|

Equipment recommendations for spot-welding

machines

As a consequence of increased demands with regard to lightweight

construction and crash safety, the use of new high performance

steels is necessary.

As a consequence of the operating concept, which is still usual

practice today, of the general setting of parameters, the use of

the spot-welding equipment available now means there is some

uncertainty about the quality of body repairs involving the new

steel materials.

As a result of the combination of different steel materials,

sheet metal thicknesses, layers of sheet metal and coatings it is

necessary for the new resistance spot-welding systems to include

programs which are designed for the respective specific

application.

Adam Opel AG has accepted these problems and developed and

tested a new spot welding apparatus generation together with

renowned manufacturers. This new general of apparatuses will take

over complete control and monitoring of the spot welding process

for the user.

Advantages of the new generation of resistance

spot-welding equipment:

Advantages in brief:

- Program settings with a fixed definition relating to the

respective vehicles / areas to be welded

- Recognition of differences in fit (between contact

surfaces)

- Detection of dirt on the area to be spot-welded

- Detection of paint or cataphoretic dip-coat primer on the area

to be spot welded

- Acoustic and / or visual information about the approval /

rejection of the spot-weld for the welders.

- Monitoring of the welding process and its result

- Monitoring of electrode cap wear

- Brief induction for welders

Detailed explanation of the advantages:

As is already the case for Opel MIG-brazing, the user is given

pre-defined program settings which are adapted to the respective

vehicle and welding task.

Therefore the user only needs to select the setting defined for

the area to be welded. This produces a very good and consistent

weld quality combined with optimised working time for the user. In

addition to the latter, the new resistance spot-welding equipment

recommended by Opel automatically detects that the preconditions

are not present for a reliable welded connection between the sheet

metal to be joined (e.g. because of paint residue, dirt or

differences in fit).

In this case, the user is informed visually and / or

acoustically. The equipment then tries to set up the preconditions

for optimum welding conditions automatically. If the welding

conditions cannot be achieved, the unit rejects the welding

task.

If the unit enables the welding process on the basis of the

checked preconditions for welding being found to be OK, the second

quality assurance stage commences immediately with the monitoring

of the welding process and its results.

The results of the individual parameter enquiries are available

on completion of a spot weld. If the values are not in the preset

range, the operator is warned visually and / or acoustically that

this is the case. The spot-weld is then outside the defined limit

values and additional measures must be taken by the operator.

A further additional innovation is the monitoring of the wear on

the electrode cap, which requests the operator to undertake

maintenance work on it or replace it. This measure also ensures a

consistently high quality of weld.

Further important information on this topic:

All requirements described for the new spot welding apparatus

generation are necessary so as to be able to - for example - repair

the high strength B-pillar of the Vectra-C / Signum by means of the

time-optimised spot welding process. In the medium term, Adam Opel

AG will adjust the worktime specifications to suit the new

resistance spot welding apparatus generation.

In connection with this matter, we wish to point out once again

expressly that, when undertaking body repairs to all Opel vehicles,

it is essential to follow the Service Instructions / Repair

Instructions and that the component must be repaired using the mode

of procedure described. In addition, the subject of MIG-brazing is

included in the video VT 52.

Resistance spot welding apparatuses recommended by

Adam Opel AG:

The following apparatuses have passed the function and welding

tests defined by Adam Opel AG.

Only the machines from the recommended manufacturers mentioned

in the recommendation have special welding programmes/parameter

settings/parameter documentation programmed for Opel/Vauxhall

vehicles and are updated for each new future Opel/Vauxhall product.

Opel/Vauxhall can provide no information for machines other than

the recommended ones and does not have welding programmes or

parameter settings.

Recommended resistance spot-welding machines

Note: All of the

recommended machines listed below can be purchased directly from

the respective manufacturers. Please contact the manufacturers at

the addresses specified below to find a representative in your

area.

|

1.1 ELMATECH

|

ELMATECH AG

|

|

Wisseraue 1

|

|

D-51597 Morsbach

|

|

Germany

|

|

www.elmatech.de

|

|

The following products fulfil the requirements:

|

|

1.1.

|

MIDIspot QSVM 9000 / 9000T

|

|

Reference number:

|

|

1.1

|

1_3926.1

|

1.2 CELETTE

|

Celette SA

|

|

13, Route de Bechevienne

|

|

38217 VIENNE CEDEX

|

|

France

|

|

www.celette.com

|

|

The following products fulfil the requirements:

|

|

1.2.

|

MIDIspot QSVM 9000 / 9000T

|

|

Reference number:

|

|

1.2.

|

ETC.QSVM 9000 / 9000T

|

1.3 DALEX

|

DALEX Schweißmachinen GmbH & Co. KG

|

|

Postfach 1162

|

|

D-57529 Wissen/Sieg

|

|

Germany

|

|

www.dalex.de

|

|

|

|

The following products fulfil the requirements:

|

|

1.3.

|

DALEX RZ 906

|

|

Reference number:

|

|

1.3.

|

DALEX RZ 906

|

|

Connection values:

|

|

|

Compressed air:

|

min. 6 bar constant

|

|

Fuse:

|

32 A , slow-acting

|

|

Connection rating:

|

25 kVA

|

|

Mains supply line:

|

min. 4 x 10 mm 2

|

|

Standard voltage:

|

400 V/50 Hz

|

|

Special voltage:

|

200 - 440 V/50 - 60 Hz

|

|

Recommended spot-welding pliers:

- C-pliers C90

- C-pliers C350

- C-pliers C500

- C-pliers C-S47

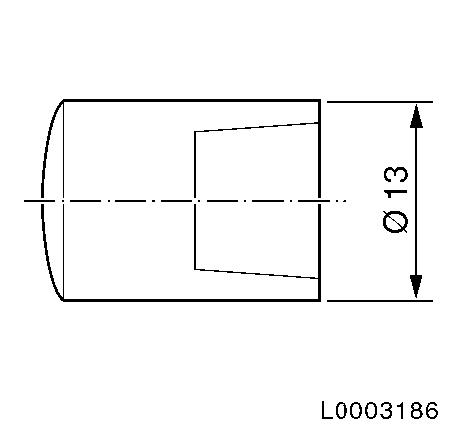

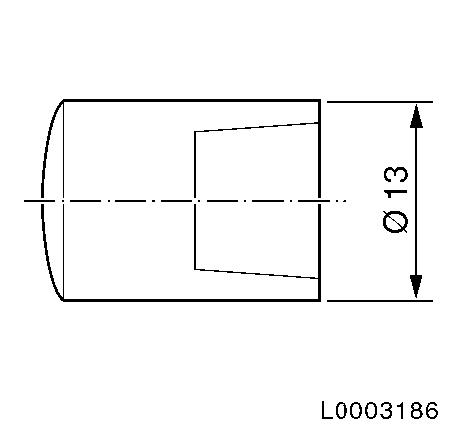

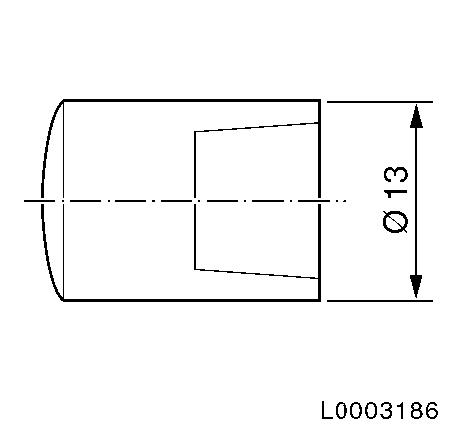

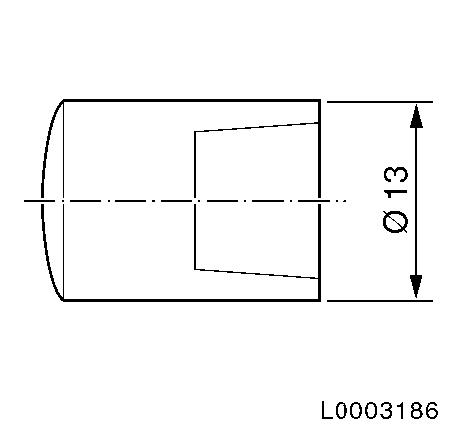

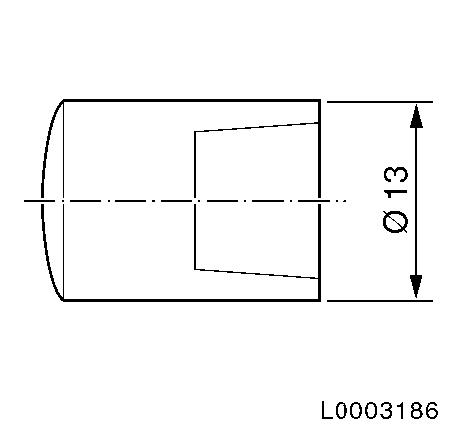

Recommended electrodes:

The electrodes required for the Opel/Vauxhall vehicles

(electrode cap diameter 13 mm ),

ball-shaped, radius 15 mm ) are

included in the scope of delivery

|

|

|

2. TECHNA /CEBOTECH

|

CEBOTECH GmbH

|

|

Walter-Wezel-Straße 33a

|

|

D-74889 Sinsheim-Hilsbach

|

|

Germany

|

|

www.cebotech.de

|

|

The following products fulfil the requirements:

|

|

2.1.

|

CEBOTECH Spot9000 Plus

|

|

Reference number:

|

|

2.1.

|

3650E

|

|

Remarks:

|

|

Production of the CEBOTECH Spot9000 Plus ended in 2006. The

devices sold can be upgraded in the future with updates from

ELMATECH.

|

|

|

|

Connection values:

|

|

|

Compressed air:

|

min. 6 bar constant

|

|

Fuse:

|

32 A , slow-acting

|

|

Connection rating:

|

25 kVA

|

|

Mains supply line:

|

min. 4 x 10 mm 2

|

|

Standard voltage:

|

400 V/50 Hz

|

|

Special voltage:

|

200 - 440 V/50 - 60 Hz

|

|

Recommended spot-welding pliers:

| |

Reference number

|

|

C-pliers C90

|

8685W

|

|

C-pliers C350

|

8686W

|

|

C-pliers C500

|

8688W

|

|

C-pliers C-S47

|

8689

|

Recommended electrodes:

The electrodes required for the Opel/Vauxhall vehicles

(electrode cap diameter 13 mm ),

ball-shaped, radius 15 mm ) are

included in the scope of delivery

|

|

|

3.1 ELEKTRON BREMEN

|

Electron-Bremen GmbH

|

|

Am Hohentorshafen 17 - 19

|

|

D-28197 Bremen

|

|

Germany

|

|

www.elektron-bremen.de

|

|

The following products fulfil the requirements:

|

|

3.1.

|

Elektron MI-100control

|

|

Reference number:

|

|

3.1.

|

515 965

|

|

3.1.2

|

Elektron MI-100control T

|

| |

Reference number:

|

|

3.1.2

|

540 472

|

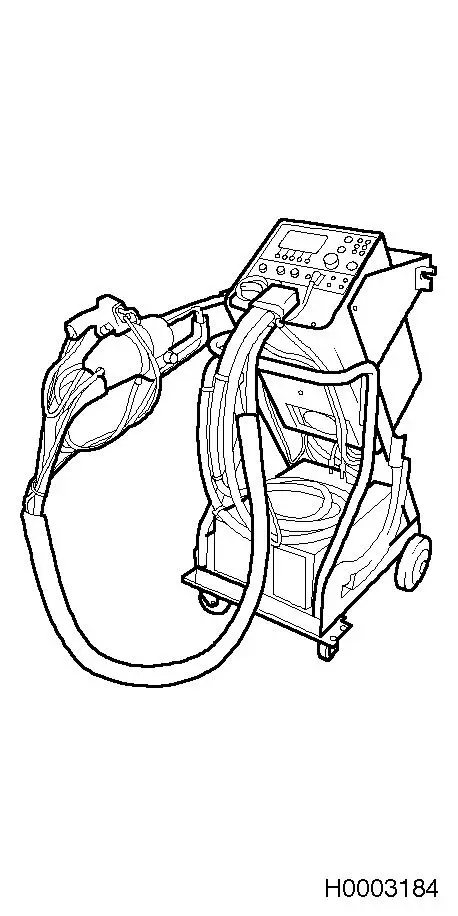

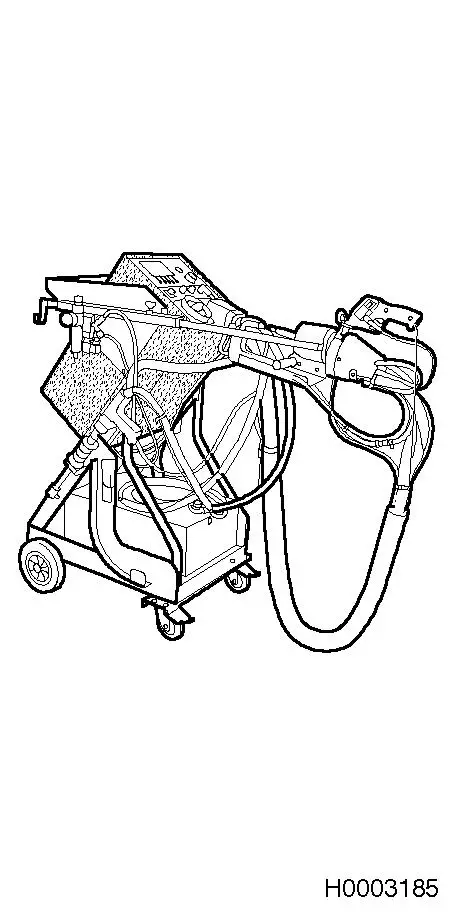

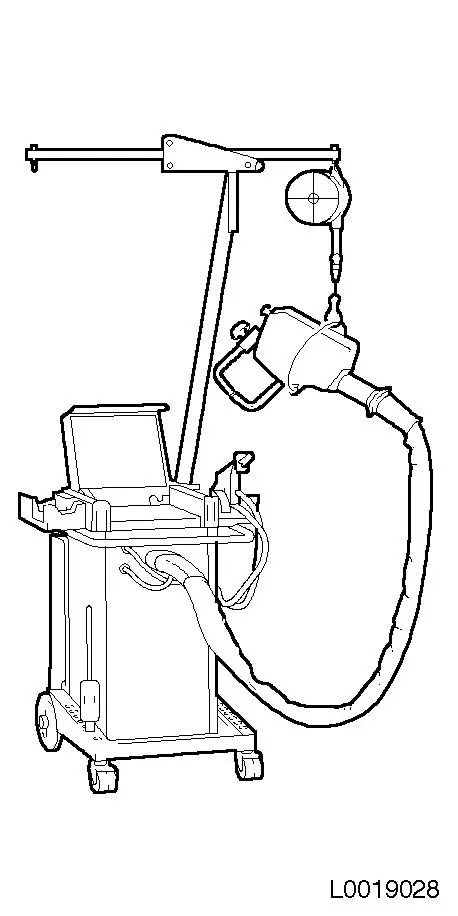

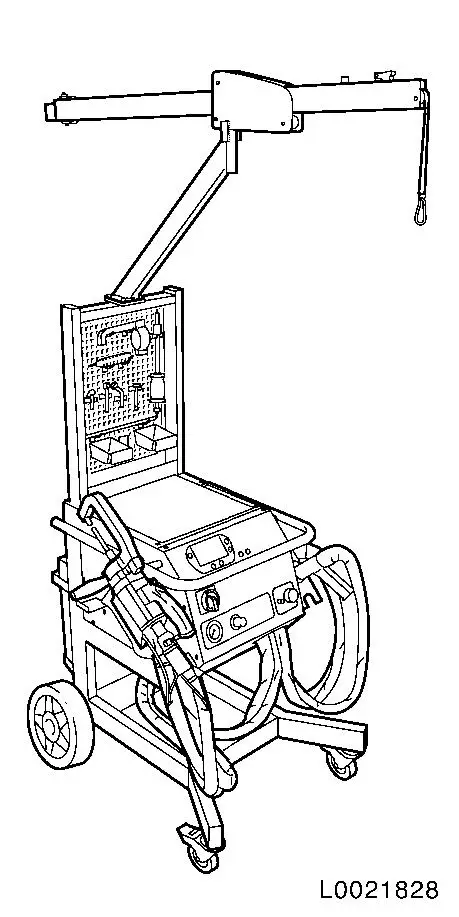

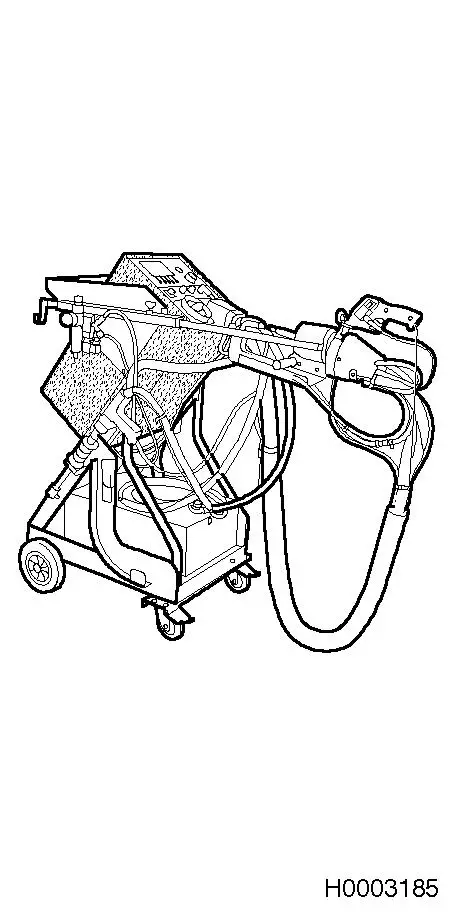

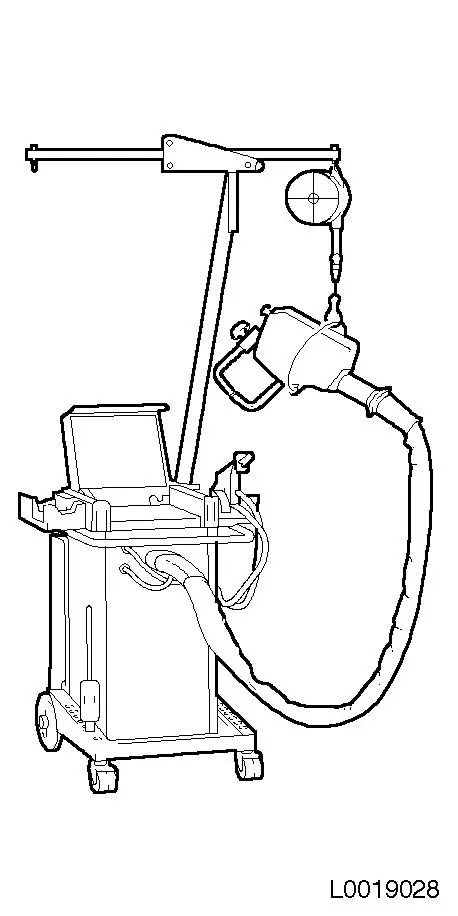

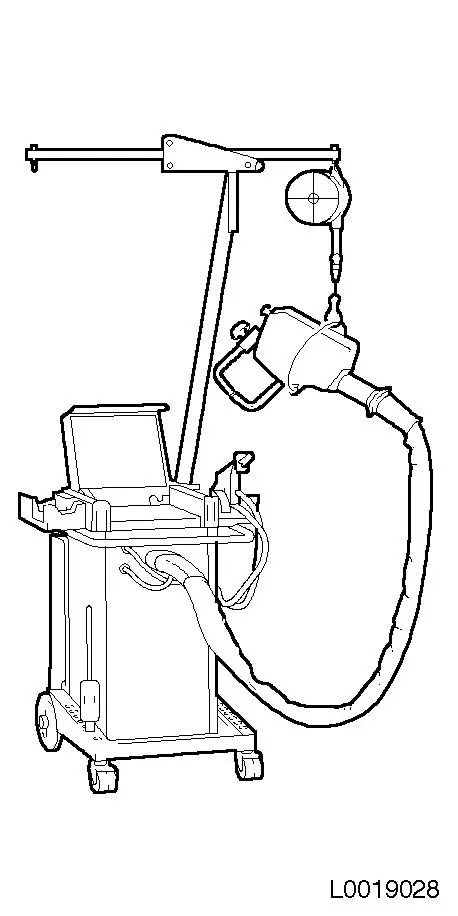

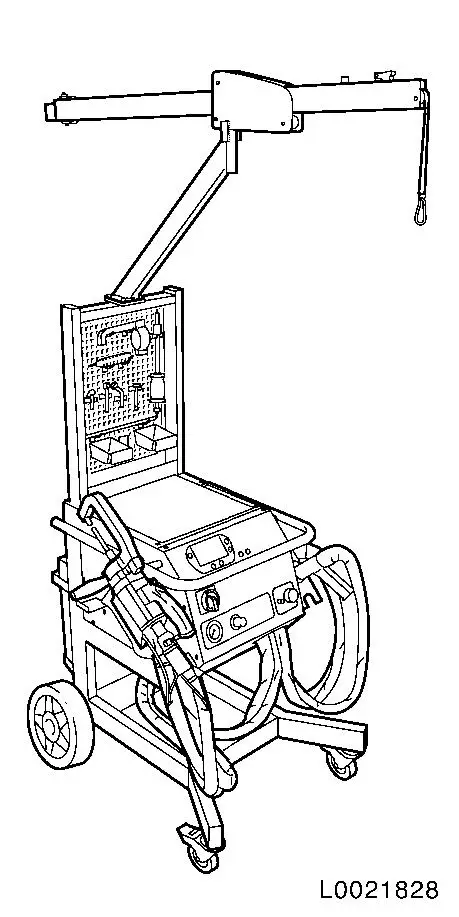

Scope of delivery:

- Power supply unit (mobile)

- Balancer

- Spot pliers optionally:

- Welding gun

- Remover

- Service box with contents

|

Connection values:

|

|

|

Compressed air:

|

min. 6 bar constant

|

|

Fuse:

|

32 A , slow-acting

|

|

Connection rating:

|

60 kVA / 20% ED

|

|

Mains supply line:

|

6 mm 2 -

10 m

|

|

Standard voltage:

|

400 V/50 Hz

|

|

Special voltage:

|

208 - 240 V/50 - 60 Hz

|

|

|

|

Recommended additional electrode

arms:

- Electrode set 01/415 MX, coded (reference number: 419 667)

- Electrode set 02/06/415 MX, coded (reference number: 419

668)

- Electrode set 04/415 MX, coded (reference number: 419 669)

- Electrode set 03 MX, coded (reference number: 419 674)

Recommended electrodes:

The electrodes required for the Opel/Vauxhall vehicles

(electrode cap diameter 13 mm, ball-shaped, radius 15 mm) are

included in the delivery.

|

|

|

3.2 STANNERS Equipment Ltd.

|

Stanners Equipment Ltd.

|

|

Coopies Lane Industrial Estate

|

|

Morpeth

|

|

Northumberland

|

|

NE61 6JN

|

|

United Kingdom

|

|

www.stanners-equipment.co.uk

|

|

The following products fulfil the requirements:

|

|

3.2.

|

Elektron MI-100 Inverter Control

|

|

Reference number:

|

|

3.2.

|

515 965

|

Scope of delivery:

- Power supply unit (mobile)

- Balancer

- Spot pliers optionally:

- Welding gun

- Remover

- Service box with contents

|

Connection values:

|

|

|

Compressed air:

|

min. 6 bar constant

|

|

Fuse:

|

32 A , slow-acting

|

|

Connection rating:

|

60 kVA / 20% ED

|

|

Mains supply line:

|

6 mm 2 -

10 m

|

|

Standard voltage:

|

400 V/50 Hz

|

|

Special voltage:

|

208 - 240 V/50 - 60 Hz

|

|

|

|

Recommended additional electrode

arms:

- Electrode set 01/415 MX, coded (reference number: 419 667)

- Electrode set 02/06/415 MX, coded (reference number: 419

668)

- Electrode set 04/415 MX, coded (reference number: 419 669)

- Electrode set 03 MX, coded (reference number: 419 674)

Recommended electrodes:

The electrodes required for the Opel/Vauxhall vehicles

(electrode cap diameter 13 mm, ball-shaped, radius 15 mm) are

included in the delivery.

|

|

|

4.1 Car-O-Liner

Car-O-Liner AB

PO Box 7

736 21 Kungsör

SWEDEN

www.car-o-liner.com

|

The following products fulfil the requirements:

|

|

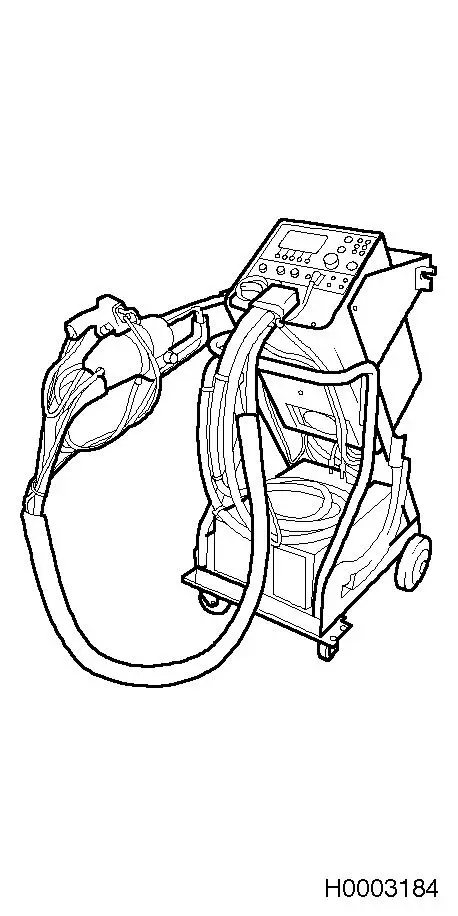

4.1.

|

Resistance spot welding machine CR 510

|

|

Reference number:

|

|

CR510 400V

|

139 05 00 330

|

|

CR510 230V

|

139 05 00 333

|

|

CR510 460V

|

139 05 00 336

|

|

Connection values:

|

|

|

Compressed air:

|

min. 6 bar constant

|

|

Fuse:

|

32 A , slow-acting

|

|

Connection rating:

|

32 kVA

|

|

Mains supply line:

|

min. 4 x 10 mm 2

|

|

Voltage:

|

400 V / 50 Hz

|

| |

230 V / 60 Hz

|

|

|

Recommended spot pliers:

| |

Reference number:

|

|

C-pliers 80 W

|

139 40 26 302

|

|

C-pliers 330 W

|

139 40 26 304

|

|

C-pliers 600 W

|

139 40 26 311

|

|

Wing set

|

139 40 26 310

|

|