|

J 312315 replace valve stem seal (Z 14 XE, Z 16

YNG with air conditioning, RHD)

|

1. Open bonnet

Important: On

vehicles as of model year 04 with ESP - the steering angle sensor

loses its basic adjustment each time the battery is disconnected.

It must be recalibrated.

2. Disconnect battery

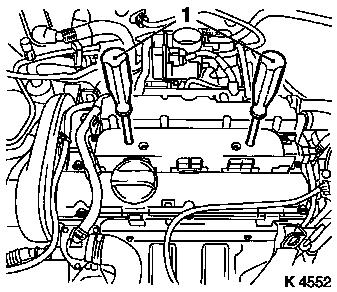

3. Remove engine cover.

- Unscrew oil filler pipe cap

- Remove 2 bolts

- Screw on oil filler pipe cap

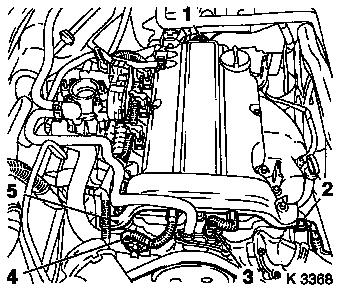

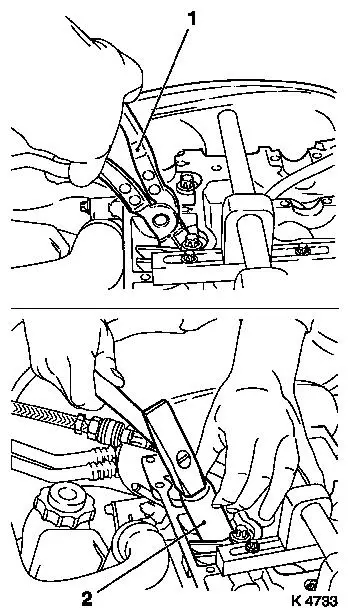

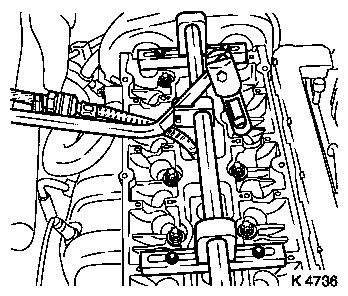

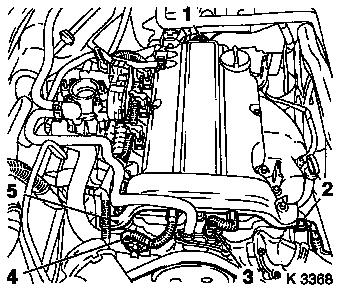

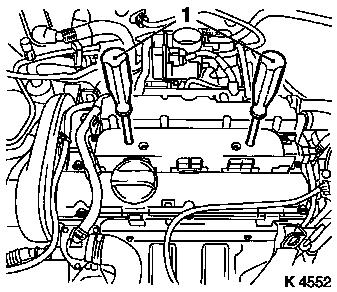

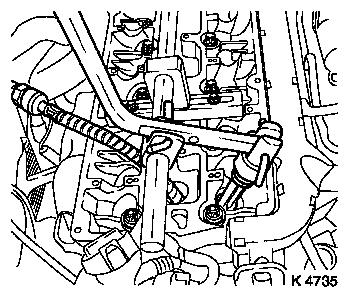

4. Remove air cleaner housing (1)

- Disconnect wiring harness plug

- Intake air temperature sensor (4), tank vent valve (2)

- Unclip tank vent valve

- Remove air intake hose

- Detach engine vent hose (5)

- Unscrew bolts (3)

|

|

|

5. Loosen front right wheel

6. Raise vehicle

7. Remove front right wheel

8. Raise vehicle

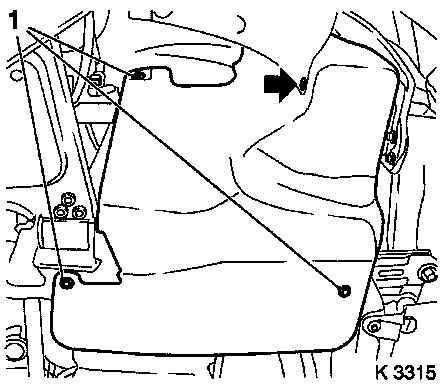

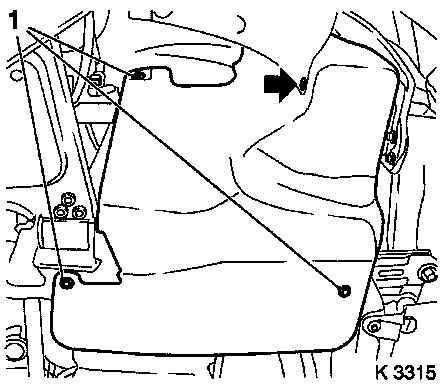

9. Remove ribbed V-belt cover

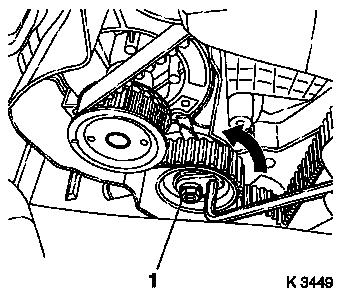

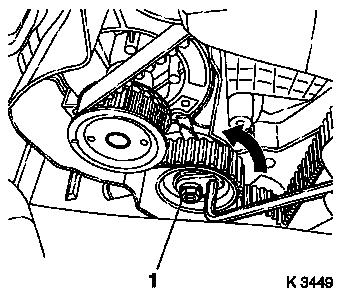

- Remove 3 bolts (1)

- Remove clip (arrow).

|

|

|

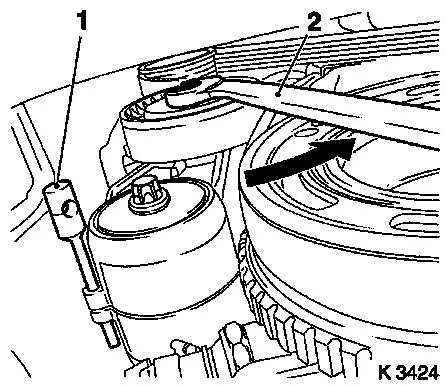

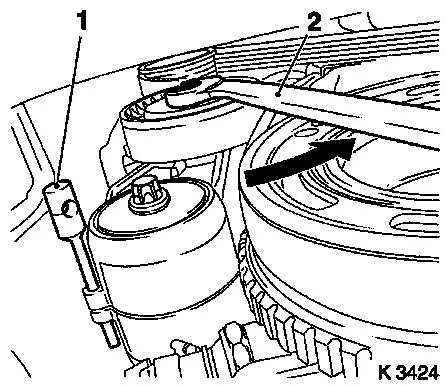

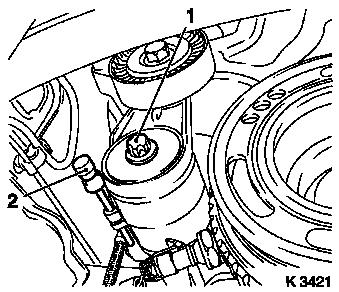

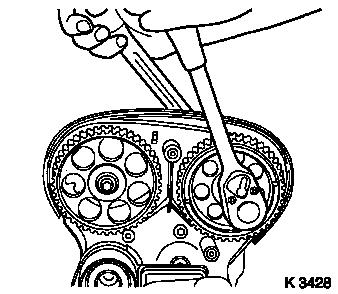

10. Remove ribbed V-belt

- Tension ribbed V-belt tensioner in direction of arrow

- With KM-913-A (2) (SW 15)

- Insert KM-6130 (1)

- Note: Mark running direction

|

|

|

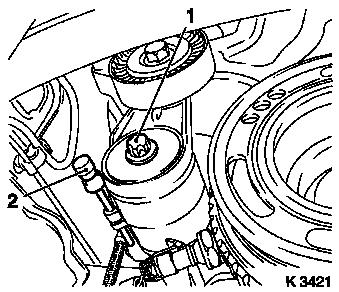

11. Remove ribbed V-belt tensioner

- Tension ribbed V-belt tensioner.

- Remove KM-6130 (2)

- Release ribbed V-belt tensioner

- Remove bolt (1)

|

|

|

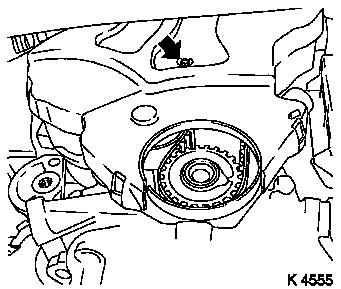

12. Detach crankshaft ribbed V-belt pulley

- Lever out front closure plug

- Insert KM-911

- Remove bolt

- Remove KM-911

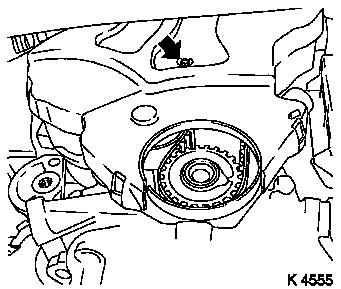

13. Loosen lower part of toothed belt cover

- Remove bolt (arrow)

- Unclip from rear toothed belt cover

|

|

|

14. Lower vehicle

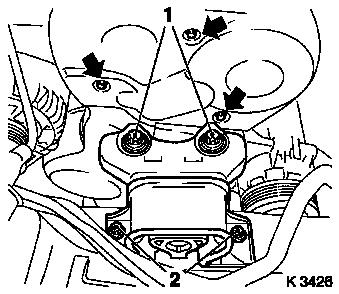

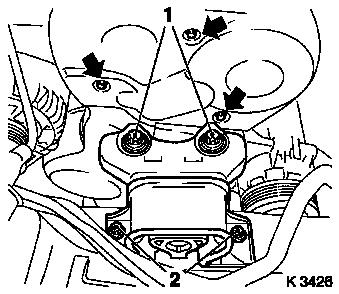

15. Remove toothed belt cover upper

part

- Remove 3 bolts (arrows)

- Unclip from rear toothed belt cover

|

|

|

16. Remove lower part of toothed belt cover

- Unclip from rear toothed belt cover

- Note: Remove downwards

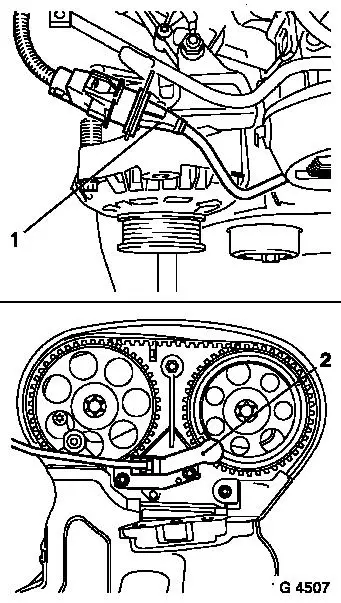

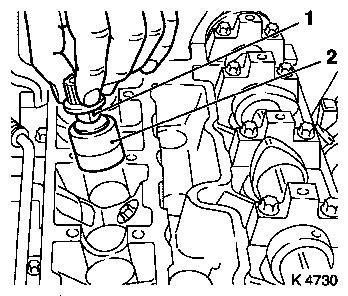

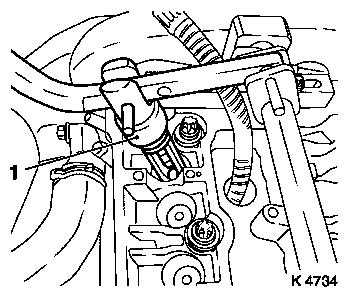

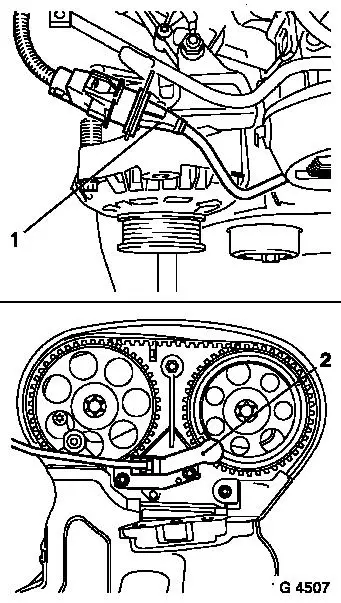

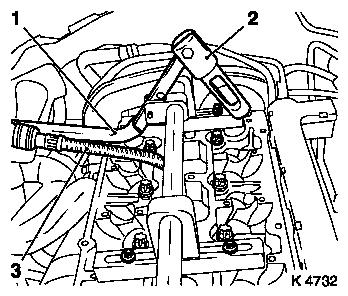

17. Disconnect camshaft sensor wiring harness plug

- Unclip out of bracket

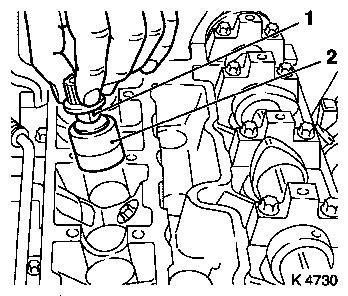

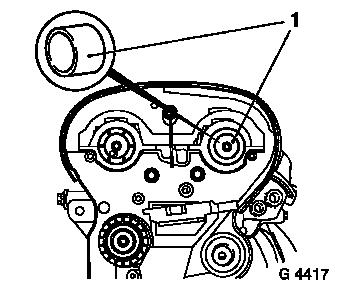

- Disconnect wiring harness plug (1)

18. Remove camshaft sensor (2)

|

|

|

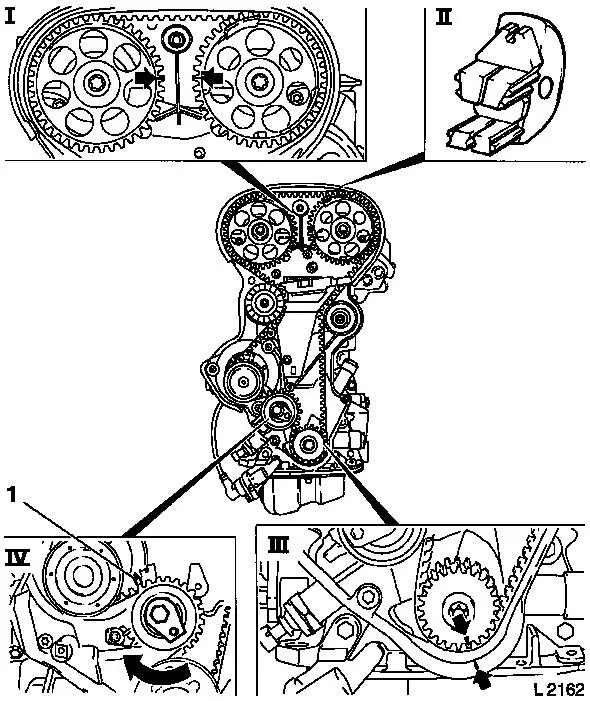

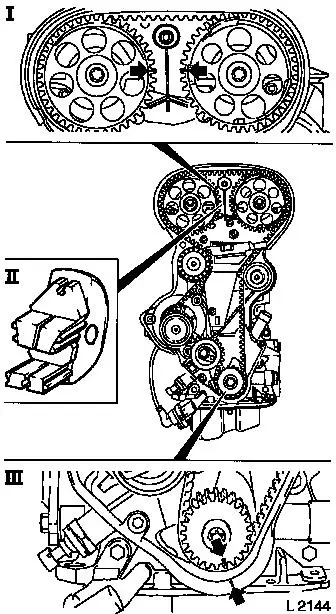

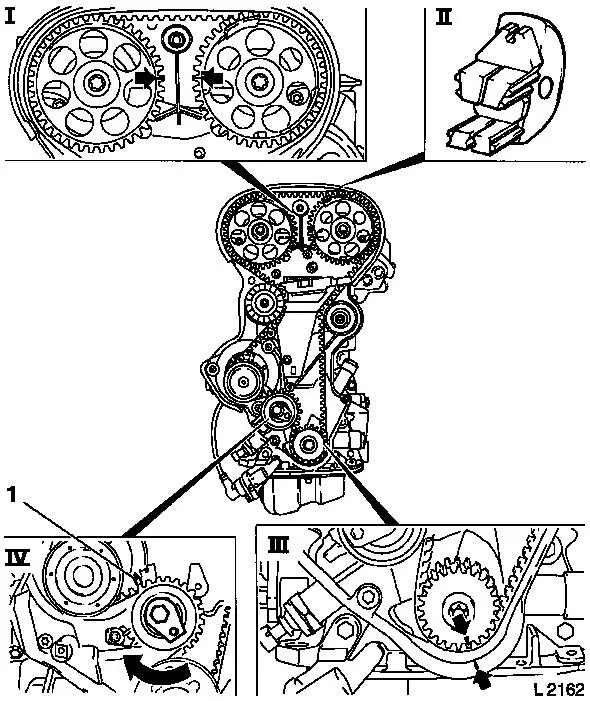

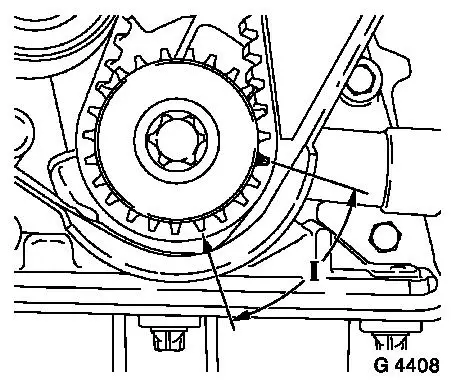

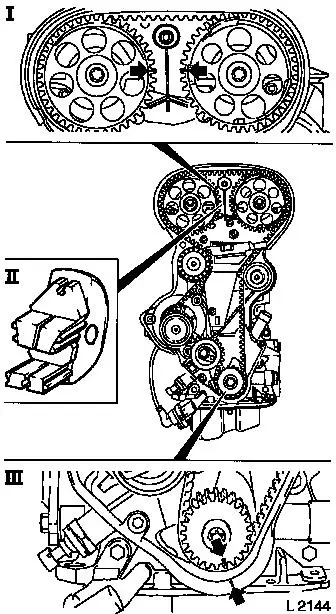

19. Set 1st cylinder to TDC

- Install crankshaft V-belt pulley bolt

- Set crankshaft to mark.

- Turn crankshaft evenly

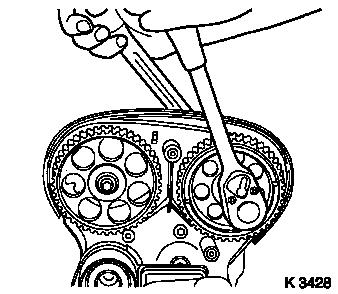

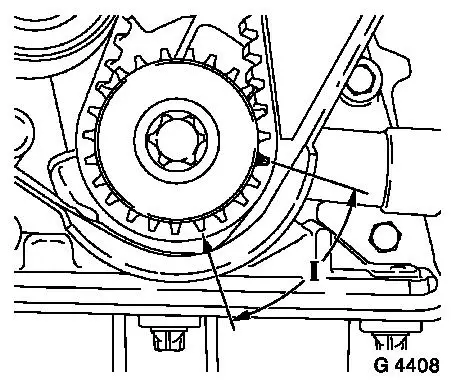

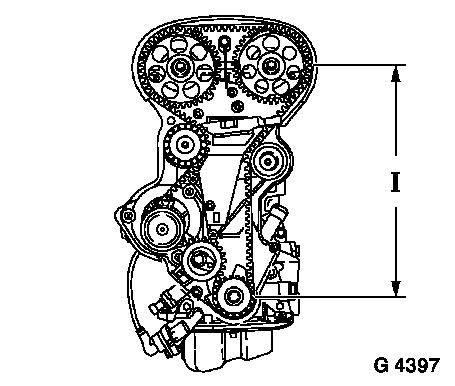

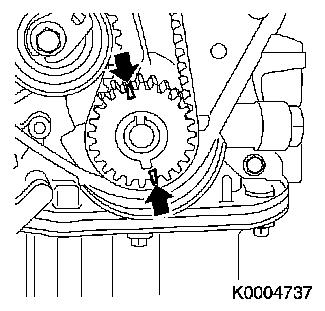

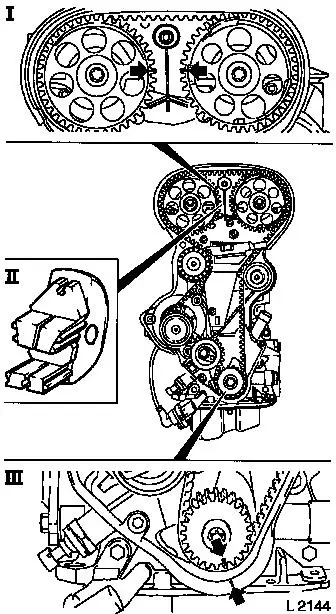

- Note: Marks on drive gear toothed belt and rear toothed belt

cover must align (III)

- Fix camshaft sprockets in position.

- Note: Marks must be opposite one another and aligned with the

top edge of the cylinder head (I)

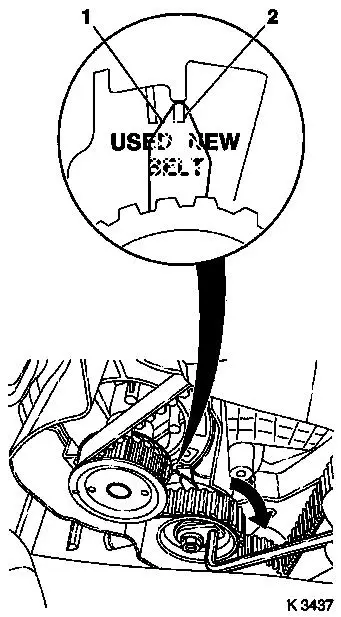

- Insert KM-852 (II)

20. Remove toothed belt

- Release toothed belt tension roller (IV)

- Loosen bolt

- Turn adjusting eccentric in direction of arrow (clockwise)

until pointer (1) of the toothed belt tension roller is located

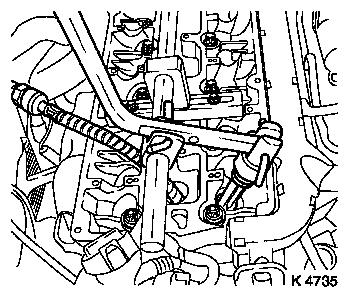

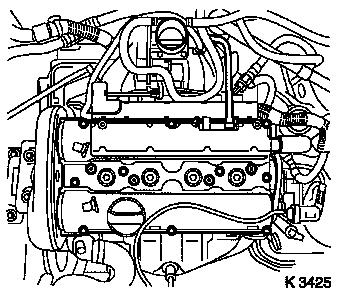

just before left stop.

|

|

|

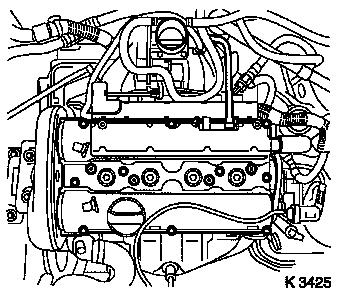

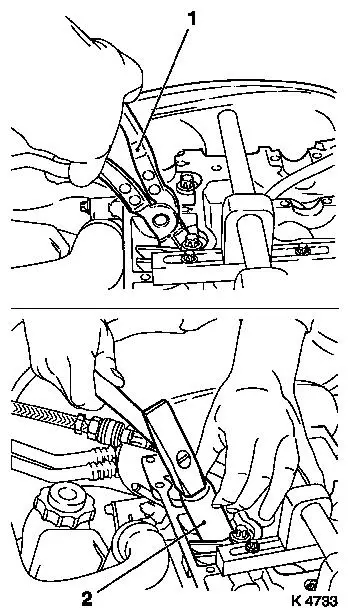

21. Remove ignition module

- Disconnect wiring harness plug

- Remove 4 bolts

- Remove using KM-6009 (1)

- Caution: Do not tilt

|

|

|

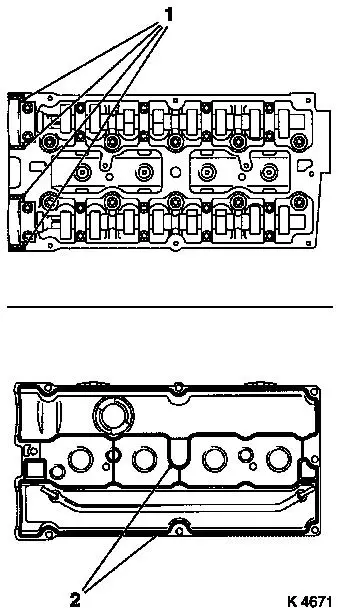

22. Remove cylinder head cover

- Detach engine vent hose

- Detach crankshaft vent hose

- Remove 10 bolts

- Remove seal

- Detach wiring harness plug for temperature sensor

|

|

|

23. Remove KM-852

24. Remove exhaust camshaft sprocket

- Remove bolt

- Counterhold camshaft at hexagonal section

25. Remove intake camshaft sprocket

- Remove bolt

- Counterhold camshaft at hexagonal section

|

|

|

26. Loosen upper rear toothed belt cover

27. Remove exhaust camshaft

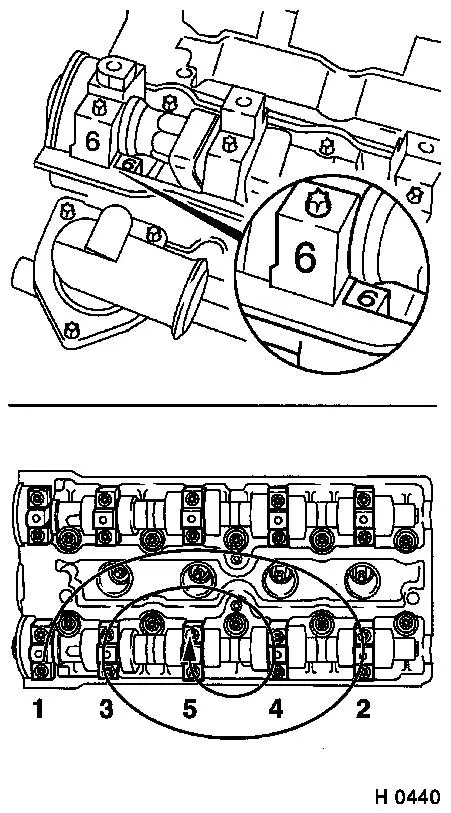

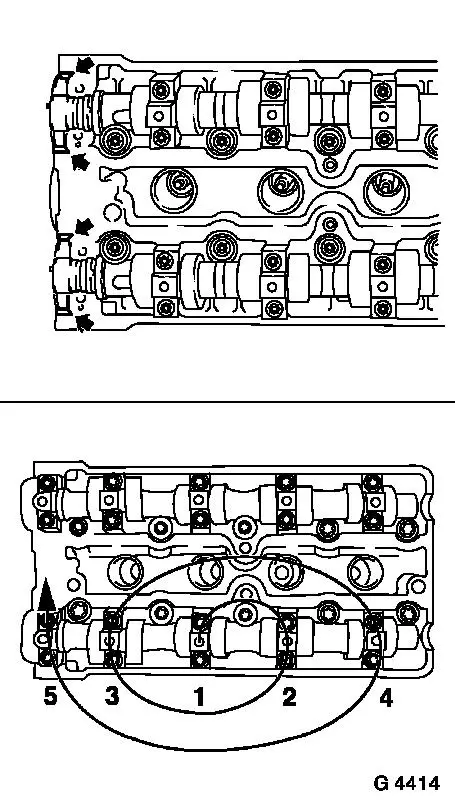

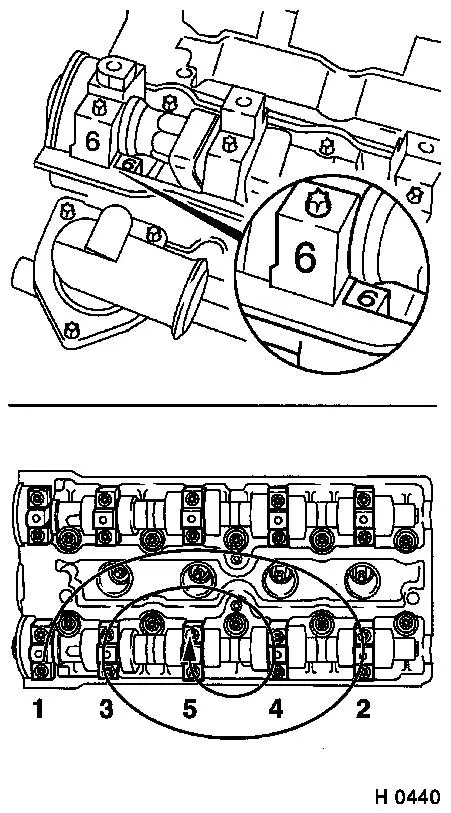

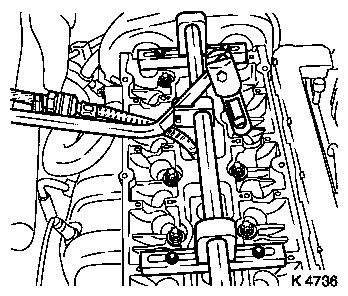

- Remove camshaft bearing cap

- Unscrew 10 bolts

- Caution: Note identification

- Release camshaft bearing cap working in inward spiral from

outside in steps of 1/2 to 1 turn

- Note: Camshaft must be evenly released from the bearing

seats

- Remove camshaft seal ring

|

|

|

28. Remove hydraulic valve lifter (2)

29. Remove intake camshaft

- Remove camshaft bearing cap

- Unscrew 10 bolts

- Caution: Note identification

- Release camshaft bearing cap working in inward spiral from

outside in steps of 1/2 to 1 turn

- Note: Camshaft must be evenly released from the bearing

seats

- Remove camshaft seal ring

|

|

|

30. Remove hydraulic valve lifter

31. Remove spark plugs

- 4 off

- Remove using KM-194-E

32. Raise vehicle

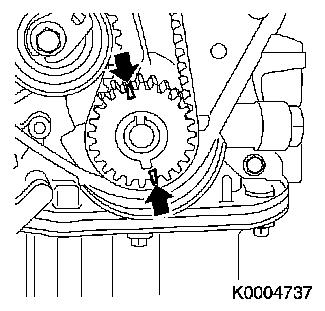

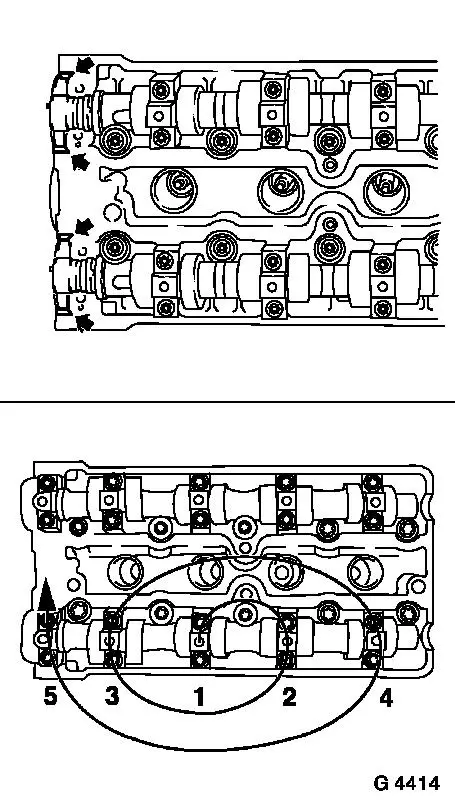

33. Attach guide mark

- On drive gear toothed belt

- Note: Offset 180° from 1st cylinder TDC mark

(Zünd-OT-Zylinder-1) (arrows)

|

|

34. Lock crankshaft

35. Lower vehicle

|

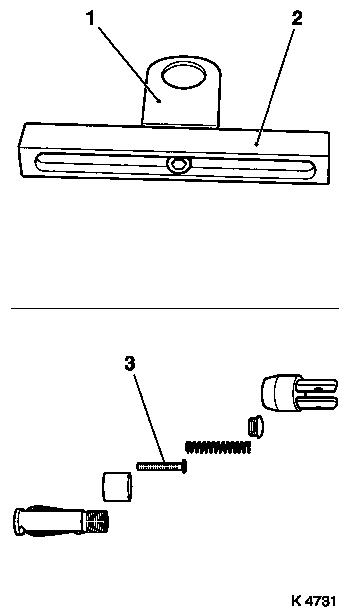

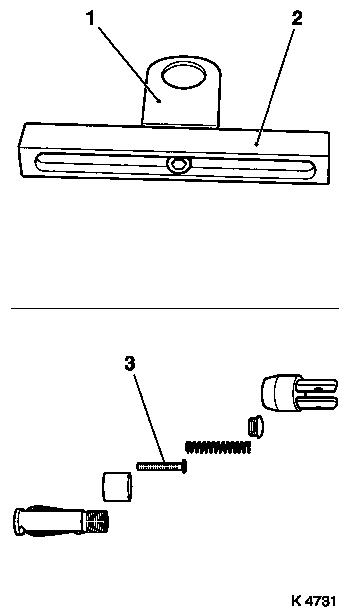

36. Assemble automatic valve spring

compressor

- Adjust supports

- Note: Adjust support heads (1) in the centre to support feet

(2) and tighten

- Assemble lever arm

- Assemble assembly kit

- Insert thrust piece 6a (3)

- Note: Observe manufacturer's instructions

|

|

|

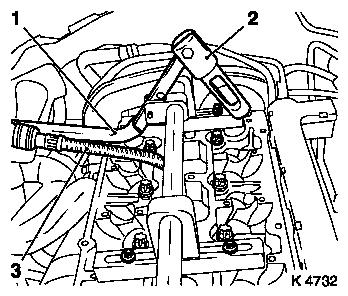

37. Attach automatic valve spring compressor

- Attach supports

- At position of camshaft bearing caps 1 and 4

- Slide installation shaft into supports

- Note: Align installation shaft in the centre above spark plug

bore

- Tighten 4 bolts

- Install lever arm (1)

- Note: Removal head (2) must face intake side

- Secure installation shaft

38. Install compressed air adapter (3)

- Screw into spark plug thread of 1st cylinder

- Apply compressed air to 1st cylinder

|

|

|

39. Remove intake valve springs for 1st cylinder

- 2 off

- Carefully push valve springs downwards

- With lever arm

- Note: Removal head must be positioned vertically above the

valve stem

- Remove valve keepers, valve head, valve spring

- Note: Do not use magnetic tool

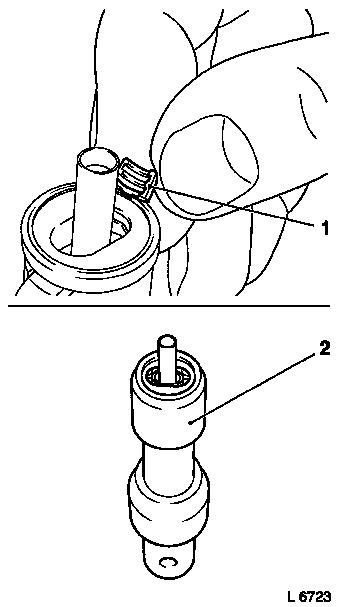

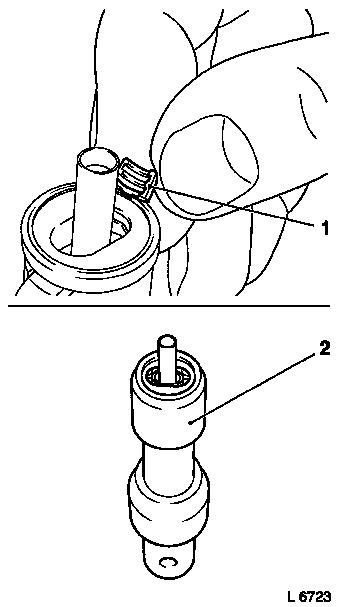

40. Replace valve stem seals

- 2 off

- Detach using KM-840 (1)

- Attach new valve stem seal to valve stem

- Drive in to stop using KM-835-A (2)

|

|

|

41. Install intake valve springs for

1st cylinder

- Insert valve spring, valve head

- Insert valve keepers (1) in assembly head

- Slide clamping sleeve (2) in direction of lever arm mount

- Caution: Insert valve keepers with taper towards valve

- Push clamping sleeve towards valve

- Attach assembly head to lever arm

- Carefully push valve springs downwards

- With lever arm

- Caution: Installation head must be positioned vertically above

the valve stem.

- Note: Valve keepers must engage audibly.

|

|

42. Check installation position

- Caution: Do not attempt a second time without checking that

both valve keepers are seated in the assembly head. Check seating

of valve keepers. Verify pressurisation

43. Transfer lever arm

- Remove lever arm

- Detach assembly head

- Attach removal head

- Install lever arm

- Note: Removal head must face exhaust side

|

44. Remove exhaust valve springs for

1st cylinder

- 2 off

- Carefully push valve springs downwards

- With lever arm

- Note: Removal head (1) must be positioned vertically above the

valve stem

- Remove valve keepers, valve head, valve spring

- Note: Do not use magnetic tool

|

|

45. Replace valve stem seals

- 2 off

- Detach using KM-840

- Attach new valve stem seal to valve stem

- Drive in to stop using KM-835-A

46. Install exhaust valve springs for 1st cylinder

- Insert valve springs, valve head

- Insert valve keepers in assembly head

- Push clamping sleeve towards lever arm mount

- Caution: Insert valve keepers with taper towards valve

- Push clamping sleeve towards valve

- Attach assembly head to lever arm

- Carefully push valve springs downwards

- With lever arm

- Caution: Installation head must be positioned vertically above

the valve stem.

- Note: Valve keepers must engage audibly

47. Check installation position

- Caution: Do not attempt a second time without checking that

both valve keepers are seated in the assembly head. Check seating

of valve keepers. Verify pressurisation

48. Transfer compressed air adapter

- Interrupt compressed air feed

- Unscrew from spark plug thread of 1st cylinder

- Screw into spark plug thread of 4th cylinder

- Apply compressed air to 4th cylinder

|

49. Transfer lever arm

- Loosen installation shaft

- Remove lever arm

- Detach assembly head

- Attach removal head

- Install lever arm

- Secure installation shaft

|

|

50. Replace valve stem seals for 4th cylinder

51. Interrupt compressed air feed

52. Raise vehicle

53. Remove KM-911

54. Set 3rd cylinder to TDC

- Turn crankshaft evenly (180°)

- Note: Guide mark on drive gear toothed belt must be aligned

with mark on rear toothed belt cover

55. Lock crankshaft

56. Lower vehicle

57. Transfer automatic valve spring compressor

- Transfer supports

- At position of camshaft bearing caps 1 and 5

- Slide installation shaft into supports

- Note: Align installation shaft in the centre above spark plug

bore

- Tighten 4 bolts

- Install lever arm

- Note: Removal head must face intake side

- Secure installation shaft

|

58. Transfer compressed air adapter

- Out of spark plug thread of 4th cylinder

- Screw into spark plug thread of 2nd cylinder

- Apply compressed air to 2nd cylinder

|

|

59. Replace valve stem seals for 2nd cylinder

60. Transfer compressed air adapter

- Interrupt compressed air feed

- Unscrew from spark plug thread of 2nd cylinder

- Screw into spark plug thread of 3rd cylinder

- Apply compressed air to 3rd cylinder

61. Replace valve stem seals for 3rd cylinder

62. Interrupt compressed air feed

63. Detach automatic valve spring compressor

64. Remove compressed air adapter

65. Inspect components

- Camshafts, camshaft bearing caps, hydraulic valve lifters,

cylinder head, ribbed V-belt, ribbed V-belt tensioner, ribbed

V-belt pulleys, toothed belt drive, spark plugs

66. Install spark plugs

- Tighten using KM-194-E (25 Nm / 18.5 lbf. ft.)

67. Raise vehicle

68. Remove KM-911

|

69. Position crankshaft

- Note: Adjust crankshaft 60° in front of ign. TDC for

cylinder 1

|

|

|

70. Lower vehicle

71. Clean cylinder head

72. Install hydraulic valve lifters

- 8 off

- Coat sliding surfaces with engine oil

- Caution: Note allocation

73. Install intake camshaft

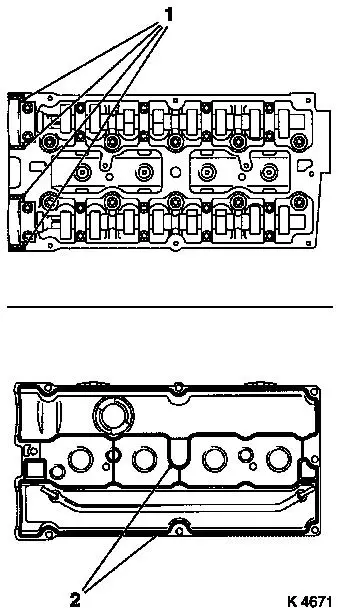

- Coat sliding surfaces with engine oil

- Apply sealant

- In camshaft seal ring area (arrows)

- Caution: Do not apply sealant to oil duct area. Complete

assembly operations within 10 minutes

- Insert camshaft, camshaft bearing cap

- Caution: Note mark and allocation

- Install camshaft bearing cap

- Tighten camshaft bearing caps in spiral pattern from inside

outwards (8 Nm / 6 lbf. ft.)

- Remove excess sealant

|

|

74. Install hydraulic valve lifters

- 8 off

- Coat sliding surfaces with engine oil

- Caution: Note allocation

75. Install exhaust camshaft

- Coat sliding surfaces with engine oil

- Apply sealant

- In camshaft seal ring area

- Caution: Do not apply sealant to oil duct area. Complete

assembly operations within 10 minutes

- Insert camshaft, camshaft bearing cap

- Caution: Note mark and allocation

- Install camshaft bearing cap

- Tighten camshaft bearing caps in spiral pattern from inside

outwards (8 Nm / 6 lbf. ft.)

- Remove excess sealant

|

76. Install intake camshaft seal ring

- Replace seal ring

- Coat seal lip with grease

- Place seal ring on camshaft journal

- Install camshaft seal ring

- With KM-422 (1), bolt and washer of crankshaft pulley

77. Install exhaust camshaft seal ring

- Replace seal ring

- Coat seal lip with grease

- Place seal ring on camshaft journal

- Install camshaft seal ring

- With KM-422, bolt and washer of crankshaft pulley

|

|

78. Fasten upper rear toothed belt cover

- Tighten bolts (6 Nm / 4.4 lbf. ft.)

79. Install intake camshaft sprocket

- Replace bolt

- Note: 2 people

- Tighten bolt (50 Nm / 37 lbf. ft. + 60° + 15°)

- Counterhold camshaft at hexagonal section

80. Install exhaust camshaft sprocket

- Replace bolt

- Note: 2 people

- Tighten bolt (50 Nm / 37 lbf. ft. + 60° + 15°)

- Counterhold camshaft at hexagonal section

|

81. Lock camshaft pulleys

- Note: Marks must be opposite one another and aligned with the

top edge of the cylinder head (I)

- Insert KM-852 (II)

- Turn the camshafts at hexagonal section

82. Lock crankshaft

- Set crankshaft to mark.

- Turn crankshaft evenly

- Note: Marks on drive gear toothed belt and rear toothed belt

cover must align (III)

|

|

|

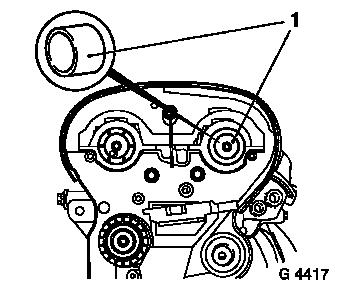

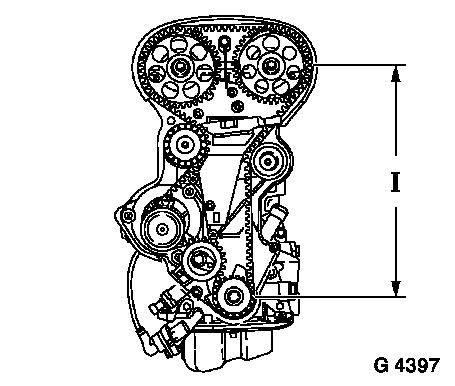

83. Attach toothed belt

- Position toothed belt

- Note: Tensioned side must be taut (I)

|

|

|

84. Tension toothed belt

- Tension toothed belt tension roller

- Turn adjusting eccentric in direction of arrow (anticlockwise)

until pointer of the toothed belt tension roller is located just

before left stop

- Fasten toothed belt tension roller bolt (1)

|

|

|

85. Remove KM-852

86. Timing, Check

- Turn crankshaft (720°)

- At crankshaft ribbed V-belt pulley bolt

- Note: In direction of engine rotation

- Set crankshaft to mark.

- Note: Marks on drive gear toothed belt and rear toothed belt

cover must align (III)

- Insert KM-852 (II)

- Note: Marks must be opposite one another and aligned with the

top edge of the cylinder head (I)

|

|

|

87. Remove KM-852

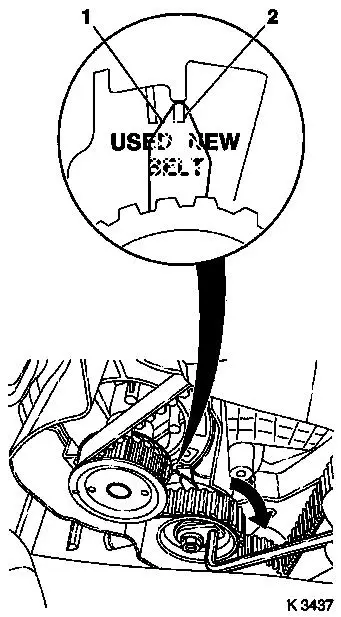

88. Toothed Belt Tension, Adjust

- Release toothed belt tension roller

- Turn adjustment eccentric in the direction of the arrow

(clockwise) until pointer (1) is aligned with the notch mark at the

toothed belt tension roller (2).

- Adjust used toothed belts to the marking USED

- Adjust new toothed belts to the marking NEW

- Tighten toothed belt tension roller bolt (20 Nm / 15 lbf.

ft.)

|

|

89. Toothed Belt Tension, Check

- Turn crankshaft (720°)

- Note: Pointers on the toothed belt tension roller and notch

mark must align

- Adjust used toothed belts to the marking USED

- Adjust new toothed belts to the marking NEW

90. Clean threads

- Camshaft sensor to cylinder head

91. Install camshaft sensor

- Note: Insert bolts with locking compound

- Tighten bolts (8 Nm / 6 lbf. ft.)

92. Install lower part of toothed belt cover

- Clip to rear of toothed belt cover

- Tighten bolt (4 Nm / 3 lbf. ft)

93. Install upper part of toothed belt cover

- Clip to rear of toothed belt cover

- Tighten bolts (4 Nm / 3 lbf. ft)

|

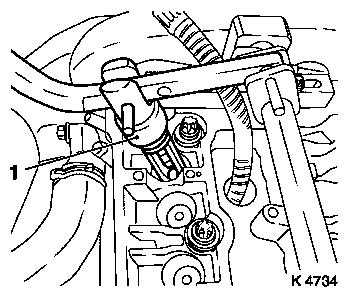

94. Install cylinder head cover

- Replace gasket (2)

- Apply sealant (1)

- Caution: Complete assembly operations within 10 minutes

- Tighten bolts (8 Nm / 6 lbf. ft.)

- Attach engine vent hose

|

|

95. Connect wiring harness plug of camshaft sensor

- Connect wiring harness plug.

- Clip to bracket

96. Connect wiring harness plug of temperature sensor

97. Install ignition module

- Remove KM-6009

- Tighten bolts (8 Nm / 6 lbf. ft.)

- Connect wiring harness plug.

98. Raise vehicle

99. Install ribbed V-belt tensioner

- Tighten bolt (35 Nm / 26 lbf. ft.)

- Tension ribbed V-belt tensioner.

- Insert KM-6130

100. Attach crankshaft ribbed V-belt pulley

- Insert KM-911

- Replace bolt

- Tighten bolt (95 Nm / 70 lbf. ft. + 30° + 15°.)

- Remove KM-911

- Insert front closure plug

101. Install ribbed V-belt

- Note: Note running direction and installation position

- Release ribbed V-belt tensioner

- Remove KM-6130

102. Install ribbed V-belt cover

- Screw in bolts

- Install clip

103. Lower vehicle

104. Mount right front wheel

105. Lower vehicle

106. Attach front right wheel

- Tighten bolts (110 Nm / 81 lbf. ft.)

107. Install air cleaner housing

- Tighten bolt

- Install suction hose

- Attach engine vent hose

- Clip in tank vent valve

- Connect wiring harness plug.

108. Install engine cover

- Unscrew oil filler pipe cap

- Insert retaining lugs

- Tighten bolts (8 Nm / 6 lbf. ft.)

- Screw on oil filler pipe cap

109. Connect battery

110. Calibrate steering angle sensor

Note: Rotate the

steering wheel one time from its right-hand to its left-hand

stop.

111. Program volatile memories

112. Close bonnet

|