|

Valve Clearance, Check and Adjust (Y 17 DTL)

Condition:

Timing checked – see operation "Timing, Check".

|

1. Open bonnet

Important: On

vehicles from model year 04 with ESP - the steering angle sensor

loses its basic adjustment each time the battery is disconnected.

It must be recalibrated.

2. Disconnect battery

|

|

|

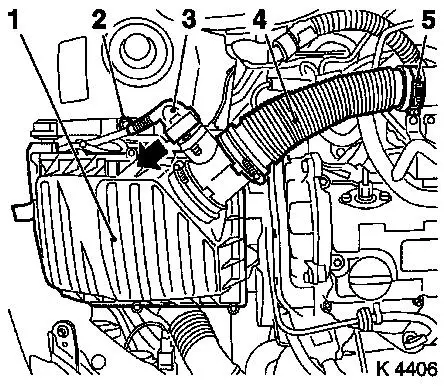

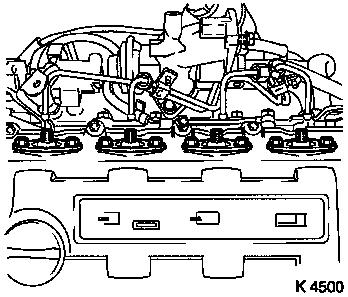

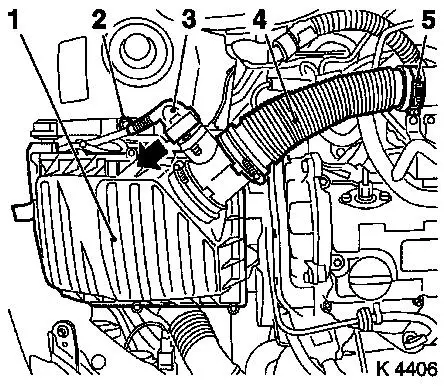

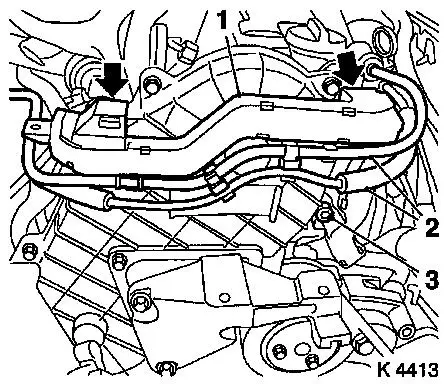

3. Remove air cleaner housing (1)

- Remove wiring harness plug for hot film mass air flow meter

(3)

- Release in direction of arrow

- Remove air intake hose (4)

- Remove bolt (2)

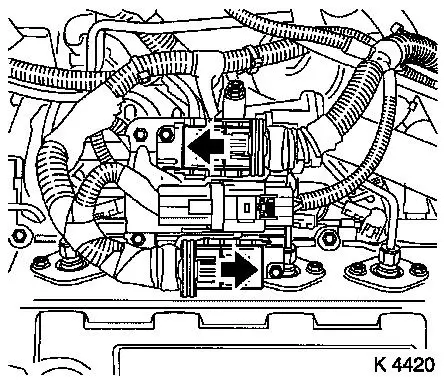

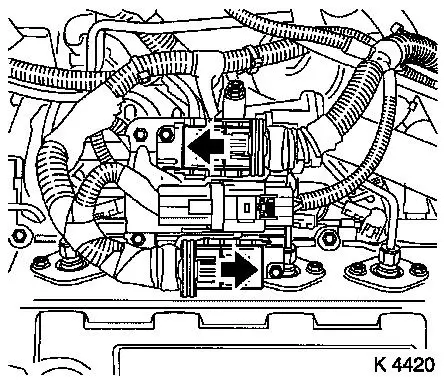

4. Remove wiring harness plug for engine management

- 3 off

- Release 2 wiring harness plugs in direction of arrow

|

|

|

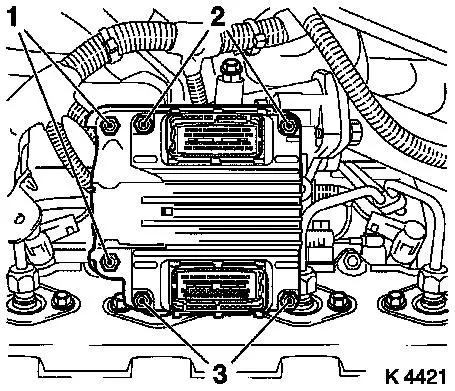

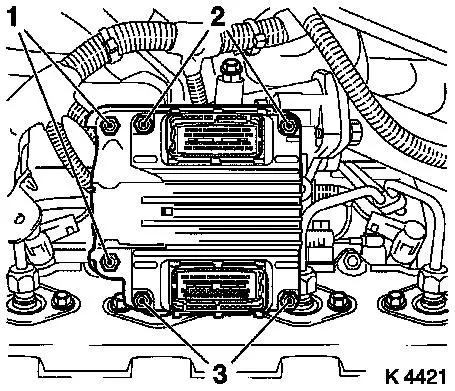

5. Remove engine control unit

- Remove wiring harness plug bracket

- Unscrew 2 bolts (2), 2 nuts (3)

|

|

|

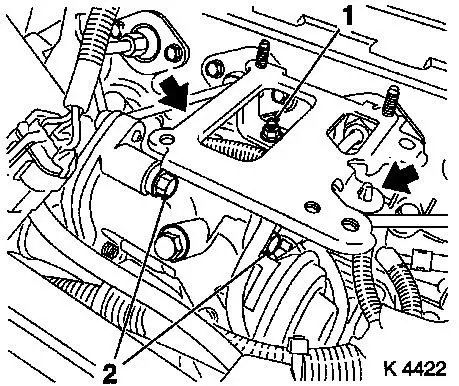

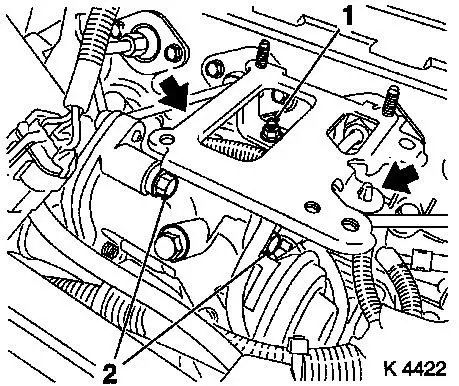

6. Remove engine control unit bracket

- Unscrew 2 bolts (2), nut (1)

- Unclip wiring harness (arrows)

7. Remove right rear engine transport shackle

8. Loosen left rear engine transport shackle

9. Remove injection lines

|

|

|

10. Remove outer injector nozzle seals

11. Remove oil dipstick guide tube bracket

|

|

|

12. Detach alternator wiring harness

- Disconnect wiring harness plug

- Unscrew nut

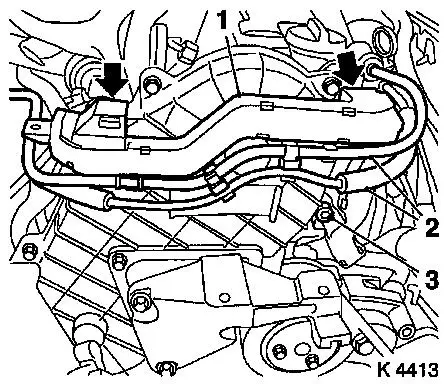

13. Remove wiring trough (1)

- Unclip vacuum lines (2)

- Unclip wiring trough

- Remove bolt

|

|

|

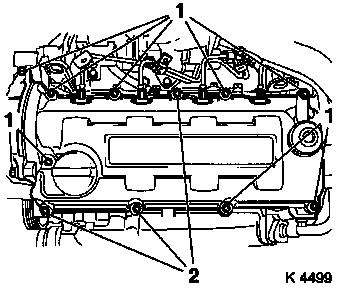

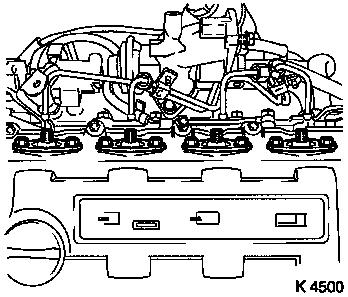

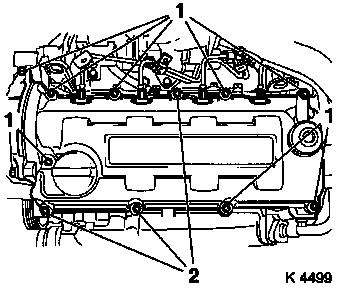

14. Remove camshaft housing cover

- Unscrew 7 bolts (1), 3 studs (2)

15. Remove camshaft housing cover

- Note! 2. mechanic

- Carefully push injection lines to rear

- Remove engine vent hose

|

|

|

16. Detach inner oil leak line

- Remove 5 banjo bolts

- Note! Note sealing rings

17. Remove injector nozzles

- Remove injection nozzle bracket (1)

- Remove injector nozzles

|

|

|

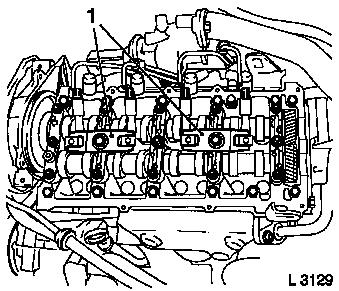

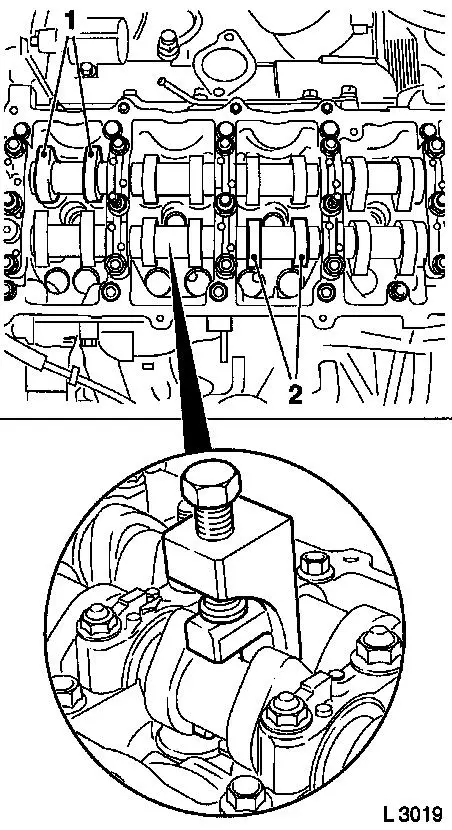

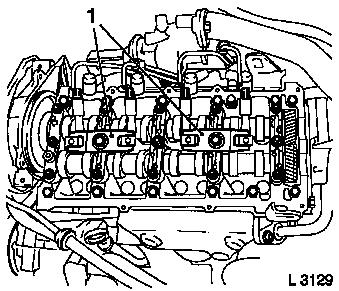

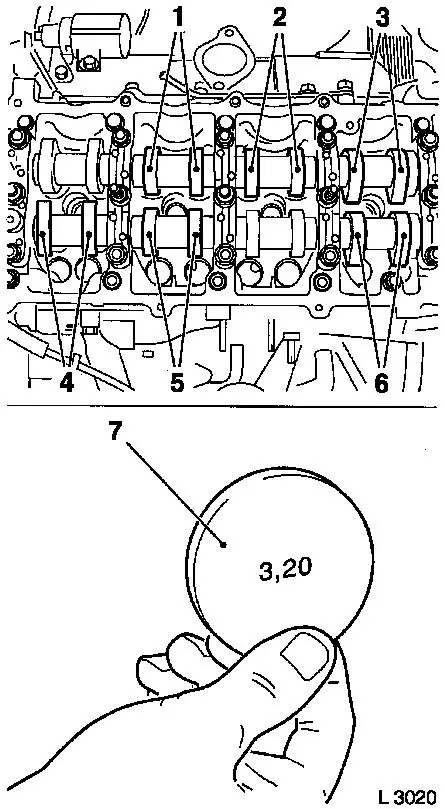

18. Turn crankshaft

- Turn crankshaft until cam pairs (1) and (2) point upwards

19. Check valve clearance

- Using feeler gauge

- Test values: Intake valve/Exhaust valve (0.35 – 0.45

mm)

- Note! The valve clearances are checked on a cold engine –

room temperature

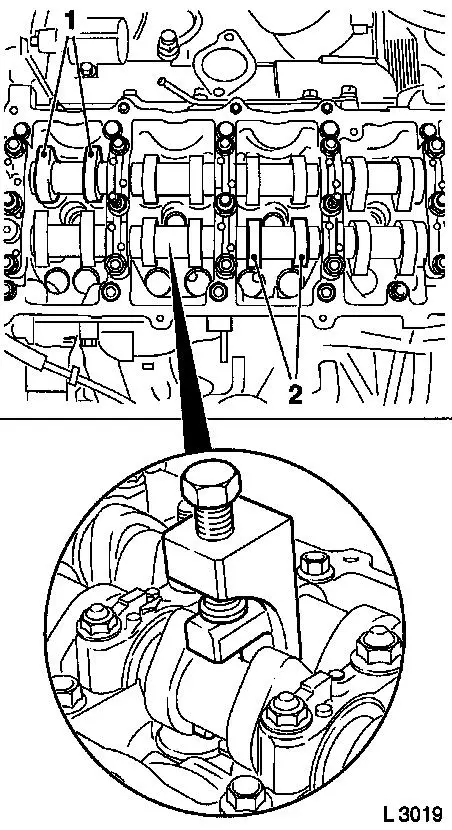

20. Adjust valve clearance

- Turn cup tappet until tappet groove points outwards

- Press down cup tappets using KM-6090

- Note! Note different tool versions for intake and exhaust

valves

- Mark – IN = Intake side

- Mark – EX = Exhaust side

- Caution! Ensure that valves do not interfere with piston

head

- Remove adjustment shim

|

|

|

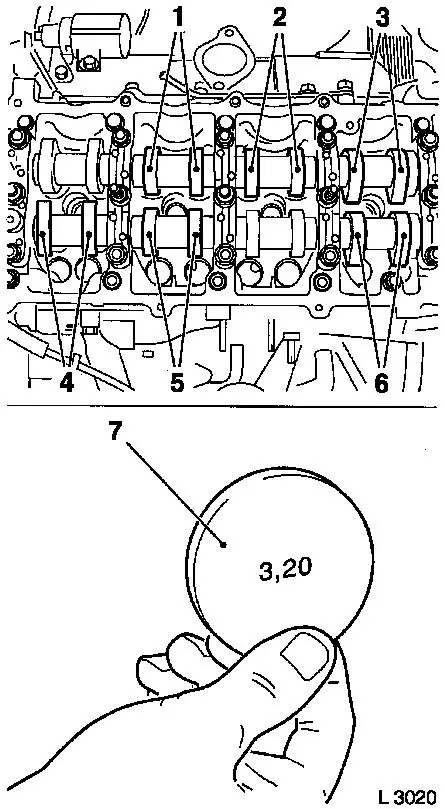

Example for determination of shim

thickness

|

1.

|

Thickness of installed shim

|

|

3.15 mm

|

|

2.

|

Measurement between cam and cup tappets

|

+

|

0.45 mm

|

|

|

|

=

|

3.60 mm

|

|

3.

|

Nominal valve play

|

-

|

0.40 mm

|

|

4.

|

Thickness of new shim

|

=

|

3.20 mm

|

21. Insert adjustment shim

- Coat new shim (7) with engine oil and insert in cup tappet with

identification mark facing downwards.

22. Turn crankshaft

- In direction of engine rotation by 180°

- Check and adjust valve pair (6) and (2)

- In direction of engine rotation by 180°

- Check and adjust valve pair (5) and (3)

- In direction of engine rotation by 180°

- Check and adjust valve pair (4) and (1)

- Note! Valve clearances must be checked again for all adjusted

valves

|

|

23. Install injector nozzles

- Renew seal rings

- Renew copper sealing washers

- Insert injection nozzles in cylinder head.

- Install injector nozzle bracket (22.1 Nm/16.3 lbf. ft.)

24. Attach inner oil leak line

- Renew seal rings

- Tighten banjo bolt (14.7 Nm / 10.8 lbf. ft.)

|

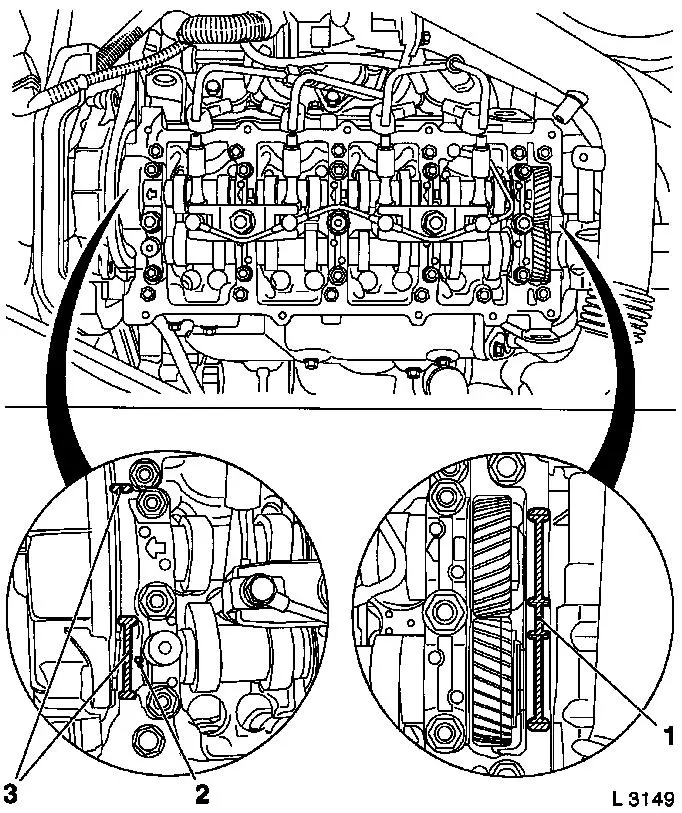

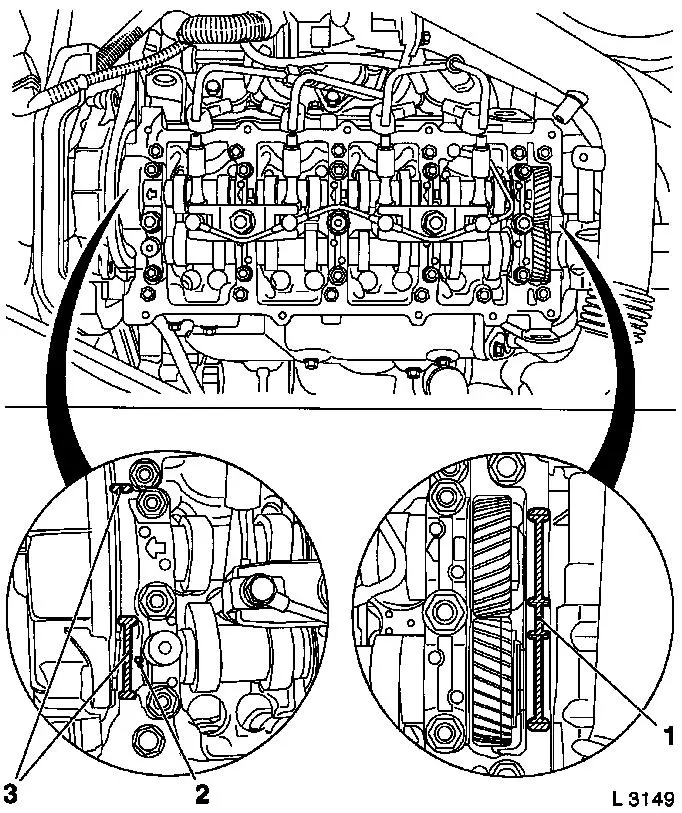

25. Install camshaft housing cover.

- Replace gasket

- Apply adhesive sealant compound (white)

- Caution! Oil return bore (2) must not be covered with adhesive

sealing compound or by the camshaft housing cover gasket

26. Install camshaft housing cover

- Note! 2. mechanic

- Carefully push injection line to rear

27. Tighten camshaft housing cover

- Tighten bolts, studs (9.8 Nm/7.2 lbf. ft.)

28. Attach engine vent hose

|

|

29. Install oil dipstick guide tube bracket

30. Install outer injector nozzle seals

- Replace seals

- Tighten bolts

31. Install injection lines

- Tighten union nuts (22.5 Nm/16.6 lbf. ft.)

32. Fasten left rear engine transport shackle

- Tighten bolts (20 Nm / 15 lbf. ft.)

33. Install right rear engine transport shackle

- Tighten bolts (20 Nm / 15 lbf. ft.)

34. Attach wiring trough

- Clip-in wiring trough

- Clip in vacuum lines

- Tighten bolt

35. Attach alternator wiring harness

- Connect wiring harness plug.

- Tighten nuts

36. Install engine control unit bracket

- Tighten bolts (24.5 Nm/18.1 lbf. ft.)

- Tighten nut (9.8 Nm/7.2 lbf. ft.)

- Attach wiring harness

37. Install engine control unit

- Tighten bolts, nuts (5.9 Nm/4.4 lbf. ft.)

- Install wiring harness plug bracket

38. Attach engine control unit wiring harness plug

39. Install air cleaner housing

- Tighten bolt

- Fasten air intake hose.

- Tighten clamp (3.5 Nm / 2.6 lbf. ft.)

- Connect wiring harness plug to hot film mass air flow

meter

40. Connect battery

41. Calibrate steering angle sensor

Note: Rotate the

steering wheel one time from its right-hand to its left-hand

stop.

42. Program volatile memories

43. Close bonnet

|