|

Camshaft Housing, Replace (Z 17 DTH, without AC,

LHD)

Remove Remove

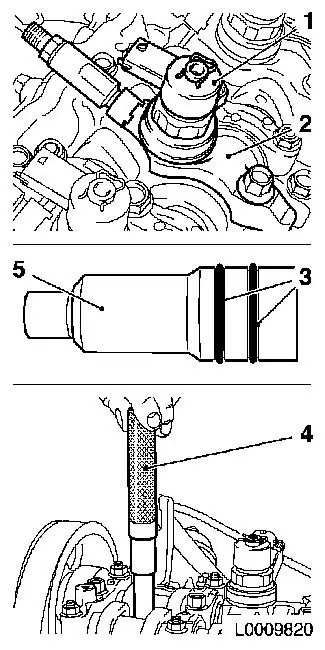

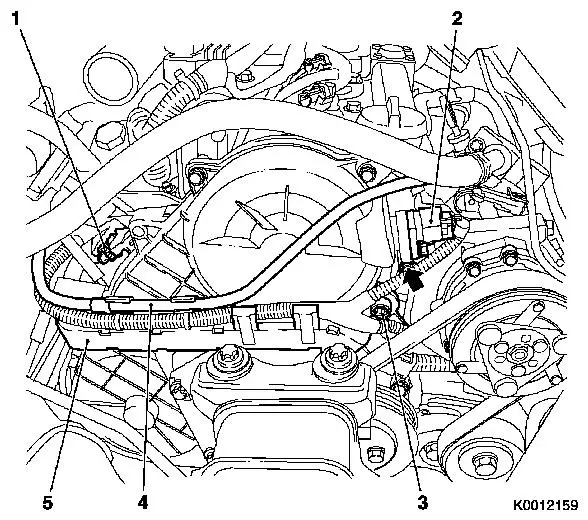

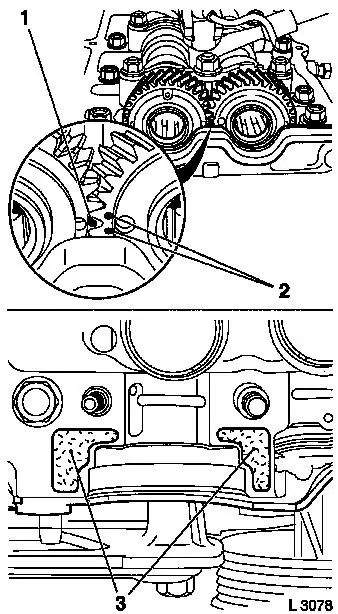

| 1. |

Remove camshaft housing cover

|

| 2. |

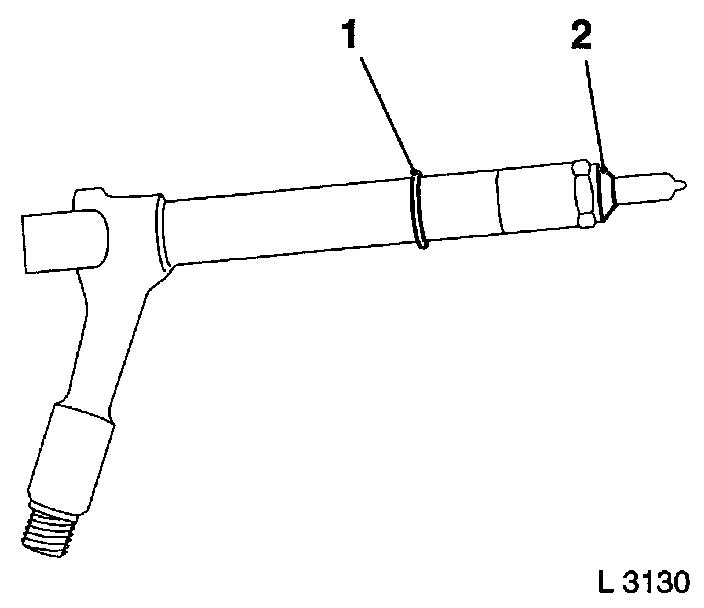

Remove 4 injectors

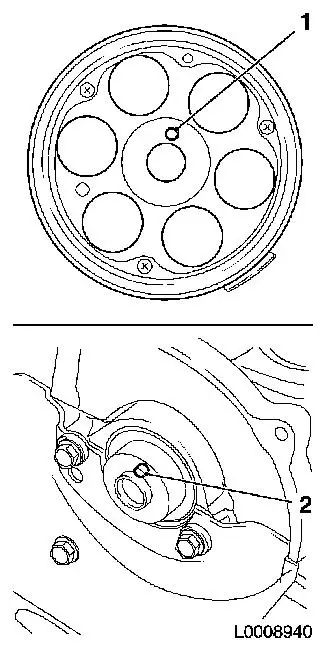

Note: Mark 4x injectors

(1)

Important: If the heat insulation

sleeve (5) is also pulled out together with the injector during

removal, new gaskets (3) must be installed and the heat insulation

sleeve driven into the cylinder head using KM-6357 (4)

|

| • |

Remove 4 injector brackets (2)

|

|

|

|

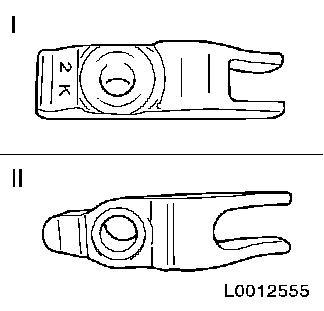

| 3. |

Check injector bracket

Note: If an old

injector bracket was installed, it must be replaced with a new

one

- New injector bracket

- Old injector bracket

|

|

|

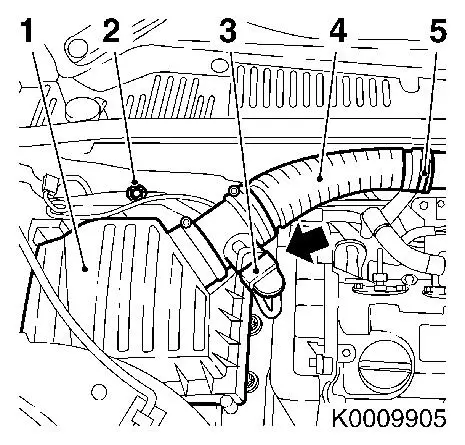

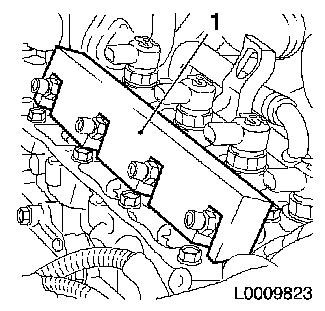

| 4. |

Remove air cleaner housing (1)

| • |

Disconnect wiring harness plug of hot film mass air flow meter

(3)

| – |

Release in direction of arrow

|

|

| • |

Remove air intake hose (4)

|

| • |

Disconnect wiring harness

|

|

|

|

| 6. |

Remove ribbed V-belt cover

|

|

|

|

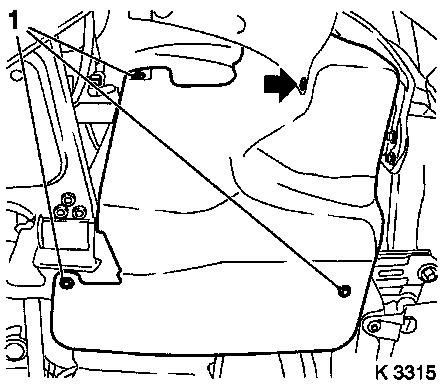

| 7. |

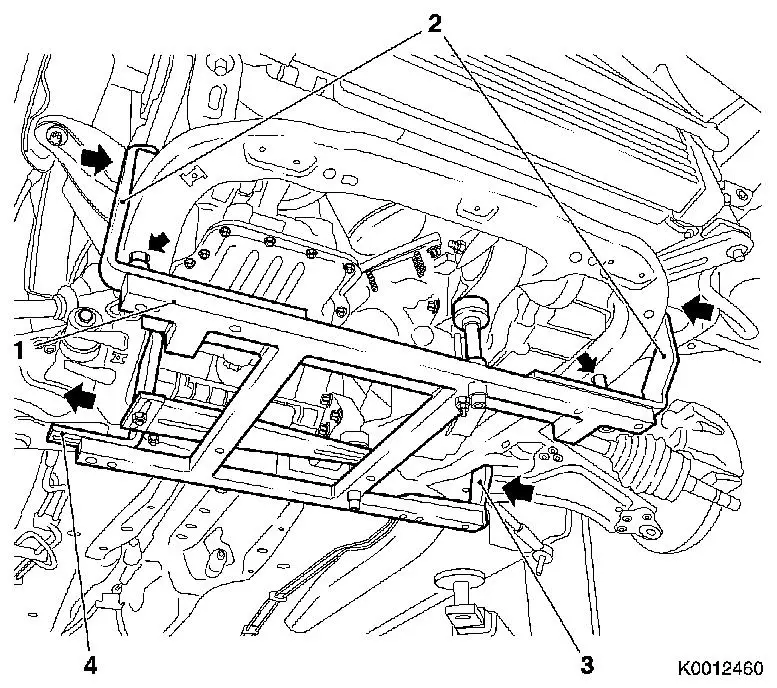

Attach KM-6394

| • |

Position KM-6394 (1) at the front on

the front axle body

Note: Both locating

pins (arrows) must be seated in the holes in the front axle

body

|

| • |

Push front bracket (2) in the direction of the arrow

|

| • |

Place rear bracket (4), right hand side, on front axle body

|

| • |

Attach rear bracket (3), left hand side

|

|

|

|

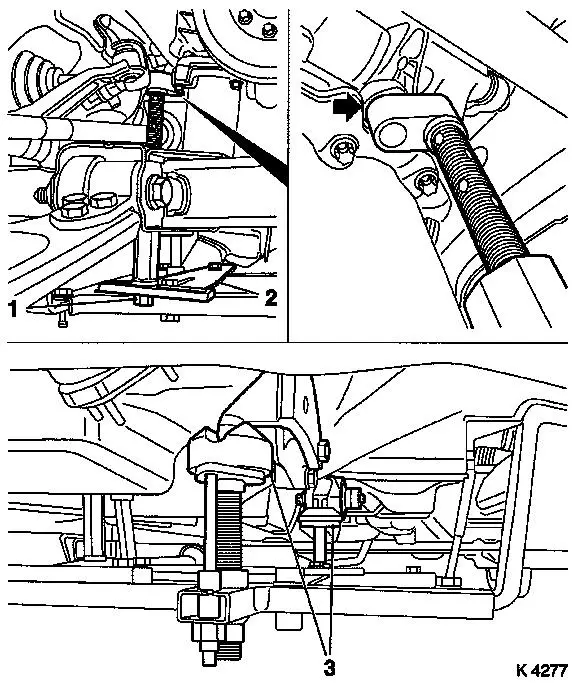

| 8. |

Install support

| • |

On KM-6394

| – |

Adjust bracket (2) for support

|

|

|

| 9. |

Adjust 3x support

| • |

Transmission side

Note: Turn spindles

until mounts (3) are positioned at guide journals free of play

|

| • |

Engine timing side

| – |

Insert journal of the support in the bore of the cylinder block

free of play (arrow)

|

|

|

|

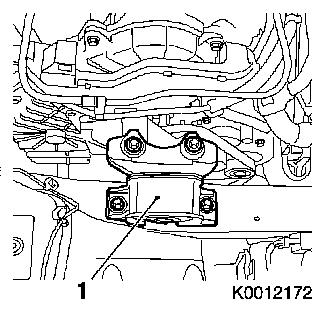

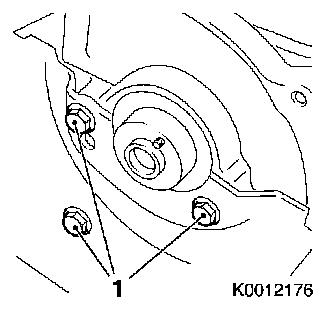

| 11. |

Remove right engine damping block (1)

|

|

|

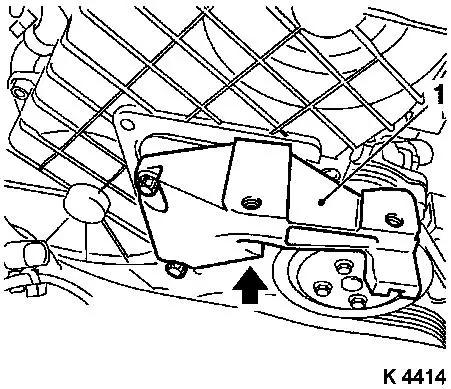

| 12. |

Detach right engine bracket (1)

| • |

Unscrew 3 bolts

Note: Lower bolt cannot

be removed

|

| • |

With right engine bracket adapter

|

|

|

|

|

| 13. |

Detach wiring trough of engine management wiring harness

| • |

Unclip wiring trough (5)

|

| • |

Disconnect 2 wiring harness plugs

| – |

Charge pressure sensor (1)

|

|

|

|

| 14. |

Remove camshaft sensor bracket

|

| 15. |

Remove upper toothed belt cover

Important: Take care not to

damage the increment counter on the camshaft sprocket when removing

the upper toothed belt cover

|

| • |

Unscrew 8 bolts

Note: Pay attention to

different bolt lengths

|

|

|

|

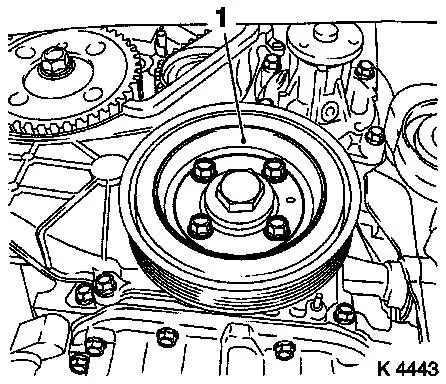

| 17. |

Loosen coolant pump ribbed V-belt pulley (1)

|

|

|

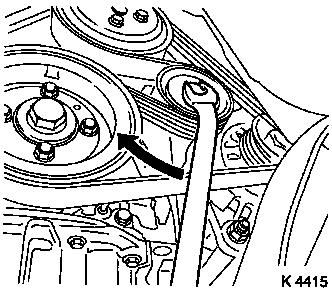

| 18. |

Remove ribbed V-belt

| • |

Tension ribbed V-belt tensioner in direction of arrow

|

| • |

Use KM-913-A

Note: Mark running

direction.

|

|

|

|

| 19. |

Detach coolant pump ribbed V-belt pulley

|

| 20. |

Remove torsional vibration damper (1)

|

|

|

| 21. |

Detach lower part of toothed belt cover

|

|

|

| 22. |

Remove right engine bracket with right engine bracket

adapter

|

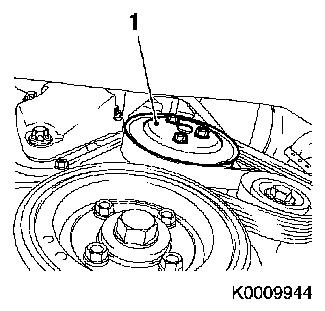

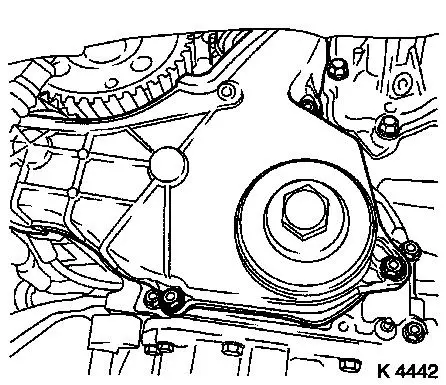

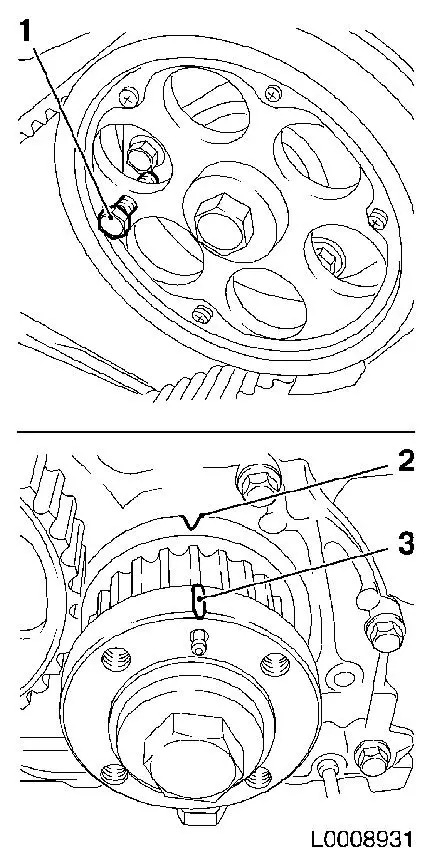

| 24. |

Set 1st cylinder to TDC

| • |

Turn crankshaft evenly until TDC fixing bolt (1) can be screwed

in

Note: Mark (3) on

toothed belt drive gear must align with mark (2) on oil pump

cover

|

|

|

|

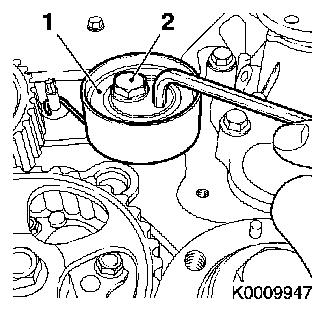

| 26. |

Loosen toothed belt tension roller (1)

| • |

Loosen bolt of toothed belt tension roller (2)

|

| • |

Rotate toothed belt tension roller anticlockwise approx.

90°

|

| • |

Tighten bolt of toothed belt tension roller

|

|

|

|

| 27. |

Remove toothed belt

Note: Mark running

direction.

|

| 28. |

Remove toothed belt guide roller

|

| 30. |

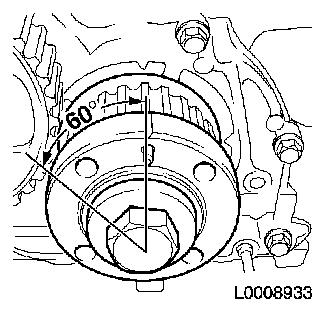

Rotate crankshaft 60° against direction of engine

rotation

|

|

|

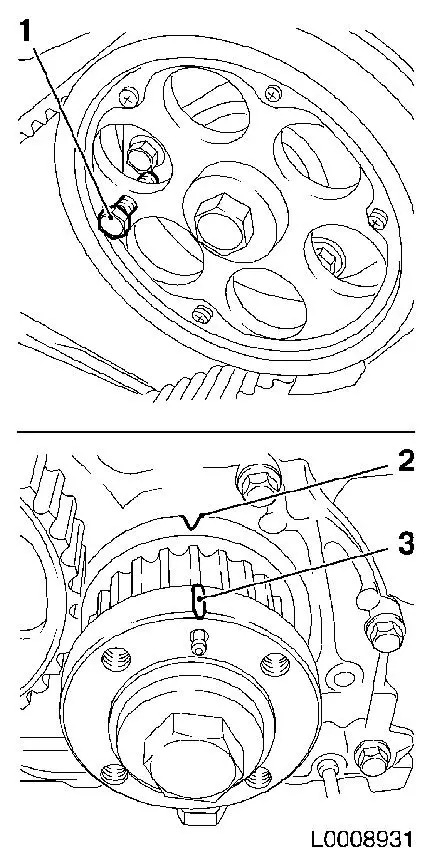

| 31. |

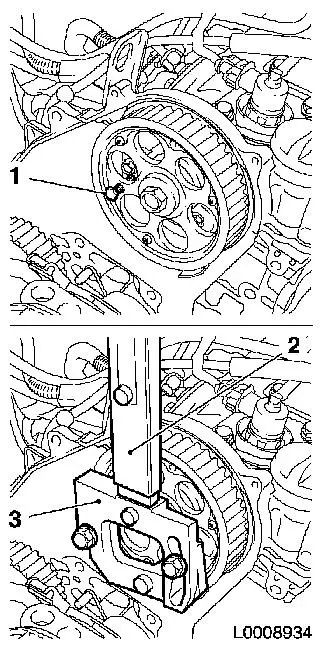

Detach camshaft pulley

| • |

Unscrew TDC fixing bolt (1)

|

| • |

Use KM-6347 (3) in combination with

KM-956-1 (2)

|

|

|

|

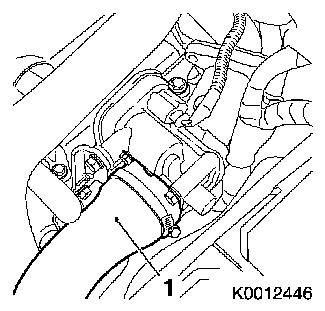

| 32. |

Detach connection hose (1) from intercooler for intake pipe

|

|

|

|

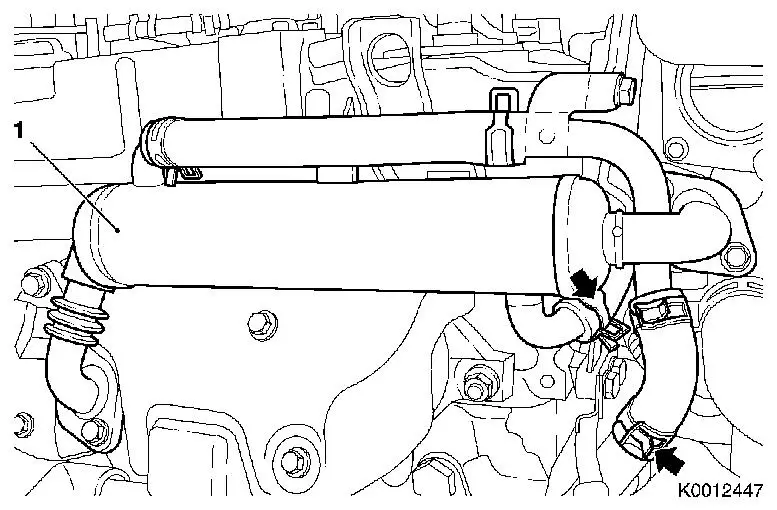

| 33. |

Detach EGR cooler (1)

| • |

Release 2 clamps (arrows)

|

|

|

| 34. |

Front left engine transport shackle

|

| 35. |

Remove throttle valve module bracket

|

| 36. |

Detached rear toothed belt cover from camshaft housing

|

|

|

|

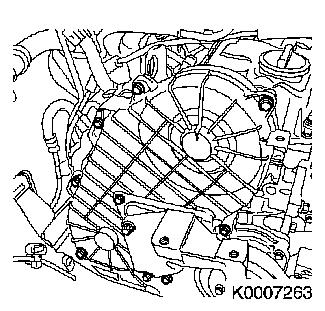

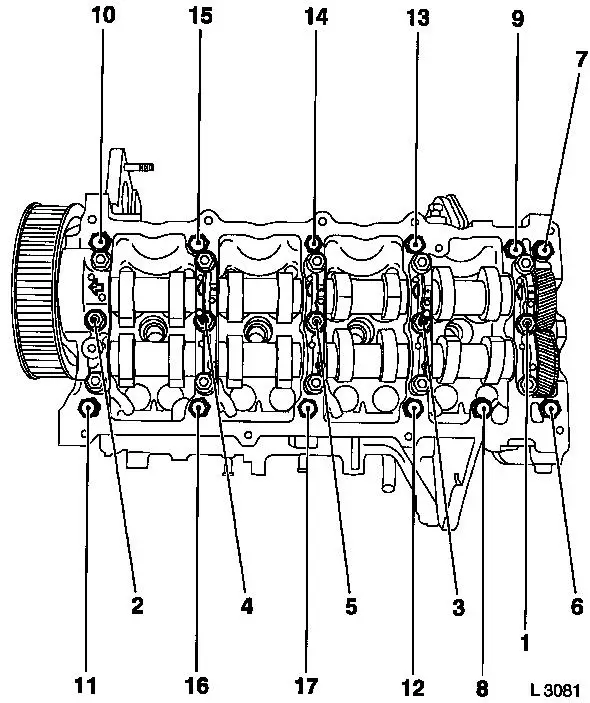

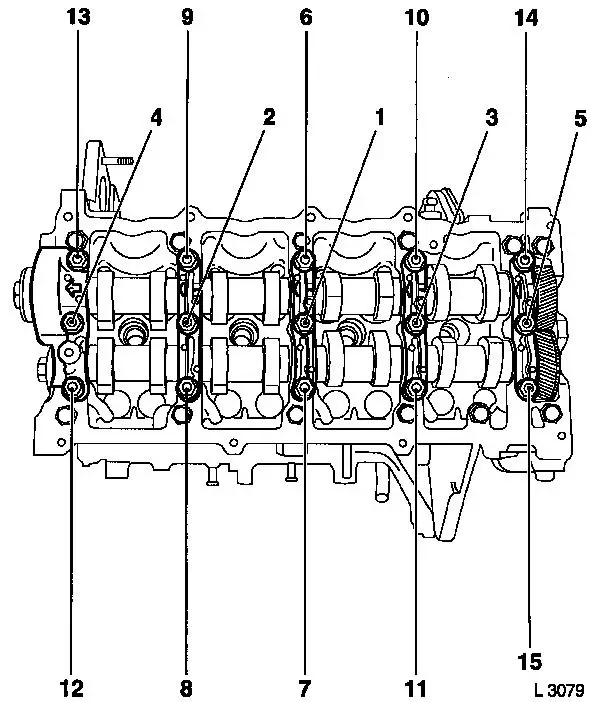

| 37. |

Remove camshaft housing

| • |

Loosen 17 bolts 1/2 turn in sequence illustrated and

unscrew

|

|

|

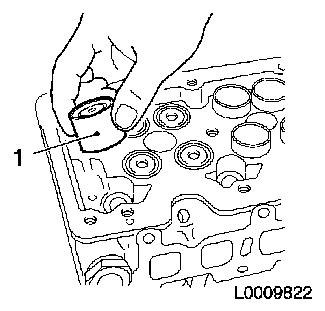

| 38. |

Remove 16 cup tappets (1)

Note: Note order and

installation position

|

|

|

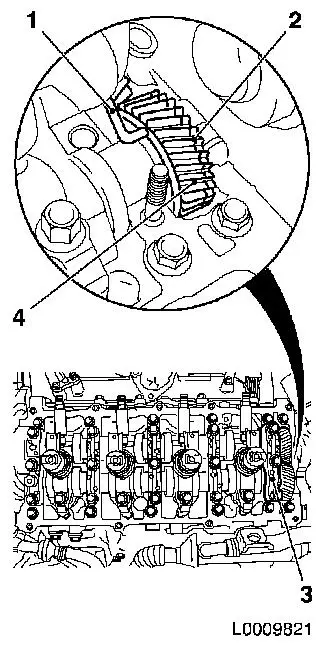

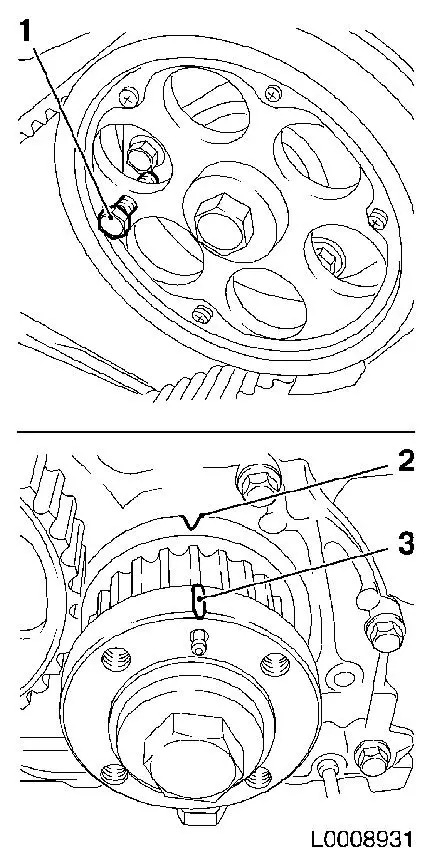

| 39. |

Lock exhaust camshaft compensating sprocket

| • |

Remove camshaft bearing cap (3)

|

| • |

Use KM-6092-10 (1)

Note: Insert into

exhaust camshaft sprocket (4) and exhaust camshaft compensating

sprocket (2) as far as it will go. Exhaust camshaft sprocket and

exhaust camshaft compensating sprocket must be locked so they

cannot turn

|

|

|

|

| 40. |

Remove 2x camshaft

Note: Note markings on

camshaft bearing caps

| • |

Remove front camshaft seal ring

|

|

| 41. |

Clean sealing surfaces

|

Install

Install

Important: When installing the

camshafts, care must be taken that the marking (1) on the exhaust

camshaft sprocket is between the two markings (2) for the intake

camshaft sprocket and that the markings are approximately on the

same level as the upper edge of the camshaft housing.

|

| 43. |

Install 2x camshaft

| • |

Insert camshaft in camshaft housing

|

| • |

Apply surface sealant (green) to the sealing surfaces (3) of

the 1st camshaft bearing cap

|

|

|

|

|

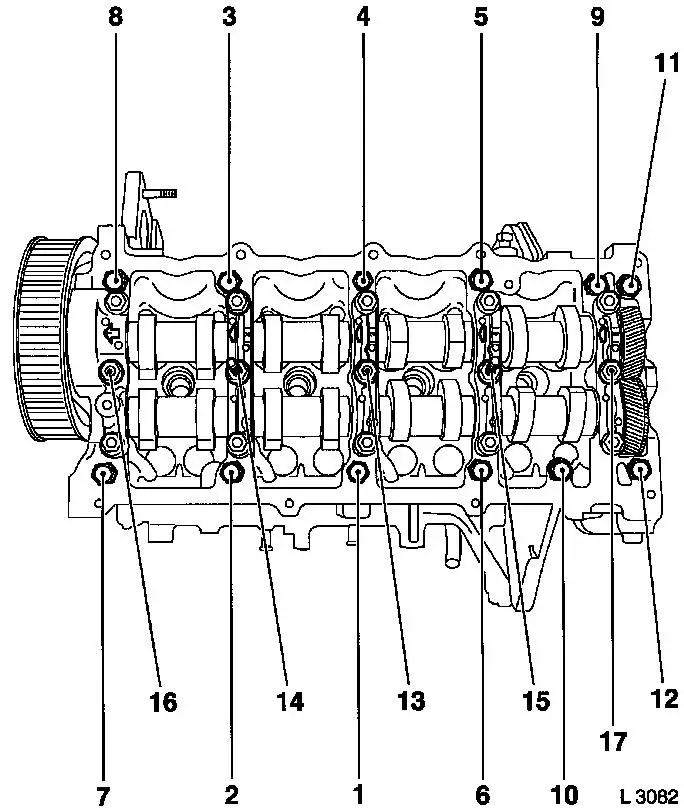

| 44. |

Install 5 camshaft bearing caps

Note: Coat bearing

positions with engine oil

| • |

Fit camshaft bearing caps (1 - 4)

|

| • |

Fit camshaft bearing cap (5)

|

| • |

Tighten camshaft bearing caps

| – |

10 nuts (M8) 21.6 Nm

Note: Tighten camshaft

bearing caps in stages of 1/2 to 1 turn in the order shown

|

|

|

|

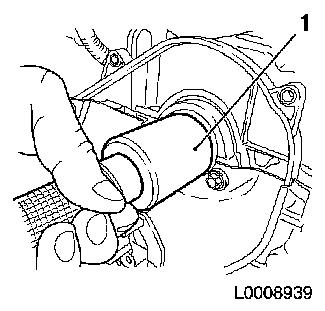

| 45. |

Install front camshaft seal ring

|

|

|

| 46. |

Insert 16x cup tappet

Note: Observe

allocation.

|

|

| 47. |

Install camshaft housing

| • |

Replace gasket

Note: Note tightening

sequence (1 - 17)

| – |

Tighten 12 bolts 21.6 Nm

|

| – |

Tighten 5 bolts 26.5 Nm

|

|

|

|

| 48. |

Attach rear toothed belt cover

|

| 49. |

Install bracket for throttle valve module

|

| 50. |

Install front left engine transport shackle

|

| 51. |

Attach EGR cooler

| • |

To connection, exhaust return pipe, exhaust manifold

| – |

Tighten 4 bolts 28.5 Nm

|

|

|

| 52. |

Attach connection hose of intercooler to intake pipe

|

Warning: The different camshaft

sprockets (with different part numbers) have different torques for

the camshaft sprocket bolt.

|

| 53. |

Attach camshaft sprocket with part number 97320335

| • |

Camshaft journal (2) must engage in the bore in the camshaft

sprocket (1)

|

| • |

Use KM-6347 in combination with KM-956-1

|

| • |

Install TDC-fixing bolt

|

|

| 54. |

Attach camshaft sprocket with part number 98021306

| • |

Camshaft journal (2) must engage in the bore in the camshaft

sprocket (1)

|

| • |

Use KM-6347 in combination with KM-956-1

|

| • |

Install TDC-fixing bolt

|

|

|

|

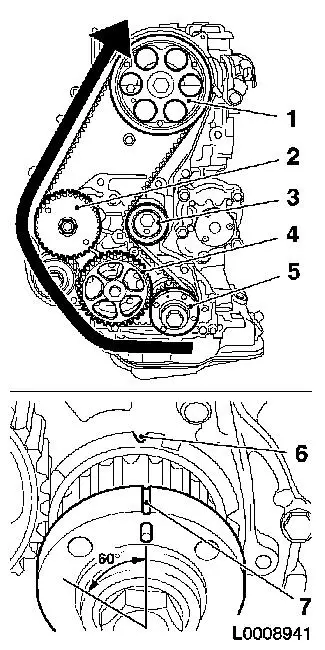

| 56. |

Rotate crankshaft to 1st cylinder TDC

| • |

Mark on toothed belt drive gear (3) must align with cast lug

(2) on oil pump cover

|

|

|

|

| 57. |

Install toothed belt

Note: TDC locking bolt

must be installed in the camshaft sprocket and marking (6) and (7)

must align.

| • |

Position toothed belt

| – |

Toothed belt must be tensioned in the direction of the arrow

from the toothed belt drive gear (5) via the oil pump drive gear

(4), via the high pressure pump drive gear (2) to the camshaft

sprocket (1)

|

|

| • |

Loosen toothed belt tension roller (3)

|

| • |

Remove TDC locking bolt

|

| • |

Rotate crankshaft 60° against direction of engine

rotation

|

| • |

Tighten toothed belt tension roller 38Nm

|

|

|

|

| 58. |

Timing, Check

| • |

Turn crankshaft approx. 780° in direction of engine

rotation

|

| • |

Mark on toothed belt drive gear (3) must align with cast lug

(2) on oil pump cover

|

| • |

Screw in TDC fixing bolt (1)

Note: If the TDC fixing

bolt cannot be screwed in, basic adjustment must be repeated

|

| • |

Unscrew TDC fixing bolt

|

|

|

|

| 60. |

Install right engine bracket

| • |

Fit right engine bracket with adapter

|

| • |

Insert and tighten lower bolt

|

|

| 61. |

Attach lower part of toothed belt cover

|

| 62. |

Install torsional vibration damper

| • |

Tighten 4 bolts 19.6 Nm

|

|

| 63. |

Attach coolant pump ribbed V-belt pulley

|

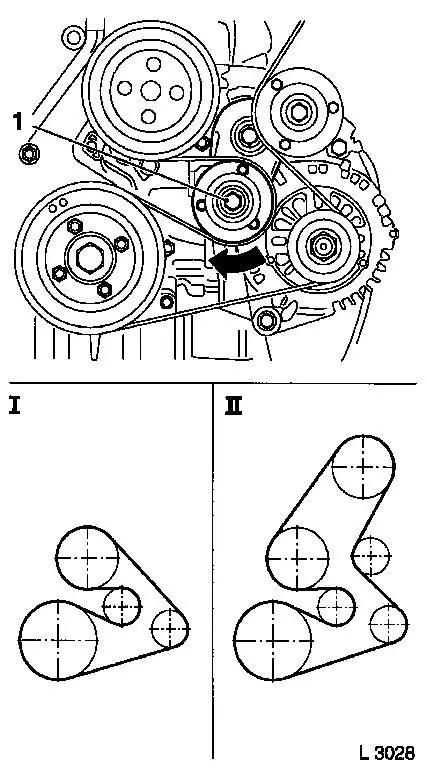

| 64. |

Install ribbed V-belt

Note: Observe running

direction and installation position

| • |

Relieve tension of ribbed V-belt tensioner (1) in the direction

of the arrow

|

| • |

Use KM-913

| – |

I Ribbed V-belt without AC

|

| – |

II Ribbed V-belt with AC

|

|

|

|

|

| 65. |

Fasten coolant pump ribbed V-belt pulley

| • |

Tighten 3 bolts 16.3 Nm

|

|

| 67. |

Install camshaft sensor bracket

|

| 68. |

Install upper toothed belt cover

| • |

Tighten 8 bolts 9.8 Nm

Note: Note different

bolt lengths

|

|

| 69. |

Attach wiring trough of engine management wiring harness

| • |

Connect 2 wiring harness plugs

|

|

| 70. |

Fasten right engine bracket

| • |

Tighten 2 upper bolts 40 Nm

|

|

| 71. |

Install right engine damping block

| • |

On engine bracket

| – |

Tighten 2 bolts 60 Nm + 30° +

15°

|

|

|

| 73. |

Fasten right engine bracket

| • |

Tighten lower bolt 40 Nm

|

|

| 76. |

Attach ribbed V-belt cover

|

| 78. |

Install air cleaner housing

| • |

Fasten air intake hose.

|

| • |

Connect wiring harness plug of hot film mass air flow meter

|

|

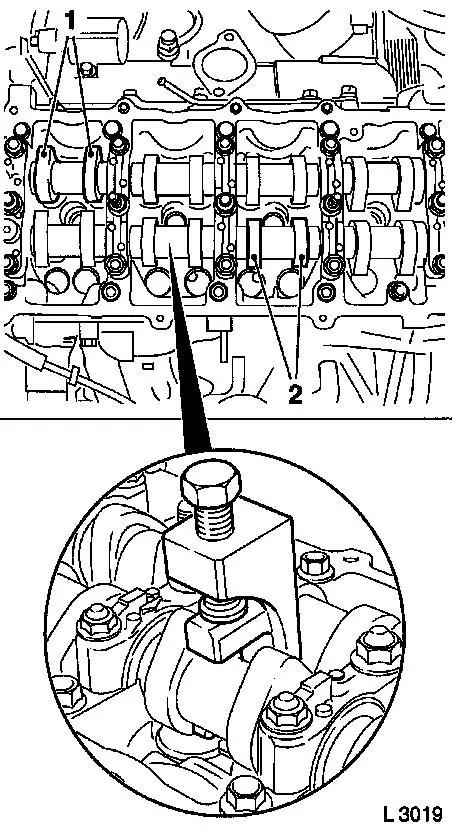

| 79. |

Turn crankshaft

| • |

Turn crankshaft until cam pairs (1) and (2) point upwards

|

|

|

|

| 80. |

Check valve clearance

| • |

Using feeler gauge

Note: The valve play is

checked on a cold engine – room temperature.

| – |

Test values: Intake valves/Exhaust valves (0.35 – 0.45

mm)

|

|

|

| 81. |

Adjust valve clearance

| • |

Turn cup tappet until tappet groove points outwards

|

Important: Make sure that the

valves are not set when the piston is in "TDC". The valves could

strike the piston head

|

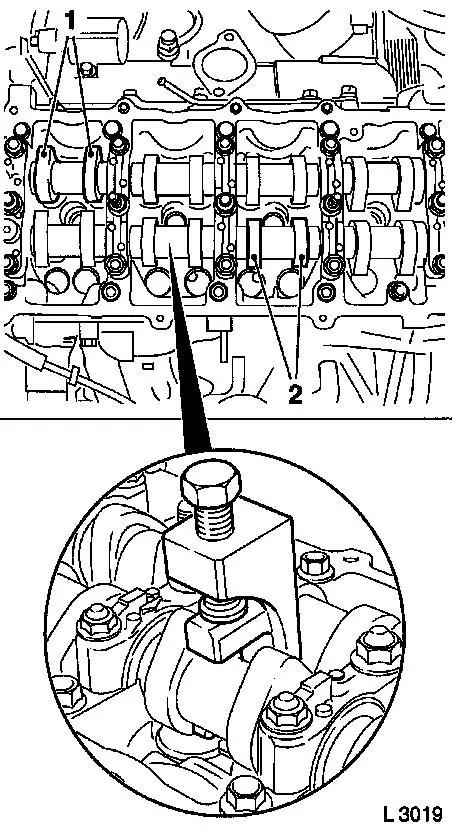

| • |

Press down cup tappets

Note: Note different

tool versions for intake and exhaust valves

| – |

Mark – IN = Intake side

|

| – |

Mark – EX = Exhaust side

|

|

|

|

|

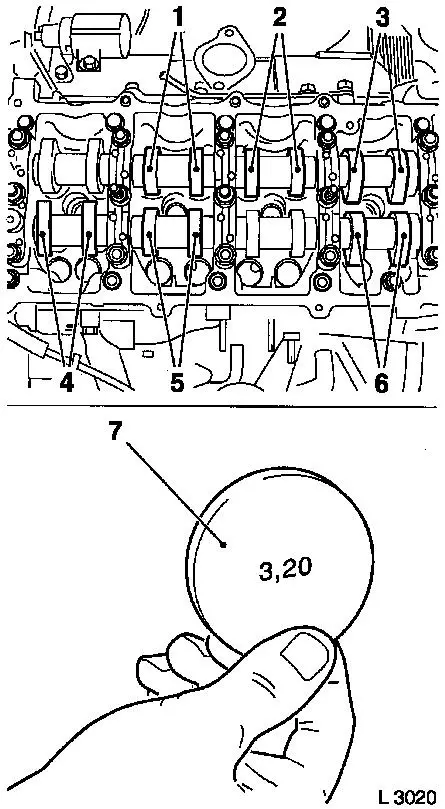

| 82. |

Example for determination of shim thickness:

|

1. Thickness of installed shim

|

3.15 mm

|

|

2. Measurement between cam and cup tappets

|

+ 0.45 mm

|

| |

= 3.60 mm

|

|

3. Nominal valve clearance

|

- 0.40 mm

|

|

| 83. |

Insert adjustment shim

| • |

Coat new shim (7) with engine oil and insert in cup tappet with

identification mark facing downwards

|

|

| 84. |

Turn crankshaft

| • |

In direction of engine rotation by 180°

| – |

Check and adjust valve pair (6) and (2)

|

|

| • |

In direction of engine rotation by 180°

| – |

Check and adjust valve pair (5) and (3)

|

|

| • |

In direction of engine rotation by 180°

| – |

Check and adjust valve pair (4) and (1)

Note: The clearance of

all adjusted valves must be re-checked

|

|

|

|

|

| 85. |

Detach accumulator

| • |

Unscrew 2x bolts 1 - 1 1/2 turns

|

|

| 86. |

Replace 8 injector seals

| • |

4 copper seal rings (2)

|

|

|

|

| 87. |

Install 4 injectors

| • |

Install 4x brackets

| – |

Align injectors with EN-48560 (1)

|

|

|

|

|

| 88. |

Fasten 4x accumulator high pressure lines to injectors

| • |

Hand-tighten 8x union nuts

|

|

| 89. |

Fasten 4x injectors

| • |

Tighten 4 bolts in three stages

|

|

|

|

| 91. |

Remove 4x accumulator high pressure lines at injectors

| • |

Seal off connections of accumulator using suitable sealing

plugs

|

| • |

Seal off connections of injectors with protective caps

|

|

| 92. |

Install camshaft housing cover

Note: See operation

"Camshaft Housing Cover, Remove".

|

|