|

J330100 All Pistons with Con-rod, Remove and

Install (Z 18 XE, with Air Conditioning, LHD)

Note: KM-6394 must be used as of model year 04 instead of

KM-6169-1 .

Note: The customer

should be informed of the choice between ECOService and

ECOService-Flex before the oil change.

Remove Remove

| 2. |

Disconnect battery

Note: In vehicles from

model year 04 onwards with ESP - the steering angle sensor loses

its basic adjustment each time the battery is disconnected and must

be recalibrated.

|

| 3. |

Remove engine cover.

| • |

Unscrew oil filler pipe cap

|

| • |

Screw on oil filler pipe cap

|

|

| 4. |

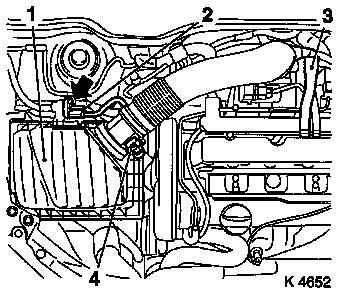

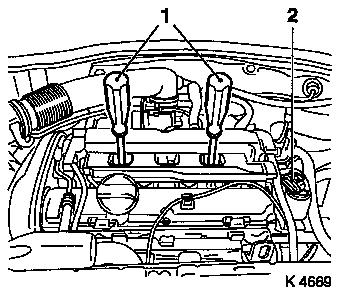

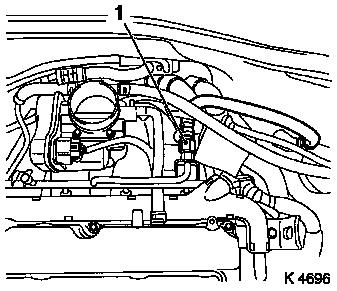

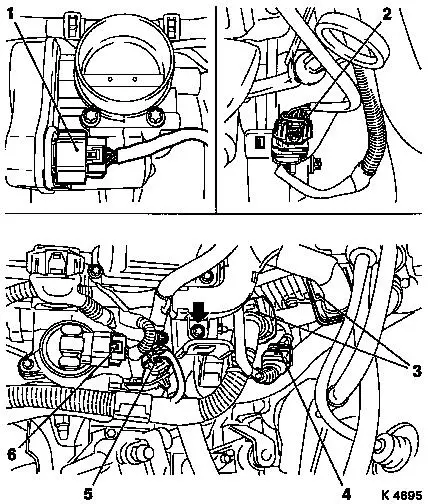

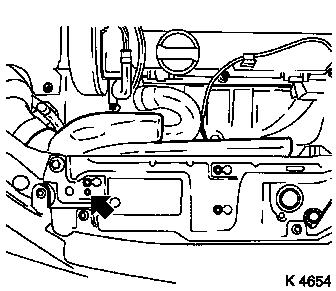

Remove air cleaner housing (1)

| • |

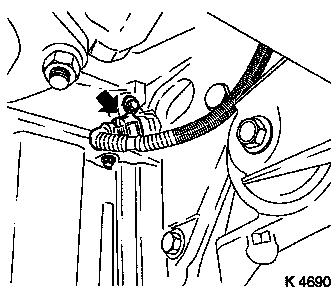

Disconnect 2 wiring harness plugs

| – |

Hot film mass air flow meter (4), tank vent valve (2)

|

|

| • |

Detach engine vent hose (3)

|

|

|

|

| 5. |

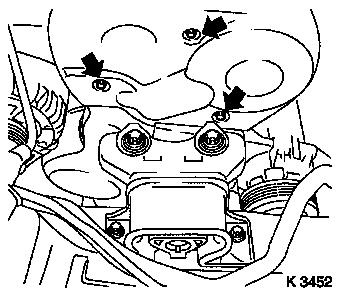

Remove upper part of toothed belt cover

| • |

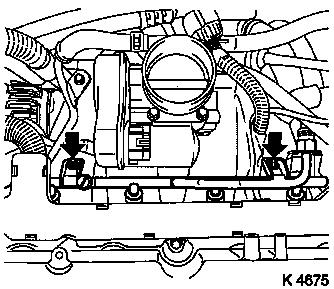

Unscrew 3 bolts (arrows)

|

| • |

Unclip from rear toothed belt cover

|

|

|

|

| 7. |

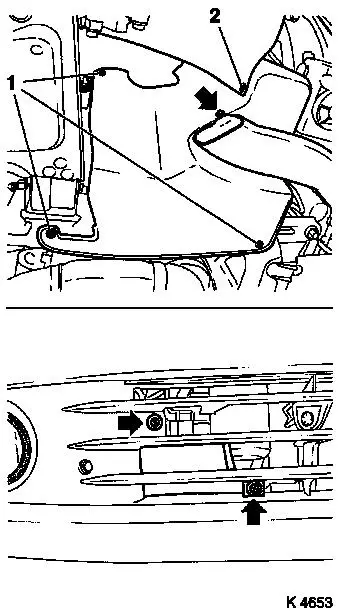

Remove right-hand air duct

| • |

Unscrew 3 bolts (arrows)

|

|

| 8. |

Remove ribbed V-belt cover

|

|

|

| 10. |

Detach front right wheel

|

| 12. |

Remove right front wheel.

|

| 14. |

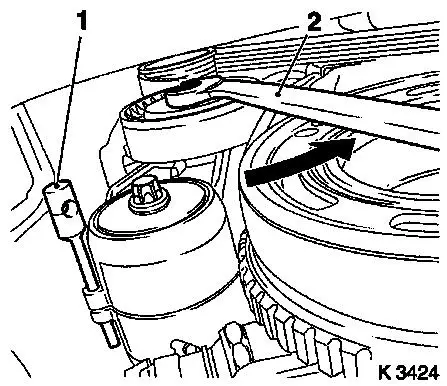

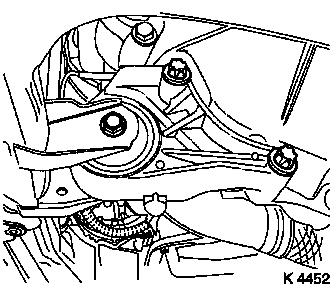

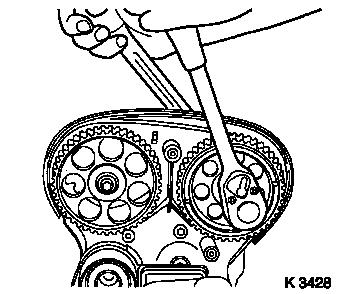

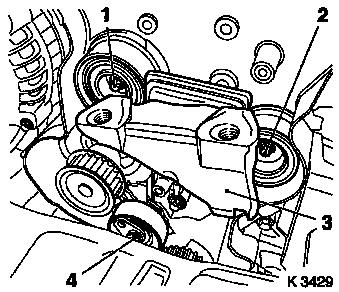

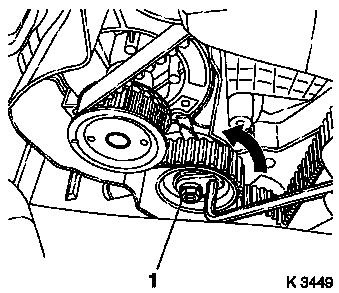

Remove ribbed V-belt

| • |

Tension ribbed V-belt tensioner in direction of arrow with

KM-913-A (2)

|

|

|

|

| 15. |

Remove ribbed V-belt tensioner

| • |

Tension ribbed V-belt tensioner.

|

| • |

Release ribbed V-belt tensioner

|

|

|

|

| 16. |

Detach crankshaft ribbed V-belt pulley

| • |

Prise front closure plug out of oil pan

|

|

|

|

| 17. |

Release lower part of toothed belt cover

| • |

Unclip from rear toothed belt cover

|

|

|

|

| 19. |

Loosen exhaust system

Note: Bends in the flex

pipe with an angle as little as 5 – 10 degrees from the

intended installation position may result in damage with subsequent

total failure of the flex pipe.

| • |

When removing the centre muffler, a catalytic converter, an

exhaust manifold or an exhaust manifold with catalytic converter,

the exhaust system piece remaining in the vehicle must be prevented

from swinging uncontrollably.

Note: The exhaust

system piece with the flex pipe inside can be secured for this

purpose using suitable means, such as a wire on the vehicle

underbody.

|

| • |

Remove wiring harness plug for catalytic converter control

oxygen sensor

|

| • |

Suspend front exhaust pipe from left front axle body

|

|

| 20. |

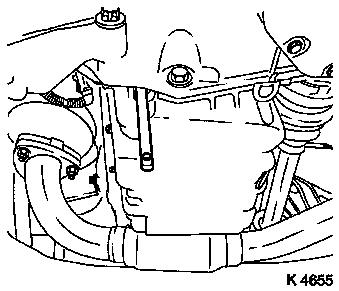

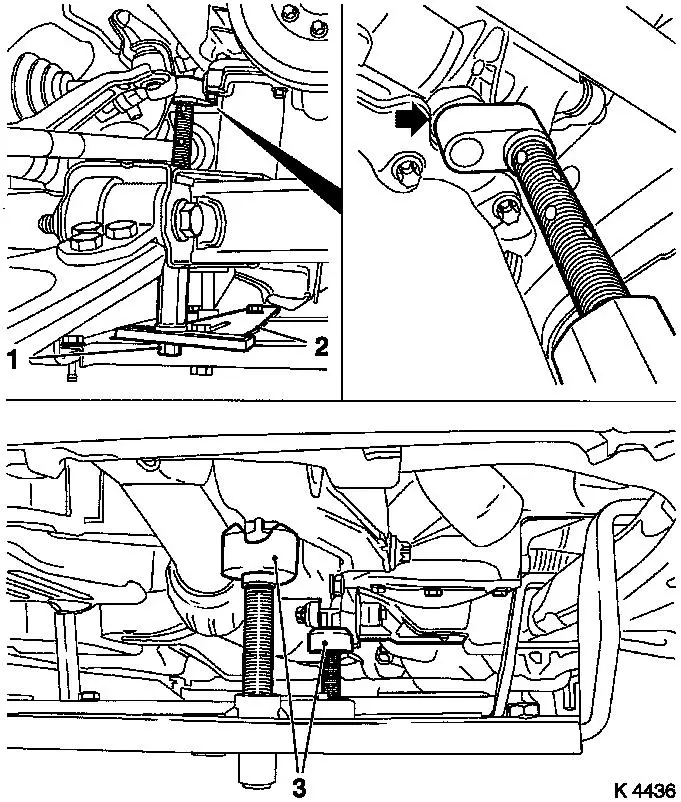

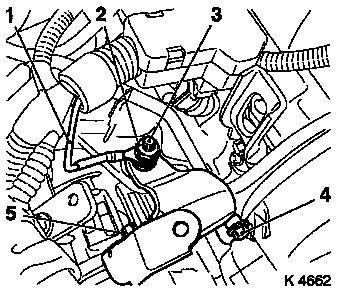

Release shift guide (3)

| • |

Remove retaining clip (2)

|

|

| 21. |

Release rear reaction member (4)

|

|

|

| 22. |

Remove front reaction member

|

|

|

| 24. |

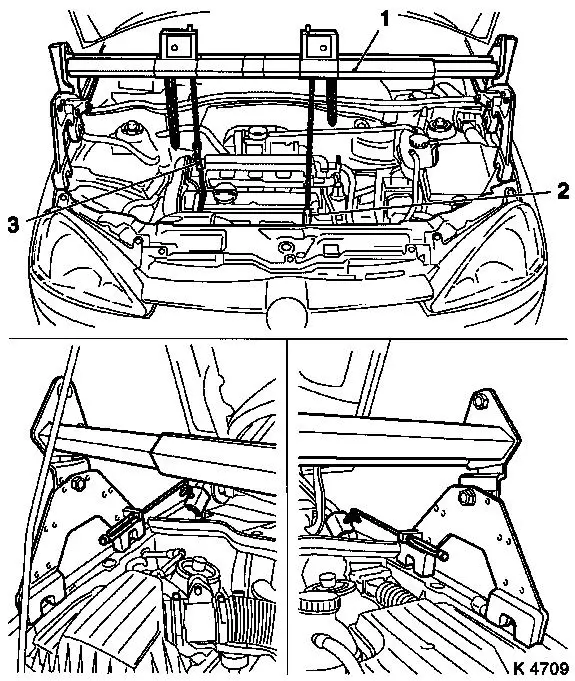

Use MKM-883-1 (1)

Note: Second person

required

|

| 25. |

Fasten MKM-883-1

Note: Observe

manufacturer's instructions

|

| 26. |

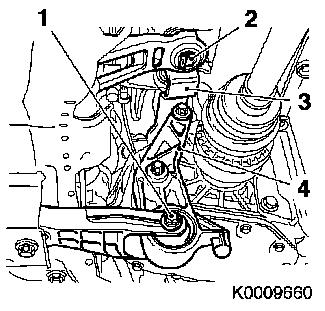

Attach engine

| • |

To right engine transport shackle (3)

|

| • |

To front left engine transport shackle (2)

Note: The front left

engine transport shackle is used only to stabilise the engine

|

|

|

|

| 27. |

Detach right engine damping block

|

| 28. |

Lift engine

| • |

Carefully raise the engine approx. 40 mm on the timing side

with MKM-883-1

Note: Observe

manufacturer's instructions

|

|

|

|

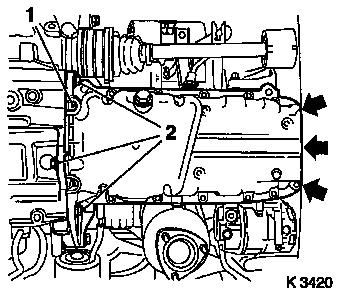

| 30. |

Remove oil pan

| • |

Lever out rear sealing plug (1)

|

| • |

Oil pump

| – |

Unscrew 3 bolts (arrows)

|

|

|

|

|

| 32. |

Lower engine

Note: When lowering pay

attention to the shift guide and rear reaction member

|

| 34. |

Fasten rear reaction member

|

| 35. |

Install front reaction member

| • |

Tighten bolted connection 60 Nm

|

|

| 36. |

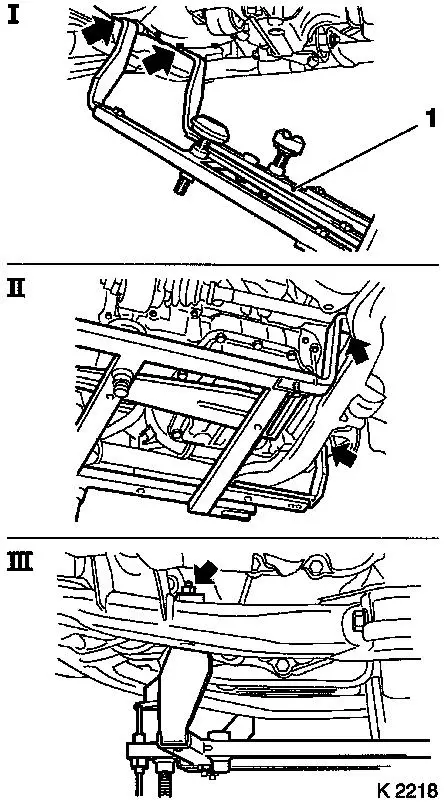

Attach KM-6169 (1)

| • |

Attach KM-6169 to left of front axle

body (arrows, illus. I)

Note: Guide pin must be

seated in bore in front axle body

|

| • |

Attach both right holders on the front axle body (arrows,

Illus. II).

Note: Guide pin must be

seated in bore in front axle body (arrow, Fig. III)

|

|

|

|

| 37. |

Install support to KM-6169

| • |

Adjust bracket (2) for support

|

|

| 38. |

Adjust supports

| • |

Transmission side

| – |

Turn spindles until mounts (3) are positioned at guide journals

free of play

|

|

| • |

Engine timing side

| – |

Insert journal of the support in the bore of the cylinder block

without play (arrow)

|

|

|

|

|

| 40. |

Drain coolant

| • |

Place collecting basin underneath.

|

| • |

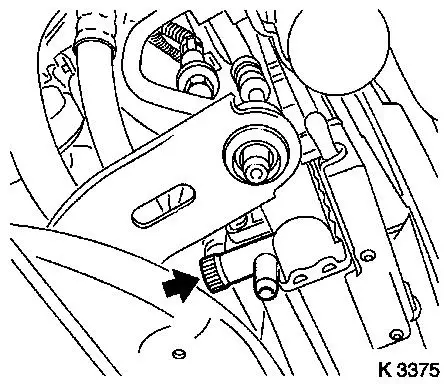

Open drain bolt (arrow)

|

|

| 43. |

Remove MKM-883-1

Note: Second person

required

|

|

|

| 44. |

Remove right engine damping block

| • |

Loosen engine bracket adapter

|

|

|

|

| 45. |

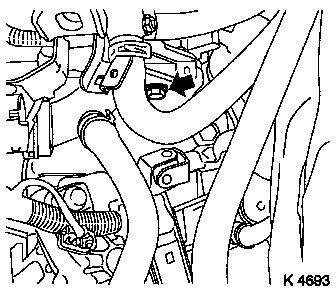

Remove preheater line for throttle valve module

| • |

Disconnect wiring harness plug for coolant temperature

sensor

|

|

| 46. |

Remove upper part of toothed belt cover

| • |

Unclip from rear toothed belt cover

|

|

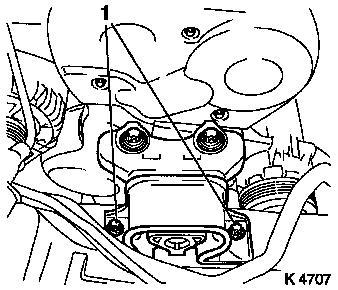

| 47. |

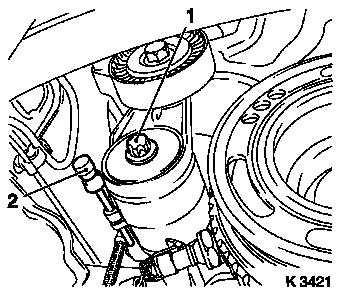

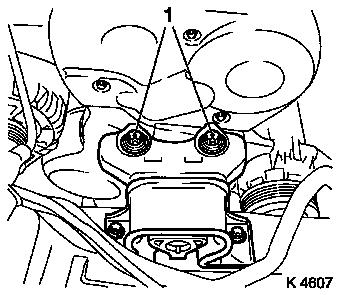

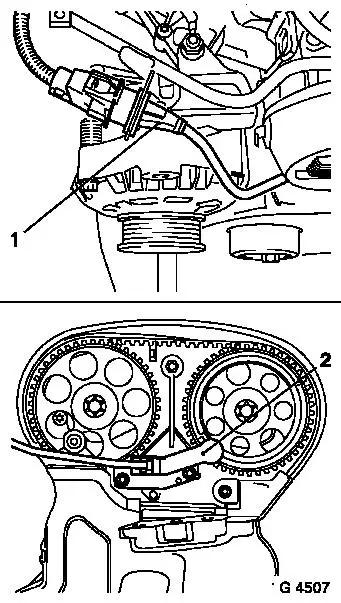

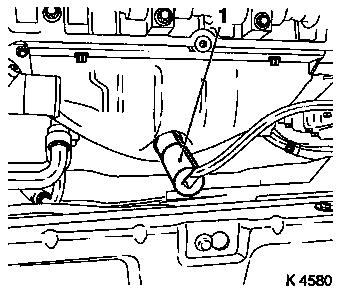

Remove camshaft sensor (2)

| • |

Disconnect wiring harness plug (1)

|

|

| 48. |

Remove lower part of toothed belt cover

| • |

Unclip from rear toothed belt cover

|

|

|

|

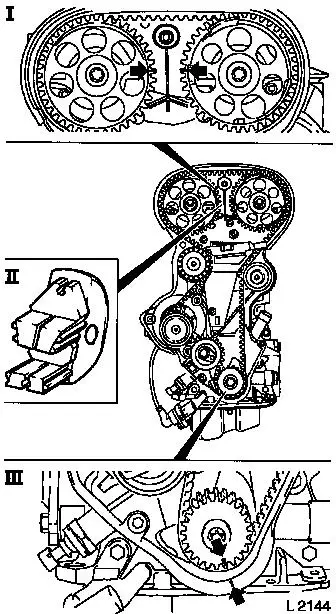

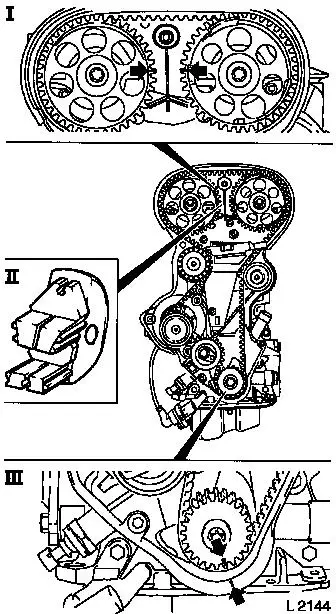

| 49. |

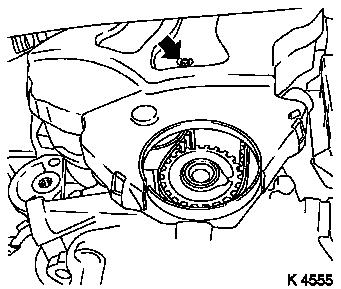

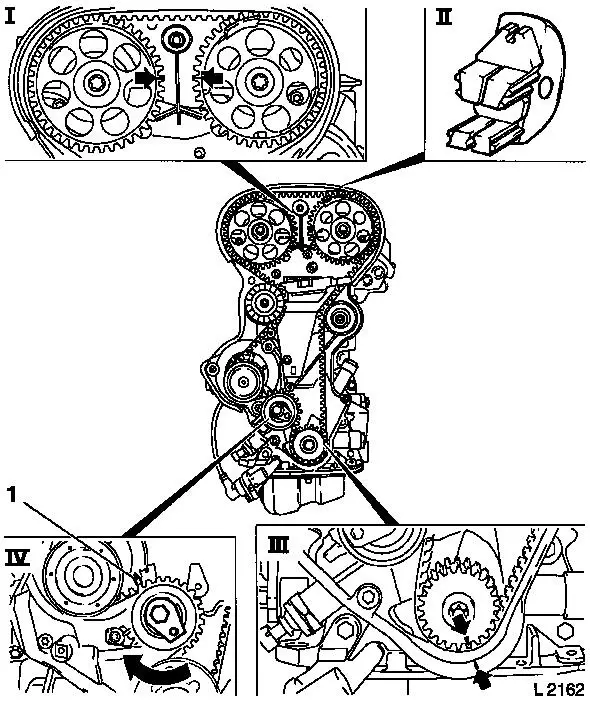

Set 1st cylinder to TDC of combustion stroke

| • |

Install crankshaft V-belt pulley bolt

|

| • |

Set crankshaft to mark.

| – |

Marks on drive gear toothed belt and rear toothed belt cover

must align (III).

|

|

| • |

Fix camshaft sprockets in position.

| – |

Marks must be opposite one another and aligned with the top

edge of the cylinder head (I)

|

|

|

| 50. |

Remove toothed belt

Note: Mark running

direction.

| • |

Release toothed belt tension roller (IV)

| – |

Turn adjusting eccentric in direction of arrow (clockwise)

until pointer (1) of the toothed belt tension roller is located

just before left stop.

|

|

|

|

|

| 51. |

Remove ignition module

| • |

Disconnect wiring harness plug (2)

|

| • |

Extract using KM-6009 (1)

Note: Do not tilt

|

|

| 52. |

Remove cylinder head cover

| • |

Detach engine vent hose

|

| • |

Unclip wiring harness of mixture regulation heated oxygen

sensor

|

|

|

|

| 53. |

Remove camshaft sprockets

| • |

Unscrew 2 bolts

| – |

Counterhold camshafts at hexagonal section

|

|

|

|

|

| 54. |

Remove exhaust side toothed belt guide roller

|

| 55. |

Remove intake side toothed belt guide roller

|

| 56. |

Remove right engine bracket (3)

|

| 57. |

Remove toothed belt tension roller

|

| 59. |

Remove toothed belt drive pulley

| • |

Unscrew crankshaft ribbed V-belt pulley bolt

|

|

| 60. |

Release rear toothed belt cover

|

|

|

| 61. |

Release alternator

| • |

Release alternator support

| – |

Unscrew 2 upper bolts (1)

|

|

|

|

|

| 62. |

Detach intake manifold support

|

|

|

| 63. |

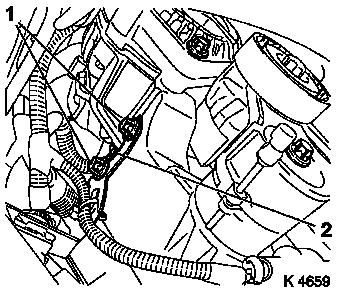

Remove wiring harness for engine management

| • |

Disconnect 2 wiring harness plugs

| – |

Oil pressure switch (1), crankshaft sensor (arrow)

|

|

|

|

|

| 65. |

Remove rear of toothed belt cover

|

| 66. |

Pull fuel evaporation hose from throttle valve module

|

|

|

| 67. |

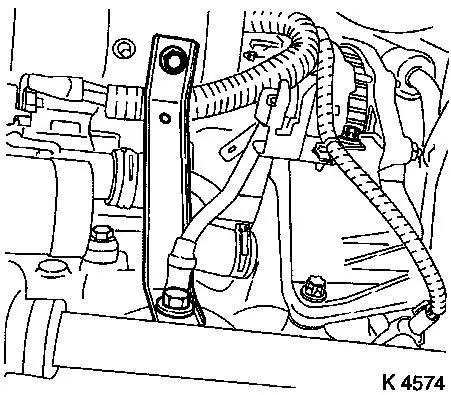

Remove alternator shackle

| • |

Remove ground cable (1)

|

| • |

Unscrew 2x bolts (4, 5)

|

| • |

Swing alternator backwards.

|

|

|

|

Important: Observe safety

precautions and national regulations

|

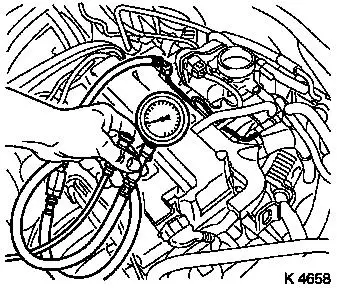

| 68. |

Release fuel pressure with KM-J-34730-91 on fuel distributor pipe

| • |

Unscrew test connection protective cap

|

|

|

|

| 69. |

Detach fuel line (1) from fuel distributor pipe

|

|

|

| 70. |

Remove wiring harness for engine management

| • |

Disconnect 7x wiring harness plugs

| – |

Throttle valve module (1), engine control unit (3), knock

sensor (4), combination plug (5), EGR valve (6), mixture regulation

oxygen sensor (2)

|

|

| • |

Remove wiring trough

| – |

Unscrew from engine transport shackle (arrow)

|

|

| • |

Set wiring harness to one side

|

|

|

|

| 71. |

Remove fuel distributor pipe

| • |

Unscrew 2x bolt (arrows)

|

| • |

Pull out fuel distributor pipe with injectors and engine

management wiring harness

|

|

| 72. |

Detach preheater return hose for throttle valve module from

throttle valve module

|

| 73. |

Detach heating return hose from intake manifold

|

| 74. |

Remove right rear engine transport shackle

|

|

|

| 75. |

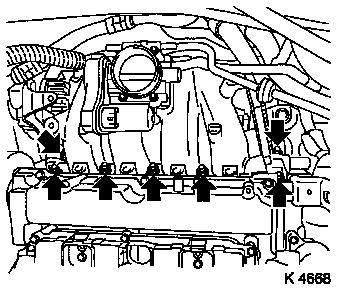

Remove intake manifold

| • |

Unscrew 7x nuts (arrows)

|

| • |

Remove brake servo vacuum line

|

|

|

|

| 77. |

Detach centre coolant hose from coolant pump connection,

coolant flange

|

| 78. |

Detach upper radiator hose from thermostat housing

|

|

|

| 79. |

Remove intake pipe

| • |

Pull intake pipe out of bracket

|

|

|

|

| 80. |

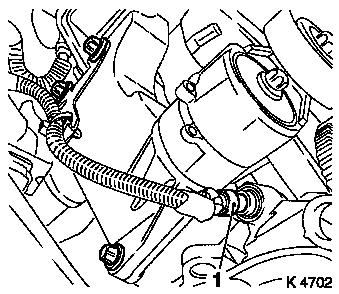

Remove heated oxygen sensor for mixture regulation

| • |

Screw out carefully using KM-6129

(1)

|

|

| 81. |

Remove exhaust manifold heat shield

|

| 82. |

Detach oil dipstick guide tube

| • |

Swivel the oil dipstick guide tube to one side

|

|

|

|

| 83. |

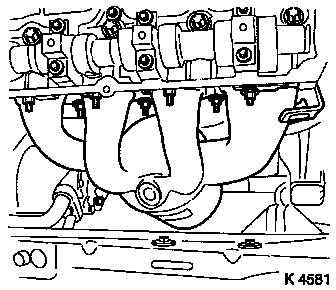

Remove exhaust manifold

| • |

Unscrew 10x nut

| – |

Remove engine transport shackle

|

|

|

|

|

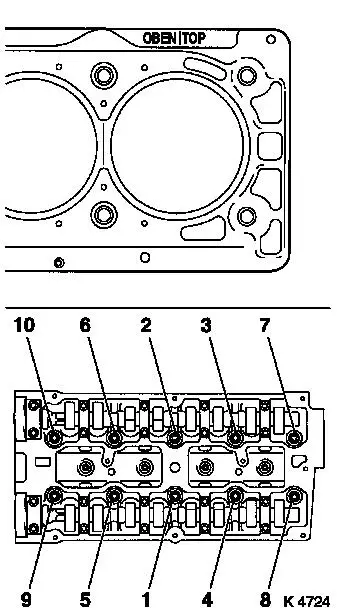

| 84. |

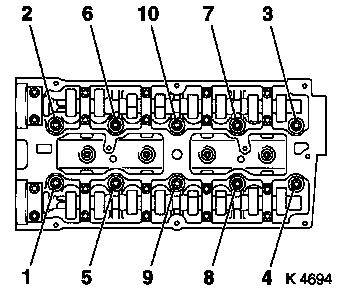

Remove cylinder head bolts

Note: Undo bolts in

order shown

| • |

Unscrew 10 bolts

| – |

Loosen 10x bolts (90 °)

|

| – |

Loosen 10x bolts (180 °)

|

|

|

| 85. |

Remove cylinder head

Note: Second person

required

| • |

Place cylinder head on wooden blocks

|

| • |

Remove cylinder head gasket

|

|

|

|

| 87. |

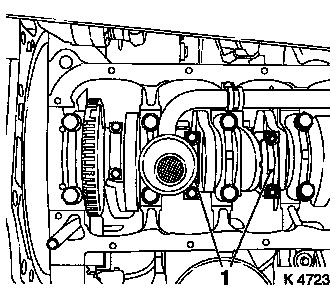

Remove con-rod bearing cap (1)

Note: Observe cylinder

sequence

| • |

Mark con-rods with con-rod bearing caps

|

| • |

Unscrew 4 bolts

Note: The mating

surfaces of the cod-rods and con-rod bearing caps form an

individual fit and must not be damaged or interchanged. Do not lay

on mating surfaces.

|

| • |

Push piston with con-rod upwards

|

|

| 91. |

Rotate crankshaft in direction of engine rotation

(180°)

|

|

|

| 92. |

Remove con-rod bearing cap (1)

Note: Observe cylinder

sequence

| • |

Mark con-rods with con-rod bearing caps

|

| • |

Unscrew 4 bolts

Note: The mating

surfaces of the cod-rods and con-rod bearing caps form an

individual fit and must not be damaged or interchanged. Do not lay

on mating surfaces.

|

| • |

Push piston with con-rod upwards

|

|

| 95. |

Remove con-rod bearing shells

Note: Note sequence

| • |

Mark con-rod bearing shells

|

|

Install

Install

| 96. |

Inspect crank drive components

|

| 97. |

Insert con-rod bearing shells into con-rods and con-rod bearing

caps

|

| 98. |

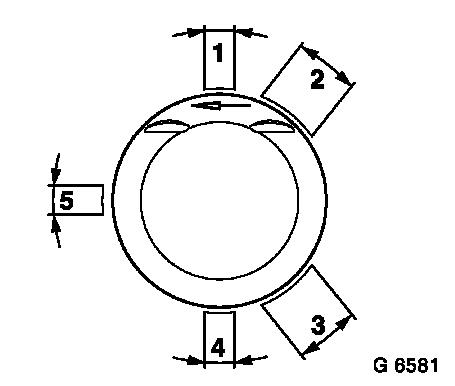

Adjust piston ring gaps

| • |

Turn piston rings

| – |

Upper rings in position (1)

|

| – |

Middle rings in position (4)

|

|

| • |

Turn oil scraper ring

| – |

Intermediate ring in position (5)

|

| – |

Steel band rings in position (2) or (3)

|

|

|

|

|

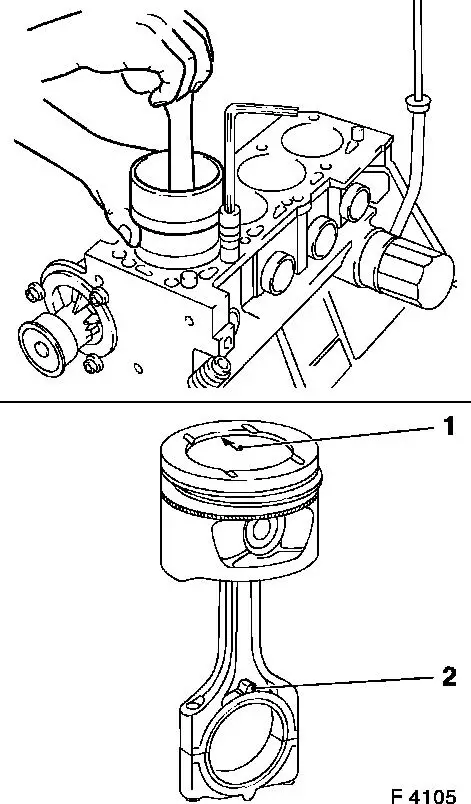

| 99. |

Install piston

Note: Arrow (1) on

bottom of piston points to engine timing side. Bead (2) on con-rod

should face transmission side

| • |

Coat piston and cylinder bores with engine oil

|

| • |

Compress piston rings with piston ring tensioner

|

|

| 101. |

Attach con-rod bearing cap

Note: Bead on con-rod

bearing cap should face transmission side

| • |

Coat con-rod journal with engine oil

|

| • |

Tighten 4x bolts 25 Nm + 30°

|

|

|

|

| 102. |

Rotate crankshaft in direction of engine rotation

(180°)

|

| 104. |

Install piston

Note: Arrow (1) on

bottom of piston points to engine timing side. Bead (2) on con-rod

should face transmission side

| • |

Coat piston and cylinder bores with engine oil

|

| • |

Compress piston rings with piston ring tensioner

|

|

| 106. |

Attach con-rod bearing cap

Note: Bead on con-rod

bearing cap should face transmission side

| • |

Coat con-rod journal with engine oil

|

| • |

Tighten 4x bolts 25 Nm + 30°

|

|

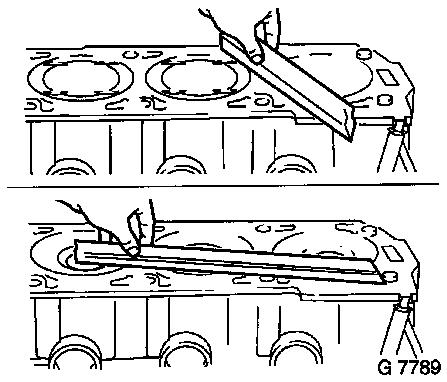

| 108. |

Clean sealing surfaces

| • |

Cylinder block, crankshaft bearing bridge, oil pan, cylinder

head, timing case, exhaust manifold, oil filter housing, thermostat

housing, cylinder head cover

|

|

| 109. |

Check for plane surface

| • |

Cylinder head, cylinder block

|

| • |

With straightedge, feeler gauge

|

|

|

|

| 110. |

Attach cylinder head

| • |

Attach cylinder head gasket

| – |

OBEN/TOP mark must point upwards.

|

|

|

| 111. |

Install cylinder head bolts

Note: Note tightening

sequence.

| • |

Tighten 10x bolts 25 Nm + 90° +

90° + 90° + 45°

|

|

|

|

|

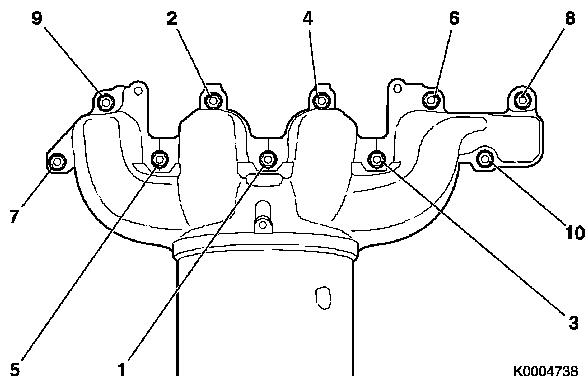

| 112. |

Install exhaust manifold

| • |

Position engine transport shackle

|

| • |

Tighten 10x nuts 12 Nm + 12 Nm

Note: The nuts must be

tightened in two stages in accordance with the tightening

sequence

| – |

Note tightening sequence.

|

|

| • |

Attach bracket for engine control unit wiring harness

|

|

|

| 113. |

Fasten oil dipstick guide tube

|

| 114. |

Install exhaust manifold heat shield

|

| 115. |

Install oxygen sensor, mixture regulation, heated

| • |

Apply assembly paste (white) to thread

|

| • |

Tighten oxygen sensor 30 Nm

|

|

| 117. |

Attach upper radiator hose

|

| 118. |

Attach centre coolant hose

|

| 120. |

Install intake manifold

| • |

Attach brake servo vacuum line

| – |

Connection must audibly engage

|

|

|

| 121. |

Install right rear engine transport shackle

|

| 122. |

Attach heating return hose

|

| 123. |

Attach preheater hose for throttle valve module

|

| 124. |

Install fuel distributor pipe

| • |

Replace 4x injector seal rings

|

| • |

Connect fuel distributor pipe with injectors and engine

management wiring harness

|

|

| 125. |

Attach wiring harness for engine management

| • |

Connect 7x wiring harness plugs

|

| • |

Attach ground cable with bracket for knock sensor wiring

harness plug

|

|

| 127. |

Attach fuel evaporation hose

|

| 128. |

Install alternator shackle

|

| 129. |

Install rear toothed belt cover

|

| 130. |

Install toothed belt drive pulley

|

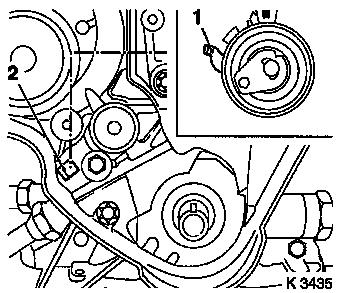

| 131. |

Install toothed belt tension roller

| • |

Detent lever (1) of toothed belt tension roller must engage in

guide web (2) of oil pump.

|

| • |

Bolt in bolt

Note: Adjust toothed

belt tension before tightening bolt.

|

|

|

|

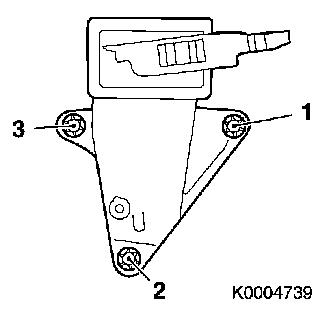

| 132. |

Install right engine bracket

| • |

Insert bolts with locking compound (red)

|

| • |

Tighten bolts 65 Nm + 45° -

60°

Note: Note tightening

sequence (1 - 3).

|

|

|

|

| 133. |

Install intake side toothed belt guide roller

Note: The toothed belt

guide roller with the greater diameter is installed at the intake

side.

|

| 134. |

Install exhaust side toothed belt guide roller

|

| 135. |

Install 2x camshaft sprockets

Note: Second person

required

| • |

Tighten 2x bolts 50 Nm + 60° +

15°

| – |

Counterhold camshafts at hexagonal section

|

|

|

| 136. |

Fix camshaft sprockets in position.

| • |

Marks must be opposite one another and aligned with the top

edge of the cylinder head (I)

|

| • |

Use KM-852 (II)

| – |

Turn the camshafts at hexagonal section

|

|

|

| 137. |

Lock crankshaft

| • |

Install crankshaft V-belt pulley bolt

|

| • |

Set crankshaft to mark.

| – |

Marks on drive gear toothed belt and rear toothed belt cover

must align (III).

|

|

|

|

|

| 138. |

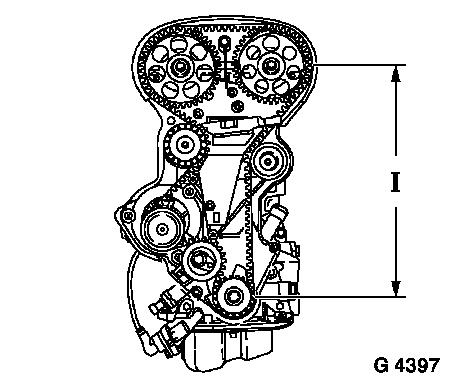

Install toothed belt

Note: Note running

direction

| • |

Position toothed belt

Note: Tensioned side

must be taut (I)

|

|

|

|

| 139. |

Tension toothed belt

| • |

Tension toothed belt tension roller

| – |

Turn adjusting eccentric in direction of arrow (anticlockwise)

until pointer of the toothed belt tension roller is located just

before left stop

|

|

| • |

Fasten toothed belt tension roller bolt (1)

|

|

|

|

| 141. |

Timing, Check

| • |

Turn crankshaft in direction of engine rotation at the

crankshaft ribbed V-belt pulley bolt (720°)

|

| • |

Set crankshaft to mark.

| – |

Marks on drive gear toothed belt and rear toothed belt cover

must align (III).

|

|

| • |

Use KM-852 (II)

| – |

Marks must be opposite one another and aligned with the top

edge of the cylinder head (I)

|

|

|

|

|

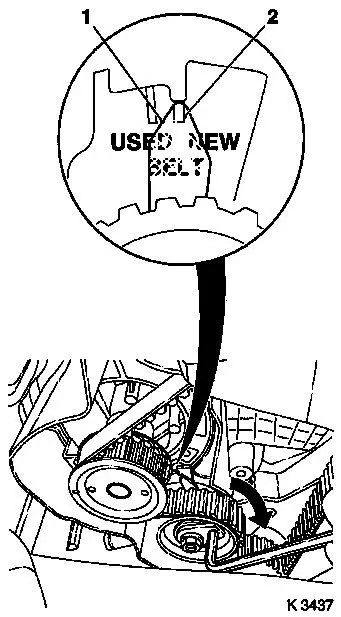

| 143. |

Adjust toothed belt tension

| • |

Release toothed belt tension roller

|

| • |

Turn adjustment eccentric in direction of arrow (clockwise)

until tension roller toothed belt pointer (1) is aligned with notch

mark (2).

| – |

Adjust used toothed belts to the marking USED

|

| – |

Adjust new toothed belts to the marking NEW

|

|

| • |

Tighten toothed belt tension roller bolt 20 Nm

|

|

| 144. |

Check toothed belt tension

| • |

Pointer on the toothed belt tension roller and notch mark must

align.

| – |

Adjust used toothed belts to the marking USED

|

| – |

Adjust new toothed belts to the marking NEW

|

|

|

|

|

| 145. |

Install lower part of toothed belt cover

| • |

Clip to rear of toothed belt cover

|

|

| 146. |

Install camshaft sensor

| • |

Insert bolts with locking compound

|

|

| 147. |

Install upper part of toothed belt cover

| • |

Clip to rear of toothed belt cover

|

|

| 148. |

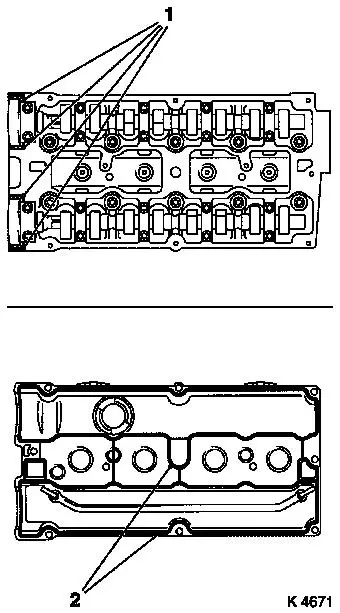

Install cylinder head cover

| • |

Apply sealant (1)

Note: Complete assembly

operations within 10 minutes

|

| • |

Attach engine vent hose

|

| • |

Clip in cable for mixture regulation heated oxygen sensor

|

|

|

|

| 149. |

Install ignition module

|

| 150. |

Install preheater line for throttle valve module

|

| 151. |

Connect coolant temperature sensor wiring harness plug

|

| 152. |

Connect camshaft sensor wiring harness plug

|

| 153. |

Use MKM-883-1

Note: Second person

required

|

| 154. |

Fasten MKM-883-1

Note: Observe

manufacturer's instructions

|

| 155. |

Attach engine

| • |

To right engine transport shackle

|

| • |

To front left engine transport shackle

Note: The front left

engine transport shackle is used only to stabilise the engine

|

|

| 159. |

Release rear reaction member

|

| 160. |

Remove front reaction member

|

| 162. |

Lift engine

Note: Observe

manufacturer's instructions

| • |

Carefully raise the engine approx. 40 mm on the timing side

with MKM-883-1

|

|

| 164. |

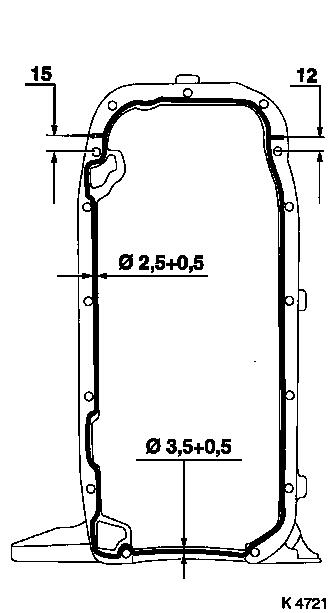

Install oil pan

| • |

Apply sealant

Note: Complete assembly

operations within 10 minutes

|

| • |

At cylinder block

| – |

Tighten 12x bolts 10 Nm

|

|

| • |

Insert rear closure plug

|

|

|

|

| 166. |

Lower engine

Note: When lowering pay

attention to the shift guide and rear reaction member

|

| 168. |

Fasten rear reaction member

|

| 169. |

Install front reaction member

| • |

Tighten bolted connection 60 Nm

|

|

| 170. |

Attach exhaust system

|

| 171. |

Attach wiring harness for engine management

| • |

Connect 2 wiring harness plugs

|

|

| 172. |

Attach KM-6169

| • |

Position KM-6169 on the left on the

front axle body

| – |

Guide pin must be seated in bore in front axle body

|

|

| • |

Attach both right holders on the front axle body

| – |

Guide pin must be seated in bore in front axle body

|

|

|

| 173. |

Install support to KM-6169

| • |

Adjust mount for support

|

|

| 174. |

Adjust supports

| • |

Transmission side

| – |

Turn spindles until mounts are positioned at guide journals

free of play

|

|

| • |

Engine timing side

| – |

Insert journal of the support in the bore of the cylinder block

free of play

|

|

|

| 176. |

Clean thread on cylinder head.

|

| 177. |

Install right engine damping block

| • |

Fasten engine bracket adapter

| – |

Tighten bolts 60 Nm + 30° -

45°

|

|

| • |

Fasten engine damping block

|

|

| 180. |

Remove MKM-883-1

Note: Second person

required

|

| 185. |

Fasten alternator

| • |

Fasten alternator support

|

|

| 186. |

Attach intake manifold support

|

| 187. |

Install ribbed V-belt tensioner

| • |

Tension ribbed V-belt tensioner with KM-913-A

|

|

| 188. |

Attach crankshaft ribbed V-belt pulley

| • |

Tighten bolt 95 Nm + 30° +

15°

|

| • |

Insert front closure plug

|

|

| 189. |

Install ribbed V-belt

Note: Observe running

direction and installation position

| • |

Slacken ribbed V-belt tensioner with KM-913-A

|

|

| 190. |

Install ribbed V-belt cover

|

| 191. |

Install right-hand air duct

|

| 193. |

Attach front right wheel

|

| 195. |

Fasten right front wheel.

|

| 196. |

Install air cleaner housing

| • |

Attach engine vent hose

|

| • |

Clip in tank vent valve

|

| • |

Connect 2 wiring harness plugs

|

|

| 197. |

Install engine cover.

| • |

Unscrew oil filler pipe cap

|

| • |

Screw on oil filler pipe cap

|

|

| 199. |

Calibrate steering angle sensor

| • |

Rotate the steering wheel one time from its right-hand to its

left-hand stop

|

|

| 200. |

Program volatile memories

|

| 201. |

Top up engine oil

| • |

Start engine and allow to run until oil pressure telltale

extinguishes.

|

| • |

Check engine oil level, if necessary correct.

|

|

| 202. |

Top up and bleed cooling system

|

| 203. |

Reset service interval using TECH 2

Note: If the customer

decides to have ECOService - connect TECH2 and reprogram engine

control unit

|

| 204. |

Fill out the service sticker

|

|