|

Engine with Transmission, Remove and Install

Remove Remove

Important: On vehicles as of

model year 04 with ESP - every time the battery is disconnected,

the steering angle sensor loses its basic setting. It must be

recalibrated.

|

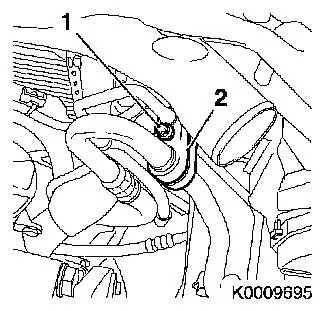

| 2. |

Disconnect battery

|

| 3. |

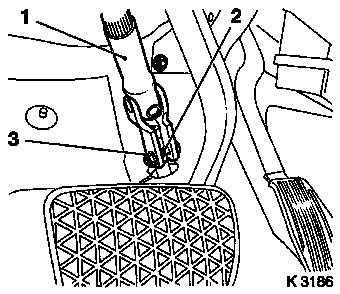

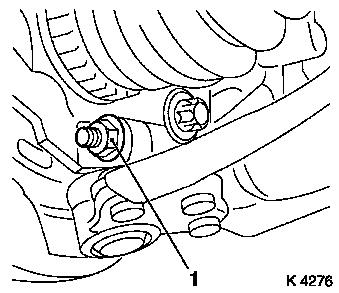

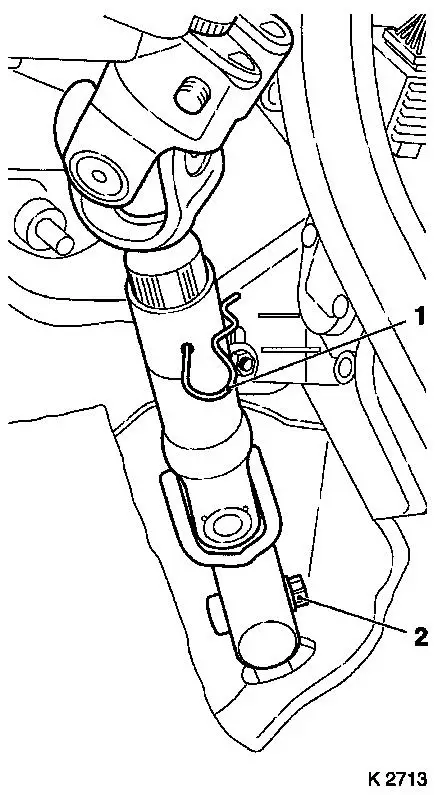

Detach steering intermediate shaft (1)

| • |

Remove lower clamp bolt (2)

|

| • |

Steering in straight ahead position

|

Important: Do not alter steering

wheel position.

|

| • |

Remove steering intermediate shaft

|

|

|

|

| 5. |

Detach front panelling

Note: On Tigra-B (Model

R97): detach front panelling

|

| 8. |

Remove lower engine compartment cover / splash protection

|

| 9. |

Drain coolant

| • |

Place collecting basin underneath.

|

|

|

|

| 11. |

Remove air cleaner housing

|

| 12. |

Remove coolant compensation tank

|

| 13. |

Remove fuel filter (2)

| • |

Disconnect wiring harness plug (3)

|

|

| 14. |

Remove fuel filter crash box

|

| 15. |

Detach brake servo vacuum line (5)

|

|

|

| 16. |

Detach 2 coolant hoses

|

| 17. |

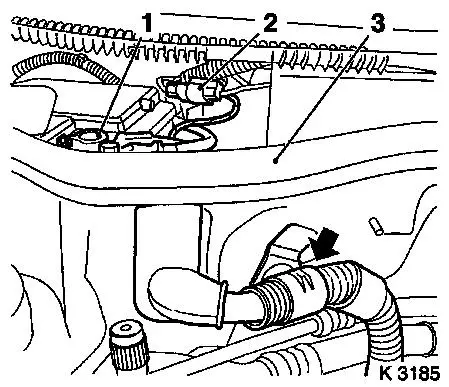

Disconnect fan motor wiring harness

| • |

Disconnect 2 wiring harness plugs (1)

|

|

| 18. |

Disconnect wiring harness for engine management

| • |

Disconnect engine control unit wiring harness plug (2)

|

| • |

Disconnect wiring harness

|

|

| 19. |

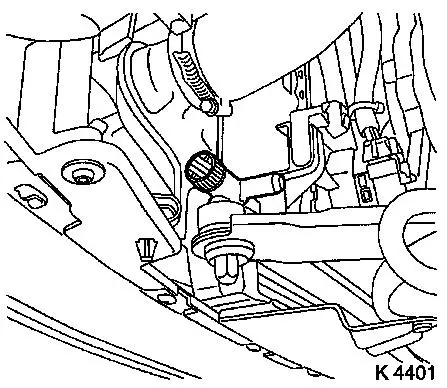

Detach ground cable

| • |

From side member

| – |

Remove castellated nut (arrow)

|

|

|

|

|

| 20. |

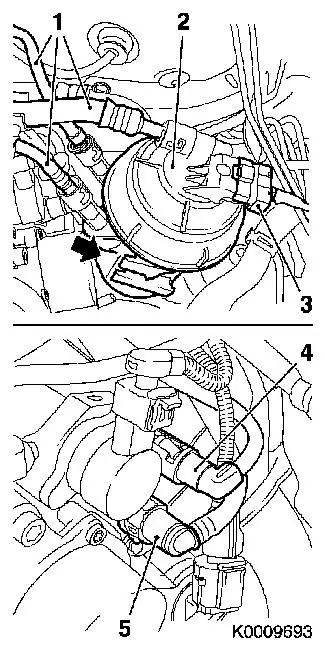

Disconnect starter/alternator wiring harness

| • |

Detach positive cable (1)

|

| • |

Disconnect central plug (2)

|

| • |

Unclip wiring harness from bracket (arrow)

|

|

|

|

| 21. |

Drain air conditioning system

|

| 22. |

Disconnect refrigerant line of block connector (2)

|

|

|

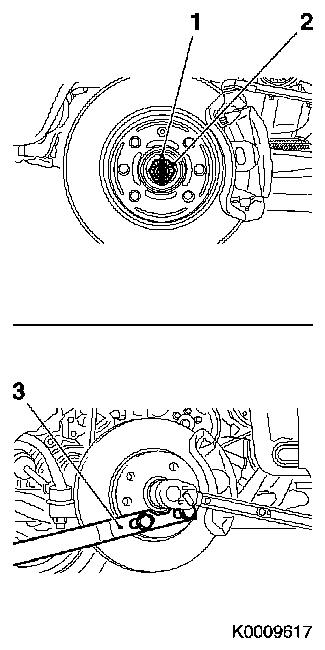

| 24. |

Close coolant drain bolt

|

| 25. |

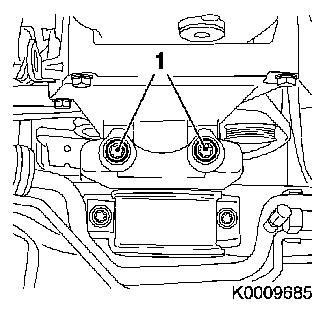

Release 2x axle shaft

| • |

Remove 2 cotter pins (1)

|

| • |

Unscrew 2 nuts (2)

| – |

Counterhold using KM-468-B

|

|

|

|

|

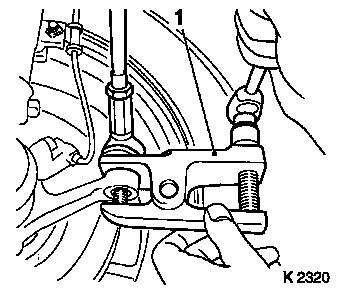

| 26. |

Detach 2x tie rod ball joints

|

|

|

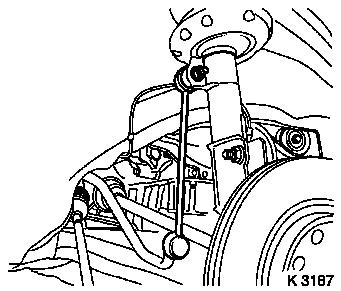

| 27. |

Detach 2x swing arm

| • |

From spring strut support tube

|

| • |

Unscrew 2 nuts

Note: Counterhold with

open-ended wrench

|

|

|

|

| 28. |

Detach 2 guide joints

|

|

|

| 29. |

Press out 2x axle shaft

|

| 31. |

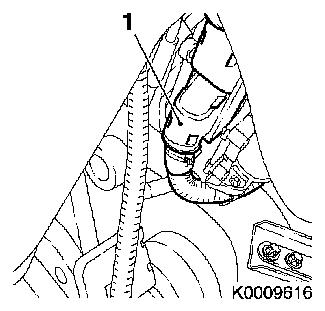

Disconnect MTA transmission wiring harness plug (1)

| • |

Disconnect wiring harness

|

|

|

|

Important: When removing the

centre muffler, a catalytic converter, an exhaust manifold, or an

exhaust manifold with catalytic converter, secure that portion of

the exhaust system remaining on the vehicle against uncontrolled

suspension. The exhaust system piece with the flex pipe inside can

be secured for this purpose using suitable means, such as a wire on

the vehicle underbody. Bends in the flex pipe with an angle as

little as 5 – 10 degrees from the intended installation

position may result in damage with subsequent total failure of the

flex pipe.

|

| 32. |

Remove exhaust system

|

| 33. |

Remove exhaust system

| • |

Detach exhaust system

Note: 2nd mechanic

required.

|

|

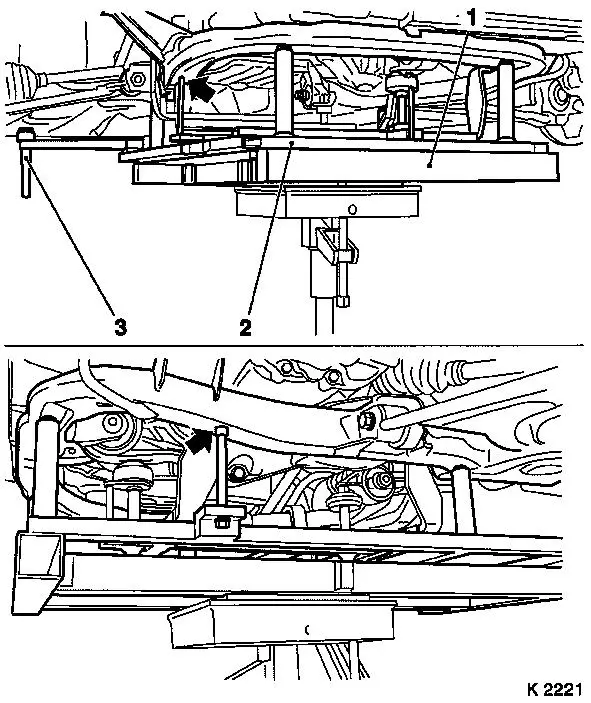

| 34. |

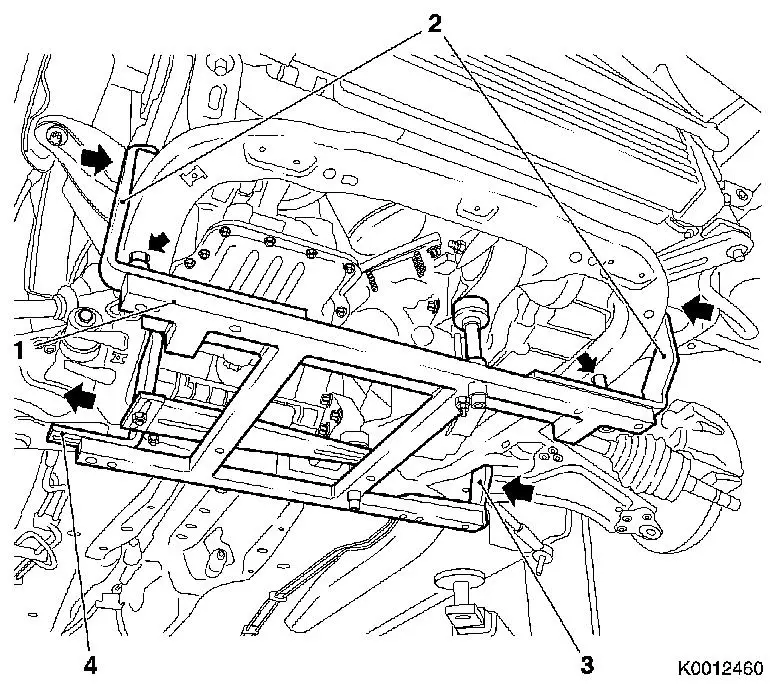

Attach KM-6394

| • |

Position KM-6394 (1) at the front on

the front axle body

Note: Both locating

pins (arrows) must be seated in the bores in the front axle

body.

|

| • |

Push front bracket (2) in the direction of the arrow

|

| • |

Place rear bracket (4), right hand side, on front axle body

|

| • |

Attach rear bracket (3), left hand side

|

|

|

|

|

| 35. |

Install support

| • |

On KM-6394

| – |

Adjust bracket (2) for support

|

|

|

| 36. |

Adjust 3x support

| • |

Transmission side

Note: Turn spindles

until mounts (3) are positioned at the guide journals free of

play.

|

| • |

Engine timing side

| – |

Insert journal of the support in the bore of the cylinder block

free of play (arrow)

|

|

|

|

| 38. |

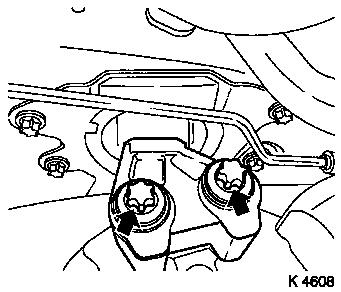

Detach right engine damping block

| • |

Loosen right engine bracket

|

|

|

|

| 39. |

Detach left engine damping block

| • |

Loosen left engine bracket

|

|

|

|

|

| 41. |

Insert hydraulic jack

|

| 42. |

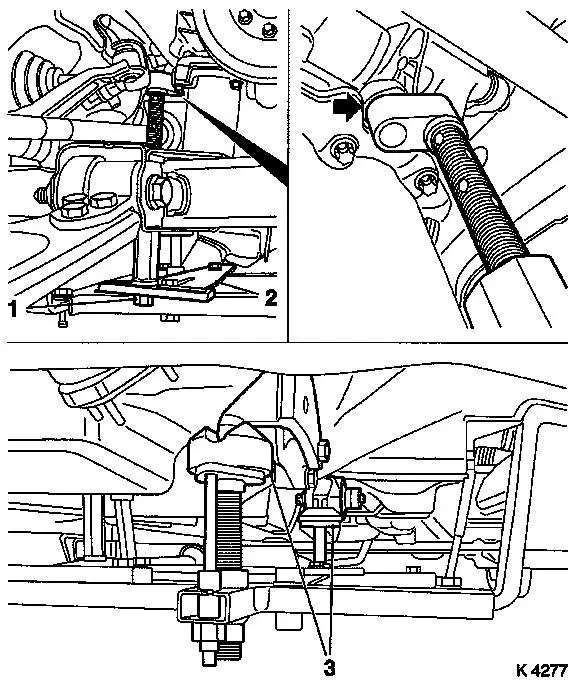

Attach KM-6168 (2)

| • |

Position KM-6168

| – |

On KM-904 (1)

Note: Note differing

centring bolt diameters

|

|

| • |

Position KM-6168

| – |

Without play under front axle body

Note: Pay attention to

centring point in front axle body (arrows); lower body positioning

pins (3)

|

|

|

|

|

| 43. |

Release front axle body

Important: The removal of the

front axle body with an impulse or impact screwdriver is not

permitted

|

| • |

Unscrew 4 bolts (arrows)

|

|

|

Important: Carefully lower front

axle body with engine and transmission downwards out of engine

compartment. Do not damage attaching parts

|

| 44. |

Lower drive unit

Note: Second person

required

|

Important: Before installing the

front axle body, the lock nut threads must be checked for ease of

movement. Replace lock nuts if necessary

|

| 46. |

Check threads of 4 lock nuts

|

Install

Install

Important: Carefully guide the

front axle body with engine and transmission upwards into the

engine compartment. Guide the body positioning pins into body the

positioning holes. Do not damage attaching parts.

|

| 48. |

Raise drive unit

Note: Second person

required

|

| 49. |

Fasten front axle body

Important: Installation of the

front axle body with an impulse or impact screwdriver is not

permitted

|

| • |

Tighten 4 bolts 90 Nm + 45° +

15°

|

|

| 50. |

Remove hydraulic jack

|

| 52. |

Fasten left engine damping block

| • |

Tighten 2 new bolts 80 Nm + 60° -

75°

|

|

| 53. |

Fasten right engine damping block

| • |

Tighten 2 new bolts 60 Nm + 30° -

45°

|

|

| 57. |

Attach exhaust system

Note: Second person

required

|

| 58. |

Attach exhaust system

|

| 59. |

Connect MTA transmission wiring harness plug

|

| 60. |

Install lower engine compartment cover / splash protection

|

| 62. |

Attach front panelling

Note: On Tigra-B (Model

R97): attach front panelling

|

| 64. |

Attach 2x guide joint

| • |

Tighten 2 new bolts 60 Nm

|

|

| 65. |

Attach 2x swing arm

| • |

Tighten 2 new nuts 65 Nm

Note: Counterhold with

open-ended wrench

|

|

| 66. |

Attach 2 tie rods

| • |

Tighten 2 new nuts 35 Nm

|

|

| 67. |

Secure 2x axle shaft

| • |

Tighten 2 nuts 120 Nm

| – |

Counterhold using KM-468-B

|

|

| • |

Tighten 2 nuts 20 Nm + 90°

| – |

Counterhold using KM-468-B

|

|

| • |

Install 2 cotter pins

Note: If necessary,

unscrew the nut until a pin hole aligns with the next castle nut

groove

|

|

| 70. |

Fasten front wheels

| • |

Tighten 8x bolts 110 Nm

|

|

| 71. |

Connect refrigerant line block connector

|

| 72. |

Attach starter/alternator wiring harness

| • |

Route and secure wiring harness

|

|

| 73. |

Attach engine management wiring harness

| • |

Connect engine management wiring harness

|

|

| 74. |

Connect fan motor wiring harness

| • |

Connect 2 wiring harness plugs

|

|

| 75. |

Attach 2x coolant hose

|

| 76. |

Attach brake servo vacuum line

Note: Connection must

audibly engage

|

| 77. |

Install fuel filter crash box

|

| 78. |

Install fuel filter

| • |

Connect 2 wiring harness plugs

|

|

| 79. |

Install coolant compensation tank

|

| 80. |

Install air cleaner housing

|

| 81. |

Install steering intermediate shaft

Note: Wheels in

straight-ahead position

| • |

Push on steering intermediate shaft

Note: The bore for the

clamp bolt must be on the flat-milled side of the stub axle

|

| • |

Adjust length compensator

|

|

|

|

| 82. |

Fill air conditioning system

|

| 85. |

Program volatile memory

|

|