|

Replace valve stem seals

Remove Remove

| 1. |

Remove camshaft housing

|

| 2. |

Remove roller cam follower with hydraulic valve lifter

|

| 3. |

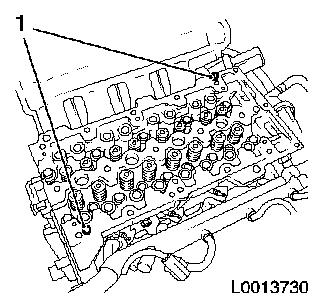

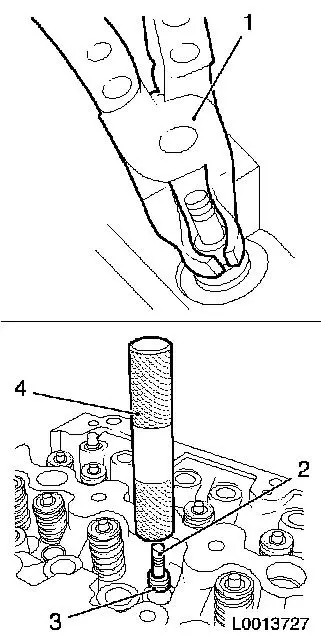

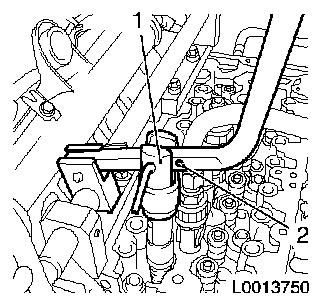

Remove 2 x camshaft housing centring pins (1)

|

|

|

| 4. |

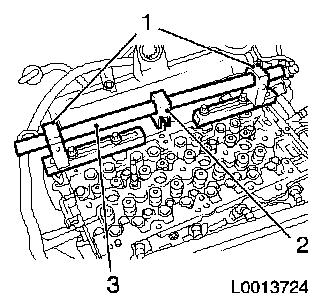

Attach MKM-6086

| • |

Adjust 2 supports MKM-6086-6 1

| – |

Set support heads on outside of support feet

|

|

| • |

Slide joint MKM-6086-8 (2) onto

mounting shaft MKM-6086-4 (3)

| – |

Slide 2 supports MKM-6086-6 onto the

mounting shaft MKM-6086-4

|

|

| • |

Attach both supports with the mounting shaft to the cylinder

head

Important: Note screw length of

blind hole thread

|

| – |

Screw in 4 bolts

|

|

|

|

|

Important: Note screw length of

blind hole thread

|

| 5. |

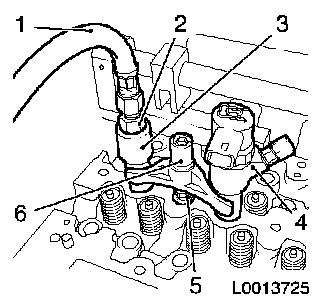

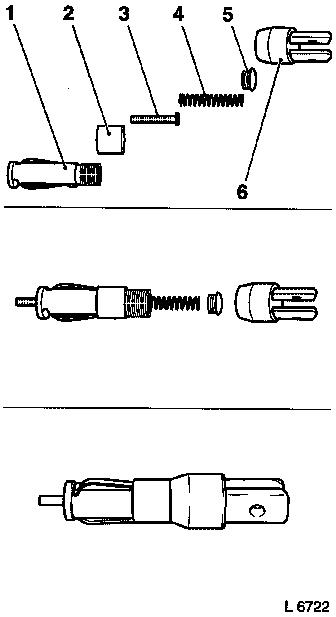

Attach EN-46782 together with EN-46783 (2) and MKM-6086-17 (1) to cylinder 1

| • |

Fit EN-46782 with gasket and injector

(4) on cylinder 2

|

|

|

|

| 6. |

Attach lever arm

| • |

Attach lever arm MKM-6086-7 (3)

together with adapter MKM-6086-12 (2) and

removal head MKM-6086-11 (4) to joint

MKM-6086-8 (1)

|

|

Important: Check that compressed

air is being applied

|

| 7. |

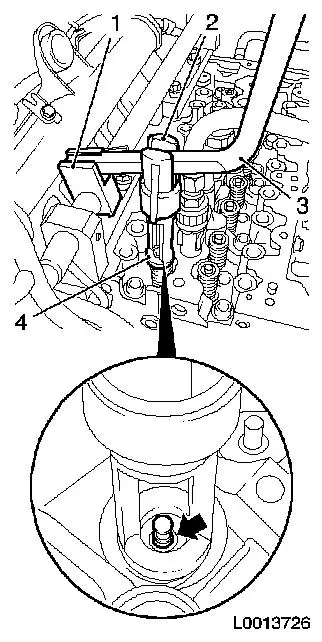

Remove 2 cylinder no.1 intake valve springs

Important: Removal head must be

vertically above the valve stem

|

| • |

Carefully push valve spring down with lever arm MKM-6086-7

|

| • |

Remove 2 split cotters (arrow)

|

| • |

Remove valve heads and valve springs

|

|

|

|

| 8. |

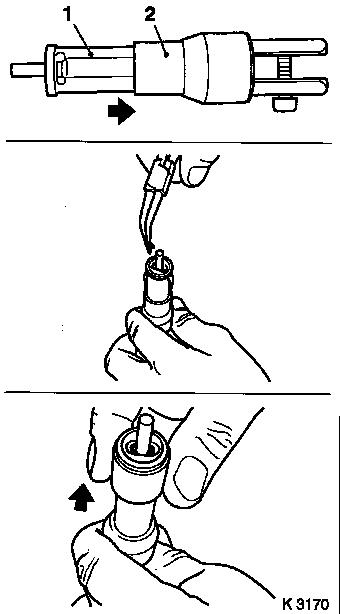

Replace 2x valve stem seals

| • |

Detach using KM-840 (1)

|

| • |

Attach new valve stem seal (3) to valve stem (2)

Note: Moisten new valve

stem seals with oil.

|

| • |

Using EN-46779 (4), drive in as far

as the stop

|

|

|

|

| 9. |

Complete the assembly head MKM-6086-100-1

Note: Follow

manufacturer's instructions.

| • |

Assemble the assembly head, which consists of a mount (1),

securing sleeve (2), thrust piece MKM-6086-13 (3), spring (4), screwed connection (5)

and lever mount MKM-6086-12 (6)

|

|

|

|

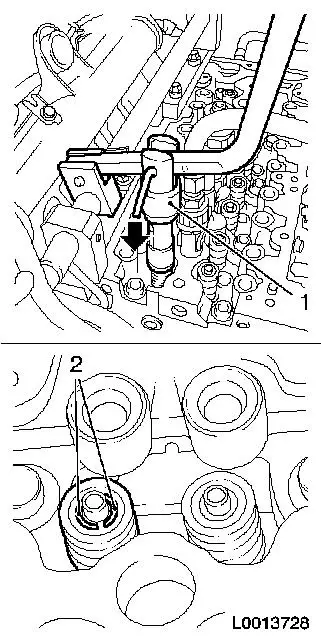

| 10. |

Install 2 intake valve springs, cylinder 1

| • |

Insert valve springs and caps

|

| • |

Insert valve keepers in assembly head MKM-6086-100-1 (1)

Important: Insert valve keepers

with taper facing the valve.

|

| – |

Slide clamping sleeve (2) in direction of lever arm mount

|

| – |

Push clamping sleeve towards valve

|

|

| • |

Attach assembly head to lever arm

|

|

|

|

Important: Check that compressed

air is being applied

|

| 11. |

Install valve keepers

Important: Assembly head (1) must

be vertically above the valve stem. Valve keepers (2) must engage

audibly.

|

| • |

Carefully push valve springs downwards (arrow)

|

Important: Do not make 2nd

attempt without checking that both valve keepers are in the

assembly head.

|

| • |

Check seat of valve keepers (2)

|

|

|

|

| 12. |

Attach removal head MKM-6086-11 to

adapter MKM-6086-12 .

|

| 13. |

Mount adapter (1) on hole (2)

|

|

|

| 14. |

Remove 2 valve springs from cylinder 1 exhaust valve

|

| 15. |

Replace valve stem seal

|

| 16. |

Attach removal head MKM-6086-100-1 to

adapter MKM-6086-12 .

|

| 17. |

Install 2 valve springs to cylinder 1 exhaust valve

|

| 18. |

Attach EN-46783 to cylinder 2

| • |

Interrupt compressed air feed

|

| • |

Remove EN-46782 with injector from

cylinder 2

|

| • |

Install EN-46782 in cylinder 2

| – |

Insert cylinder 1 with injector

|

|

| • |

Apply compressed air to cylinder 2

|

|

| 19. |

Remove 2 valve springs from cylinder 1 exhaust valve

|

| 20. |

Replace valve stem seal

|

| 21. |

Install 2 valve springs to cylinder 1 exhaust valve

|

| 23. |

Remove 2 valve springs from cylinder 2 intake valve

|

| 24. |

Replace valve stem seal

|

| 25. |

Install 2 valve springs in cylinder 2 intake valve

|

| 26. |

Attach EN-46783 to cylinder 3

| • |

Interrupt compressed air feed

|

Important: Note screw length of

blind hole thread

|

| • |

Remove EN-46782 with injector from

cylinder 1

|

| • |

Install EN-46782 with gasket in

cylinder 3

| – |

Insert in cylinder 4 together with injector

|

|

| • |

Apply compressed air to cylinder 3

|

|

| 27. |

Remove 2 valve springs from cylinder3 intake valve

|

| 28. |

Replace valve stem seal

|

| 29. |

Install 2 valve springs in cylinder 3 intake valve

|

| 31. |

Remove 2 valve springs from cylinder 3 exhaust valve

|

| 32. |

Replace valve stem seal

|

| 33. |

Install 2 valve springs to cylinder 3 exhaust valve

|

| 34. |

Attach EN-46783 to cylinder 4

| • |

Interrupt compressed air feed

|

| • |

Remove EN-46782 with injector from

cylinder 4

|

| • |

Install EN-46782 in 4th cylinder

| – |

Insert cylinder 3 with injector

|

|

| • |

Apply compressed air to cylinder 4

|

|

| 35. |

Remove 2 valve springs from cylinder 4 exhaust valve

|

| 36. |

Replace valve stem seal

|

| 37. |

Install 2 valve springs to cylinder 4 exhaust valve

|

| 39. |

Remove 2 valve springs from cylinder 4 intake valve

|

| 40. |

Replace valve stem seal

|

| 41. |

Install 2 valve springs in cylinder 4 intake valve

|

| 42. |

Remove EN-46783 from cylinder 4

| • |

Interrupt compressed air feed

|

| • |

Remove EN-46782 with injector from

cylinder 3

|

|

Install

Install

| 44. |

Insert 2 camshaft housing centring pins

|

| 45. |

Install roller cam follower with hydraulic valve lifter

|

| 46. |

Install camshaft housing

|

|