|

J 312315 Valve Stem Seals, Replace (Z 18 XE, with

Air Conditioning, LHD)

Remove Remove

| 2. |

Disconnect battery

Note: In vehicles from

model year 04 onwards with ESP - the steering angle sensor loses

its basic adjustment each time the battery is disconnected and must

be recalibrated.

|

| 3. |

Remove engine cover.

| • |

Unscrew oil filler pipe cap

|

| • |

Screw on oil filler pipe cap

|

|

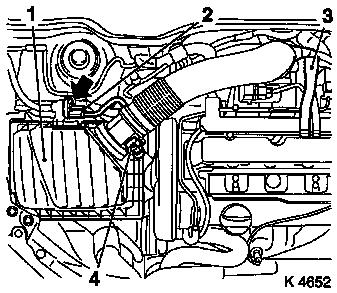

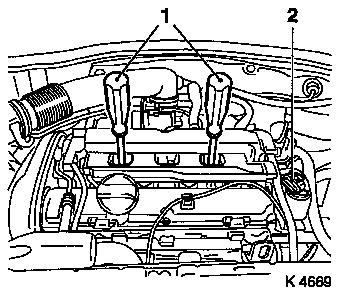

| 4. |

Remove air cleaner housing (1)

| • |

Disconnect 2 wiring harness plugs

| – |

Hot film mass air flow meter (4), tank vent valve (2)

|

|

| • |

Detach engine vent hose (3)

|

|

|

|

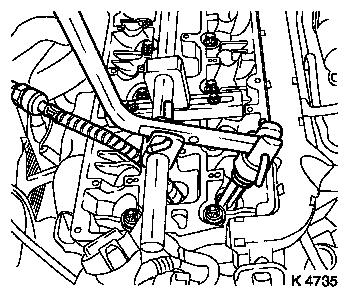

| 5. |

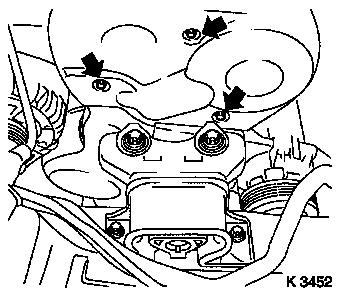

Remove upper part of toothed belt cover

| • |

Unscrew 3 bolts (arrows)

|

| • |

Unclip from rear toothed belt cover

|

|

|

|

| 7. |

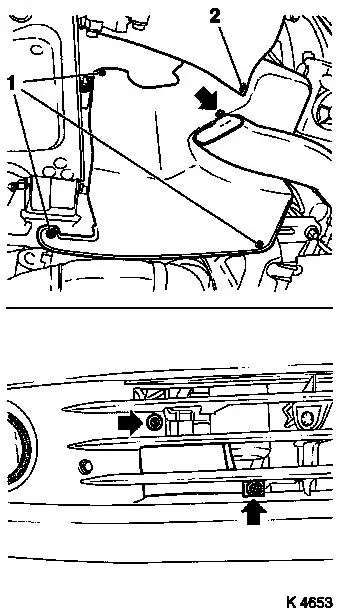

Remove right-hand air duct

| • |

Unscrew 3 bolts (arrows)

|

|

| 8. |

Remove ribbed V-belt cover

|

|

|

| 10. |

Detach front right wheel

|

| 12. |

Remove right front wheel.

|

| 14. |

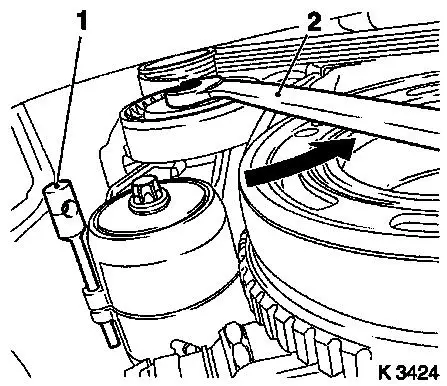

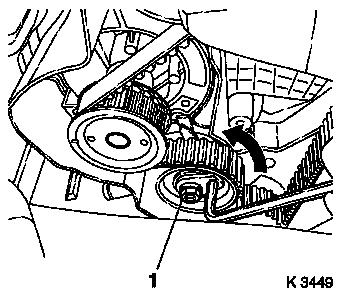

Remove ribbed V-belt

| • |

Tension ribbed V-belt tensioner in direction of arrow with

KM-913-A (2)

|

|

|

|

| 15. |

Remove ribbed V-belt tensioner

| • |

Tension ribbed V-belt tensioner.

|

| • |

Release ribbed V-belt tensioner

|

|

|

|

| 16. |

Detach crankshaft ribbed V-belt pulley

| • |

Prise front closure plug out of oil pan

|

|

|

|

| 17. |

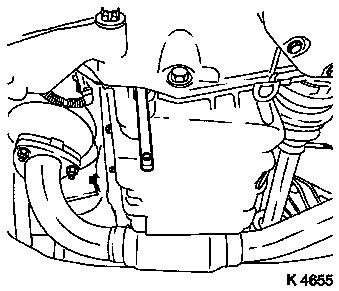

Release lower part of toothed belt cover

| • |

Unclip from rear toothed belt cover

|

|

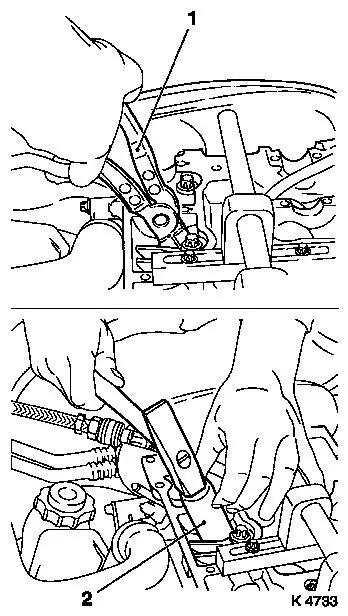

|

|

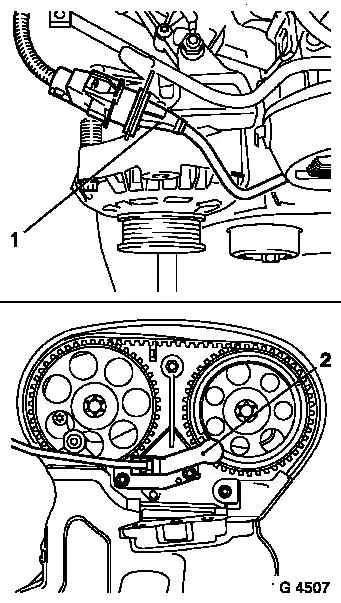

| 20. |

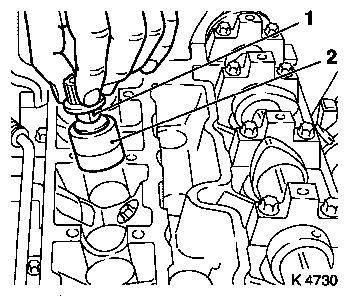

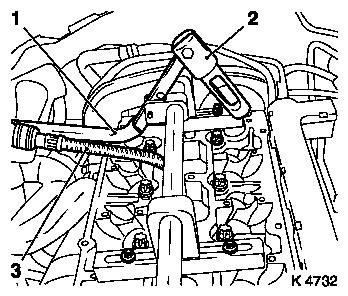

Disconnect camshaft sensor wiring harness plug (1)

|

| 21. |

Remove lower part of toothed belt cover

| • |

Unclip from rear toothed belt cover

|

|

| 22. |

Remove camshaft sensor (2)

|

|

|

|

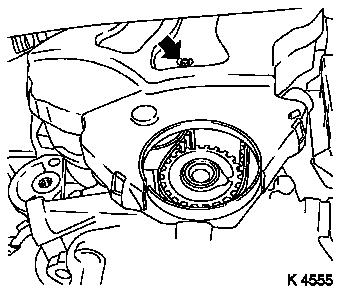

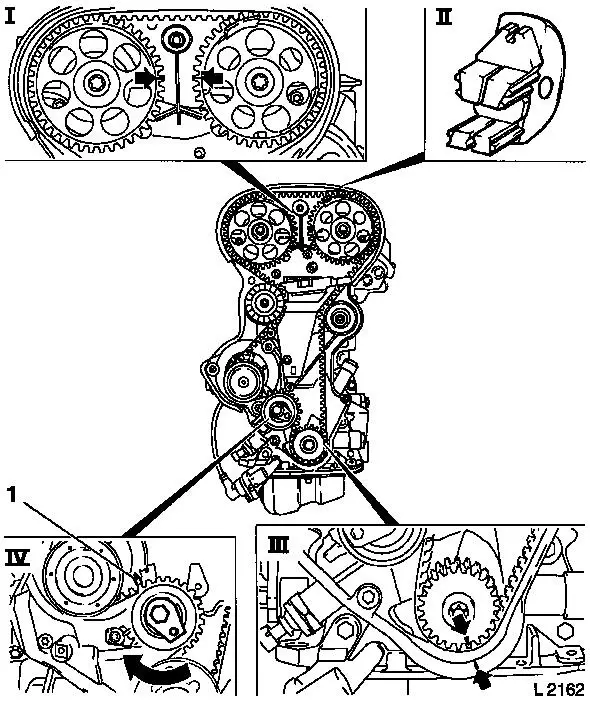

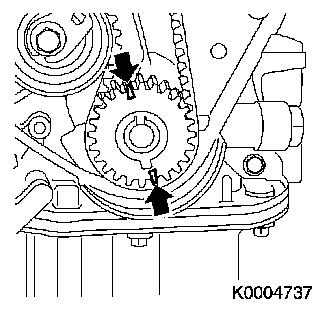

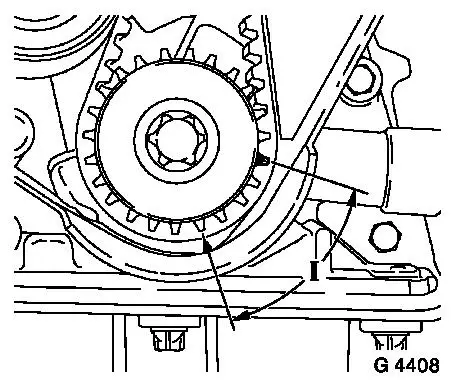

| 23. |

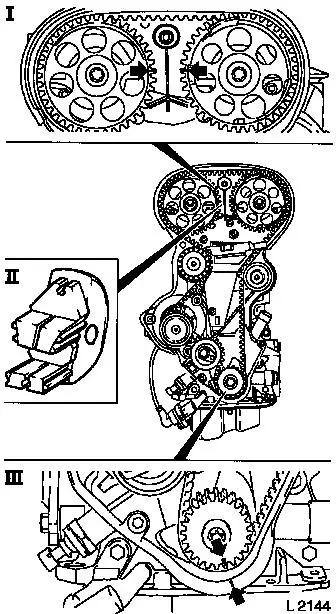

Set 1st cylinder to TDC of combustion stroke

| • |

Install crankshaft V-belt pulley bolt

|

| • |

Set crankshaft to mark.

| – |

Marks on drive gear toothed belt and rear toothed belt cover

must align (III).

|

|

| • |

Fix camshaft sprockets in position.

| – |

Marks must be opposite one another and aligned with the top

edge of the cylinder head (I)

|

|

|

| 24. |

Remove toothed belt

| • |

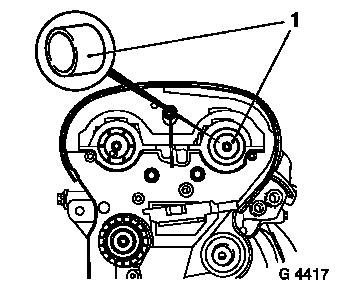

Release toothed belt tension roller (IV)

| – |

Turn adjusting eccentric in direction of arrow (clockwise)

until pointer (1) of the toothed belt tension roller is located

just before left stop.

|

|

|

|

| 25. |

Remove ignition module

| • |

Disconnect wiring harness plug (2)

|

| • |

Extract using KM-6009 (1)

Note: Do not tilt

|

|

|

|

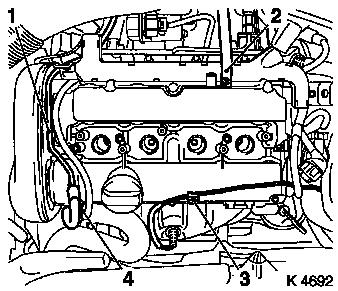

| 26. |

Release preheater line - throttle valve module (1)

| • |

Disconnect coolant temperature sensor wiring harness plug

(4)

|

| • |

Unclip wiring harness of mixture regulation heated oxygen

sensor (3)

|

|

| 27. |

Remove cylinder head cover

| • |

Detach engine vent hose (2)

|

|

|

|

| 29. |

Remove exhaust camshaft sprocket

| • |

Remove bolt

| – |

Counterhold camshaft at hexagonal section

|

|

|

| 30. |

Remove intake camshaft sprocket

| • |

Remove bolt

| – |

Counterhold camshaft at hexagonal section

|

|

|

| 31. |

Release rear toothed belt cover

|

|

|

| 32. |

Loosen upper rear toothed belt cover

|

| 33. |

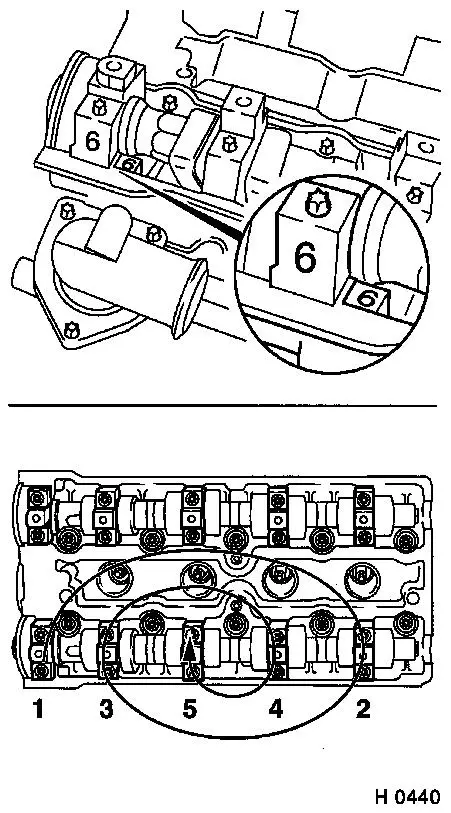

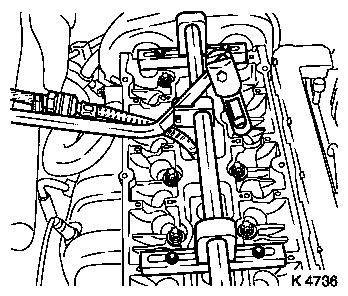

Remove exhaust camshaft

| • |

Remove camshaft bearing cap

Note: Note

identification

|

| • |

Release camshaft bearing caps in stages, working in a spiral

pattern from the outside inwards

Note: Camshaft must be

evenly released from the bearing seats

|

| • |

Remove camshaft seal ring

|

|

|

|

| 34. |

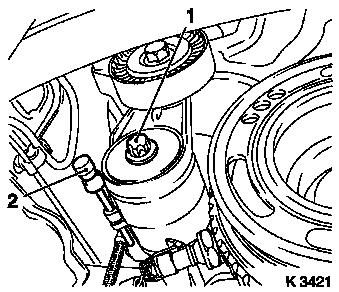

Remove 8x hydraulic valve lifters (2) with KM-845 (1)

Note: Observe

allocation.

|

|

|

| 35. |

Remove intake camshaft

| • |

Remove camshaft bearing cap

Note: Note

identification

|

| • |

Release camshaft bearing caps in stages, working in a spiral

pattern from the outside inwards

Note: Camshaft must be

evenly released from the bearing seats

|

| • |

Remove camshaft seal ring

|

|

| 36. |

Remove 8x hydraulic valve lifters with KM-845

Note: Observe

allocation.

|

| 37. |

Remove 4x spark plugs with KM-194-E

|

| 39. |

Close coolant drain bolt

|

| 40. |

Apply positioning marks to toothed belt drive gear

| • |

180° offset to no.1 cylinder TDC mark

(Zünd-OT-Zylinder-1) (arrows)

|

|

|

|

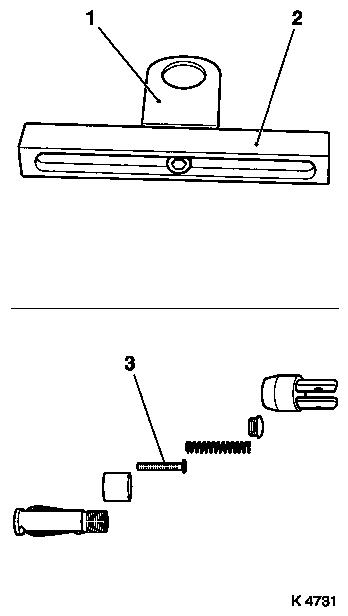

| 43. |

Assemble automatic valve spring compressor

Note: Observe

manufacturer's instructions

| • |

Adjust supports

| – |

Adjust support heads (1) so that they are centred on support

feet (2) and tighten

|

|

| • |

Assemble lever arm with joint and removal head

|

| • |

Assemble installation kit MKM-6089-200

| – |

Insert thrust piece 5b (3)

|

|

|

|

|

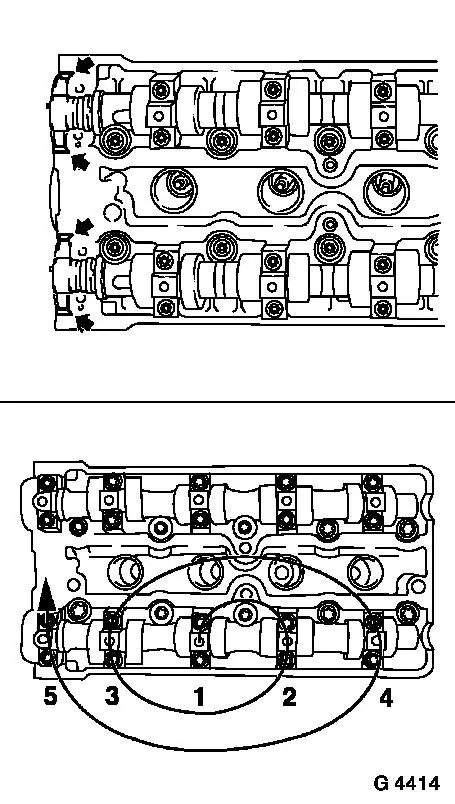

| 44. |

Attach automatic valve spring compressor

| • |

Attach supports to camshaft bearing cap positions 1 and 4

| – |

Slide installation shaft into supports

Note: Align

installation shaft so that it is centred on spark plug bore

|

|

| • |

Install lever arm (1)

| – |

Removal head (2) must face intake side

|

|

| • |

Secure installation shaft

|

|

| 45. |

Install compressed air adapter (3)

| • |

Screw into spark plug thread of 1st cylinder

|

| • |

Apply compressed air to 1st cylinder

|

|

|

|

| 46. |

Remove 2x cylinder no.1 intake valve springs

Note: Do not use

magnetised tool.

| • |

Carefully push valve spring down with lever arm

| – |

Removal head must be vertically above the valve stem

|

|

| • |

Remove valve keepers, valve head, valve spring

Note: Observe

allocation.

|

|

| 47. |

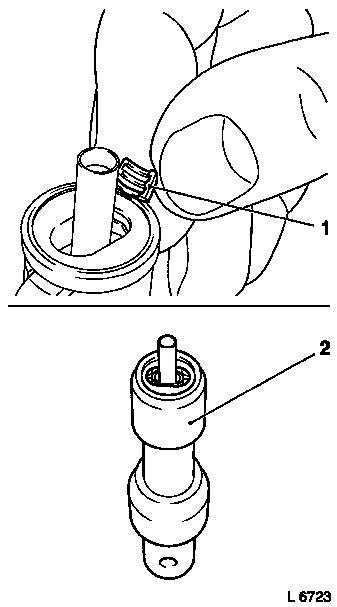

Replace 2x valve stem seals

| • |

Detach using KM-840 (1)

|

| • |

Attach new valve stem seal to valve stem

|

| • |

Drive in to stop using KM-835-A

(2)

|

|

|

|

| 48. |

Install intake valve springs for 1st cylinder

| • |

Insert valve spring, valve head

|

| • |

Insert valve keepers (1) in assembly head

| – |

Slide clamping sleeve (2) in direction of lever arm mount

|

| – |

Insert valve keepers with taper facing the valve.

|

| – |

Push clamping sleeve towards valve

|

|

| • |

Attach assembly head to lever arm

|

| • |

Carefully push valve spring down with lever arm

| – |

Assembly head must be vertically above the valve stem

|

| – |

The valve keepers must audibly engage

|

|

|

|

|

| 49. |

Check installation position

Note: Do not make 2nd

attempt without checking that both valve keepers are in the

assembly head.

| • |

Check seat of valve keepers

|

| • |

Check that compressed air is being applied

|

|

| 50. |

Transfer lever arm

| • |

Install lever arm

| – |

Removal head must face exhaust side

|

|

|

| 51. |

Remove 2x cylinder no.1 exhaust valve springs

Note: Do not use

magnetised tool.

| • |

Carefully push valve springs downwards

| – |

Removal head (1) must be vertically above the valve stem

|

|

| • |

Remove valve keepers, valve head, valve spring

Note: Observe

allocation.

|

|

|

|

| 52. |

Replace 2x valve stem seals

| • |

Detach using KM-840 (1)

|

| • |

Attach new valve stem seal to valve stem

|

| • |

Drive in to stop using KM-835-A

(2)

|

|

| 53. |

Install exhaust valve springs for 1st cylinder

| • |

Insert valve springs, valve head

|

| • |

Insert valve keepers in assembly head

| – |

Push clamping sleeve towards lever arm mount

|

| – |

Insert valve keepers with taper facing the valve.

|

| – |

Push clamping sleeve towards valve

|

|

| • |

Attach assembly head to lever arm

|

| • |

Carefully push valve spring down with lever arm

| – |

Assembly head must be vertically above the valve stem

|

| – |

The valve keepers must audibly engage

|

|

|

| 54. |

Check installation position

Note: Do not make 2nd

attempt without checking that both valve keepers are in the

assembly head.

| • |

Check seat of valve keepers

|

| • |

Check that compressed air is being applied

|

|

| 55. |

Transfer compressed air adapter

| • |

Interrupt compressed air feed

|

| • |

Unscrew from spark plug thread of 1st cylinder

|

| • |

Screw into spark plug thread of 4th cylinder

|

| • |

Apply compressed air to 4th cylinder

|

|

| 56. |

Transfer lever arm

| • |

Loosen installation shaft

|

| • |

Secure installation shaft

|

|

|

|

| 57. |

Replace 4x valve stem seals for cylinder no. 4

|

| 58. |

Interrupt compressed air feed

|

| 61. |

Set 3rd cylinder to TDC of combustion stroke

| • |

Turn crankshaft evenly (180°)

|

| • |

Toothed belt drive gear positioning mark must align with mark

on rear toothed belt cover.

|

|

| 64. |

Transfer automatic valve spring compressor

| • |

Transfer supports to camshaft bearing cap positions 1 and 5

| – |

Slide installation shaft into supports

|

| – |

Align installation shaft so that it is centred on spark plug

bore

|

|

| • |

Install lever arm

Note: Removal head must

face intake side

|

| • |

Secure installation shaft

|

|

| 65. |

Transfer compressed air adapter

| • |

Unscrew from spark plug thread of 4th cylinder

|

| • |

Screw into spark plug thread of 2nd cylinder

|

| • |

Apply compressed air to 2nd cylinder

|

|

|

|

| 66. |

Replace 4x valve stem seals for cylinder no. 2

|

| 67. |

Transfer compressed air adapter

| • |

Interrupt compressed air feed

|

| • |

Unscrew from spark plug thread of 2nd cylinder

|

| • |

Screw into spark plug thread of 3rd cylinder

|

| • |

Apply compressed air to 3rd cylinder

|

|

| 68. |

Replace 4x valve stem seals for cylinder no. 3

|

| 69. |

Interrupt compressed air feed

|

| 70. |

Detach automatic valve spring compressor

|

| 71. |

Remove compressed air adapter

|

Install

Install

| 72. |

Inspect components

| • |

Camshafts, camshaft bearing caps, hydraulic valve lifters,

cylinder head, ribbed V-belt, ribbed V-belt tensioner, ribbed

V-belt pulleys, toothed belt drive, spark plugs

|

|

| 73. |

Install spark plugs

| • |

Tighten 4x with KM-194-E , 25 Nm

|

|

| 76. |

Position crankshaft

| • |

Set crankshaft to 60° before no.1 cylinder TDC of

combustion stroke

|

|

|

|

| 79. |

Insert 8x hydraulic valve lifters

| • |

Coat sliding surfaces with engine oil

Note: Observe

allocation.

|

|

| 80. |

Install intake camshaft

| • |

Coat sliding surfaces with engine oil

|

| • |

Apply sealant in the area of the camshaft seal ring

(arrows)

Note: Do not apply

sealant in vicinity of oil channels. Complete installation work

within 10 minutes.

|

| • |

Insert camshaft, camshaft bearing cap

Note: Observe

identification and allocation

|

| • |

Tighten 10x bolts for camshaft bearing caps 8 Nm

| – |

Tighten in stages, working in a spiral pattern from the inside

outwards

|

|

|

|

|

| 81. |

Insert 8x hydraulic valve lifters

| • |

Coat sliding surfaces with engine oil

Note: Observe

allocation.

|

|

| 82. |

Install exhaust camshaft

| • |

Coat sliding surfaces with engine oil

|

| • |

Apply sealant in the area of the camshaft seal ring

(arrows)

Note: Do not apply

sealant in vicinity of oil channels. Complete installation work

within 10 minutes.

|

| • |

Insert camshaft, camshaft bearing cap

Note: Observe

identification and allocation

|

| • |

Tighten 10x bolts for camshaft bearing caps 8 Nm

| – |

Tighten in stages, working in a spiral pattern from the inside

outwards

|

|

|

| 83. |

Install intake camshaft seal ring

| • |

Coat seal lip with grease

|

| • |

Place seal ring on camshaft journal

|

| • |

Install camshaft seal ring

| – |

With KM-422 (1), bolt and camshaft

sprocket washer

|

|

|

|

|

| 84. |

Install intake camshaft seal ring

| • |

Coat seal lip with grease

|

| • |

Place seal ring on camshaft journal

|

| • |

Install camshaft seal ring

| – |

With KM-422 , bolt and camshaft

sprocket washer

|

|

|

| 85. |

Fasten upper rear toothed belt cover

|

| 86. |

Install camshaft sprocket on exhaust side

Note: Attach camshaft

sprocket with cylinder recognition to exhaust camshaft.

| • |

Attach KM-6347 , KM-956-1

|

| • |

Tighten bolt 50 Nm + 60° +

15°

Note: Second person

required

|

| • |

Remove KM-6347 , KM-956-1

|

|

| 87. |

Install camshaft sprocket on the intake side

Note: Attach camshaft

sprocket with cylinder recognition to exhaust camshaft.

| • |

Attach KM-6347 , KM-956-1

|

| • |

Tighten bolt 50 Nm + 60° +

15°

Note: Second person

required

|

| • |

Remove KM-6347 , KM-956-1

|

|

| 88. |

Fix camshaft sprockets in position.

| • |

Marks must be opposite one another and aligned with the top

edge of the cylinder head.

|

| • |

Use KM-852

| – |

Turn the camshafts at hexagonal section

|

|

|

| 89. |

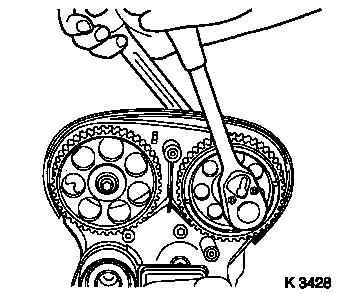

Put toothed belt in place

| • |

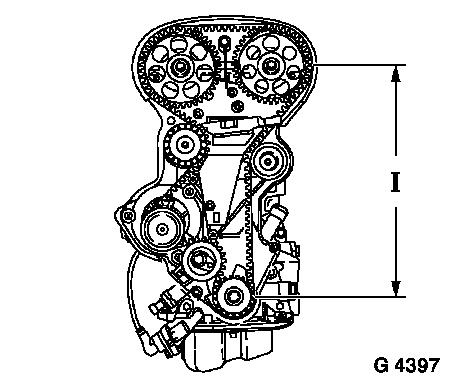

Position toothed belt

Note: Tensioned side

(I) must be taut.

|

|

|

|

| 90. |

Tension toothed belt

| • |

Tension toothed belt tension roller

| – |

Turn adjusting eccentric in direction of arrow (anticlockwise)

until pointer of the toothed belt tension roller is located just

before left stop

|

|

| • |

Fasten toothed belt tension roller bolt (1)

|

|

|

|

| 92. |

Timing, Check

| • |

Turn crankshaft in direction of engine rotation at the

crankshaft ribbed V-belt pulley bolt (720°)

|

| • |

Set crankshaft to mark.

| – |

Marks on drive gear toothed belt and rear toothed belt cover

must align (III).

|

|

| • |

Use KM-852 (II)

| – |

Marks must be opposite one another and aligned with the top

edge of the cylinder head (I)

|

|

|

|

|

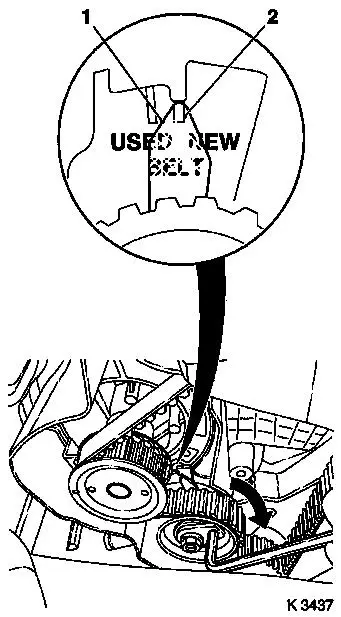

| 94. |

Adjust toothed belt tension

| • |

Release toothed belt tension roller

|

| • |

Turn adjustment eccentric in the direction of the arrow

(clockwise) until pointer (1) of toothed belt tension roller is

aligned with the appropriate notch mark

| – |

Adjust used toothed belts to the marking USED

|

| – |

Adjust new toothed belts to the marking NEW (2)

|

|

| • |

Tighten toothed belt tension roller bolt 20 Nm

|

|

| 95. |

Check toothed belt tension

| • |

Pointer on the toothed belt tension roller and notch mark must

align.

| – |

Adjust used toothed belts to the marking USED

|

| – |

Adjust new toothed belts to the marking NEW

|

|

|

| 96. |

Clean threads

| • |

Camshaft sensor to cylinder head

|

|

|

|

| 98. |

Install camshaft sensor

| • |

Insert bolts with locking compound (red)

|

|

| 99. |

Install lower part of toothed belt cover

| • |

Clip to rear of toothed belt cover

|

|

| 100. |

Install upper part of toothed belt cover

| • |

Clip to rear of toothed belt cover

|

|

| 101. |

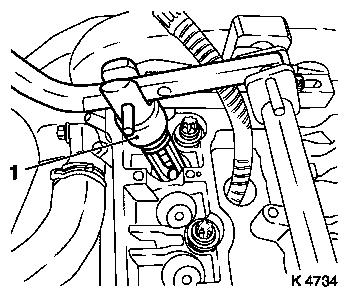

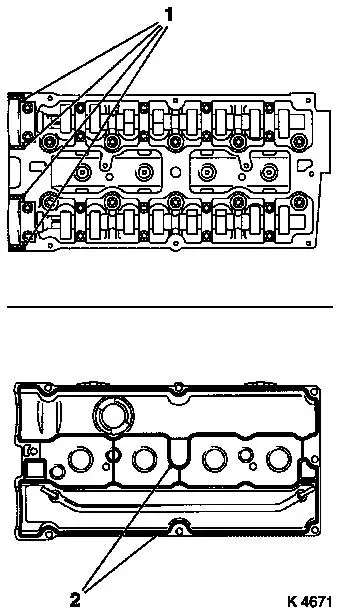

Install cylinder head cover

| • |

Apply sealant (1)

Note: Complete assembly

operations within 10 minutes

|

| • |

Attach engine vent hose

|

|

| 102. |

Fasten preheater line - throttle valve module

| • |

Connect coolant temperature sensor wiring harness plug

|

| • |

Clip in wiring harness of mixture regulation heated oxygen

sensor

|

|

| 103. |

Connect wiring harness plug from camshaft sensor

|

|

|

| 104. |

Install ignition module

| • |

Connect wiring harness plug

|

|

| 106. |

Install ribbed V-belt tensioner

| • |

Tension ribbed V-belt tensioner with KM-913-A

|

|

| 107. |

Attach crankshaft ribbed V-belt pulley

| • |

Tighten bolt 95 Nm + 30° +

15°

|

| • |

Insert front closure plug

|

|

| 108. |

Install ribbed V-belt

Note: Observe running

direction and installation position

| • |

Slacken ribbed V-belt tensioner with KM-913-A

|

|

| 109. |

Install ribbed V-belt cover

|

| 110. |

Install right-hand air duct

|

| 112. |

Attach front right wheel

|

| 114. |

Fasten right front wheel.

|

| 115. |

Install air cleaner housing

| • |

Attach engine vent hose

|

| • |

Clip in tank vent valve

|

| • |

Connect 2 wiring harness plugs

|

|

| 116. |

Install engine cover.

| • |

Unscrew oil filler pipe cap

|

| • |

Screw on oil filler pipe cap

|

|

| 118. |

Calibrate steering angle sensor

| • |

Rotate the steering wheel one time from its right-hand to its

left-hand stop

|

|

| 119. |

Program volatile memories

|

|