|

Removing and installing crankshaft (Y 17 DTL)

| 1. |

Remove engine

Note: See operation "J

4501 00 Remove and install engine".

|

| 2. |

Detach manual transmission from engine

Note: See operation "J

4501 00 007 Remove and install manual transmission from/to

engine".

|

| 3. |

Drain engine oil

| • |

Place collecting basin underneath.

|

|

| 4. |

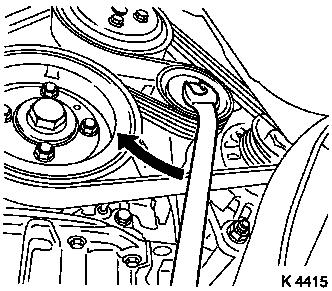

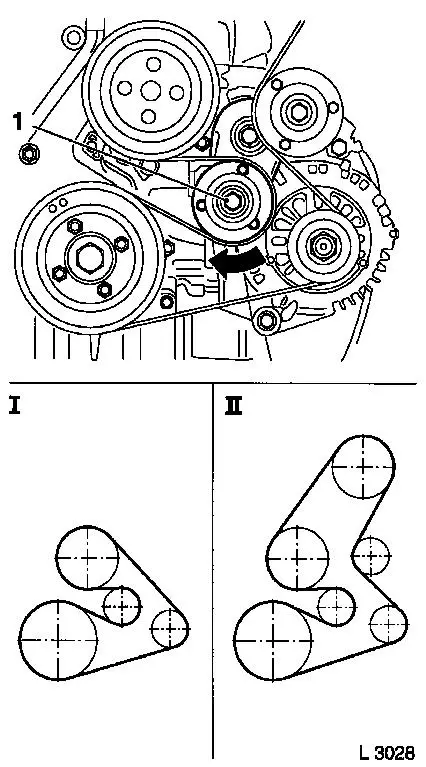

Remove ribbed V-belt

| • |

Tension ribbed V-belt tensioner in direction of arrow

Note: Mark direction of

rotation

|

|

|

|

| 5. |

Remove oil dipstick guide tube

|

| 6. |

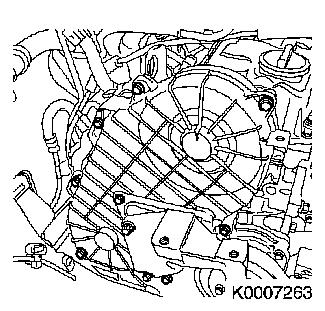

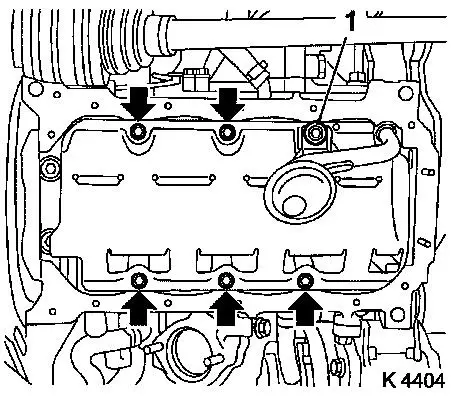

Detach upper toothed belt cover

| • |

Remove 8 bolts

Note: Note dissimilar

bolt lengths

|

|

|

|

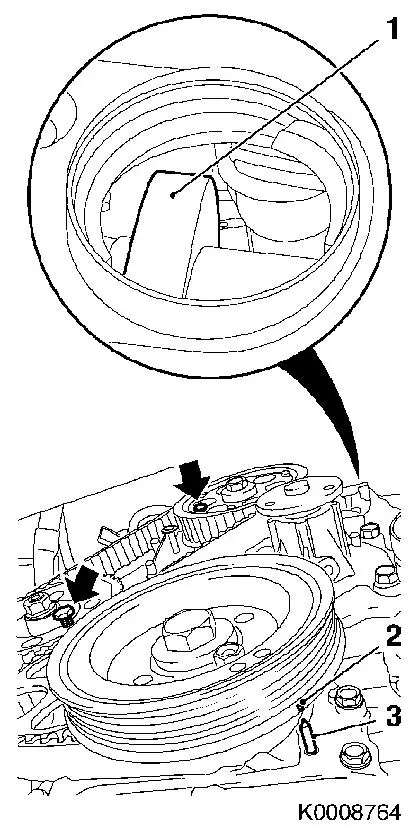

| 7. |

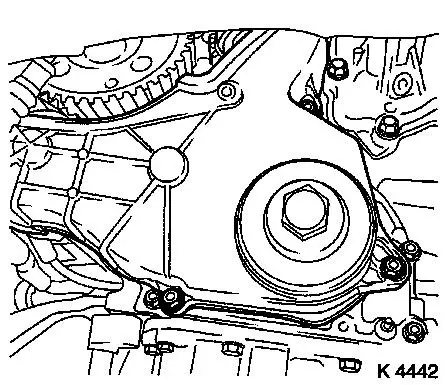

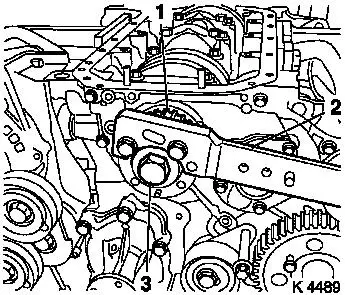

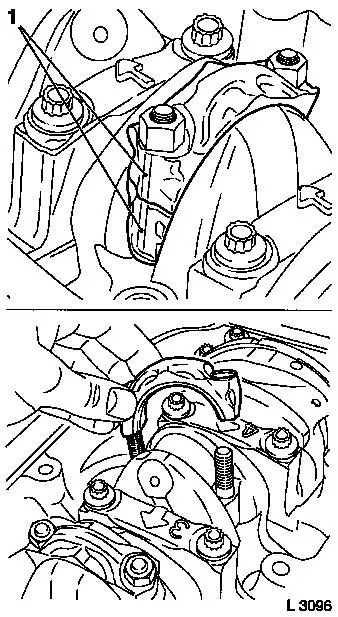

Set no.1 cylinder to TDC

| • |

Rotate crankshaft evenly until torsional vibration damper mark

(2) is flush with pin (3) on oil pump cover. Pair of no.1 cylinder

exhaust cams (1) must be on top.

|

| • |

Screw in the TDC fixing bolts (arrows)

| – |

Drive gear injection pumps (M8)

|

|

|

|

|

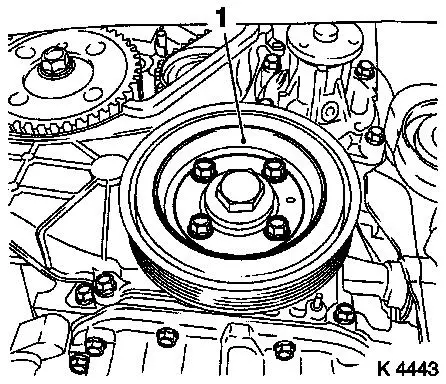

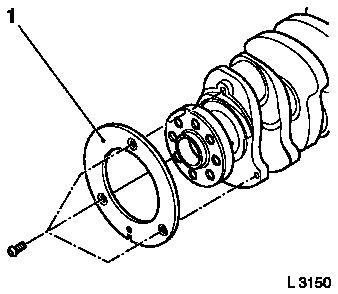

| 8. |

Remove torsional vibration damper (1)

|

| 9. |

Detach coolant pump ribbed V-belt pulley

|

|

|

| 10. |

Detach lower part of toothed belt cover

|

|

|

| 11. |

Detach right engine bracket

|

| 12. |

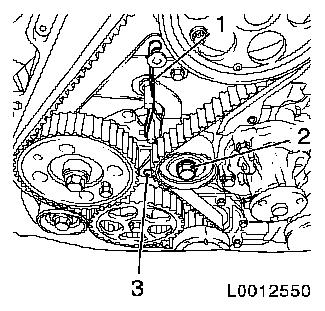

For toothed belt tension roller with leaf spring:

| • |

loosen toothed belt tensioner

| – |

Screw in bolt (M10) in lower bore (3) of toothed belt

tensioner

|

| – |

Remove tension spring (1)

|

|

|

|

|

| 13. |

For toothed belt tension roller with spiral spring:

| • |

Loosen toothed belt tension roller (1)

| – |

Rotate toothed belt tension roller anticlockwise approx.

90°

|

|

|

|

|

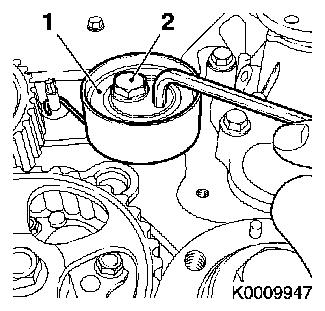

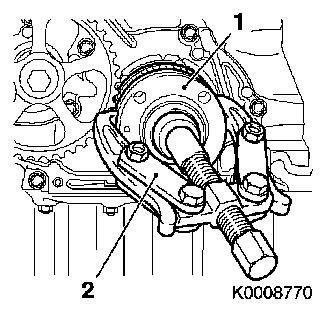

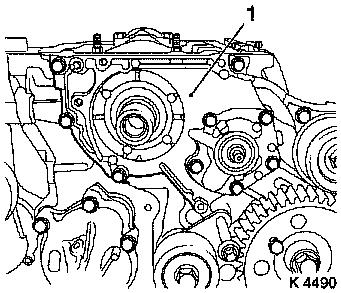

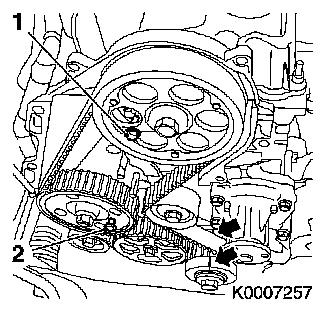

| 14. |

Remove oil pump drive gear (1)

| • |

Unscrew nut (2)

Note: Counterhold using

socket wrench and unscrew nut using spanner (2).

|

|

|

|

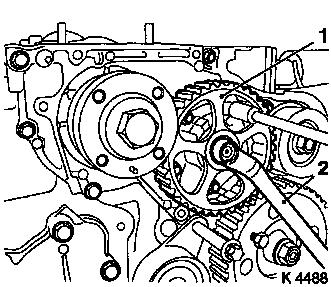

| 15. |

Remove toothed belt drive gear bolt (3)

| • |

Counterhold toothed belt drive gear (1) using KM-662-C (2)

Note: 2nd mechanic

|

|

|

|

| 16. |

Remove toothed belt drive gear (1)

|

| 17. |

Remove clutch

Note: Remove clutch -

see operation "Remove and install thrust plate and clutch disc

(without SAC)" in group "K".

|

|

|

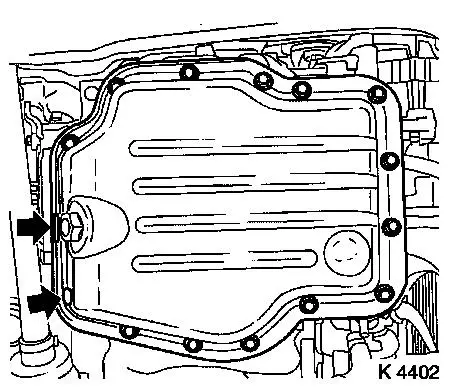

| 20. |

Detach oil pan lower part

| • |

Remove using KM-J-37228

|

|

|

|

| 21. |

Detach oil pan upper part

Note: Bolts (1) have

been unscrewed.

| • |

Remove 14 bolts

Note: Note dissimilar

bolt lengths

|

| • |

Remove 2 nuts

Note: Use wide

spatula.

|

|

|

|

| 22. |

Remove oil intake pipe

|

|

|

| 23. |

Remove oil baffle plate

| • |

Remove 5 bolts (arrows)

|

|

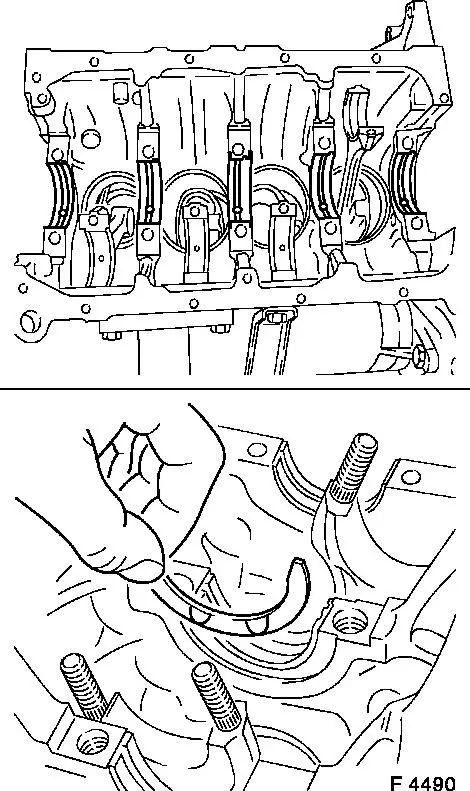

| 24. |

Remove con-rod bearing caps

| • |

Remove con-rod bearing shells

Note: Pay attention to

identifier on con-rod bearing cover and con-rod (1). If not

present, mark with identifier.

|

|

| 25. |

Remove con-rod bearing shells

| • |

Mark con-rod bearing shells

Note: Follow order.

|

|

|

|

| 26. |

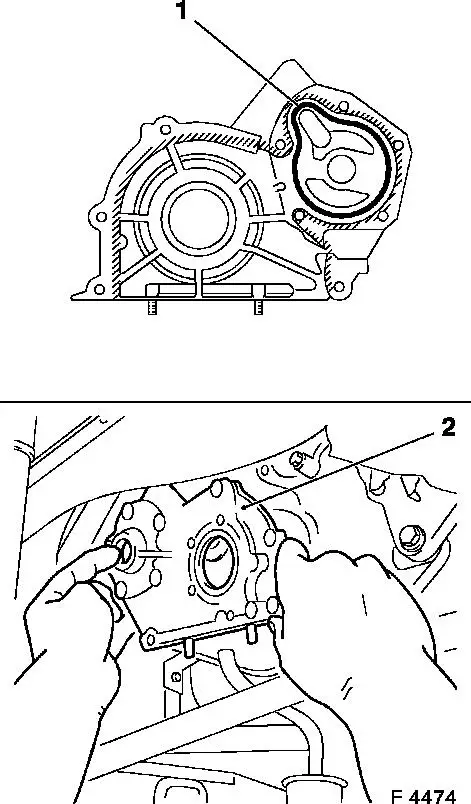

Remove oil pump cover (1)

| • |

Remove 9 bolts

Note: Note dissimilar

bolt lengths

|

| • |

Remove inner and outer rotors

|

|

|

|

| 27. |

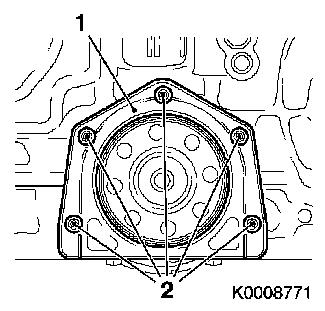

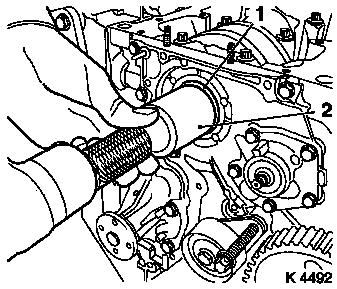

Remove rear crankshaft cover sealing ring (1)

Important: Note guide bushings

when removing.

|

| • |

Carefully prise off rear crankshaft sealing ring cover

|

|

|

|

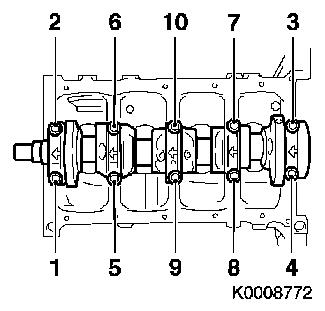

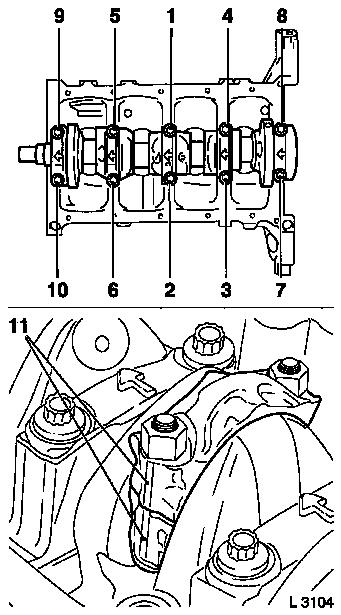

| 28. |

Remove crankshaft

| • |

Remove crankshaft bearing cover

Note: Undo crankshaft

bearing cover fastening screws in depicted order (1 - 10).

| – |

Remove 10 bolts

Note: Place crankshaft

onto wooden blocks.

|

|

|

|

|

| 29. |

Remove crankshaft bearing shells

| • |

Mark crankshaft bearing shells

Note: Note markings on

crankshaft bearing shells.

|

|

|

|

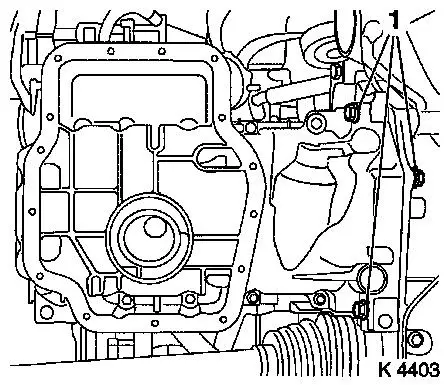

| 31. |

Remove crankshaft pulse pick-up (1)

|

|

|

| 32. |

Clean components

| • |

Oil pan lower section, oil pan upper section, cylinder

block

|

|

| 34. |

Install crankshaft pulse pick-up

| • |

Tighten bolts ( 10.8 Nm )

|

|

| 35. |

Insert con-rod bearing shells

| • |

In con-rod, con-rod bearing cap

|

|

Important: Pay attention to

identification and allocation

|

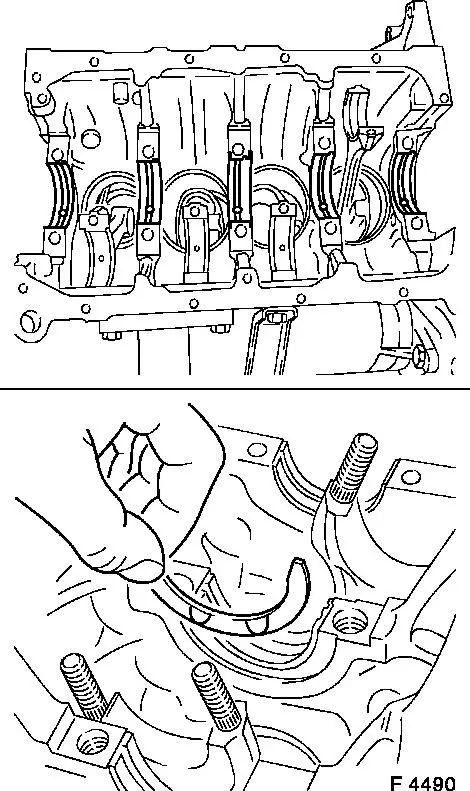

| 36. |

Insert crankshaft bearing shells

| • |

In cylinder block and crankshaft bearing cover

|

|

| 37. |

Replace thrust rings

| • |

Oil grooves face outward

|

|

|

|

| 38. |

Insert crankshaft

| • |

Coat crankshaft journals with engine oil

Note: Note installation

position.

|

|

| 39. |

Fit crankshaft bearing cover

Important: Note installation

position. Arrows point to engine control side.

|

| • |

Renew bolts

|

| • |

Tighten bolts ( 88.2 Nm )

Note: Note tightening

order (1 - 10).

|

|

|

|

| 40. |

Attach con-rod bearing cap

Important: Note cylinder order

markings on con-rod bearing cover and con-rod (11). Narrow bead

faces engine control side.

|

| • |

Replace nuts

|

| • |

Tighten nuts ( 24.5 Nm + 100° +

15° )

|

|

| 41. |

Remove rear crankshaft sealing ring

Important: Do not damage sealing

surface.

|

| • |

Lever out seal ring

|

|

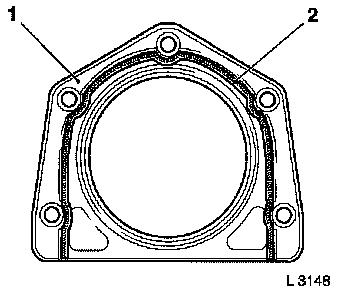

| 42. |

Fit rear crankshaft sealing ring cover (1)

Note: Ensure correct

seating of guide bushings.

| • |

Apply adhesive sealing compound (black) (2)

Note: Use screw locking

compound (red)

|

| • |

Tighten bolts ( 9.8 Nm )

Note: Fit screws within

10 minutes.

|

|

|

|

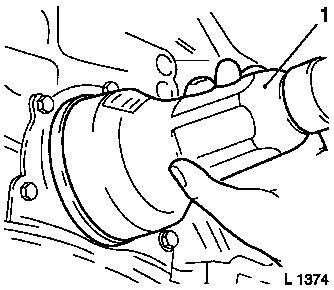

| 43. |

Fit rear crankshaft sealing ring

| • |

Coat sealing lip with grease

|

| • |

Attach KM-658-2 to crankshaft

journal

|

| • |

Slide sealing ring onto KM-658-2

|

| • |

Drive in until flush using KM-658-1

(1)

|

|

|

|

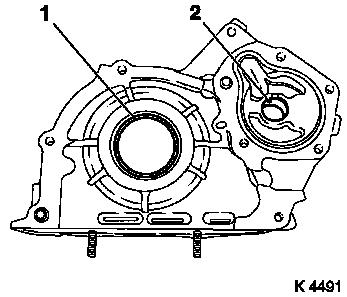

| 44. |

Remove oil pump cover sealing rings

| • |

Front crankshaft sealing ring (1), oil pump sealing ring

(2)

Important: Do not damage sealing

surface.

|

| – |

Prise out sealing rings

|

|

|

|

|

| 45. |

Attach oil pump

| • |

Insert inner and outer rotor

|

| • |

Apply adhesive sealing compound (black)

|

| • |

Attach oil pump cover (2)

| – |

Note different bolt lengths

|

| – |

Tighten bolts ( 9.8 Nm )

|

|

|

|

|

| 46. |

Install oil pump cover sealing rings

| • |

Coat sealing lips with silicon grease (white)

|

| • |

Install oil pump seal ring

| – |

Drive in until flush using KM-657

|

|

| • |

Install front crankshaft sealing ring (1)

| – |

Drive in until flush using KM-656

(2)

|

|

|

|

|

| 47. |

Install oil baffle plate

| • |

Tighten bolts ( 18.6 Nm )

|

|

| 48. |

Install oil intake pipe

| • |

Tighten bolt ( 18.6 Nm )

|

|

| 50. |

Attach oil pan upper section

| • |

Apply silicon sealing compound (grey)

|

| • |

Tighten bolts, nuts ( 9.8 Nm

)

|

|

| 51. |

Attach oil pan lower section

| • |

Apply silicon sealing compound (grey)

|

| • |

Tighten bolts ( 9.8 Nm )

|

|

| 52. |

Screw in oil drain screw

|

| 54. |

Attach flywheel

| • |

Tighten bolts ( 29,4 Nm + 45° +

15° )

Note: Use screw locking

compound (red)

|

|

| 55. |

Install clutch

Note: Remove clutch -

see operation "Remove and install thrust plate and clutch disc

(without SAC)" in group "K".

|

| 57. |

Install toothed belt drive gear

| • |

Install sheet metal panel

|

| • |

Insert toothed belt drive gear in place

|

|

| 58. |

Tighten toothed belt drive gear

| • |

Counterhold using KM-662-C

Note: 2nd mechanic

|

| • |

Tighten bolt ( 196 Nm )

|

|

| 59. |

Install oil pump drive gear

Note: Pay attention to

installation position

| • |

Tighten nut ( 44.1 Nm )

|

|

| 60. |

Install toothed belt

| • |

Set no.1 cylinder to TDC

| – |

Mark on toothed belt drive gear must align with lug on oil pump

cover (arrows)

|

|

|

|

|

| 61. |

Install toothed belt

| • |

Position toothed belt

Note: Toothed belt must

be taut from toothed belt drive gear via oil pump drive gear and

injection pump drive gear

|

| • |

For toothed belt tension roller with leaf spring:

|

| • |

Unscrew TDC-fixing bolt

|

| • |

Rotate crankshaft 60° against direction of engine

rotation

|

| • |

Tighten bolt of toothed belt tension roller

| – |

For toothed belt tension roller with spiral spring 49 Nm

|

| – |

For toothed belt tension roller with leaf spring 38.2 Nm

|

|

| • |

For toothed belt tension roller with leaf spring: unscrew bolt

(M10) from lower bore of toothed belt tensioner

|

|

| 62. |

Timing, Check

| • |

Turn crankshaft approx. 780° in direction of engine

rotation

|

| • |

Mark on toothed belt drive gear must align with casting lug at

oil pump cover

|

| • |

Install TDC-fixing bolt

Note: If the TDC fixing

bolts cannot be screwed in, basic adjustment must be repeated

|

| • |

Unscrew TDC-fixing bolts

|

|

| 63. |

Attach right engine bracket

| • |

Screw in bolt with bushing

|

|

| 64. |

Attach lower part of toothed belt cover

| • |

Tighten bolts ( 9.8 Nm )

|

|

| 65. |

Attach upper toothed belt cover

| • |

Tighten bolts ( 9.8 Nm )

Note: Note dissimilar

bolt lengths

|

|

| 66. |

Attach coolant pump ribbed V-belt pulley

| • |

Tighten bolts ( 9.8 Nm )

|

|

| 67. |

Install torsional vibration damper

| • |

Tighten bolts ( 19.6 Nm )

|

|

| 68. |

Install oil dipstick guide tube

| • |

Tighten bolt ( 9.8 Nm )

|

|

| 69. |

Install ribbed V-belt

| • |

Tension ribbed V-belt tensioner in direction of arrow

Note: Observe running

direction

|

|

|

|

| 70. |

Attach transmission

Note: See operation "J

4501 00 007 Remove and install manual transmission from/to

engine".

|

| 71. |

Install engine

Note: See operation

"Remove and install engine".

|

| 72. |

Pour in engine oil

| • |

Start engine and allow to run until oil pressure telltale

extinguishes.

|

| • |

Check engine oil level, if necessary correct.

|

| • |

Use prescribed quantity of oil

|

|

|