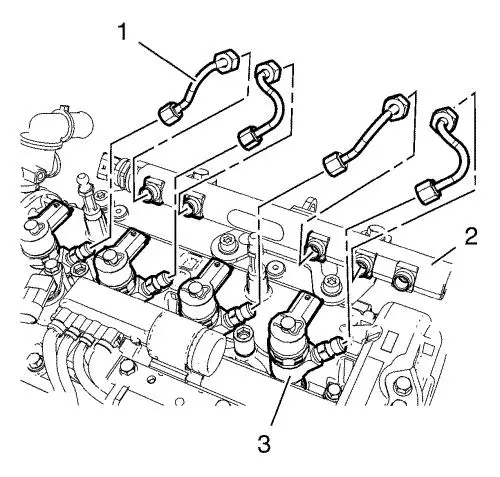

| 61. |

Install the 4 fuel injection

fuel feed pipes (1). |

| 62. |

Install the 4 fuel injection

fuel feed pipe nut M12 to 4 fuel injectors (3) and tighten to

24 N·m (18 lb ft) . |

| 63. |

Install the 4 fuel injection

fuel feed pipe nuts M14 to fuel rail (2) and tighten to 28

N·m (21 lb ft) . |

| 64. |

Tighten the 2 fuel rail bolts

to 25 N·m (18 lb ft) . |

| 65. |

Install the fuel injector fuel

return hose with the fuel separator (3). |

| 66. |

Install the fuel separator

bolt (4) and tighten to 9 N·m (80 lb in)

. |

| 67. |

Install the fuel return hose

(2) to the fuel injector pump. |

| 68. |

Install the fuel return hose

clamp (5). |

| 69. |

Install the fuel injector fuel

return hose (1) to the 4 fuel injectors. |

| 70. |

Clip in the 4 fuel injector

fuel return hose retainer springs (6). |

| 71. |

Install the fuel feed pipe (2)

to the fuel injection fuel pump (3) and the fuel rail (1).

|

| |

• |

Install fuel feed pipe nut M12

to fuel injection fuel pump and tighten to 24 N·m

(18 lb ft) . |

| |

• |

Install fuel feed pipe nut M14

to fuel rail and tighten to 28 N·m (21 lb

ft) . |

| 72. |

Install the turbocharger

wastegate actuator vacuum hose to the vacuum pump. |

| 73. |

Install the brake booster

vacuum pipe (2) to the vacuum pump (1). |

| 74. |

Install the fuel feed pipe (1)

to the fuel injection pump (4). |

| 75. |

Install the fuel return pipe

(2) to the fuel separator (3). |

| 76. |

Position the ECM wiring

harness. |

| 78. |

Clip in the wiring harness to

exhaust gas recirculation cooler. |

| 79. |

Clip in the wiring harness to

oil level indicator tube. |

| 80. |

Install the starter control

cable (3). |

| 81. |

Install the starter control

cable nut and tighten to 13 N·m (115 lb in)

. |

| 82. |

Connect the exhaust gas

recirculation cooler wiring harness plug (4). |

| 83. |

Connect the exhaust gas

recirculation valve wiring harness plug (1). |

| 84. |

Connect the generator wiring

harness plug (2). |

| 85. |

Install the exhaust gas

recirculation valve vacuum tank (2). |

| 86. |

Install the 2 exhaust gas

recirculation valve vacuum tank bolts (3) and tighten to 22

N·m (16 lb ft) . |

| 87. |

Install the turbocharger

wastegate actuator pipe (4). |

| 88. |

Install the turbocharger

wastegate actuator hose (1). |

| 89. |

Clip in the generator wiring

harness clip to the exhaust gas recirculation valve vacuum tank

(2). |

| 93. |

Clip in the wiring harness

retainer clips. |

| 94. |

Connect the backup lamp switch

wiring harness plug to the backup lamp switch. |

| 95. |

Connect the fuel injection

fuel pump wiring harness plug to the fuel injection fuel

pump. |

| 96. |

Connect the crankshaft

position sensor wiring harness plug to the crankshaft position

sensor. |

| 97. |

Connect the oil temperature

sensor wiring harness plug to the oil temperature sensor.

|

| 98. |

Connect the engine coolant

temperature sensor wiring harness plug to the thermostat

housing. |

| 99. |

Connect the glow plug wiring

harness connector (7). |

| 100. |

Clip in the ECM wiring harness

to the radiator inlet hose bracket. |

| 101. |

Install the 2 wiring harness

bracket bolts (6) and tighten to 9 N·m (80 lb

in) . |

| 102. |

Connect the throttle body

wiring harness plug (5). |

| 103. |

Connect the exhaust pressure

sensor wiring harness plug (4). |

| 104. |

Connect the oxygen sensor

wiring harness plug (3). |

| 105. |

Connect the manifold absolute

pressure sensor wiring harness plug (2). |

| 106. |

Connect the fuel rail sensor

wiring harness plug (1). |

| 107. |

Connect the 4 fuel injector

wiring harness plugs (8). |

| 108. |

Connect the camshaft sensor

wiring harness plug (1) to the camshaft sensor (3). |

| 109. |

Clip in the 3 retainer clips

to: |

| |

• |

Engine lift bracket (5)

|

| |

• |

Engine sight shield stud

bracket (4) |

| 110. |

Clip in the retainer clip to

the turbocharger wastegate actuator vacuum control solenoid valve

bracket. |

| 111. |

Connect the turbocharger

wastegate actuator vacuum control solenoid valve wiring harness

plug (1). |

| 112. |

Clip in the retainer clip (6)

to the oil filter housing. |

| 113. |

Connect the turbocharger

wastegate sensor wiring harness plug (2). |

| 114. |

Clip in the retainer clip (4)

to the exhaust temperature sensor wiring harness bracket.

|

| 115. |

Connect the exhaust

temperature sensor wiring harness plug (5). |

| 116. |

Connect the air conditioning

compressor wiring harness plug (3). |

| 117. |

Install the oxygen sensor (1)

to catalytic converter (2) and tighten to 45 N·m (33

lb ft) . |

| 118. |

Clip in the oxygen sensor plug

to exhaust pressure sensor bracket and ECM wiring harness.

|

| 119. |

Install the positive crankcase

ventilation pipe (1). |

| 120. |

Install the 2 positive

crankcase ventilation pipe bracket bolts (2) and tighten to

8 N·m (71 lb in) . |

| 121. |

Install the vacuum hose to

turbocharger wastegate actuator vacuum control solenoid

valve. |

| 122. |

Connect the positive crankcase

ventilation pipe connector wiring harness plug. |

| 123. |

Connect the positive crankcase

ventilation pipe connector (3) to the positive crankcase

ventilation oil separator. |

| 124. |

Install the charge air cooler

outlet air hose seal (2). |

| 125. |

Install the charge air cooler

outlet air hose (4) to the throttle body (1). |

| 126. |

Install the air cooler outlet

air hose bolt to the radiator inlet hose bracket and tighten to

10 N·m (89 lb in) . |

| 127. |

Install the 2 charge air

cooler outlet air hose bolts (3) and tighten to 10

N·m (89 lb in) . |

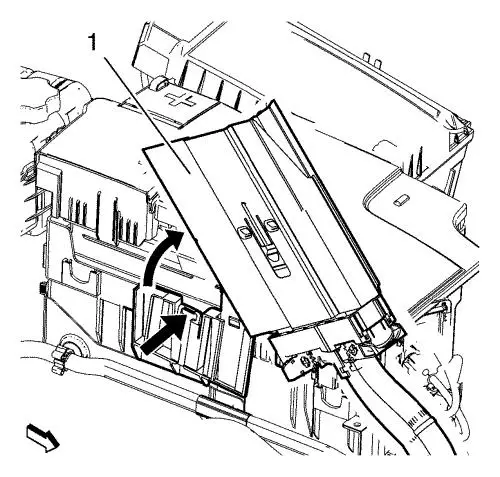

| 128. |

Install the electronic control

module (1) to the battery tray. |

|