|

Remove and install crankshaft (Z 14 XE without air

conditioning, Z 16 YNG)

|

1. Remove engine

- Note: See operation "J340100 Engine, Remove and Install"

|

|

2. Remove manual transmission from

engine

- Note: See operation "J340100 007 Manual Transmission, Detach

and Reattach from Engine"

3. Drain engine oil

- Place collecting basin underneath.

- Unscrew oil drain bolt

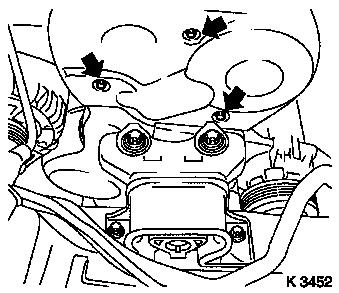

4. Remove upper part of toothed belt cover

- Remove 3 bolts

- Unclip from rear toothed belt cover

|

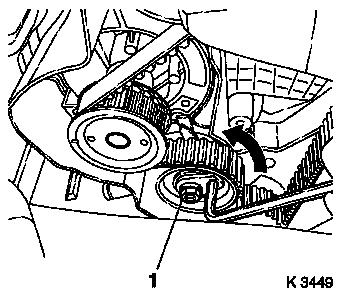

5. Detach crankshaft ribbed V-belt

pulley

- Block flywheel

- Remove bolt

|

|

|

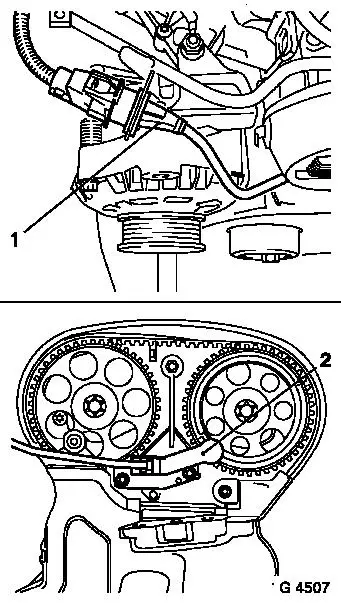

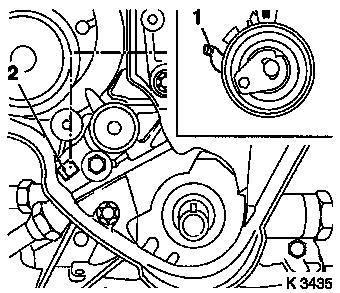

6. Remove camshaft sensor (2)

- Unclip from bracket

- Disconnect wiring harness plug (1)

- Remove 2 bolts

|

|

7. Remove lower part of toothed belt

cover

- Remove bolt

- Unclip from rear toothed belt cover

|

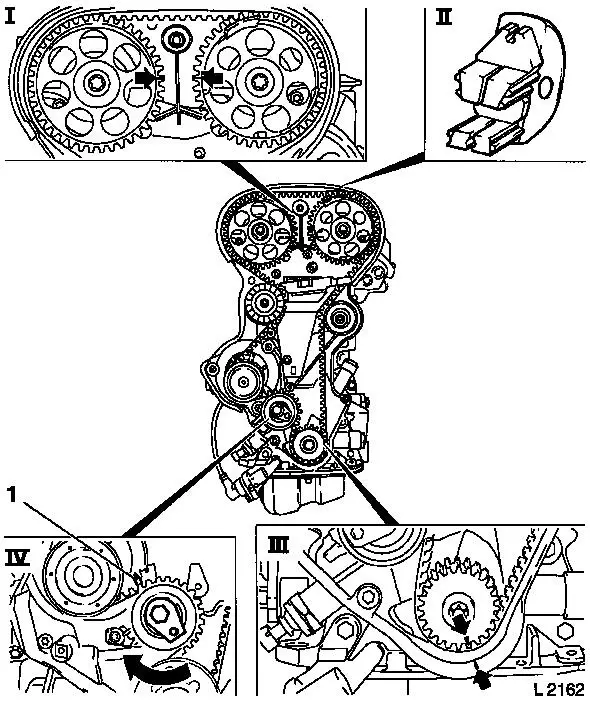

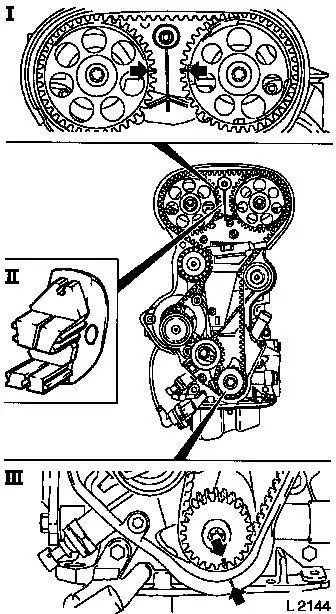

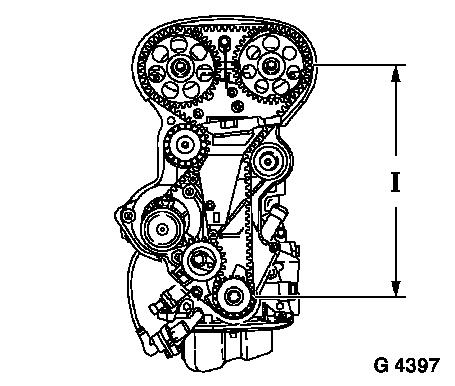

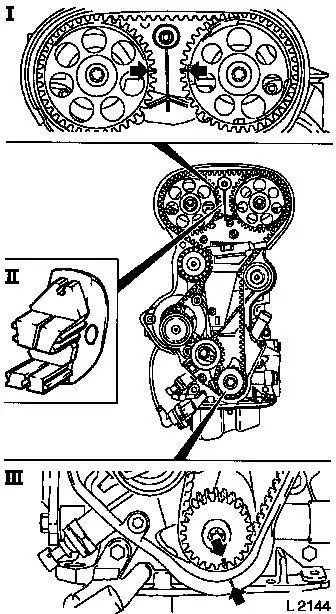

8. Set 1st cylinder to TDC

- Set crankshaft to mark.

- Turn crankshaft evenly

- Note: Marks on crankshaft ribbed V-belt pulley and rear toothed

belt cover must align (III)

- Fix camshaft sprockets in position.

- Note: Marks must be opposite one another and aligned with the

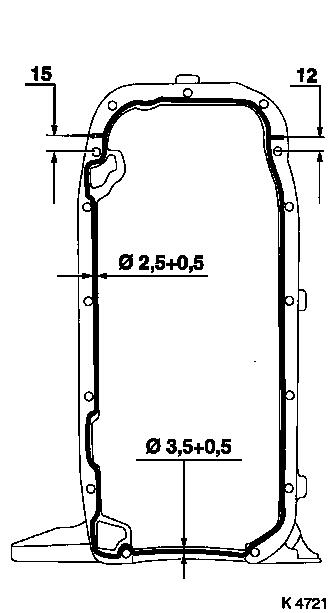

top edge of the cylinder head (I)

- Insert KM-852

|

|

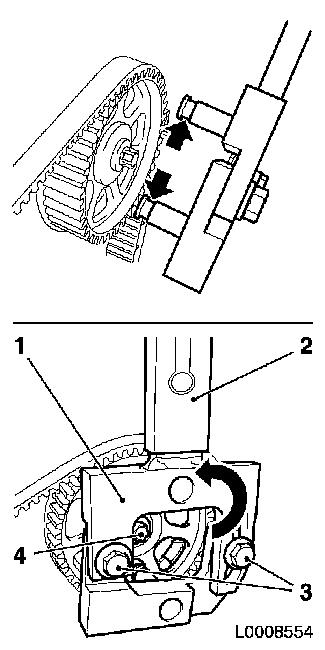

9. Remove toothed belt

- Release toothed belt tension roller (IV)

- Loosen bolt

- Turn adjusting eccentric in direction of arrow (clockwise)

until pointer (1) of the toothed belt tension roller is located

just before left stop.

- Note: Mark running direction

- Remove toothed belt.

|

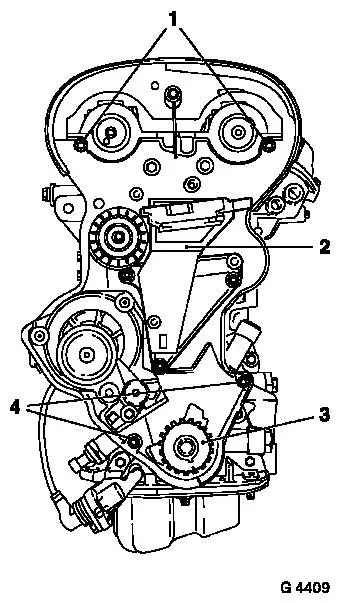

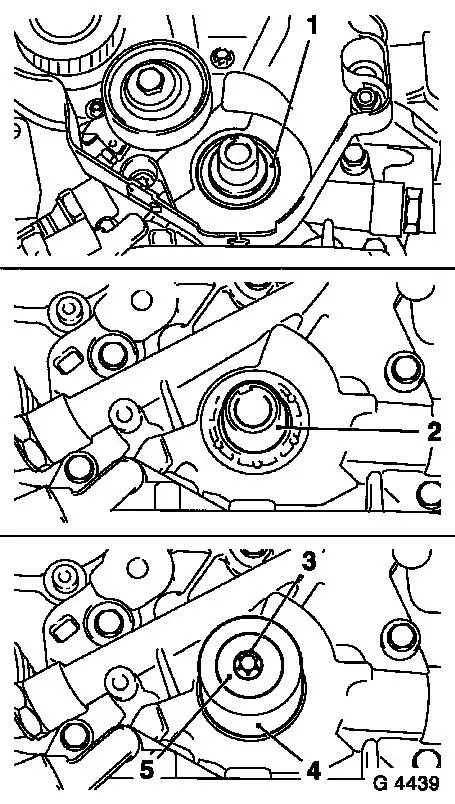

10. Remove camshaft sprocket on exhaust side

- Use KM-6347 (1), KM-956-1 (2)

- Attach KM-6347, KM-956-1

Note: Loosen the

clamping screws (3) of KM-6347 and insert KM-6347 connected to

KM-956-1 in the camshaft sprocket. The notches on KM-6347 must

engage in the camshaft sprocket (arrows). Ensure that it engages

properly.

- Turn KM-6347 in the direction of the arrow using KM-956-1

- Loosen camshaft sprocket bolt (4)

- Remove KM-6347, KM-956-1

- Unscrew camshaft sprocket bolt

|

|

11. Remove camshaft sprocket on intake side

- Use KM-6347, KM-956-1

- Attach KM-6347, KM-956-1

Note: Loosen the

clamping screws of KM-6347 and insert KM-6347 connected to KM-956-1

in the camshaft sprocket. The notches on KM-6347 must engage in the

camshaft sprocket. Ensure that it engages properly.

- Turn KM-6347 in the direction of the arrow using KM-956-1

- Loosen camshaft sprocket bolt

- Remove KM-6347, KM-956-1

- Unscrew camshaft sprocket bolt

|

12. Remove intake side toothed belt

guide roller

|

|

13. Remove exhaust side toothed belt

guide roller

14. Remove right engine bracket (2)

15. Remove toothed belt tension

roller

16. Remove toothed belt drive pulley

(3)

- Unscrew crankshaft ribbed V-belt pulley bolt

- Remove toothed belt drive pulley

17. Remove rear toothed belt cover

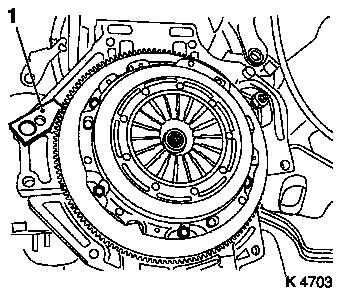

18. Remove clutch

Note: See operation

"Remove and install thrust plate and clutch disc (without SAC)" in

group "K"

|

19. Detach flywheel

- Remove 6 bolts

- Detach KM-652

|

|

20. Install oil drain bolt

- Replace seal ring

- Tighten bolt (10 Nm / 7.5 lbf. ft.)

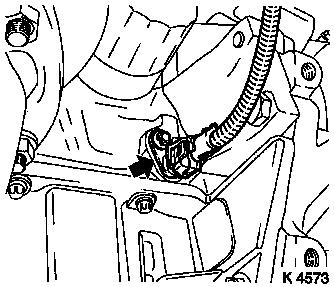

21. Remove crankshaft sensor

- Turn engine (180°)

- Disconnect wiring harness plug (arrow)

- Remove bolt

|

22. Detach oil pan

|

|

|

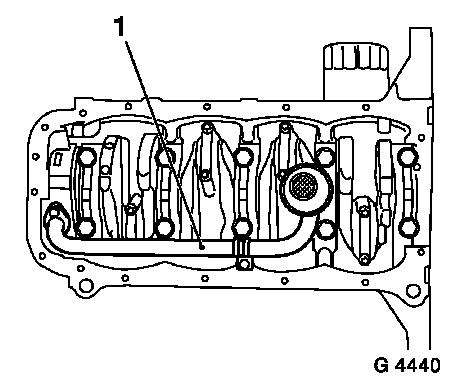

23. Remove oil intake pipe (1)

- Remove 3 bolts

- Remove seal ring

|

|

|

24. Remove oil pump

|

|

|

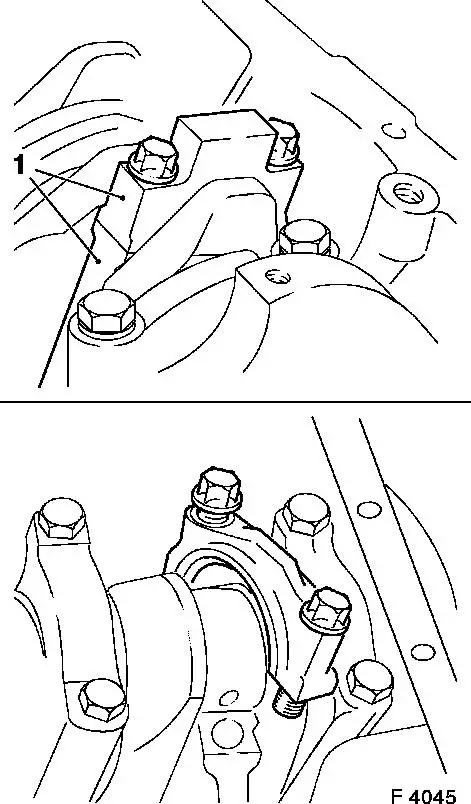

25. Detach con-rod bearing cap

- Mark con-rod bearing cap (1)

- Note: Observe cylinder sequence

- Set piston to BDC position

- 4 off

- Caution: The mating surfaces of the cod-rods and con-rod

bearing caps form an individual fit and must not be damaged or

interchanged. Do not lay on mating surfaces

|

|

|

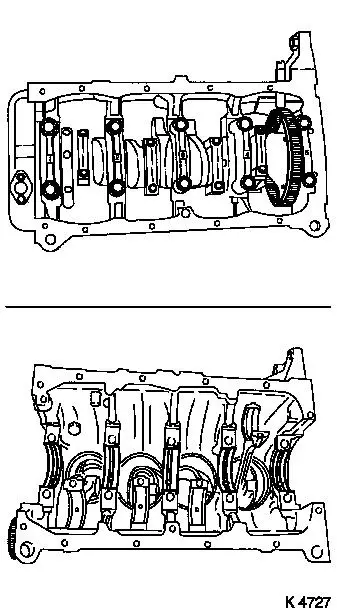

26. Remove crankshaft

- Remove crankshaft bearing cap.

- Mark crankshaft bearing cap

- Note: Observe cylinder sequence

- 5 off

- Remove 10 bolts

- Remove crankshaft rear seal ring

- Note: Place crankshaft on wooden blocks

|

|

27. Remove crankshaft bearing

shells

- Mark crankshaft bearing shells

- Note: Observe cylinder sequence

28. Remove con-rod bearing shells

- Mark con-rod bearing shells

- Note: Observe cylinder sequence

|

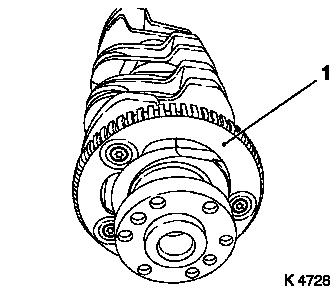

29. Detach crankshaft pulse pick-up

disc (1)

|

|

30. Clean sealing surfaces

- Cylinder block, cylinder head, cylinder head cover, oil pan,

oil pump, crankshaft rear bearing cap

31. Inspect components

- Cylinder block, cylinder head, cylinder head cover, oil pan,

oil intake pipe, oil pump, ribbed V-belt, ribbed V-belt tensioner

assembly, ribbed V-belt pulleys, toothed belt drive

32. Rework threads

- Into cylinder block

- Oil pump

33. Attach crankshaft pulse pick-up

disc

- Tighten bolts (15 Nm / 11 lbf. ft.)

34. Insert con-rod bearing shells

- Caution: Note mark and allocation

- In con-rod, con-rod bearing cap

35. Insert crankshaft bearing

shells

- Caution: Note mark and allocation

- In cylinder block, crankshaft bearing cap

- Caution: Note position of axial bearing

36. Insert crankshaft

- Coat crankshaft journal with engine oil

|

37. Install crankshaft bearing cap

- Caution: Note mark and allocation. Apply sealant in groove of

rear crankshaft bearing cap. Complete assembly operations within 10

minutes

- Renew bolts

- Tighten bolts (50 Nm / 37 lbf. ft. + 45° + 15°)

- Note: Observe tightening sequence

- Remove excess sealant

|

|

|

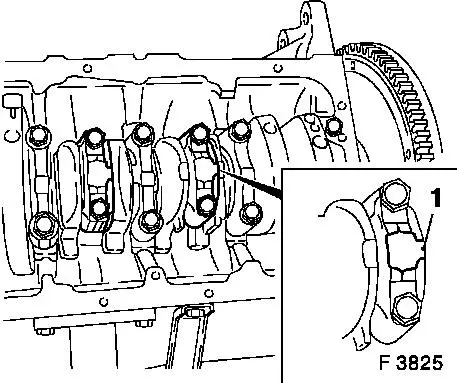

38. Attach con-rod bearing cap

- Renew bolts

- Caution: Note mark and allocation. Bead (1) on con-rod bearing

cap points towards the transmission side

- Tighten bolts (25 Nm / 18.5 lbf. ft. + 30°)

|

|

|

39. Install rear crankshaft seal

ring

- Coat seal lip with grease

- Position KM-235-6 (1) on crankshaft journal

- Push seal ring (2) onto KM-235-6

- Drive in until flush using KM-658-1 (3)

|

|

|

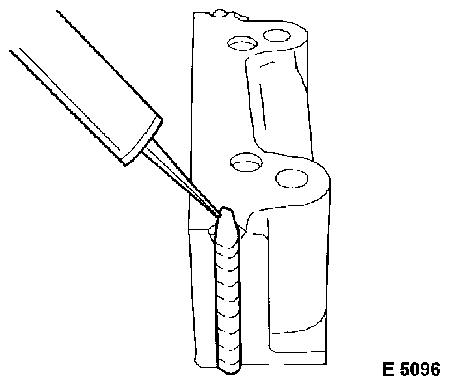

40. Remove front crankshaft seal

ring

- Lever out seal ring (1)

- Caution: Do not damage sealing surface

|

|

41. Install oil pump

- Replace gasket

- Note: Insert bolts with locking compound

- Tighten bolts (8 Nm / 6 lbf. ft.)

42. Install front crankshaft seal

ring

- Coat seal lip with grease

- Position KM-417 on crankshaft journal (2)

- Push seal ring onto KM-417

- Remove KM-417

- Install crankshaft front seal ring

- With KM-417 (4), bolt (3) and crankshaft ribbed V-belt pulley

(5)

|

43. Install oil intake pipe

- Replace seal ring

- Note: Insert bolts with locking compound

- Tighten bolts (8 Nm / 6 lbf. ft.)

|

|

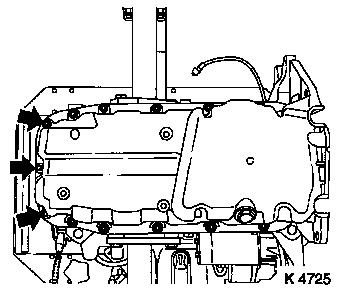

44. Attach oil pan

- Apply sealant

- Caution: Complete assembly operations within 10 minutes

- Screw in bolts

- At cylinder block

- Tighten bolts (10 Nm / 7.5 lbf. ft.)

- At oil pump

- Tighten bolts (10 Nm / 7.5 lbf. ft.)

45. Install crankshaft sensor

- Replace seal ring

- Tighten bolt (10 Nm / 7.5 lbf. ft.)

- Connect wiring harness plug.

46. Rework threads

47. Attach flywheel

- Turn engine (180°)

- Renew bolts

- Tighten bolts (35 Nm / 26 lbf. ft. + 30° + 15°)

48. Install clutch

Note: See operation

"Remove and install thrust plate and clutch disc (without SAC)" in

group "K"

49. Attach rear toothed belt cover

- Tighten bolts (6 Nm / 4.4 lbf. ft.)

50. Install toothed belt drive gear

- Install crankshaft V-belt pulley bolt

|

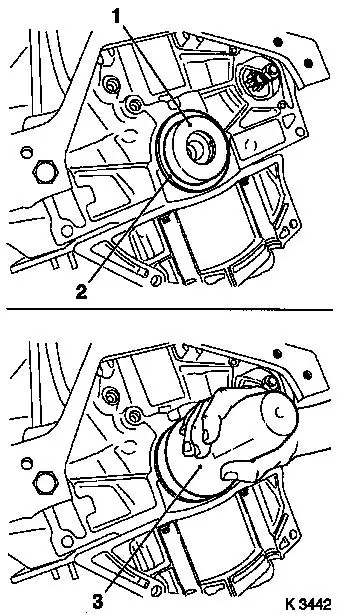

51. Install toothed belt tension

roller

- Caution: Detent lever (1) of toothed belt tension roller must

engage in guide web (2) of oil pump

- Bolt in bolt

- Note: Only tighten bolt after adjusting toothed belt

tension

|

|

52. Attach right engine bracket

- Renew bolts

- Insert bolts with locking compound (red)

- Tighten bolts (65 Nm + 45° - 60°)

53. Install intake side toothed belt guide roller

- Tighten bolt (25 Nm / 18.5 lbf. ft.)

- Caution: Toothed belt guide roller with larger diameter is

installed on intake side

54. Install exhaust side toothed belt

guide roller

- Tighten bolt (25 Nm / 18.5 lbf. ft.)

|

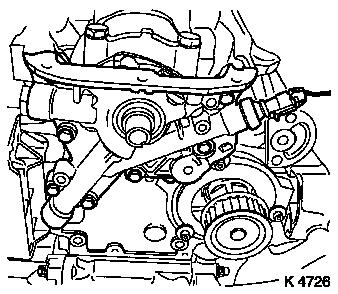

55. Fix camshaft sprockets in position

- Note: Marks must be opposite one another and aligned with the

top edge of the cylinder head (I)

- Insert KM-852 (II)

- Turn the camshafts at hexagonal section

56. Lock crankshaft

- Set crankshaft to mark.

- Turn crankshaft evenly

- Note: Marks on drive gear toothed belt and rear toothed belt

cover must align (III)

|

|

|

57. Install toothed belt

- Note: Note running direction and timing marks

- Position toothed belt

- Note: Tensioned side must be taut (I)

|

|

|

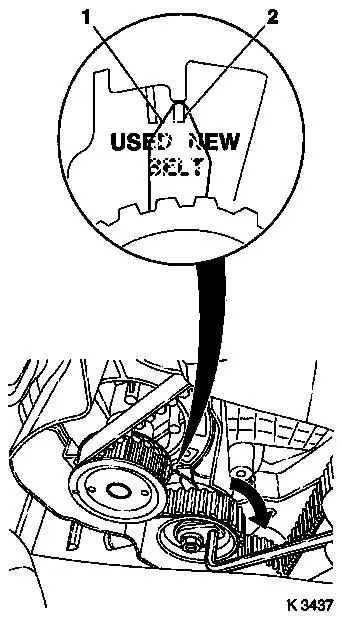

58. Tension toothed belt

- Tension toothed belt tension roller

- Turn adjusting eccentric in direction of arrow (anticlockwise)

until pointer of the toothed belt tension roller is located just

before left stop

- Fasten toothed belt tension roller bolt (1)

|

|

59. Remove KM-852

|

60. Check timing

- Turn crankshaft (720°)

- At crankshaft ribbed V-belt pulley bolt

- Note: In direction of engine rotation

- Set crankshaft to mark.

- Note: Marks on drive gear toothed belt and rear toothed belt

cover must align (III)

- Insert KM-852 (II)

- Note: Marks must be opposite one another and aligned with the

top edge of the cylinder head (I)

|

|

61. Remove KM-852

|

62. Adjust toothed belt tension

- Release toothed belt tension roller

- Turn adjustment eccentric in the direction of the arrow

(clockwise) until pointer (1) is aligned with the notch mark at the

toothed belt tension roller (2).

- Adjust used toothed belts to the marking USED

- Adjust new toothed belts to the marking NEW

- Tighten toothed belt tension roller bolt (20 Nm / 15 lbf.

ft.)

|

|

63. Check toothed belt tension

- Turn crankshaft (720°)

- Note: Pointers on the toothed belt tension roller and notch

mark must align

- Adjust used toothed belts to the marking USED

- Adjust new toothed belts to the marking NEW

64. Rework threads

- Camshaft sensor to cylinder head

65. Install camshaft sensor

- Note: Insert bolts with locking compound

- Tighten bolts (8 Nm / 6 lbf. ft.)

66. Install lower part of toothed belt

cover

- Clip to rear of toothed belt cover

- Tighten bolt (4 Nm / 3 lbf. ft)

67. Install upper part of toothed belt

cover

- Clip to rear of toothed belt cover

- Tighten bolts (4 Nm / 3 lbf. ft)

68. Attach crankshaft ribbed V-belt

pulley

- Block flywheel

- Replace bolt

- Tighten bolt (95 Nm / 70 lbf. ft. + 30° + 15°.)

- Detach KM-652

69. Connect wiring harness plug of

camshaft sensor

- Connect wiring harness plug.

- Clip to bracket

70. Attach manual transmission to

engine

- Note: See operation "J 3401 00 007 Manual Transmission, Remove

and Install from Engine"

71. Install engine

- Note: See operation "J 3401 00 Engine, Remove and Install"

|