|

J 459015 Valve Stem Seals, Replace (Y 17 DT, with

AC, LHD)

Note: KM-6394 must be used from model year 04 instead of

KM-6169-1 .

|

1. Open bonnet

Caution!

On vehicles from model year 04 with ESP - the steering angle

sensor loses its basic adjustment each time the battery is

disconnected. It must be recalibrated.

2. Disconnect battery

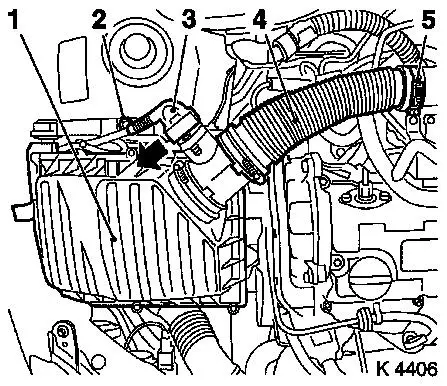

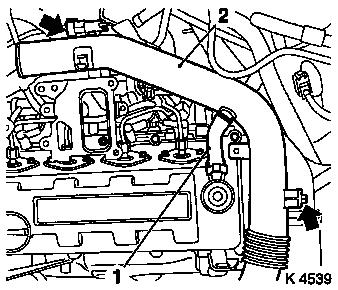

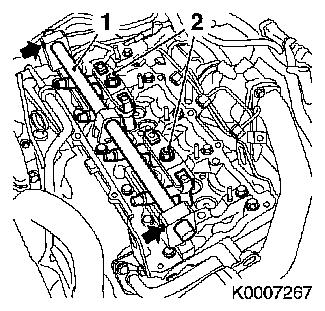

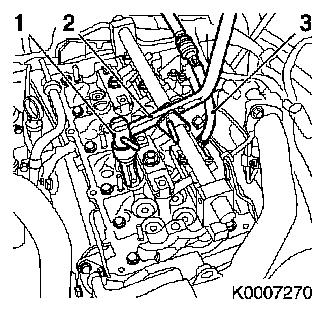

3. Remove air cleaner housing (1)

- Remove wiring harness plug for hot film mass air flow meter

(3)

- Release in direction of arrow

- Remove air intake hose (4)

- Remove bolt (2)

|

|

|

4. Loosen front right wheel

5. Raise vehicle

6. Remove front right wheel

7. Raise vehicle

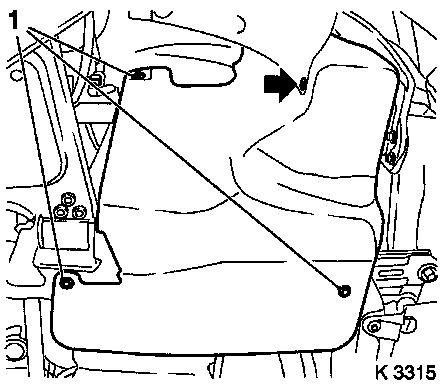

8. Detach ribbed V-belt cover

- Remove 3 bolts (1)

- Remove clip (arrow).

|

|

|

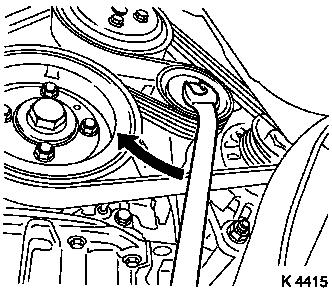

9. Detach ribbed V-belt

- Tension ribbed V-belt tensioner in direction of arrow

- Note! Mark running direction

|

|

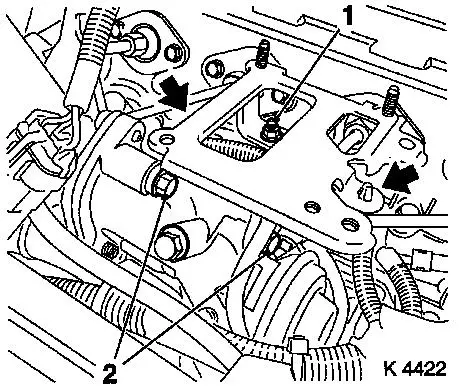

|

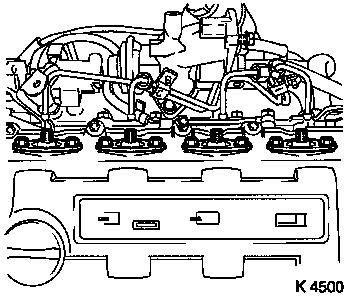

10. Release air intake pipe

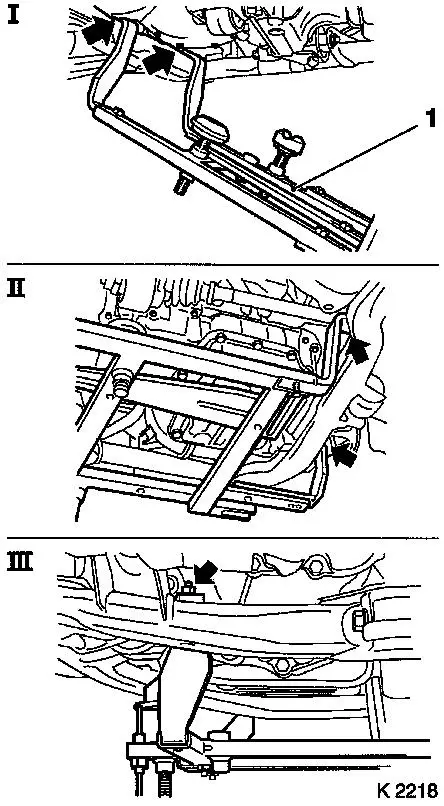

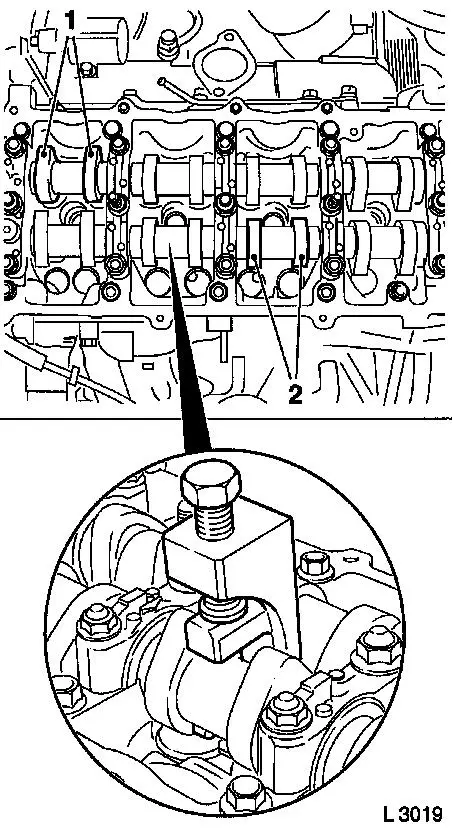

11. Attach KM-6169 (1)

- Place left of KM-6169 onto front axle body (arrows, illus.

I)

- Note! Guide pin must be seated in bore in front axle body

- Attach both right holders on the front axle body (arrows,

Illus. II).

- Note! Guide pin must be seated in bore in front axle body

(arrow, Illus. III)

- Tighten bolt

|

|

|

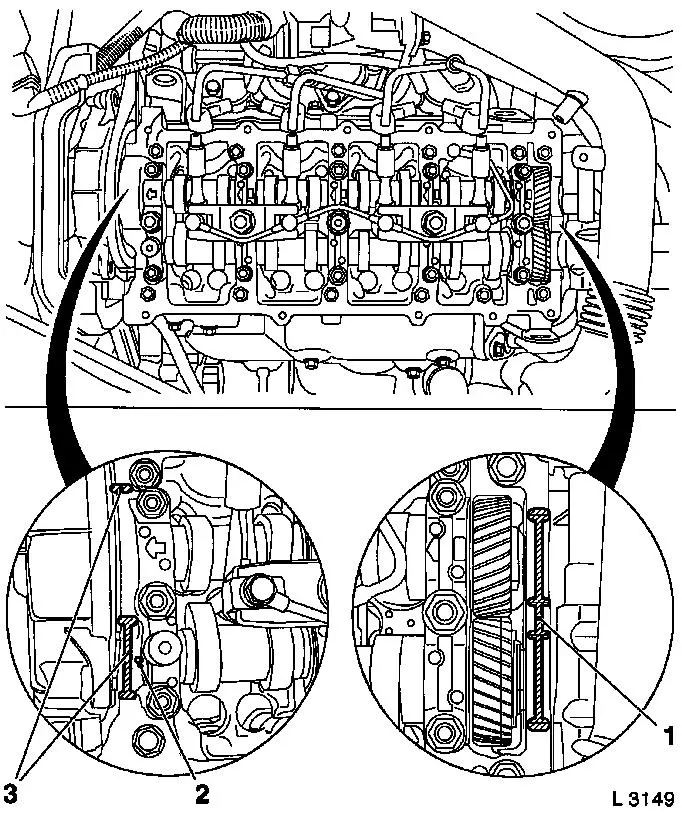

12. Install support

- To KM-6169

- Adjust bracket (2) for support

- Screw on nut (1)

13. Adjust supports

- Transmission side

- Note! Turn spindles until the mounts (3) are positioned at the

guide journals free of play

- Engine timing side

- Insert journal of the support in the bore of the cylinder block

without play (arrow)

- Tighten nuts (1)

|

|

|

14. Lower vehicle

15. Drain coolant

- Place collecting basin underneath.

- Open drain bolt

|

|

|

16. Remove oil dipstick guide tube

bracket

- Remove bolt, 2 nuts (arrows)

- Unclip vacuum hoses

|

|

|

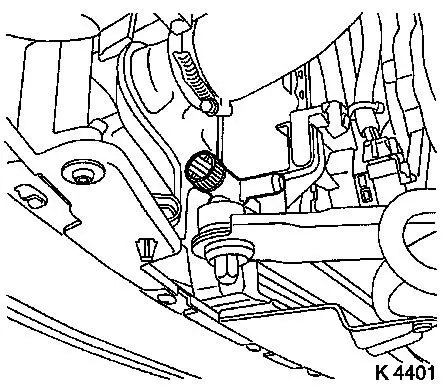

17. Remove wiring harness plug for

engine management

- Wiring harness plug, engine control unit

- Release in direction of arrow

- Disconnect combination plug (grey)

- Disconnect combination plug (black)

|

|

|

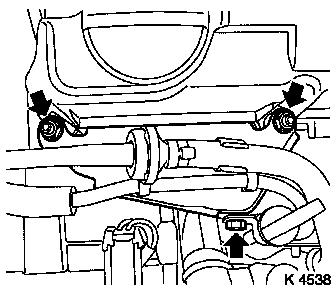

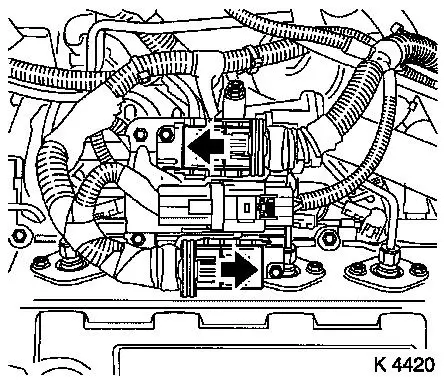

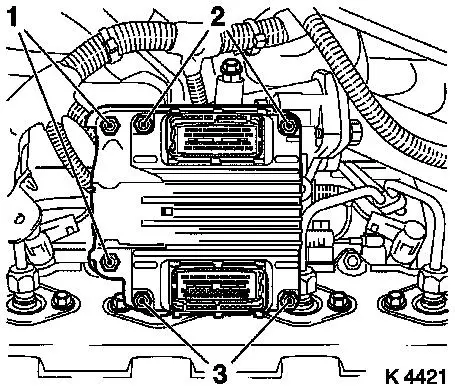

18. Remove engine control unit

- Remove wiring harness plug bracket

- Unscrew 2 bolts (2), 2 nuts (3)

|

|

|

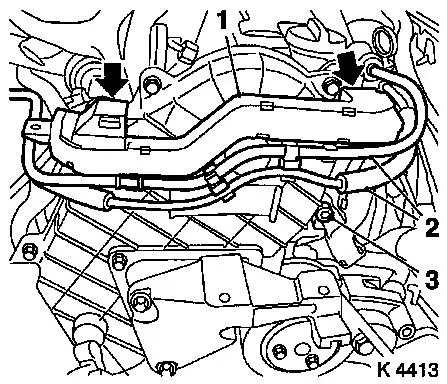

19. Remove air intake pipe (2)

- Remove 2 bolts (arrows)

- Detach engine vent hose (1)

- Detach air intake pipe from turbocharger

|

|

|

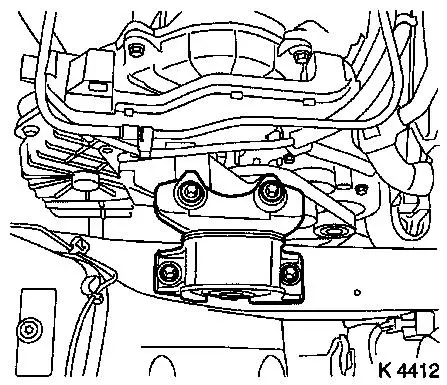

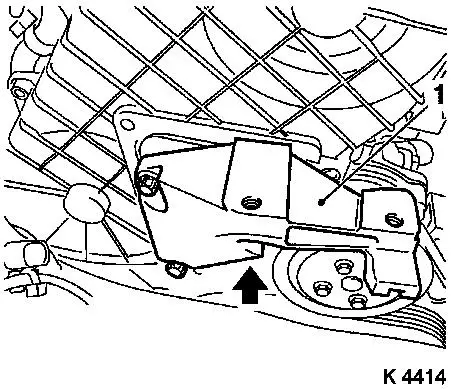

20. Remove right engine damping

block

|

|

|

21. Remove wiring trough

- Unclip vacuum line (2)

- Unclip wiring trough (1)

- Remove bolt (3)

|

|

|

22. Remove coolant pump ribbed V-belt pulley

23. Remove upper toothed belt cover

- Remove 8 bolts

- Note! Note dissimilar bolt lengths

|

|

|

24. Detach right engine bracket (1)

- Remove 3 bolts

- Remove right engine bracket, right engine bracket adapter,

upper part of toothed belt cover

|

|

|

25. Raise vehicle

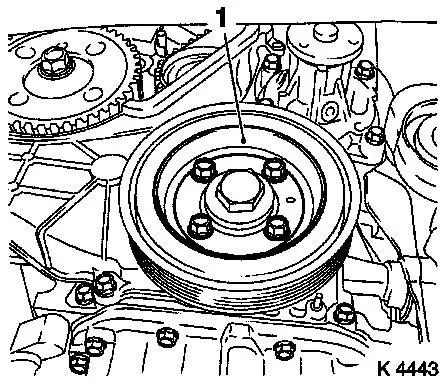

26. Remove torsional vibration damper

(1)

|

|

|

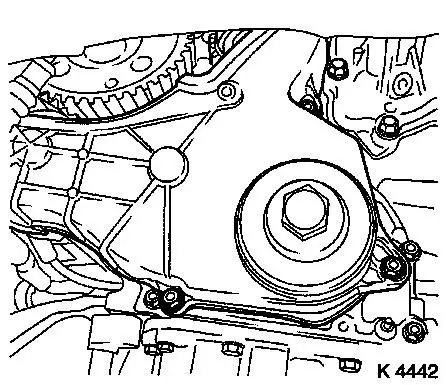

27. Remove lower toothed belt cover

|

|

|

28. Lower vehicle

29. Install right front wheel

30. Lower vehicle

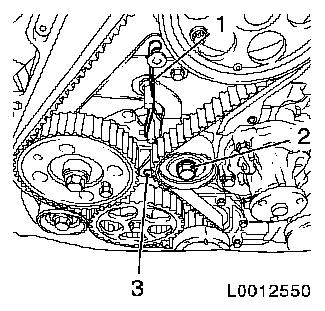

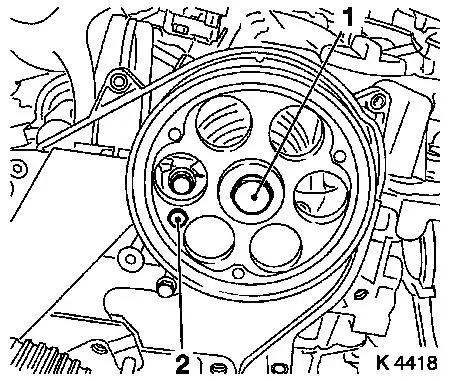

31. Set 1st cylinder to TDC of combustion stroke

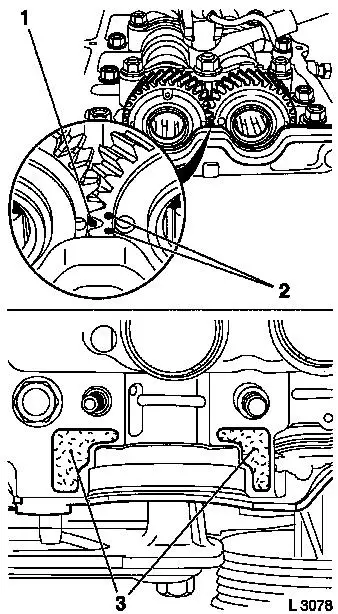

- Turn crankshaft evenly until TDC-fixing bolts can be

inserted

- Camshaft gear M6 (1)

- Injection pump drive gear M8 (2)

- Note! The mark on toothed belt drive gear must align with lug

on oil pump cover (arrows)

|

|

|

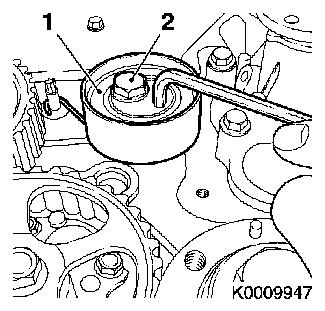

32. For toothed belt tension roller

with leaf spring:

- loosen toothed belt tensioner

- Screw in bolt (M10) in lower bore (3) of toothed belt

tensioner

- Loosen bolt (2)

- Remove tension spring (1)

|

|

|

For toothed belt tension roller with

spiral spring:

- Loosen toothed belt tension roller (1)

- Rotate toothed belt tension roller anticlockwise approx.

90°

- Tighten bolt (2)

|

|

|

33. Remove toothed belt

- Note! Mark running direction

34. Detach camshaft pulley

- Unscrew TDC-fixing bolt (2)

- Counterhold using KM-6156 and KM-956-1

- Remove bolt (1)

|

|

|

35. Release rear toothed belt cover

36. Remove engine control unit bracket

- Unscrew 2 bolts (2), nut (1)

- Unclip wiring harness (arrows)

|

|

|

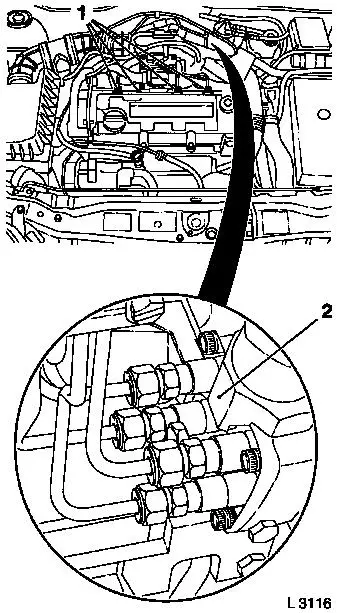

37. Detach injection line

- From camshaft housing cover (1)

- 4 off

38. Detach injection line

- From diesel injection pump (2)

- With KM-6098

- 4 off

|

|

|

39. Detach injection nozzle outer

seal

|

|

|

40. Detach right rear engine transport shackle

41. Loosen left rear engine transport shackle

42. Remove camshaft housing cover

43. Detach inner oil leak line (1)

- Remove 5 banjo bolts

- Note! Note sealing rings

|

|

|

44. Remove injector nozzles

Caution!

Ensure that upon removal of injector nozzles heat protection

sleeves remain in their position on the cylinder head.

Otherwise, heat protection sleeves must

be removed completely and installed again using sealing rings. This

is the only way to ensure that no coolant can reach the combustion

chamber, which would inevitably cause engine damage. Replace heat

protection sleeves – see operation "Replace heat protection

sleeves" in document "Check and measure cylinder head".

- Remove injection nozzle bracket

- Remove injector nozzles

|

|

|

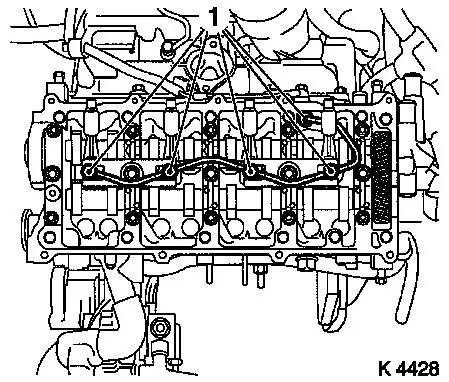

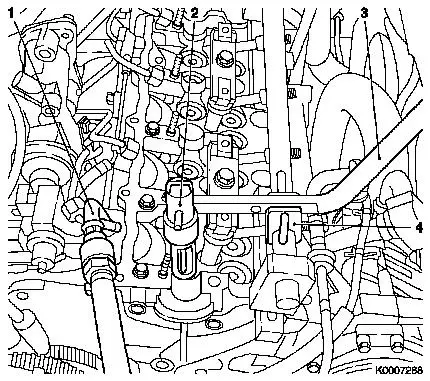

45. Lock exhaust camshaft equaliser

gear

- Insert KM-955-2 (1)

- Note! Insert in exhaust camshaft gear and exhaust camshaft

equaliser gear up to camshaft bearing cap stop. Exhaust camshaft

gear and exhaust camshaft equaliser gear must be locked in place

with rotation impossible.

|

|

|

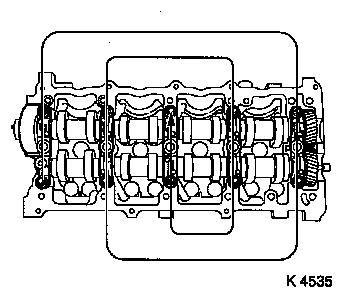

46. Remove camshaft bearing caps

- 5 off

- Unscrew 3 bolts, 10 nuts, and 2 stud bolts

- Note! Note identification on camshaft bearing caps. The

camshafts must be uniformly released from the bearing seats. Loosen

nuts, stud bolts and bolts (180° – 360°)

|

|

|

47. Remove camshafts

- Remove intake camshaft seal ring

48. Remove cup tappets

- With KM-845

- Caution! Observe installation position and allocation

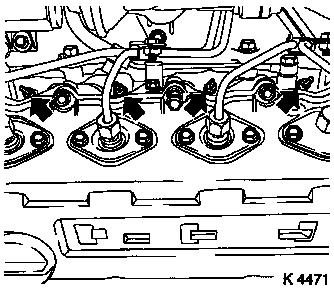

49. Remove sheathed glow plugs (arrows)

- Disconnect sheathed glow plug wiring harness plugs

- Remove sheathed glow plugs using MKM-6104.

|

|

50. Turn crankshaft

- In direction of engine rotation 90°

51. Loosen seating of valve keepers

- With KM-6171

- Loosen valve keeper seating by lightly tapping on KM-6171

52. Turn crankshaft

- In direction of engine rotation 270°

- 1st cylinder TDC of combustion stroke

53. Install stud bolts in cylinder head

|

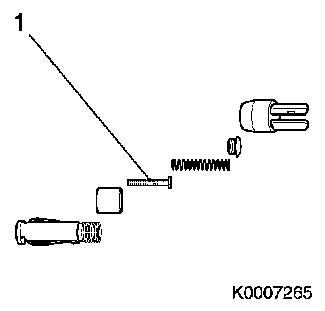

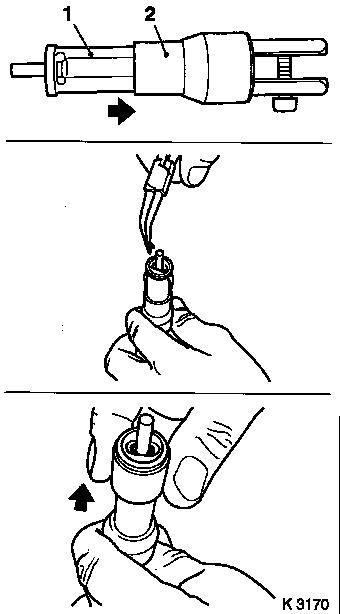

54. Assemble Automatic Valve Spring

Compressor MKM-6086

- Adjust supports

- Complete lever arm

- Using joint, removal head

- Assemble assembly head

- Insert thrust piece 6d (1)

- Note! Observe manufacturer's instructions

|

|

|

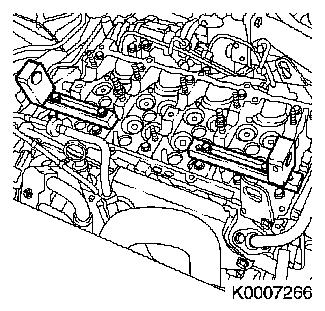

55. Attach Automatic Valve Spring

Compressor MKM-6086 supports

- To exhaust side camshaft housing cover stud bolts (1, 2 and 4,

5)

|

|

|

56. Install diesel injection nozzles

- Turn 180° offset from installation position

- 4 off

- Insert injection nozzles in cylinder head.

- Attach injection nozzle bracket

- Tighten 2 nuts (2) (22.1 Nm / 16.3 lbf. ft.)

57. Insert installation shaft and joint (1) in supports

58. Secure installation shaft

59. Fasten supports

|

|

|

60. Secure the engine against rotation

- 5. Engage gear

- Apply parking brake

- Note! Wheels must be touching the ground

61. Install compressed air adapter (1)

- Screw into sheathed glow plug thread of 1st cylinder

- Apply compressed air to 1st cylinder

62. Attach Automatic Valve Spring Compressor MKM-6068 lever arm

(3)

- To joint (4)

- Note! Removal head (2) must face toward intake side of 1st

cylinder

|

|

|

63. Remove intake valve springs for 1st cylinder

- 2 off

- Carefully push valve springs downwards

- With lever arm

- Note! Removal head must be positioned vertically above the

valve stem

- Remove valve keepers, valve heads, valve springs

- Caution! Observe allocation

- Note! Do not use magnetic tools

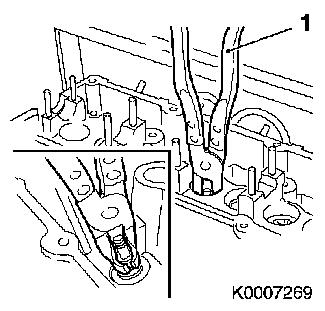

64. Replace valve stem seals

- 2 off

- Pull off using KM-840 (1)

- Attach new valve stem seal to valve stem

- Drive in using KM-6091

|

|

|

65. Remove intake valve springs for 1st

cylinder

- Insert valve springs, valve heads

- Insert valve keepers in assembly head (1)

- Slide clamping sleeve towards lever mount (arrow)

- Caution! Insert valve keepers with taper towards valve

- Slide clamping sleeve (2) towards valve (arrow)

- Attach assembly head to lever arm

- Carefully push valve springs downwards

- With lever arm

- Caution! Installation head must be positioned vertically above

the valve stem. Valve keepers must engage audibly

|

|

66. Check installation

- Caution! Do not make a 2nd attempt without checking that both

valve keepers are seated in the assembly head. Check seating of

valve keepers. Verify compressed air pressurisation

67. Transfer compressed air adapter

- Interrupt compressed air feed

- Unscrew from sheathed glow plug thread of 1st cylinder

- Screw into sheathed glow plug thread of 4th cylinder

- Apply compressed air to 4th cylinder

68. Replace 4th cylinder valve stem seals

69. Remove compressed air adapter

- Interrupt compressed air feed

- Unscrew from sheathed glow plug thread of 4th cylinder

70. Unlock engine

71. Set crankshaft to 3rd cylinder TDC of combustion stroke

- Turn crankshaft evenly (180°)

- in direction of engine rotation

72. Secure the engine against rotation

- 5. Engage gear

- Apply parking brake

- Note! Wheels must be touching the ground

73. Install compressed air adapter

- In sheathed glow plug thread

- Turn in cylinder 2

- Apply compressed air to 2nd cylinder

74. Replace 2nd cylinder valve stem seals

75. Transfer compressed air adapter

- Interrupt compressed air feed

- Unscrew from sheathed glow plug thread of 2nd cylinder

- Screw into sheathed glow plug thread of 3rd cylinder

- Apply compressed air to 3rd cylinder

76. Replace 3rd cylinder valve stem seals

77. Interrupt compressed air feed

- Note! Separate compressed air adapter from compressed air

supply

78. Detach Automatic Valve Spring Compressor MKM-6068 lever

arm

79. Release installation shaft

80. Detach installation shaft and joint from supports

81. Remove diesel injection nozzles

- Remove injection nozzle bracket

- Remove injector nozzles

82. Transfer supports

- Remove 4 nuts

- To intake side camshaft housing cover stud bolts (1, 2 and 4,

5)

- Align supports

- Secure supports

- Screw 4 nuts on stud bolts several threads

83. Install diesel injection

nozzles

- In installation position

- 4 off

- Insert injection nozzles in cylinder head.

- Attach injection nozzle bracket

- Tighten 2 nuts (22.1 Nm / 16.3 lbf. ft.)

84. Slide installation shaft and joint into supports

85. Secure installation shaft

|

86. Fasten supports

87. Attach Automatic Valve Spring Compressor MKM-6068 lever arm

(2)

- To joint

- Note! Removal head (1) must face toward exhaust side of 3rd

cylinder

88. Install compressed air adapter (3)

- Screw into sheathed glow plug thread of 3rd cylinder

- Apply compressed air to 3rd cylinder

|

|

89. Replace 3rd cylinder valve stem seals

90. Transfer compressed air adapter

- Interrupt compressed air feed

- Unscrew from sheathed glow plug thread of 3rd cylinder

- Screw into sheathed glow plug thread of 2nd cylinder

- Apply compressed air to 2nd cylinder

91. Replace 2nd cylinder valve stem seals

92. Transfer compressed air adapter

- Interrupt compressed air feed

- Unscrew from sheathed glow plug thread of 2nd cylinder

93. Unlock engine

94. Set crankshaft to 1st cylinder TDC of combustion stroke

- Turn crankshaft evenly (180°)

- In direction of engine rotation

95. Secure the engine against rotation

- 5. Engage gear

- Apply parking brake

- Note! Wheels must be touching the ground

96. Install compressed air adapter

- Screw into sheathed glow plug thread of 1st cylinder

- Apply compressed air to 1st cylinder

97. Replace 1st cylinder valve stem seals

98. Transfer compressed air adapter

- Interrupt compressed air feed

- Unscrew from sheathed glow plug thread of 1st cylinder

- Screw into sheathed glow plug thread of 4th cylinder

- Apply compressed air to 4th cylinder

99. Replace 4th cylinder valve stem seals

100. Remove compressed air adapter

- Interrupt compressed air feed

- Unscrew from sheathed glow plug thread of 4th cylinder

101. Detach Automatic Valve Spring Compressor MKM-6068 lever

arm

102. Release installation shaft

103. Detach installation shaft and joint from supports

104. Remove diesel injection nozzles

- Remove injection nozzle bracket

- Remove injector nozzles

105. Remove supports

106. Release vehicle

107. Loosen front wheel

108. Raise vehicle

109. Remove right front wheel.

110. Lower vehicle

111. Remove stud bolts from cylinder head

112. Install sheathed glow plugs

- Install sheathed glow plugs using MKM-6104

- Tighten sheathed glow plugs (19.6 Nm / 14.4 lbf. ft.)

- Connect wiring harness plug.

113. Install cup tappets

- Coat with engine oil

- Caution! Observe sequence and allocation

114. Clean camshaft housing sealing surfaces

|

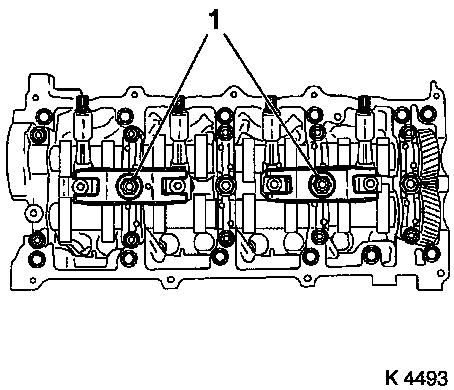

115. Insert camshafts

- Caution! Mark on exhaust camshaft gear (1) must be positioned

between both intake camshaft gear marks (2). The marks must be in

one plane with the top edge of the camshaft housing.

116. Attach camshaft bearing caps

- Note! Apply surface sealant (green) to sealing surfaces of 1st

camshaft bearing cap (3)

- 5 off

- Install nuts, stud bolts, bolts

|

|

|

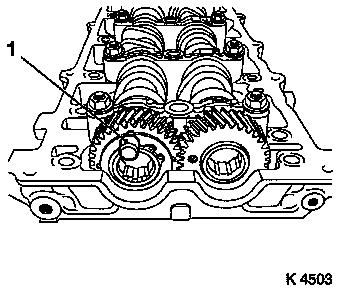

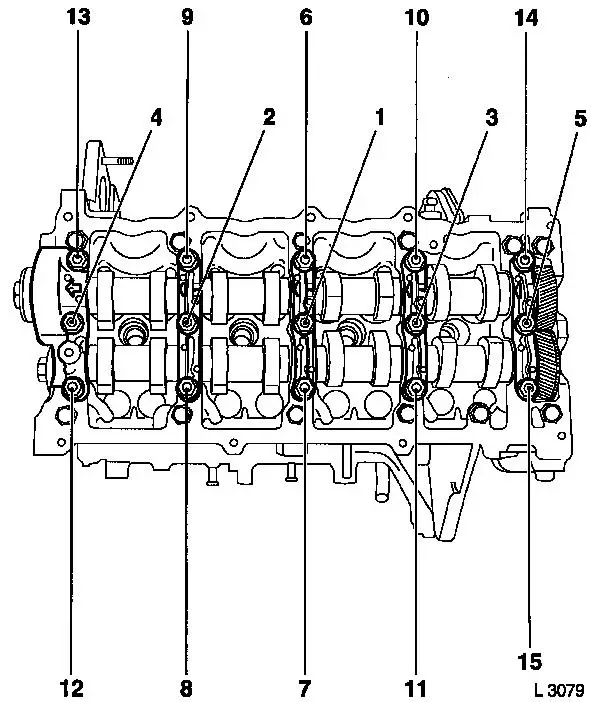

117. Tighten camshaft bearing caps

- Caution! Tighten in sequence illustrated in steps of 1/2 to 1

turn

- Tighten nuts M8 (21.6 Nm / 16 lbf. ft.)

- Tighten nuts M10 (43.1 Nm / 31.8 lbf. ft.)

- Tighten stud bolts M10 (43.1 Nm / 31.8 lbf. ft.)

- Remove KM-955-2

|

|

|

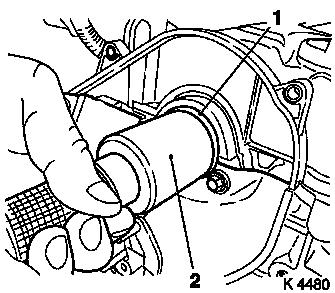

118. Install intake camshaft seal ring

(1)

- Replace seal ring

- Coat seal lips with grease

- Slide onto camshaft

- Drive in until flush using KM-656 (2)

|

|

119. Fasten rear toothed belt cover

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

120. Attach camshaft gear

- Lock in place using KM-9156 and KM-956-1

- Tighten bolt (63.7 Nm / 47.0 lbf. ft.)

- Install TDC-fixing bolt

- Note! If the TDC fixing bolt cannot be inserted, the TDC of

combustion stroke cylinder head 1 basic adjustment must be carried

out

121. Install toothed belt

Note: Toothed belt

must be taut from toothed belt drive gear via oil pump drive gear

and injection pump drive gear

- For toothed belt tension roller with leaf spring:

- Unscrew TDC-fixing bolt

- Rotate crankshaft 60° against direction of engine

rotation

- Tighten bolt of toothed belt tension roller

- For toothed belt tension roller with spiral spring 49 Nm

- For toothed belt tension roller with leaf spring 38.2 Nm

- For toothed belt tension roller with leaf spring: unscrew bolt

(M10) from lower bore of toothed belt tensioner

|

122. Check timing

- Turn crankshaft approx. 780° in direction of engine

rotation

- At toothed belt drive gear bolt

- Note! The mark on toothed belt drive gear must align with lug

on oil pump cover (arrows)

- Install TDC-fixing bolt

- Camshaft gear M6 (1)

- Injection pump drive gear M8 (2)

- Note! If the TDC fixing bolts cannot be inserted, the basic

adjustment must be repeated

|

|

123. Unscrew TDC-fixing bolts

|

124. Rotate crankshaft

- Turn crankshaft until cam pairs (1) and (2) point upwards

|

|

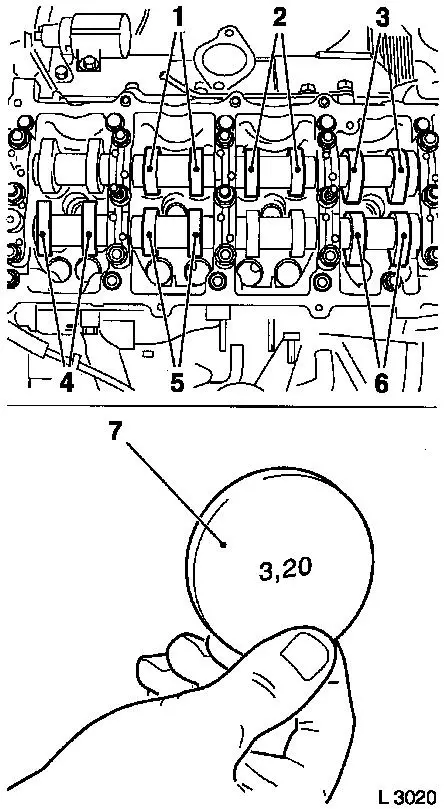

125. Adjust valve clearance

- Turn cup tappet until tappet groove points outwards

- Press down cup tappets using KM-6090

- Note! Note different tool versions for intake and exhaust

valves

- Mark – IN = Intake side

- Mark – EX = Exhaust side

- Caution! Ensure that valves do not interfere with piston

head

- Remove adjustment shim

Example for determination of shim

thickness

|

1.

|

Thickness of installed shim

|

|

3.15 mm

|

|

2.

|

Measurement between cam and cup tappets

|

+

|

0.45 mm

|

|

|

|

=

|

3.60 mm

|

|

3.

|

Nominal valve play

|

-

|

0.40 mm

|

|

4.

|

Thickness of new shim

|

=

|

3.20 mm

|

|

126. Insert adjustment shim

- Insert new shim (7), coat with engine oil, and insert in cup

tappet with identification mark facing downwards

- Note! Valve clearances must be checked again for all adjusted

valves

127. Rotate crankshaft

- In direction of engine rotation by 180°

- Check and adjust valve pair (6) and (2)

- In direction of engine rotation by 180°

- Check and adjust valve pair (5) and (3)

- In direction of engine rotation by 180°

- Check and adjust valve pair (4) and (1)

- Note! Valve clearances must be checked again for all adjusted

valves

|

|

128. Install diesel injection

nozzles

- Renew seal rings

- Renew copper sealing washers

- Insert diesel injection nozzles into cylinder head

- Attach injection nozzle bracket

- Tighten nuts (22.1 Nm / 16.3 lbf. ft.)

129. Attach inner oil leak line

- Renew seal rings

- Tighten banjo bolt (14.7 Nm/10.8 lbf. ft.)

130. Attach lower part of toothed belt cover

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

131. Attach right engine bracket

- Insert lower bolt

- Into right engine bracket and right engine bracket adapter

- Insert right engine bracket, right engine bracket adapter,

upper part of toothed belt cover

- Install 2 upper bolts

- Tighten 3 bolts (40 Nm / 29.5 lbf. ft.)

132. Fasten upper part of toothed belt cover

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

- Note! Note different bolt lengths

133. Attach coolant pump ribbed V-belt pulley

134. Raise vehicle

135. Install torsional vibration damper

- Tighten bolts (19.6 Nm / 14.5 lbf. ft.)

136. Install ribbed V-belt

137. Fasten coolant pump ribbed V-belt pulley

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

138. Lower vehicle

|

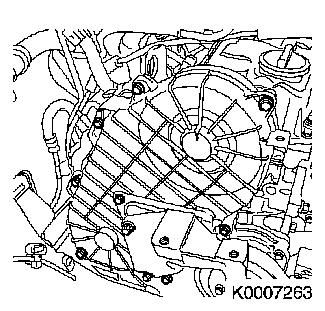

139. Install right engine damping block

- To side member

- Tighten bolts (40 Nm / 29.5 lbf. ft.)

- On engine bracket

- Tighten bolts (60 Nm/44 lbf. ft + 30° + 15°.)

140. Install camshaft housing cover.

- Replace gasket

- Apply adhesive sealant compound (white)

- Caution! Oil return bore (2) must not be covered with adhesive

sealing compound or by the camshaft housing cover gasket

- Tighten bolts, studs (9.8 Nm/7.2 lbf. ft.)

|

|

141. Attach injection nozzle outer seals

- Replace seals

- Note! Note identification

- Tighten bolts

142. Attach injection line

- To diesel injection pump

- To injection nozzles

- Tighten union nuts (22.5 Nm/16.6 lbf. ft.)

143. Fasten left rear engine transport shackles

- Tighten bolt (20 Nm / 15 lbf. ft.)

144. Install right rear engine transport shackles

- Tighten bolt (20 Nm / 15 lbf. ft.)

145. Install engine control unit bracket

- Tighten bolts (24.5 Nm/18.1 lbf. ft.)

- Tighten nut (9.8 Nm/7.2 lbf. ft.)

- Attach wiring harness

146. Install engine control unit

- Tighten bolts, nuts (5.9 Nm/4.4 lbf. ft.)

- Install wiring harness plug bracket

- Connect wiring harness plug.

- Attach wiring harness

147. Connect wiring harness plug for engine control unit

148. Attach wiring trough

- Clip-in wiring trough

- Clip in vacuum lines

- Tighten bolt

149. Install oil dipstick guide tube bracket

- Tighten nuts

- Fasten oil dipstick guide tube

- Clip in vacuum hose

150. Install air intake pipe

- Tighten bolts

- Attach engine vent hose

- Attach wiring harness

151. Install air cleaner housing

- Tighten bolt

- Fasten air intake hose.

- Fasten clamp (3.5 Nm / 2.6 lbf. ft.)

- Connect wiring harness plug to hot film mass air flow

meter

152. Raise vehicle

153. Detach support

154. Detach KM-6169

155. Attach ribbed V-belt cover

- Tighten bolts

- Install clips

156. Lower vehicle

157. Install right front wheel

158. Lower vehicle

159. Fasten right front wheel

- Tighten bolts (110 Nm / 81 lbf. ft.)

160. Check and correct engine oil level

- Check engine oil level, if necessary correct.

- Observe specified engine oil quantity

161. Connect battery

162. Calibrate steering angle sensor

Note: Rotate the

steering wheel one time from its right-hand to its left-hand

stop.

163. Top up coolant

- Note! Top up and bleed cooling system – see operation

"Top up and bleed cooling system"

- Observe specified coolant quantity

164. Program volatile memories

164. Close bonnet

|