Corsa C

|

Computerised measurement methods – Use of measuring and alignment systems Measuring and alignment systems are to be used to ensure accurate repair of a deformed body structure. These systems make is possible to not only check the frame floor groups for dimensional accuracy, but also to align body components directly and, if necessary, secure and weld in place new body parts at the right size. Opel/Vauxhall recommends use of measuring and alignment systems from the following manufacturers:

The measurement and control points for the frame body group and body structure are found in the vehicle-specific measurement data sheet from the measuring and alignment system manufacturer. Follow the operating instructions and regulations of the system manufacturer. Use of measuring system Opel/Vauxhall favors the use of a computerised measuring system for documented damage assessment before and after bodywork repair. In the case of damage calculation, a time allowance for determining the extent of damage with computerised measuring systems is obtained from the labour time guidelines. The advantages are obvious:

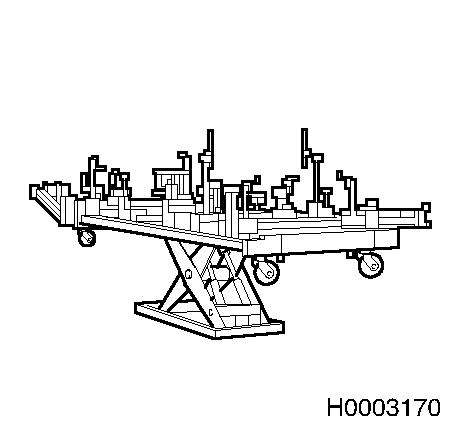

Vehicle retainers/bracket kits Basically, the separation of measurement and alignment is the qualitatively correct approach. Due to the increased use of computerised measuring systems of measuring and alignment system manufacturers in conjunction with the universal vehicle retainers and holding tools for new components, Opel/Vauxhall no longer requires a special bracket kit for each vehicle variant. The reasons for this are as follows:

Note: Opel/Vauxhall shall support any system manufacturer who wishes to offer these special bracket kits for individual vehicle variants. The decision regarding the development and production of these special bracket kits, however, rests with the individual system manufacturer. Opel/Vauxhall shall place its focus on the development of computerised measuring systems bombined with universal vehicle retrainers and holding tools for new components. Notes on vehicle floor/frame assembly All work on members, frames, struts and wheel housings is to be carried out in alignment systems.

|

||||||||||||||||||