Corsa C

|

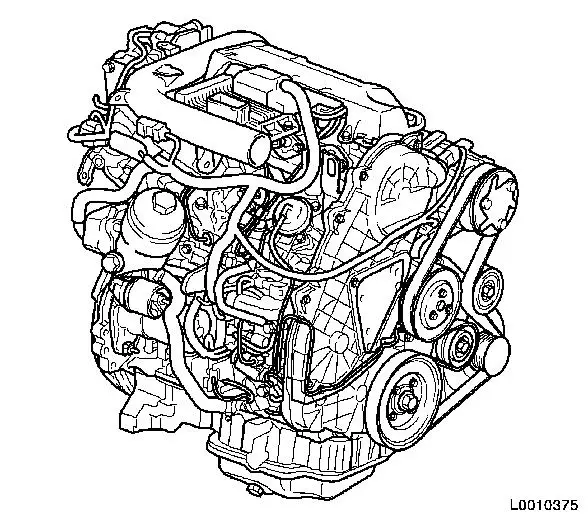

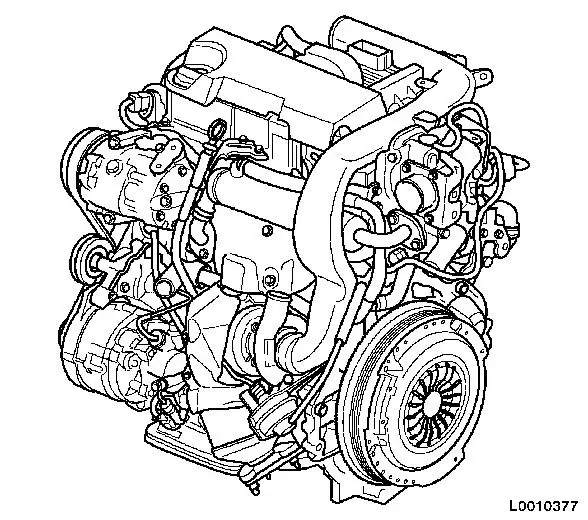

Z 17 DTH DOHC diesel engine Model year 2004 will see the introduction of the Z 17 DTH engine for the Corsa-C and Meriva. The Z 17 DTH engine is a further enhancement of the familiar Z 17 DTL engine fitted in the Astra-G.

The main changes to the Z 17 DTH engine, compared with the Z 17 DTL engine, at a glance:

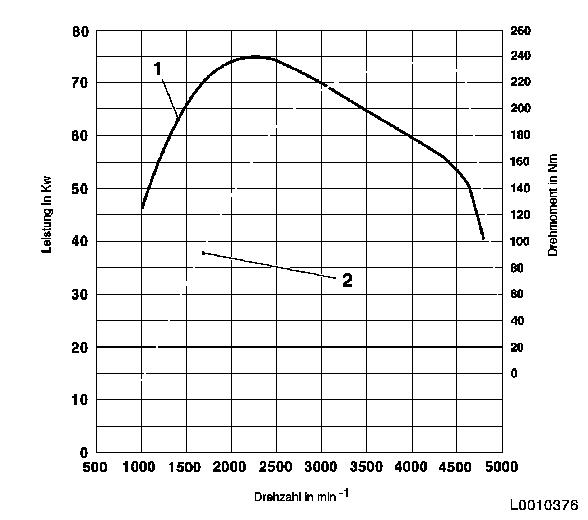

Power curve

Engine-specific data

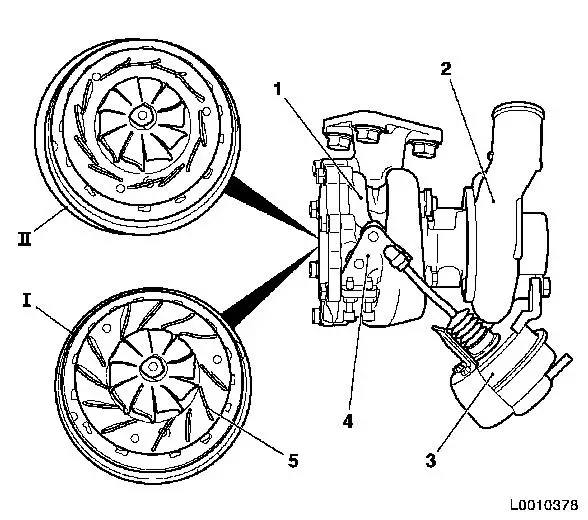

Turbocharger The Z 17 DTH engine is fitted with a turbocharger which operates with variable turbine inlet geometry. Thanks to the VNT (variable nozzle turbine), charge pressure control can be adapted depending on load and engine speed by adjusting the guide vanes in the exhaust gas turbine. The guide vanes are adjusted by a vacuum unit actuated by means of a solenoid valve.

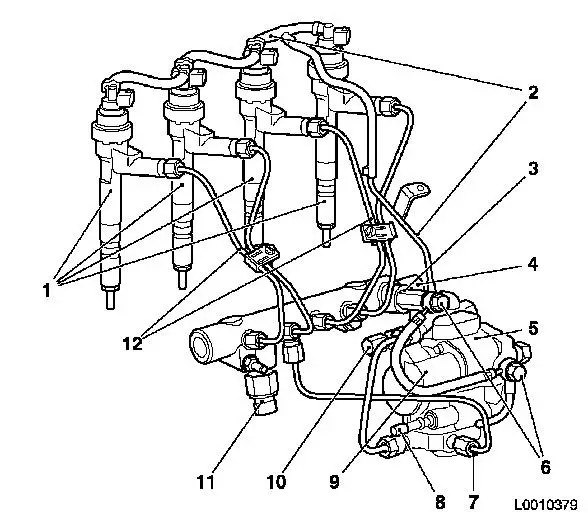

Denso Common Rail system The Z 17 DTH engine uses a Common Rail system from Denso. The main features of a Common Rail system are:

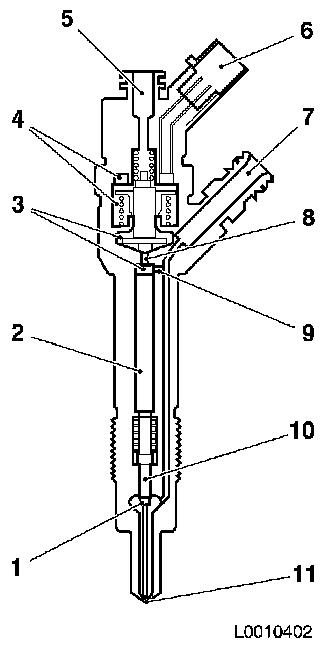

Injector The injector is a precision-made component with manufacturing tolerances of approx. 3 µm for the needle shaft and high-pressure plunger. When working on these components, the strictest cleanliness must be observed. Even particles of dirt as small as 1/1000 mm will cause malfunctions and may even destroy the injector. The quantity of fuel injected varies from 5 mm 3 at idle speed up to 50 mm 3 at full load. The load-dependent quantity of fuel is injected in a maximum time of 1 ms. The injector is actuated by the engine control unit, with the start of injection and the quantity of fuel injected being determined by the map as a function of load.

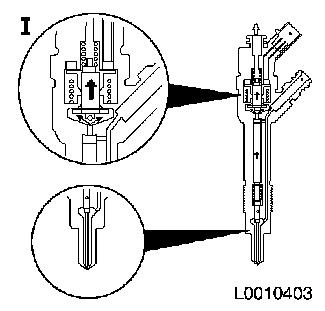

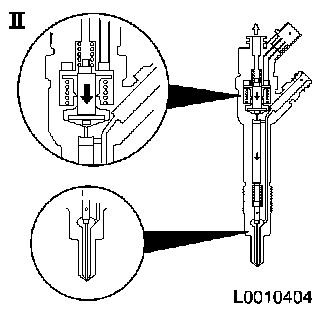

Function of the injectors The forces required to open and close the nozzle needle cannot be generated with just a solenoid valve. As a result, the nozzle needle is actuated indirectly via a hydraulic force booster system.

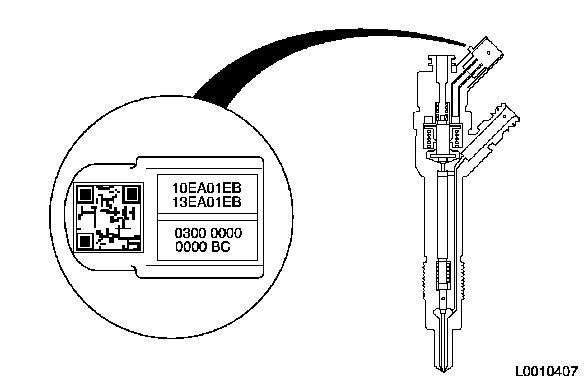

Replacing an injector Each injector has been assigned an individual code (QR code). The QR code contains correction data to compensate for various production tolerances. When replacing an injector, the new injector must be programmed into the engine control unit using TECH 2. This enables the engine control unit to record the necessary correction parameters, thus facilitating precise metering of the injection quantity.

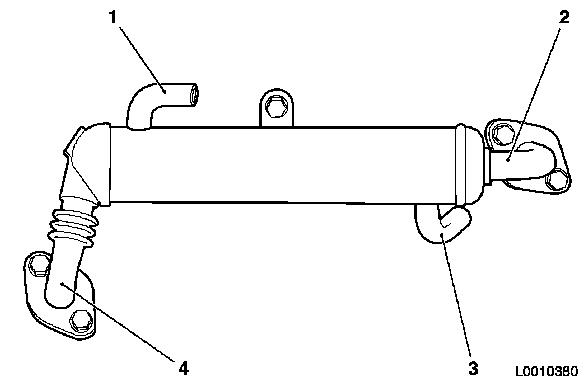

EGR cooler Like the Z 17 DTL engine, the Z 17 DTH engine has a water-cooled EGR cooler. The cooling performance has been increased by enlarging the volume. By lowering the temperature of the recirculated exhaust gas, it has been possible to reduce the No x - emissions as well as particulates.

Engine timing The engine control system of the Z 17 engine has been derived from the Y 17 DT engine, which is also fitted with a Denso engine management system. Oil life monitoring The Z 17 DTH engine uses the engine oil condition monitoring (oil life monitoring, OLM) system familiar from the Vectra-C. The monitoring function is done by the engine control unit (ECM) and the instrument assembly. Data is displayed by modified OLM software or ECO Service Flex. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||