|

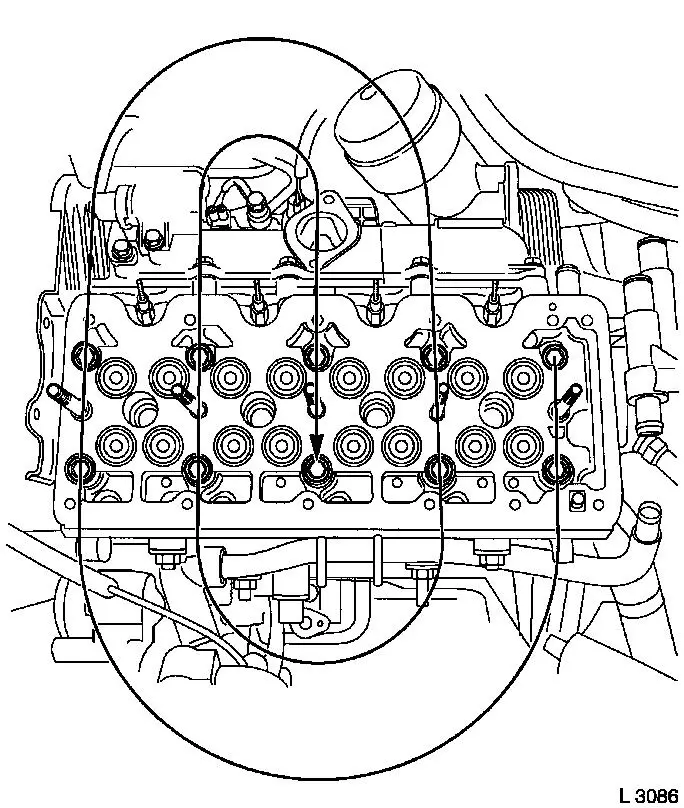

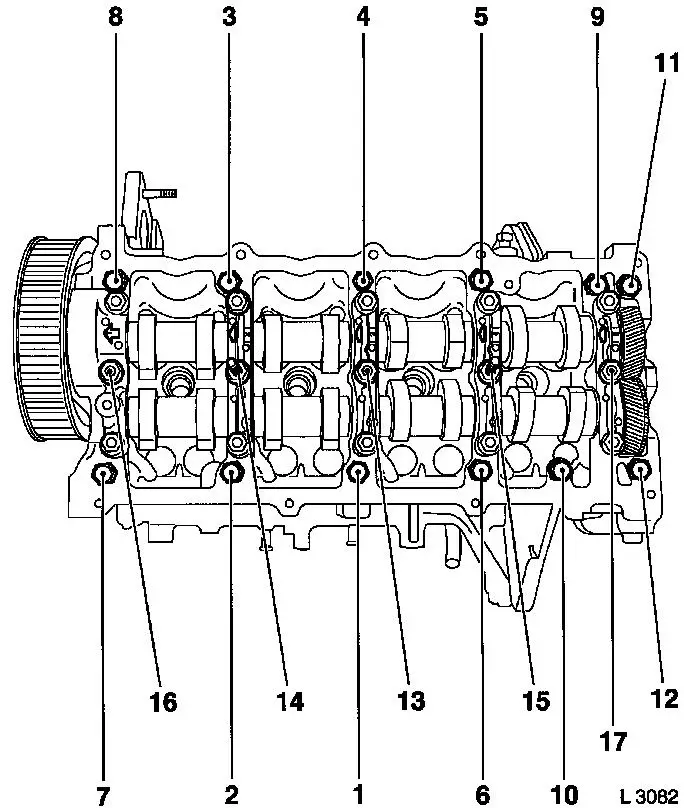

J 452700 All Pistons with Con-rods, Remove and

Install (Y 17 DT, with AC, LHD)

Note: KM-6394 must be used from model year 04 instead of

KM-6169-1 .

|

1. Open bonnet

2. Drain air conditioning

- Note! Drain air conditioning – see operation "Drain air

conditioning" in group "D"

Caution!

On vehicles from model year 04 with ESP - the steering angle

sensor loses its basic adjustment each time the battery is

disconnected. It must be recalibrated.

3. Disconnect battery

4. Remove oil filter insert

- Place collecting basin underneath.

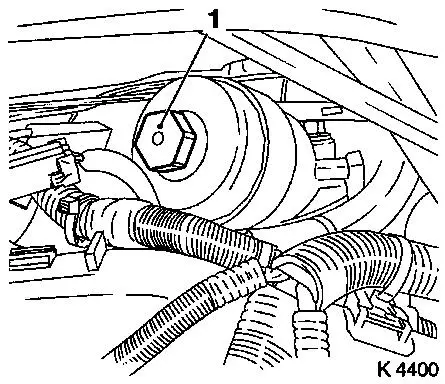

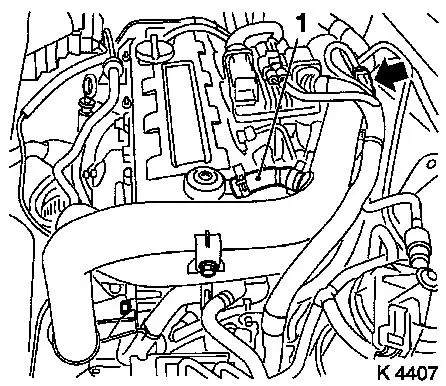

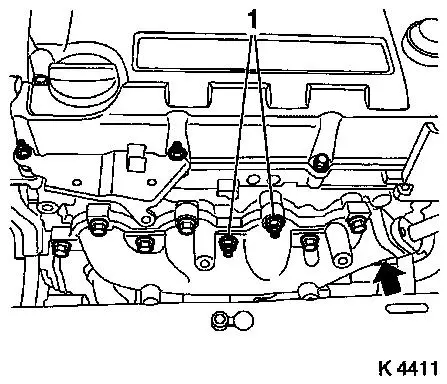

- Unscrew oil filter housing cover (1)

|

|

|

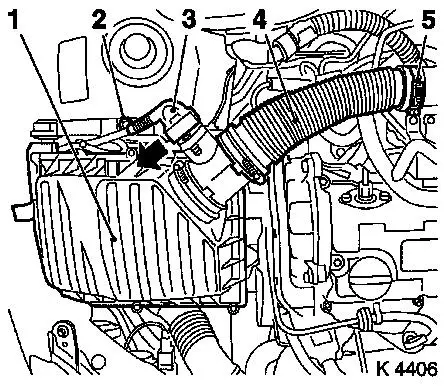

5. Remove air cleaner housing (1)

- Disconnect wiring harness plug for hot film mass air flow meter

(3)

- Release in direction of arrow

- Remove air intake hose (4)

- Remove bolt (2)

|

|

6. Detach refrigerant line

- From compressor

- Remove bolt

7. Remove oil dipstick guide tube

- Unscrew upper bolt

- Unclip vacuum lines

8. Loosen right front wheel.

9. Raise vehicle

|

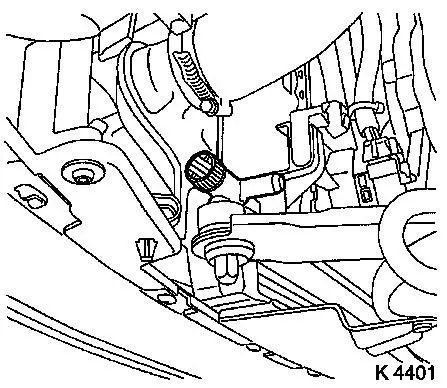

10. Drain coolant

- Place collecting basin underneath.

- Open coolant expansion tank cover

- Open drain bolt

|

|

11. Remove right front wheel.

12. Raise vehicle

13. Close coolant drain bolt

|

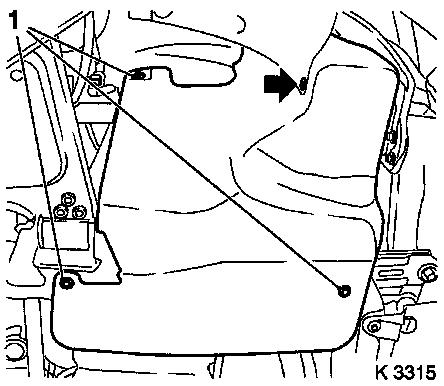

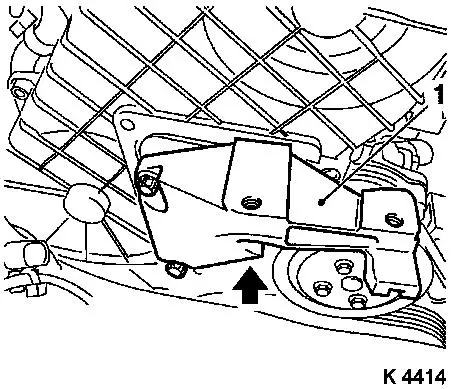

14. Remove ribbed V-belt cover

- Remove 3 bolts (1)

- Remove clip (arrow).

|

|

15. Drain engine oil

- Place collecting basin underneath.

- Remove drain bolt

16. Install drain bolt

- Replace seal ring

- Tighten bolt (78.4 Nm / 57.9 lbf. ft.)

17. Loosen front exhaust pipe

Note: When removing

the centre muffler, a catalytic converter, an exhaust manifold, or

an exhaust manifold with catalytic converter, secure that portion

of the exhaust system remaining on the vehicle against uncontrolled

suspension.

For this purpose, the exhaust system portion including the flexpipe

may be fastened to the vehicle underbody using suitable means, e.g.

wire.

Caution!

Angular dislocations of the flexpipe as small as 5 to 10 degrees

offset from the intended installation position can already cause

damage and subsequent complete failure of the flexpipe.

18. Detach exhaust system

- Remove from damping rings

- Note! 2. mechanic

- Hang exhaust system aside and suspend in place

19. Remove oil dipstick guide tube

|

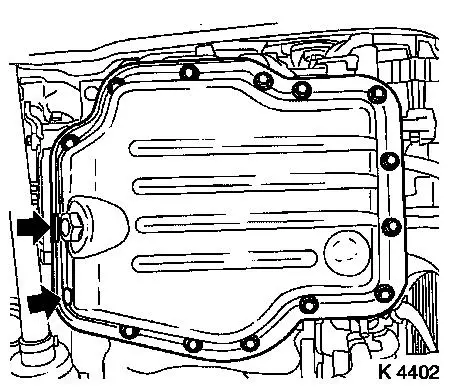

20. Detach oil pan lower part

- Remove 15 bolts

- Detach with KM-J-37228

|

|

|

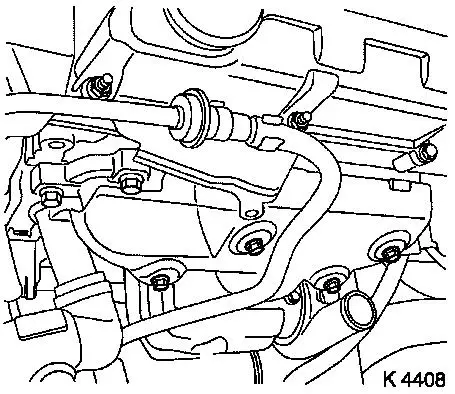

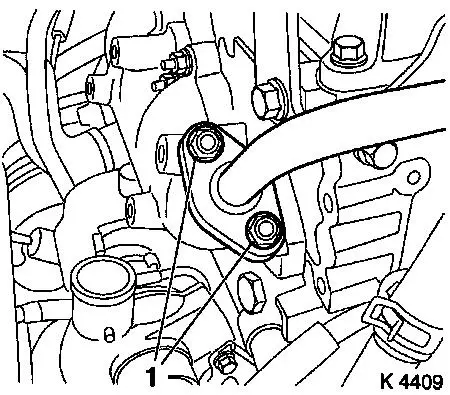

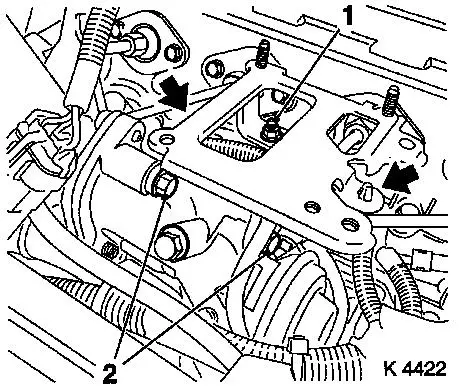

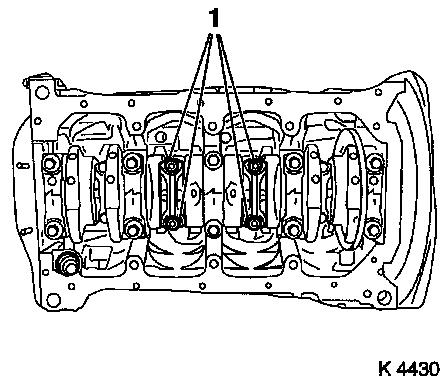

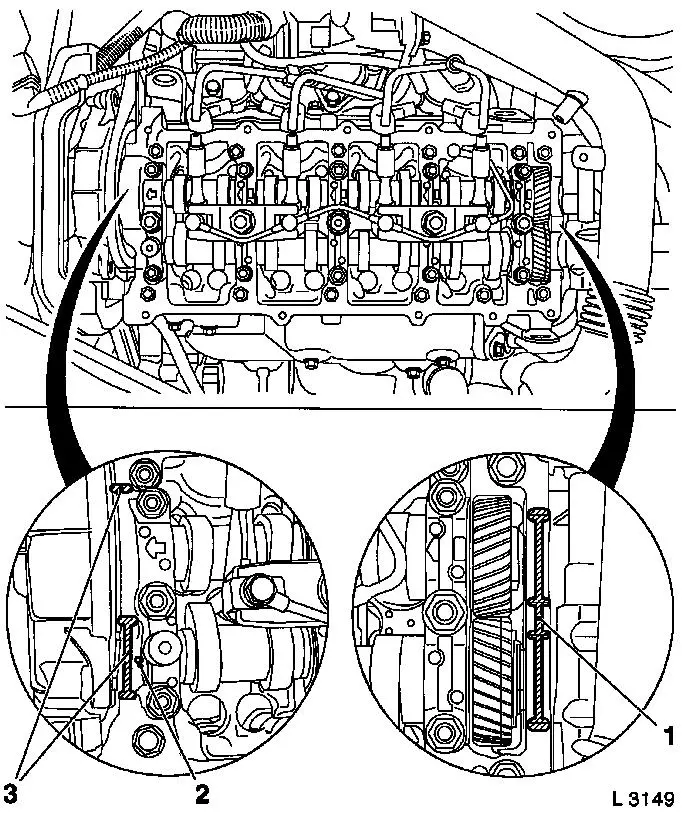

21. Detach oil pan upper part

- Remove 14 bolts

- Note! Note dissimilar bolt lengths

- Remove 3 bolts (1)

- Remove 2 nuts

- Note! Use wide spatulas

- Push oil dipstick guide tube upwards

|

|

|

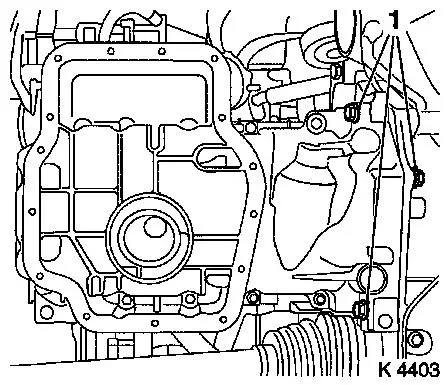

22. Detach oil intake pipe

23. Remove oil baffle plate

|

|

|

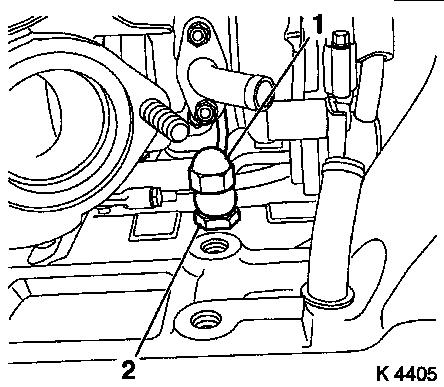

24. Detach turbocharger oil return hose

(1)

|

|

|

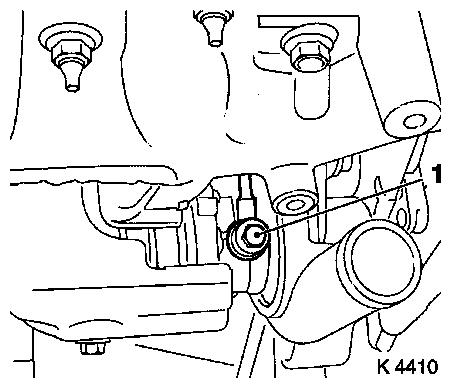

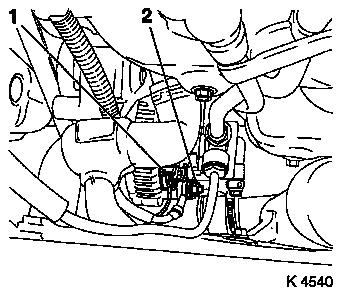

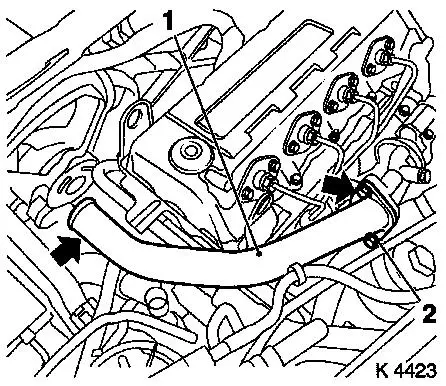

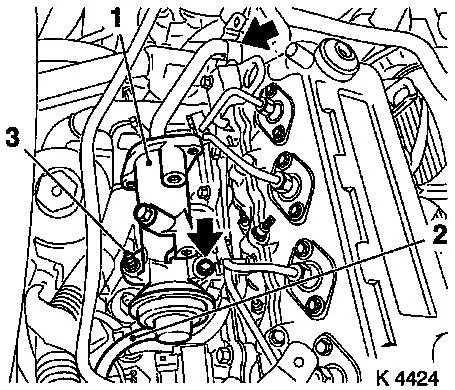

25. Remove turbocharger oil feed

line

- Unscrew nut (1)

- Note! Counterhold at threaded port (2)

|

|

26. Release turbocharger bracket

27. Detach waste gate unit vacuum hose

28. Detach air intake pipe

|

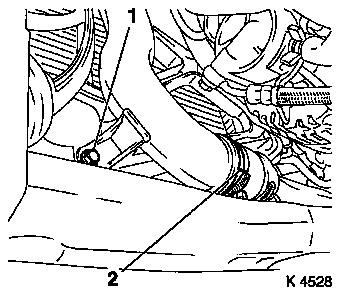

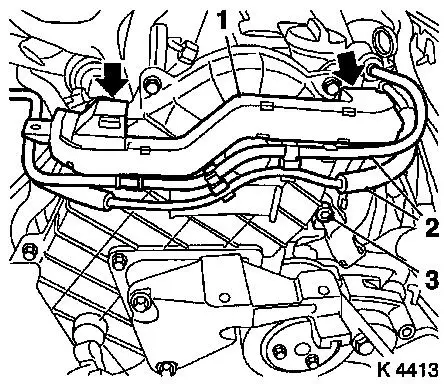

29. Detach centre charge air pipe

- from lower charge air pipe

- Remove lower bolt (1)

- Loosen clamp (2)

|

|

|

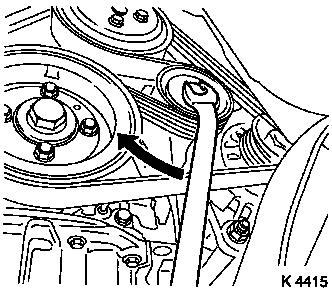

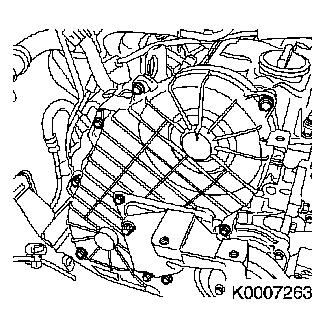

30. Remove ribbed V-belt

- Tension ribbed V-belt tensioner in direction of arrow

- Note! Mark running direction

|

|

|

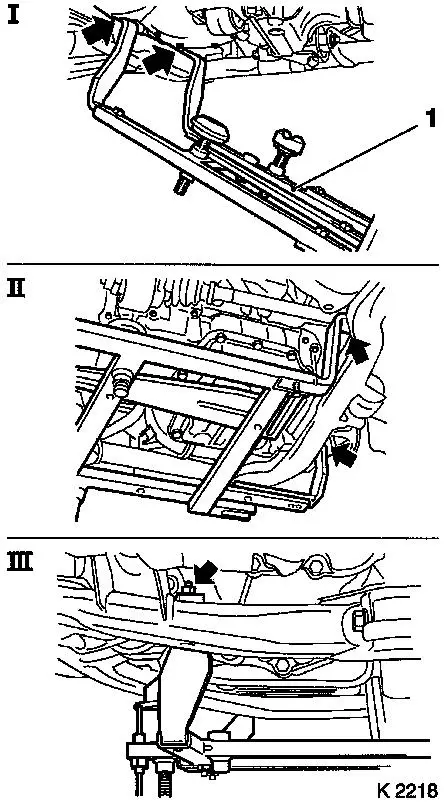

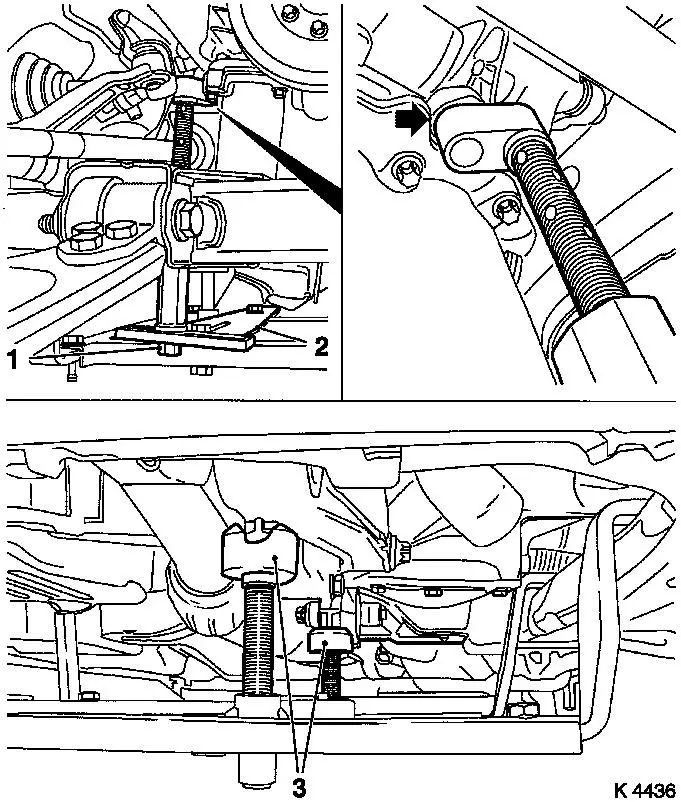

31. Attach KM-6169 (1)

- Place left of KM-6169 onto front axle body (arrows, illus.

I)

- Note! Guide pin must be seated in bore in front axle body

- Attach both right holders on the front axle body (arrows,

Illus. II).

- Note! Guide pin must be seated in bore in front axle body

(arrow, Illus. III)

- Tighten bolts

|

|

|

32. Install support

- To KM-6169

- Adjust bracket (2) for support

- Screw on nut (1)

33. Adjust supports

- Transmission side

- Note! Turn spindles until the mounts (3) are positioned at the

guide journals free of play

- Engine timing side

- Insert journal of the support in the bore of the cylinder block

without play (arrow)

- Tighten nuts (1)

|

|

34. Lower vehicle

35. Remove compressor

- Remove wiring harness plug

- Remove 3 bolts

- Note! Note dissimilar bolt lengths

36. Detach oil dipstick guide tube bracket

- From camshaft housing cover

- Unclip vacuum hoses

37. Remove oil dipstick guide tube

38. Remove compressor bracket

|

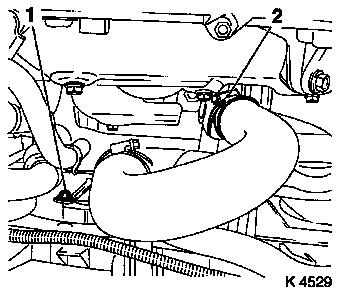

39. Detach centre charge air pipe

- Remove upper bolt (1)

- Detach charge air hose from turbocharger

|

|

|

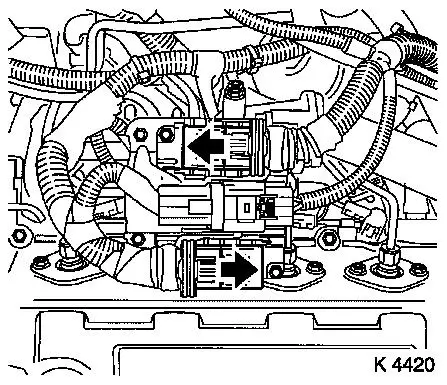

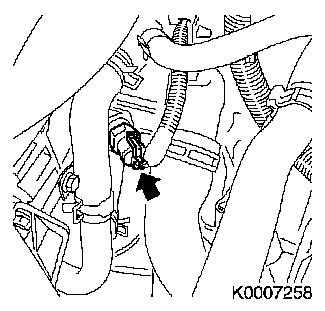

40. Remove wiring harness plug for

engine management

- Detach 2 engine control unit wiring harness plugs

- Release in direction of arrow

- Disconnect combination plug (grey)

- Disconnect combination plug (black)

|

|

|

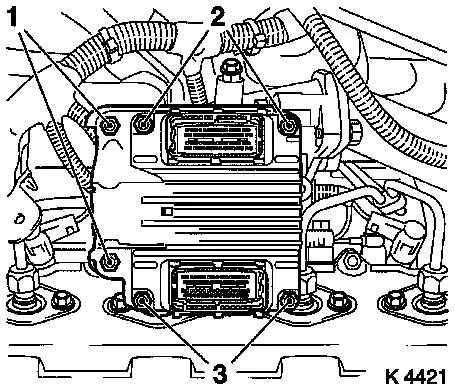

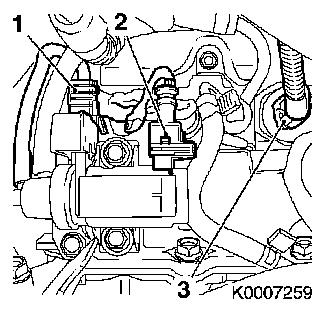

41. Remove engine control unit

- Remove wiring harness plug bracket

- Unscrew 2 bolts (2), 2 nuts (3)

|

|

|

42. Detach air intake pipe

- Remove 2 bolts

- Detach engine vent hose (1)

- Detach air intake pipe from turbocharger

- Unclip wiring harness

|

|

|

43. Unclip brake servo vacuum line

44. Detach exhaust manifold heat

shield

|

|

|

45. Remove exhaust gas recirculation

pipe

|

|

|

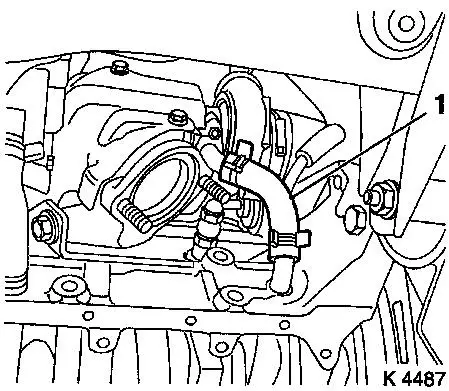

46. Remove turbocharger oil feed

line

- Unscrew banjo bolt (1)

- Remove seal rings

|

|

|

47. Remove exhaust manifold

- Remove 7 bolts

- Remove 2 nuts (1)

- Remove gasket.

|

|

|

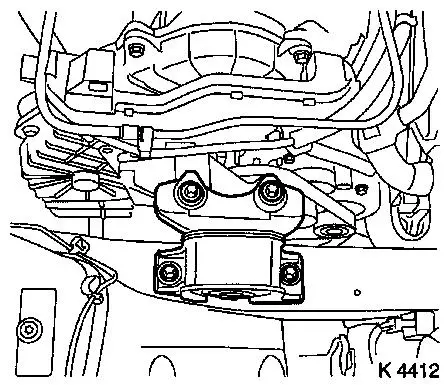

48. Remove right engine damping

block

|

|

|

49. Detach alternator wiring

harness

- Disconnect wiring harness plug (1)

- Unscrew nut (2)

- Unclip wiring harness

|

|

|

50. Detach wiring trough (1)

- Unclip vacuum lines (2)

- Unclip wiring trough

- Remove bolt (3)

|

|

|

51. Detach right engine bracket (1)

|

|

|

52. Release upper toothed belt

cover

- Remove 8 bolts

- Note! Note dissimilar bolt lengths

- Remove adapter for right engine bracket

|

|

53. Detach coolant pump ribbed V-belt

pulley

|

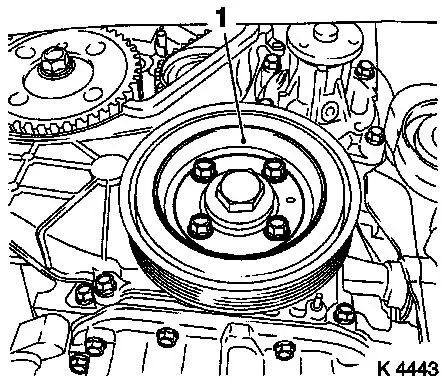

54. Remove torsional vibration damper

(1)

|

|

|

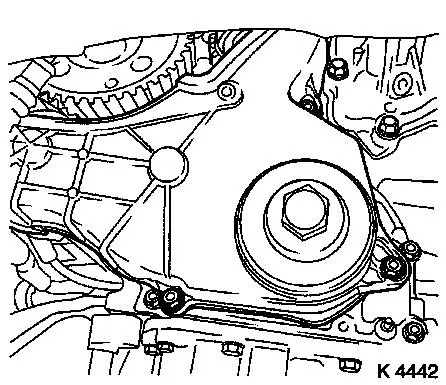

55. Remove lower toothed belt cover

|

|

|

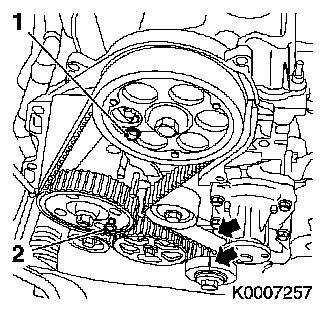

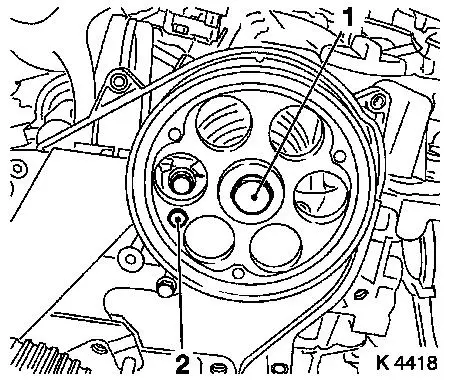

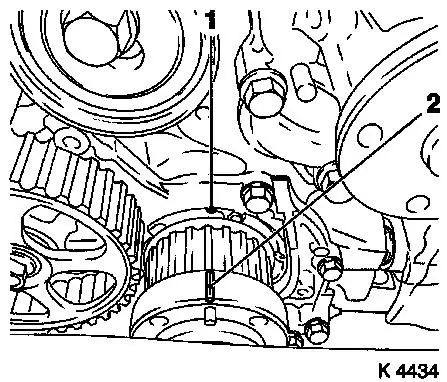

56. Set 1st cylinder to TDC

- Turn crankshaft evenly until TDC-fixing bolts can be

inserted

- Camshaft gear (M6) (1)

- Injection pump gear (M8) (2)

- Note! The mark on toothed belt drive gear must align with lug

on oil pump cover (arrows)

|

|

|

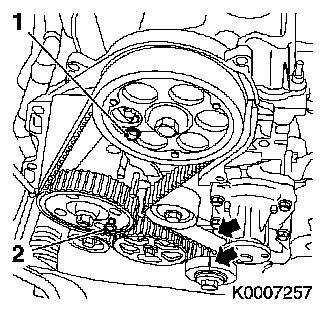

57. For toothed belt tension roller

with leaf spring:

- loosen toothed belt tensioner

- Screw in bolt (M10) in lower bore (3) of toothed belt

tensioner

- Loosen bolt (2)

- Remove tension spring (1)

|

|

|

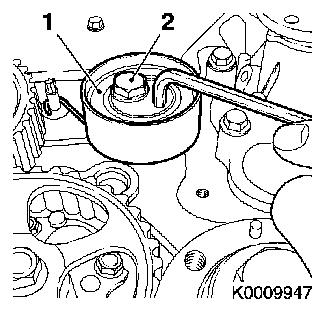

For toothed belt tension roller with

spiral spring:

- Loosen toothed belt tension roller (1)

- Rotate toothed belt tension roller anticlockwise approx.

90°

- Tighten bolt (2)

|

|

58. Remove toothed belt

- Note! Mark running direction

|

59. Detach camshaft pulley

- Unscrew TDC-fixing bolt (2)

- Counterhold camshaft gear using KM-6156 and KM-956-1

- Remove bolt (1)

|

|

60. Loosen toothed belt tension roller spring retainer

61. Release rear toothed belt cover

|

62. Remove engine control unit

bracket

- Unscrew 2 bolts (2), nut (1)

- Unclip wiring harness (arrows)

|

|

|

63. Remove wiring harness for engine

management

- Disconnect wiring harness plug

- Coolant temperature sensor (arrow), oil pressure switch, diesel

injection pump (3), sheathed glow plugs

- Unclip wiring harness

- Set wiring harness to one side

|

|

|

64. Disconnect wiring harness plug

- Exhaust gas recirculation solenoid valve (2), charge pressure

sensor (1)

|

|

|

65. Remove upper charge air pipe (1)

- Remove charge air hose

- Unscrew stud (2), 2 bolts (arrows)

66. Detach starter/alternator wiring harness bracket

- From exhaust recirculation valve

- Unscrew nut

|

|

|

67. Remove exhaust gas recirculation

valve (1)

- Unscrew studs (3), 2 bolts (arrows)

- Detach vacuum hose (2)

- Remove gasket.

|

|

|

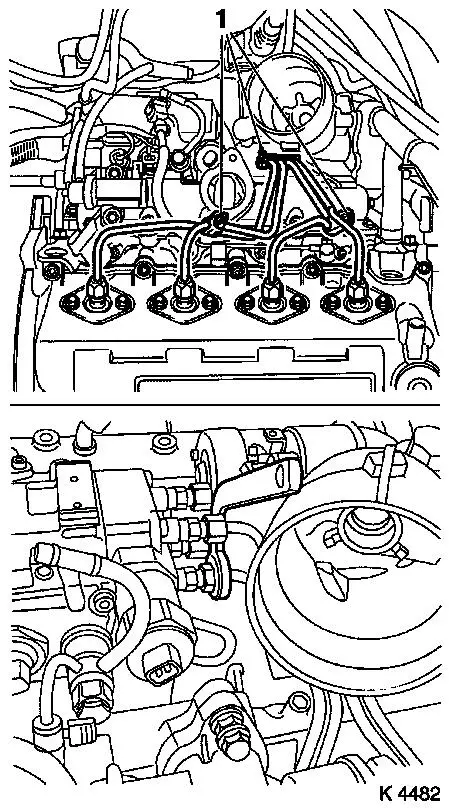

68. Detach injection line spacers (1)

69. Remove injection lines

|

|

70. Detach vacuum hose

- From exhaust gas recirculation solenoid valve

71. Detach oil leak line

|

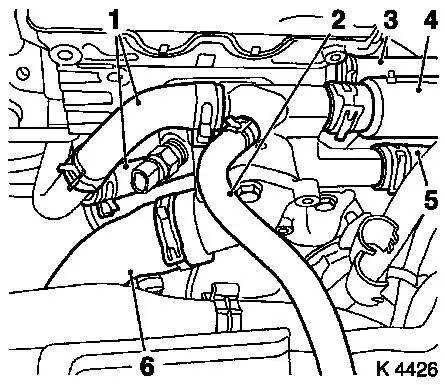

72. Detach coolant hoses

- From thermostat

- Upper radiator hose (6), coolant pipe 2 off (1), coolant

compensation tank (2), add-on heater (5), heater core (4)

- From cylinder head (3)

|

|

|

73. Detach waste gate unit vacuum hose bracket

74. Remove engine transport shackles

75. Detach injection nozzle outer seals

|

|

|

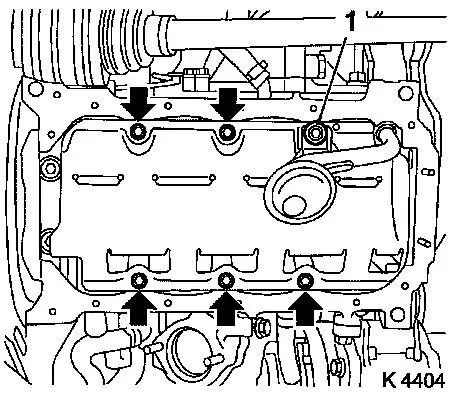

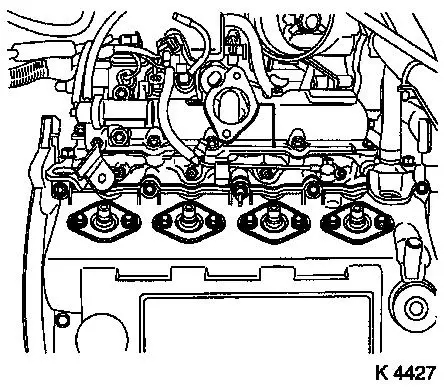

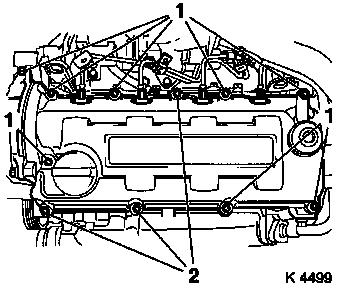

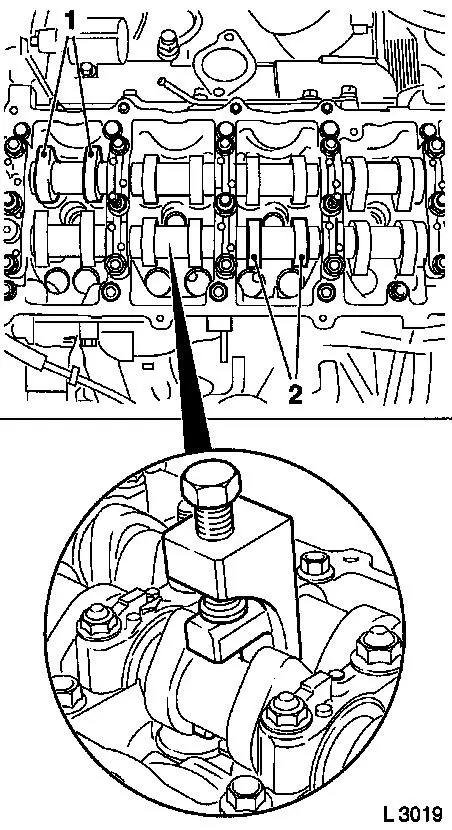

76. Remove camshaft housing cover

- Unscrew 7 bolts (1), 3 stud bolts (2)

|

|

|

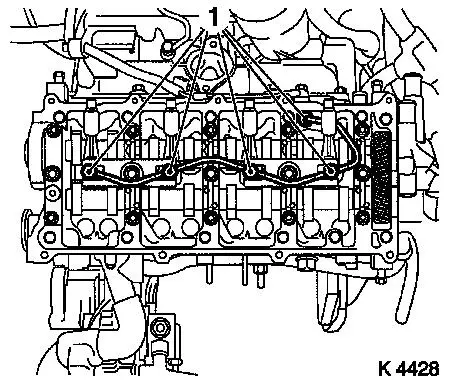

77. Detach inner oil leak line

- Unscrew 5 banjo bolts (1)

- Note! Note sealing rings

|

|

|

78. Remove injector nozzles

Caution!

Ensure that upon removal of injector nozzles heat protection

sleeves remain in their position on the cylinder head.

Otherwise, heat protection sleeves must

be removed completely and installed again using new seal rings.

This is the only way to ensure that no coolant can reach the

combustion chamber, which would inevitably cause engine damage.

Replace heat protection sleeves – see operation "Replace heat

protection sleeves" in document "Check and measure cylinder

head".

- Remove injection nozzle bracket

- Remove injector nozzles

|

|

|

79. Remove camshaft housing cover

- Loosen bolts, stud bolts (180°)

- Caution! Observe sequence

- Unscrew 2 stud bolts, 15 bolts

- Remove gasket.

|

|

|

80. Remove cup tappets

- With KM-845

- Caution! Observe installation position and allocation

81. Remove cylinder head bolts

- Remove 10 bolts

- Note! Loosen bolts in order shown (180° –

360°)

|

|

82. Remove cylinder head

- Note! 2. mechanic

- Caution! Place cylinder head on wooden blocks, note sheathed

glow plugs

- Remove cylinder head gasket

83. Raise vehicle

|

84. Remove con-rod bearing caps

- 2. and 3rd cylinder

- Remove con-rod bearing caps

- Note! Observe identification on con-rod bearing caps and

con-rods. If not present, apply identification

- Push piston upwards

|

|

85. Turn crankshaft

- In direction of engine rotation by 180°

|

86. Remove con-rod bearing caps

- 1. and 4th cylinders

- Remove con-rod bearing caps

- Note! Observe identification on con-rod bearing caps and

con-rods. If not present, apply identification

- Push piston upwards

|

|

87. Lower vehicle

88. Remove piston

- 4 off

- Remove combustion residues

89. Remove con-rod bearing shells

- From con-rod, con-rod bearing cap

90. Visually inspect components

- Crankshaft with con-rod and piston assemblies, engine timing

components, cylinder head, cylinder block, exhaust manifold,

turbocharger, valve train, ribbed V-belt drive

91. Install con-rod bearing shells

|

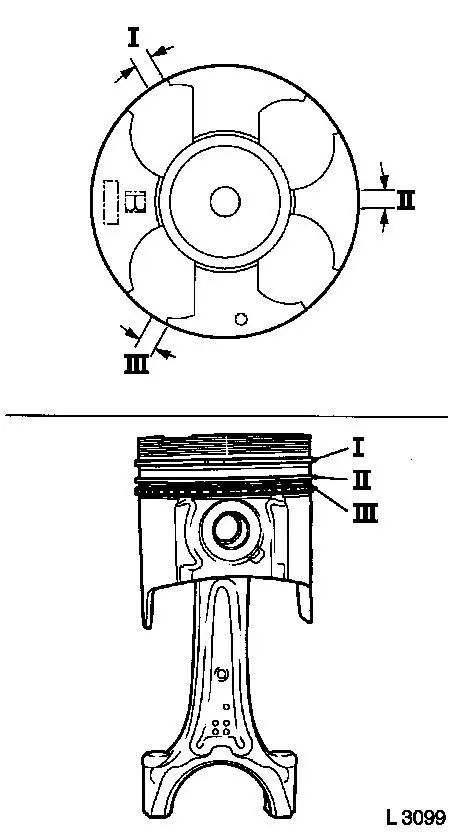

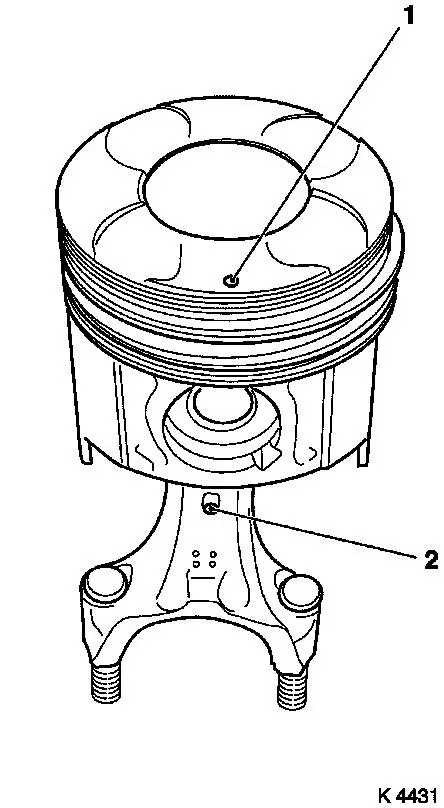

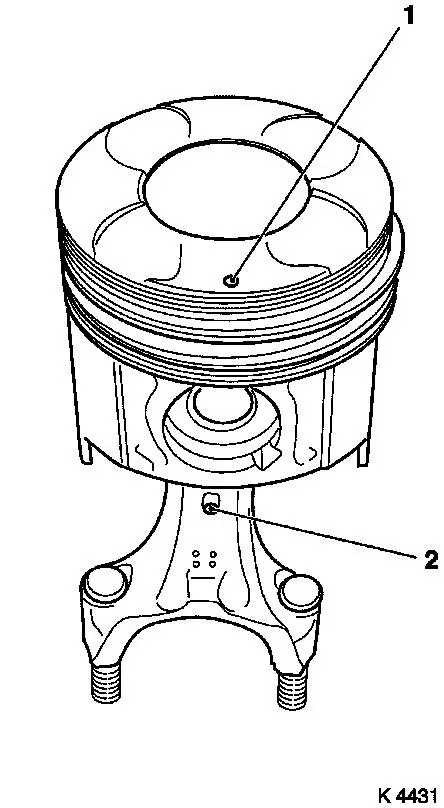

92. Adjust piston rings

- Arrange piston ring end gaps offset by 120°

- I Rectangular ring (first compression ring)

- II Tapered ring (second compression ring)

- III Double-bevelled ring (oil scraper ring)

|

|

|

93. Install piston

- 1. and 4th cylinders

- Caution! Mark (1) on piston head and mark (2) on con-rod point

to engine timing side

- Compress piston rings with piston ring tensioner

- Insert piston

|

|

94. Raise vehicle

|

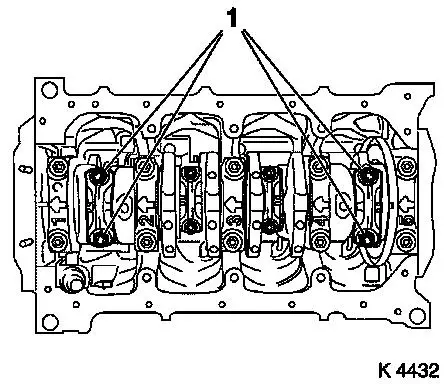

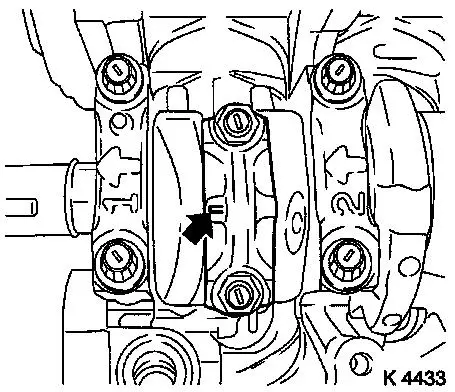

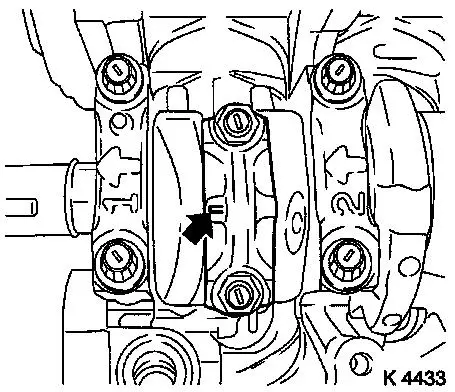

95. Attach con-rod bearing cap

- Replace nuts

- Caution! Observe identification of cylinder sequence on con-rod

bearing caps and con-rods. Small bead (arrow) points towards engine

timing side

- Tighten nuts (24.5 Nm / 18.1 lbf. ft. + 100° +

15°)

|

|

96. Turn crankshaft

- In direction of engine rotation by 180°

97. Lower vehicle

|

98. Install piston

- 2. and 3rd cylinder

- Caution! Mark (1) on piston head and mark (2) on con-rod point

to engine timing side

- Compress piston rings with piston ring tensioner

- Insert piston

|

|

99. Raise vehicle

|

100. Attach con-rod bearing cap

- Replace nuts

- Caution! Observe identification of cylinder sequence on con-rod

bearing caps and con-rods. Small bead (arrow) points towards engine

timing side

- Tighten nuts (24.5 Nm / 18.1 lbf. ft. + 100° +

15°)

|

|

101. Lower vehicle

102. Clean sealing surfaces

- Cylinder head, cylinder block, camshaft housing, camshaft

housing cover, exhaust manifold, turbocharger, exhaust gas

recirculation valve, upper charge air pipe

|

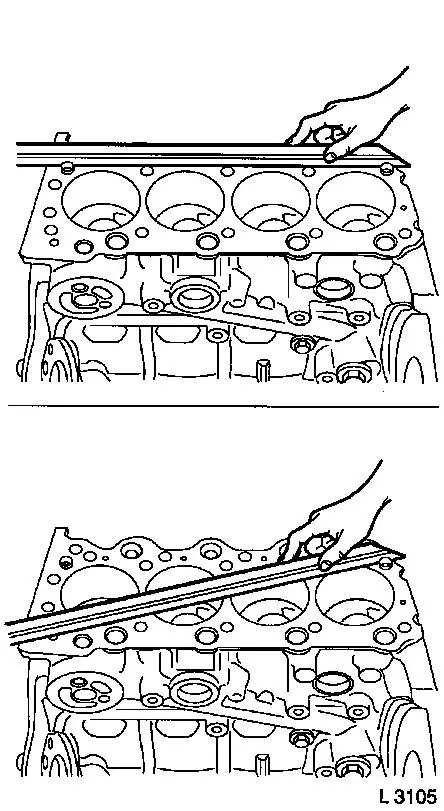

103. Check for plane surface

- Cylinder head, cylinder block

- With straightedge, feeler gauge

|

|

|

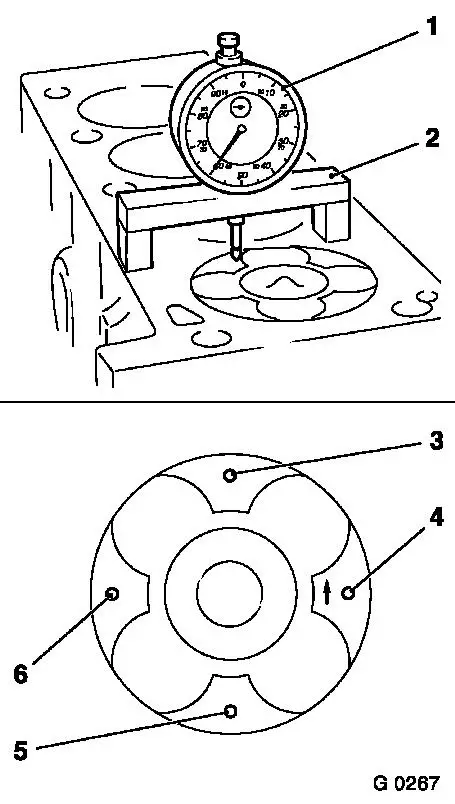

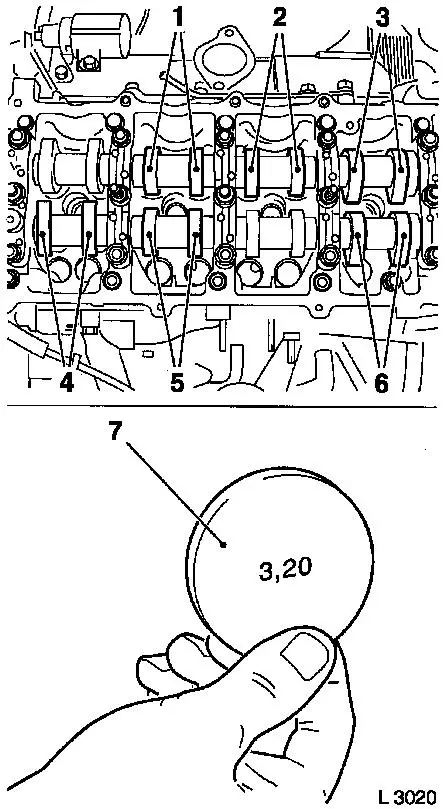

104. Measure piston projection

- Insert MKM-571-B (1) in KM-301 (2)

- Set dial to zero

- Place probe on cylinder block

- Measure piston projection on all four pistons

- Carry out measurement on two different locations (3 and 4) or

(5 and 6)

- Determine high point by turning crankshaft

|

|

105. Turn crankshaft

- approx. 60° before TDC of cylinder-1

|

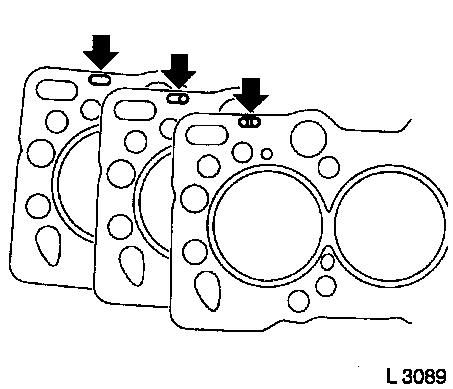

106. Replace cylinder head gasket

|

Piston projection

|

Thickness of cylinder head gasket

|

Code

|

|

0.630 – 0.696 mm

|

1.45 mm

|

no hole

|

|

0.697 – 0.763 mm

|

1.50 mm

|

one hole

|

|

0.764 – 0.830 mm

|

1.55 mm

|

two holes

|

- Caution! The largest determined piston projection is used for

the selection of the cylinder head gasket with corresponding

identification (arrows).

- Lay cylinder head gasket in place

|

|

107. Position cylinder head

|

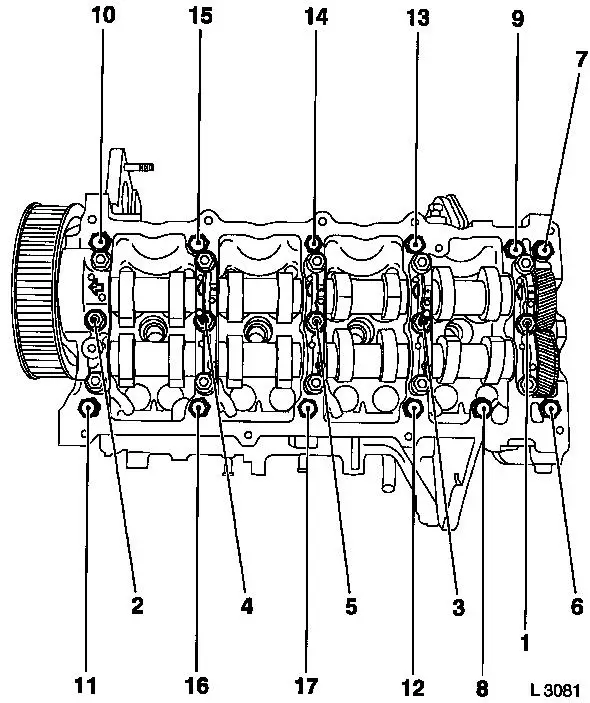

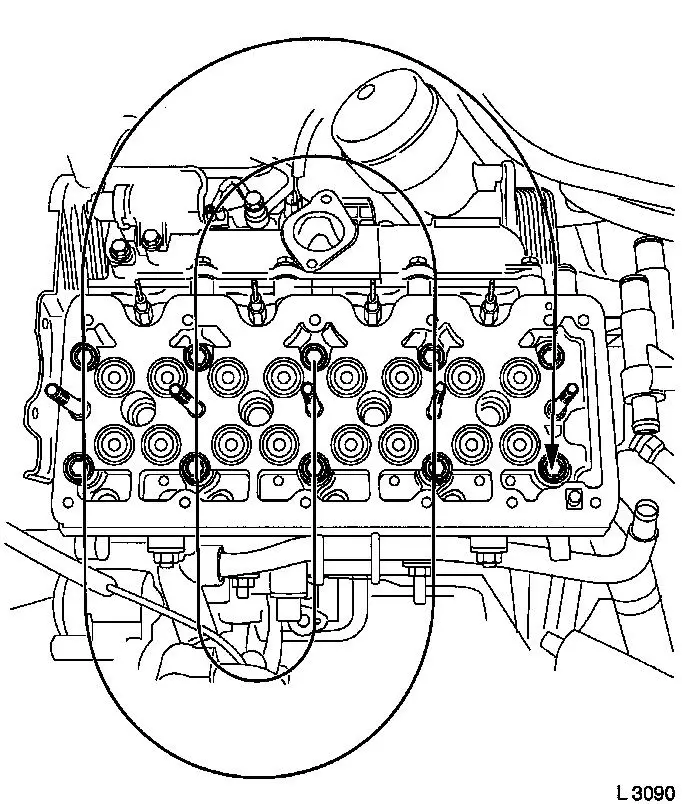

108. Fasten cylinder head

- Replace cylinder head bolts

- Screw in bolts by several threads

- Tighten cylinder head bolts (39.2 Nm + 60° + 13° +

60° + 13°)

- Note! Observe tightening sequence

|

|

109. Insert cup tappets

- Coat with engine oil

- Caution! Observe sequence and allocation

|

110. Install camshaft housing

- Replace gasket

- Tighten bolts M8 (21.6 Nm / 16 lbf. ft.)

- Tighten bolts M10 (43.1 Nm / 32 lbf. ft.)

- Caution! Observe sequence

|

|

111. Fasten rear toothed belt cover

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

112. Attach camshaft gear

- Counterhold using KM-6156 and KM-956-1

- Tighten bolt (63.7 Nm / 47.0 lbf. ft.)

- Install TDC-fixing bolt

113. For toothed belt tension roller

with leaf spring: fasten toothed belt tension roller spring

retainer

|

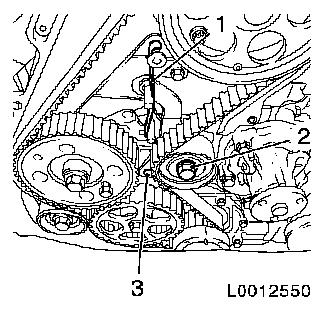

114. Set cylinder 1 to TDC

- Mark on toothed belt drive gear (2) must align with casting lug

at oil pump cover (1)

|

|

115. Install toothed belt

Note: Toothed belt

must be taut from toothed belt drive gear via oil pump drive gear

and injection pump drive gear

- For toothed belt tension roller with leaf spring:

- Unscrew TDC-fixing bolt

- Rotate crankshaft 60° against direction of engine

rotation

- Tighten bolt of toothed belt tension roller

- For toothed belt tension roller with spiral spring 49 Nm

- For toothed belt tension roller with leaf spring 38.2 Nm

116. For toothed belt tension roller with leaf spring: unscrew

bolt (M10) from lower bore of toothed belt tensioner

|

117. Check timing

- Turn crankshaft approx. 780° in direction of engine

rotation

- At toothed belt drive gear bolt

- The mark on toothed belt drive gear must align with lug on oil

pump cover (arrows)

- Install TDC-fixing bolt

- Camshaft gear M6 (1)

- Injection pump drive gear M8 (2)

- Note! If the TDC fixing bolts cannot be inserted, the basic

adjustment must be repeated

|

|

118. Unscrew TDC-fixing bolts

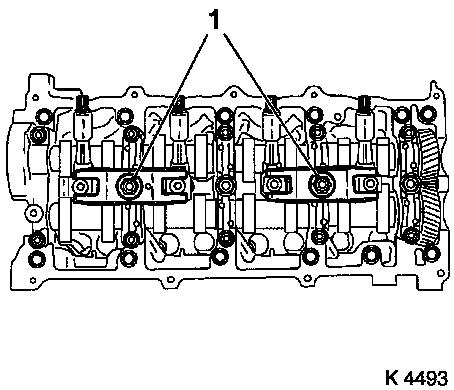

|

119. Turn crankshaft

- Turn crankshaft until cam pairs (1) and (2) point upwards

|

|

120. Check valve play

- Using feeler gauge

- Test values: Intake valves/Exhaust valves (0.35 – 0.45

mm)

- Note! Checking and adjustment of valve clearances is done on a

cold engine – room temperature

121. Adjust valve play

- Turn cup tappet until tappet groove points outwards

- Press down cup tappets using KM-6090

- Note! Note different tool versions for intake and exhaust

valves

- Mark – IN = Intake side

- Mark – EX = Exhaust side

- Caution! Ensure that valves do not interfere with piston

head

- Remove adjustment shim

Example for determination of shim

thickness

|

1.

|

Thickness of installed shim

|

|

3.15 mm

|

|

2.

|

Measurement between cam and cup tappets

|

+

|

0.45 mm

|

|

|

|

=

|

3.60 mm

|

|

3.

|

Nominal valve play

|

-

|

0.40 mm

|

|

4.

|

Thickness of new shim

|

=

|

3.20 mm

|

|

122. Insert shim

- Coat new shim with engine oil and insert in cup tappet with

identification mark facing downwards

123. Turn crankshaft

- In direction of engine rotation by 180°

- Check and adjust valve pair (6) and (2)

- In direction of engine rotation by 180°

- Check and adjust valve pair (5) and (3)

- In direction of engine rotation by 180°

- Check and adjust valve pair (4) and (1)

- Note! Valve clearances must be checked again for all adjusted

valves

|

|

124. Install lower toothed belt

cover

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

125. Install torsional vibration

damper

- Tighten bolts (19.6 Nm / 14.5 lbf. ft.)

126. Attach right engine bracket

- Insert lower bolt

- Into right engine bracket and right engine bracket adapter

- Insert right engine bracket, right engine bracket adapter,

upper part of toothed belt cover

- Install 2 upper bolts

- Tighten 3 bolts (40 Nm / 29.5 lbf. ft.)

127. Fasten upper toothed belt

cover

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

- Note! Note dissimilar bolt lengths

128. Attach coolant pump ribbed V-belt

pulley

- Tighten bolts (9.8 Nm / 7.2 lbf. ft)

129. Install right engine damping

block

- To side member

- Tighten bolts (40 Nm / 29.5 lbf. ft.)

- On engine bracket

- Tighten bolts (60 Nm/44 lbf. ft + 30° + 15°.)

130. Install injector nozzles

- Renew seal rings

- Renew copper sealing washers

- Insert injection nozzles in cylinder head.

- Install injector nozzle bracket (22.1 Nm/16.3 lbf. ft.)

131. Attach new inner oil leak line

- Renew seal rings

- Tighten banjo bolt (14.7 Nm/10.8 lbf. ft.)

|

132. Attach camshaft housing cover

- Replace gasket

- Apply adhesive sealant compound (white)

- Caution! Oil return bore (2) must not be covered with adhesive

sealing compound or by the camshaft housing cover gasket

- Tighten bolts, studs (9.8 Nm/7.2 lbf. ft.)

|

|

133. Attach injection nozzle outer

seals

- Replace seals

- Tighten bolts

134. Install injection lines

- Caution! Injection lines must be installed without tension.

Hand-tighten at injector nozzles and injection pump.

- With KM-6098

- Tighten union nuts (22.5 Nm/16.6 lbf. ft.)

135. Install injection line spacers

- Note! Note spacer positions

|

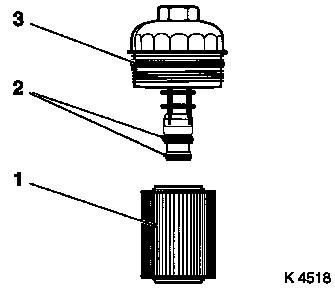

136. Install oil filter element (1)

- Replace seal rings (2)

- Replace oil filter housing cover (3)

- Install new oil filter element into cover

- Tighten oil filter housing cover (25 Nm/18.5 lbf. ft.)

|

|

137. Attach waste gate unit vacuum hose

bracket

- Tighten bolt (24.5 Nm / 18.1 lbf. ft.)

138. Attach coolant hoses

139. Attach engine transport

shackles

- 3 off

- Tighten bolts (20 Nm / 15 lbf. ft.)

140. Attach oil leak hose

141. Connect wiring harness plug

- Exhaust gas recirculation solenoid valve, charge pressure

sensork

142. Attach vacuum hose

- To exhaust gas recirculation solenoid valve

143. Install exhaust gas recirculation

valve

- Replace gasket

- Tighten studs, bolts (24.5 Nm/18.1 lbf. ft.)

- Connect vacuum hose.

144. Attach upper charge air pipe

- Clean sealing surface

- Replace gasket

- Tighten stud bolt, bolt

- Upper charge air pipe bracket to camshaft housing

- Tighten bolt (24.5 Nm / 18.1 lbf. ft.)

145. Attach starter/alternator wiring

harness bracket

146. Install alternator wiring

harness

- Tighten nuts

- Connect wiring harness plug.

- Attach wiring trough

- Clip-in wiring trough

- Tighten bolt

147. Attach wiring harness for engine

management

- Route wiring harness

- Connect wiring harness plug.

148. Install engine control unit

bracket

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

- Tighten nut (9.8 Nm/7.2 lbf. ft.)

- Attach wiring harness

149. Install exhaust manifold

- Install exhaust manifold

- Replace gasket

- Screw in bolts

- Attach exhaust gas recirculation pipe

- Replace gasket

- Screw in bolts

- Tighten bolts, nuts (23.5 Nm/17.3 lbf. ft.)

- Tighten exhaust gas recirculation pipe (28.4 Nm/20.9 lbf.

ft.)

- Exhaust gas recirculation pipe bracket to camshaft housing

- Tighten bolt (8.8 Nm / 6.5 lbf. ft.)

150. Attach turbocharger oil feed

line

- Renew seal rings

- Insert oil feed line

- Tighten banjo bolt (9.8 Nm / 7.2 lbf. ft.)

151. Attach exhaust manifold heat

shield

- Tighten bolts (11.7 Nm / 8.6 lbf. ft.)

152. Raise vehicle

153. Detach support

154. Detach KM-6169

155. Attach turbocharger oil feed

line

- Renew seal rings

- Note! Counterhold at threaded port

- Tighten nut (9.8 Nm/7.2 lbf. ft.)

156. Install turbocharger oil return hose

157. Attach turbocharger bracket

- Tighten bolt (26.5 Nm / 19.6 lbf. ft.)

158. Connect waste gate unit vacuum hose

159. Clean sealing surfaces

- Cylinder block, upper part of oil pan, lower part of oil

pan

160. Install oil baffle plate

- Tighten bolts (18.6 Nm / 13.7 lbf. ft.)

161. Install oil intake pipe

- Replace seal ring

- Tighten bolt (18.6 Nm / 13.7 lbf. ft.)

162. Attach oil pan upper part

- Apply sealing compound (grey)

- Caution! The application of silicone sealing compound (grey)

and installation of lower part of oil pan including torque test

must be performed within 10 minutes!

- Tighten bolts, nuts (9.8 Nm/7.2 lbf. ft.)

- Tighten bolts (M10) (40 Nm / 29.5 lbf. ft.)

- Replace oil dipstick guide tube sealing ring

163. Attach oil pan lower part

- Apply sealing compound (grey)

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

164. Attach exhaust system

- Note! 2. mechanic

- Install damping rings

165. Attach front exhaust pipe

- Replace gasket, nuts

- Tighten nuts (65 Nm / 48 lbf. ft.)

166. Lower vehicle

167. Install compressor bracket

- Tighten bolts (43 Nm / 31.7 lbf. ft.)

168. Install oil dipstick guide tube

169. Install compressor

- Tighten bolts (22 Nm / 16.2 lbf. ft)

- Connect wiring harness plug.

170. Attach oil dipstick guide tube

bracket

- Tighten nuts

- Clip in vacuum lines

171. Attach refrigerant line

- Renew seal rings

- Tighten bolt (20 Nm / 15 lbf. ft.)

172. Attach charge air hose

- Tighten clamp (3.5 Nm / 2.6 lbf. ft.)

173. Attach centre charge air pipe

- Insert in lower charge air pipe

- Tighten upper bolt

- Fasten turbocharger charge air hose (3.5 Nm / 2.5 lbf.

ft.)

174. Install air intake pipe

- Tighten bolts

- Attach engine vent hose

- Tighten clamp (3.5 Nm / 2.6 lbf. ft.)

- Attach wiring harness

175. Install engine control unit

- Tighten bolts, nuts (5.9 Nm/4.4 lbf. ft.)

- Install wiring harness plug bracket

- Connect wiring harness plug.

- Attach wiring harness

176. Raise vehicle

177. Fasten oil dipstick guide tube

- Tighten lower bolts (9.8 Nm / 7.2 lbf. ft.)

178. Install ribbed V-belt

- Note! Observe running direction and installation position

- Release ribbed V-belt tensioner

179. Install ribbed V-belt cover

- Tighten bolts

- Install clip

180. Fasten centre charge air pipe

- Tighten lower bolt

- Fasten clamp (3.5 Nm / 2.6 lbf. ft.)

181. Lower vehicle

182. Mount right front wheel

183. Lower vehicle

184. Fasten right front wheel

- Tighten bolts (110 Nm / 81 lbf. ft.)

185. Fasten oil dipstick guide tube

- Tighten upper bolt

- Clip in vacuum hoses

186. Install air cleaner housing

- Tighten bolt

- Fasten air intake hose.

- Tighten clamp (3.5 Nm / 2.6 lbf. ft.)

- Connect wiring harness plug to hot film mass air flow

meter

187. Top up engine oil

- Start engine and allow to run until oil pressure telltale

extinguishes.

- Check engine oil level, if necessary correct.

- Observe specified engine oil quantity

188. Top up coolant

- Note! Top up and bleed cooling system – see operation

"Top up and bleed cooling system"

- Observe specified coolant quantity

189. Connect battery

190. Calibrate steering angle

sensor

Note: Rotate the

steering wheel one time from its right-hand to its left-hand

stop.

191. Program volatile memories

192. Charge air conditioning

- Note! Charge air conditioning – see operation "Evacuate

and charge air conditioning" in group "D".

193. Close bonnet

|