|

Replace valve stem seals (Z 10 XE, Z 10 XEP,

without air conditioning, LHD)

| 1. |

On vehicles as of model year 04 with ESP - every time the

battery is disconnected, the steering angle sensor loses its basic

setting. It must be recalibrated.

|

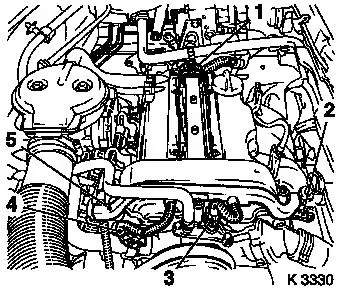

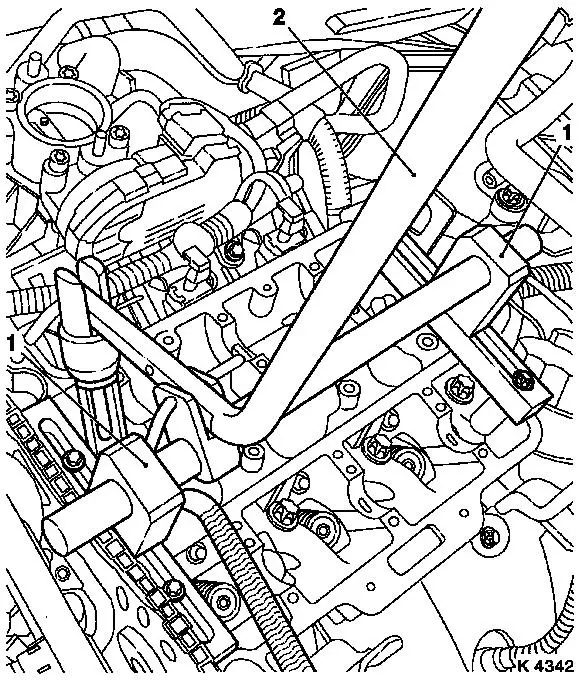

| 4. |

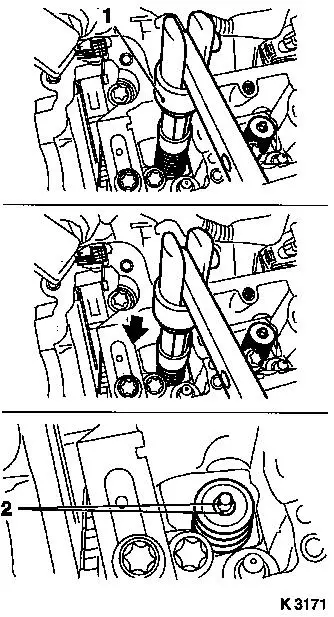

Disconnect 4x engine management wiring harness plugs

| • |

Oil pressure switch (2), coolant temperature sensor (3),

camshaft sensor (4) and ignition module (1)

|

| • |

Unclip wiring trough (5)

|

| • |

Set wiring harness to one side

|

|

|

|

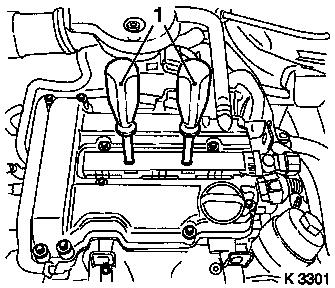

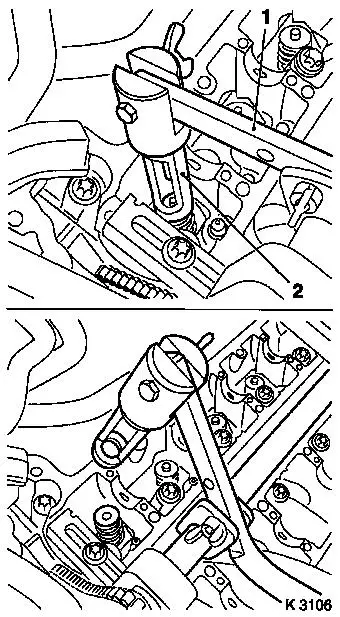

| 5. |

Remove ignition module

| • |

Remove ignition module cover

|

| • |

Extract using KM-6009 (1)

Note: Do not tilt

|

|

|

|

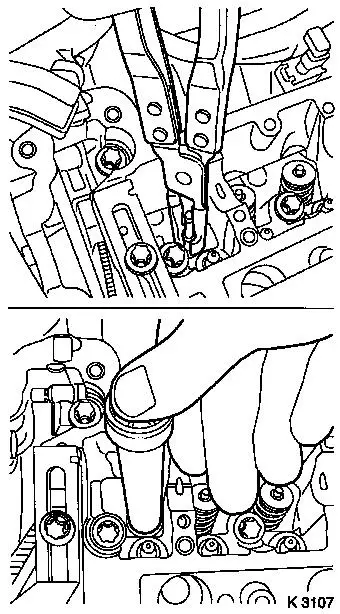

| 6. |

Remove cylinder head cover

| • |

Detach 2x engine venting hoses

|

|

|

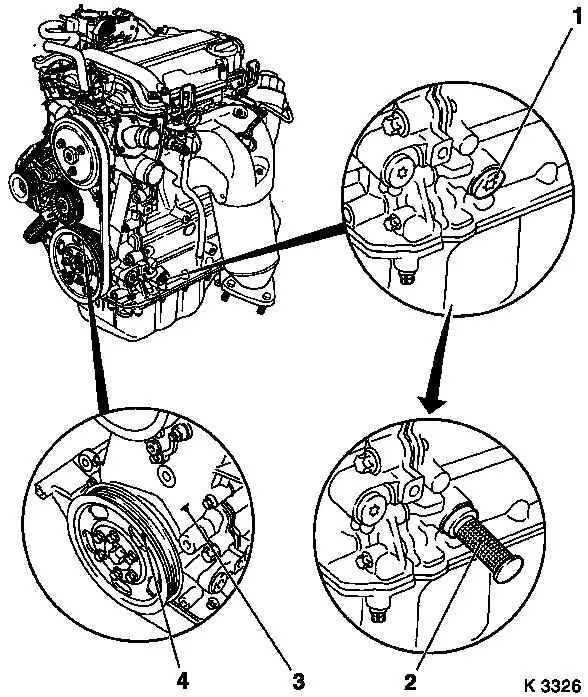

| 7. |

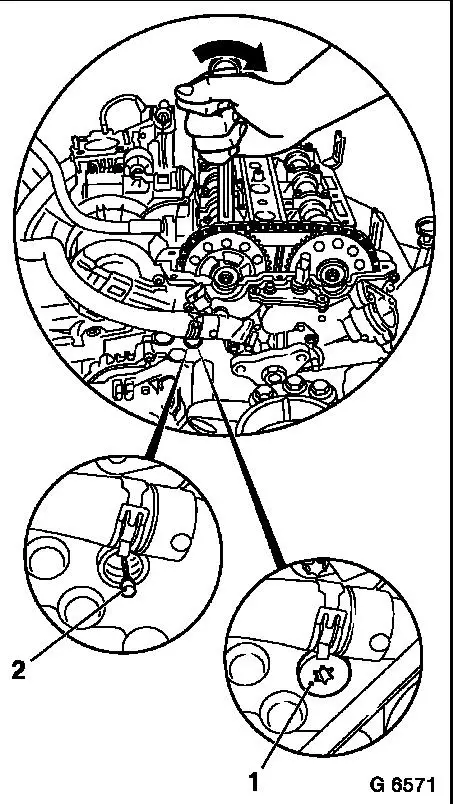

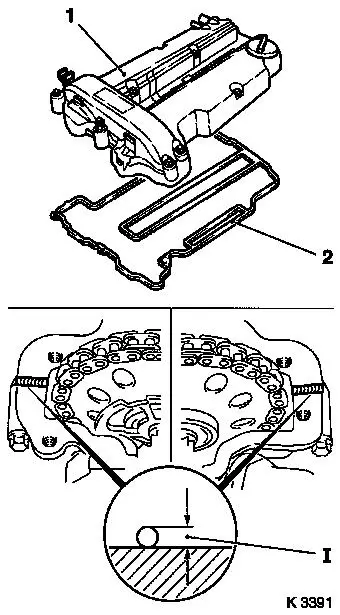

Unscrew crankshaft bearing bridge closure bolt (1)

|

| 8. |

Set no.1 cylinder to TDC

| • |

Turn crankshaft uniformly until KM-952 engages

| – |

Crankshaft belt pulley (4) must line up with lug (3) on timing

case

|

|

|

|

|

| 9. |

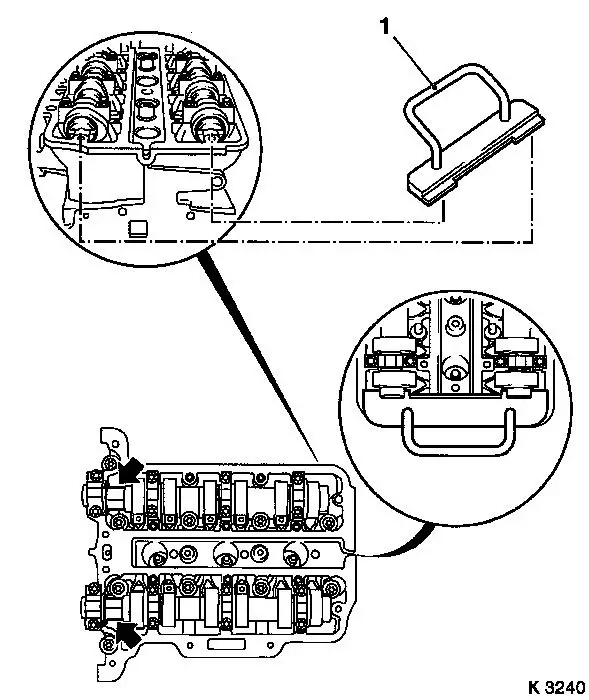

Insert KM-953

| • |

KM-953 must engage in camshaft

groove

|

|

|

| 10. |

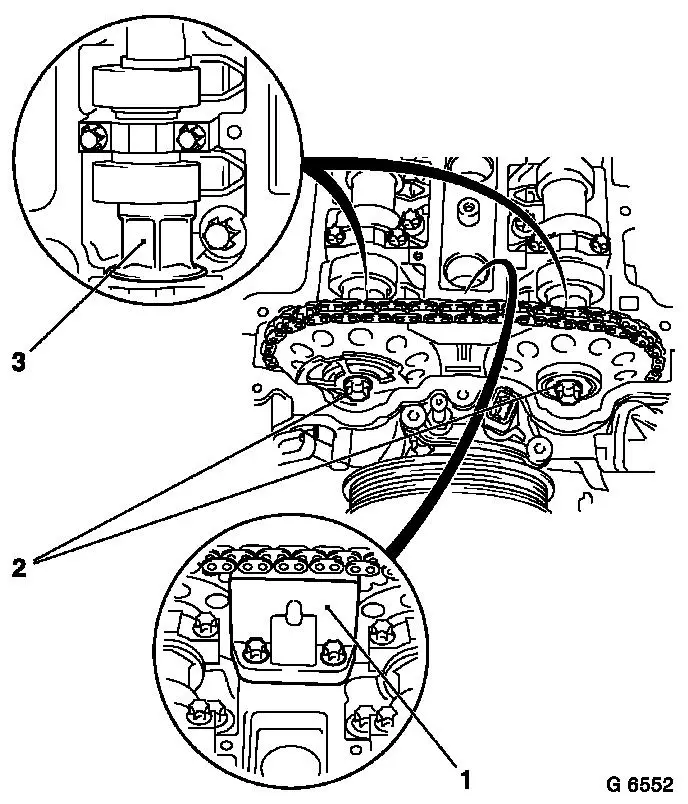

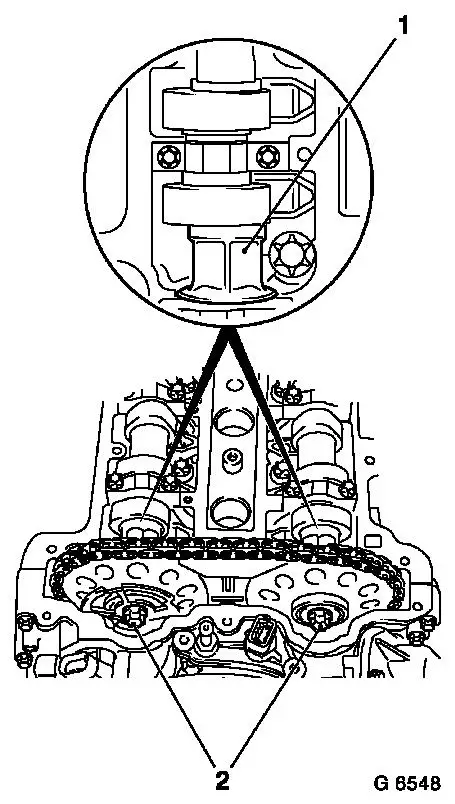

Lock chain tensioner

| • |

Unscrew closure bolt (1)

|

| • |

Load intake camshaft in direction of arrow via hexagonal

section using an open-ended spanner

|

|

|

|

|

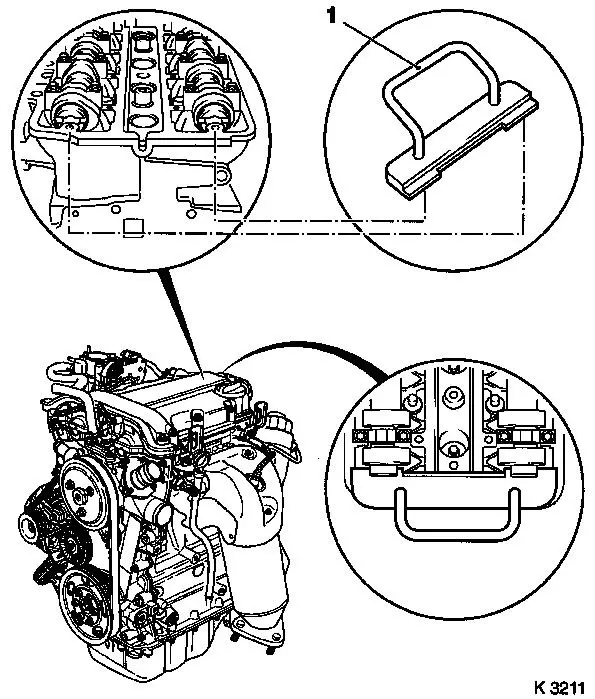

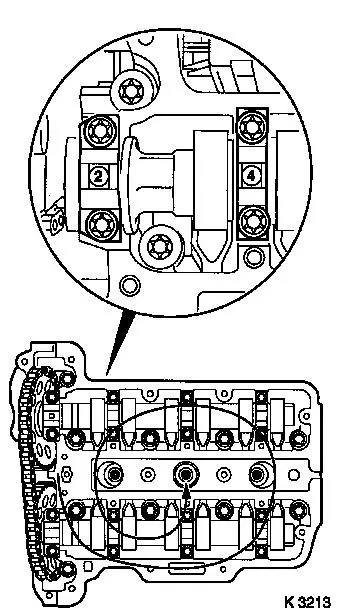

| 11. |

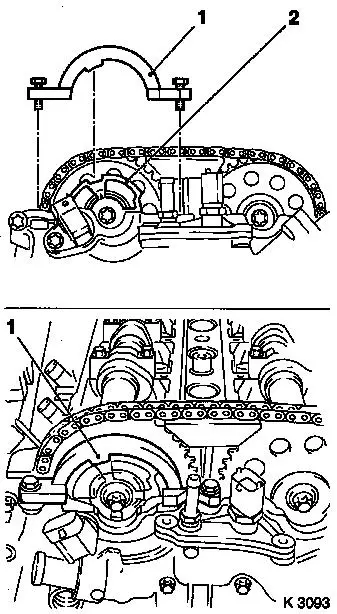

Remove sliding rail (1)

|

| 12. |

Detach camshaft sprockets

| • |

Unscrew 2 bolts (2)

| – |

Counterhold camshafts at hexagonal section (3)

|

|

| • |

Remove phase sensor disc

|

|

|

| 13. |

Remove exhaust camshaft

| • |

Remove camshaft bearing cap

|

| • |

Release camshaft bearing cap working in inward spiral from

outside in steps of 1/2 to 1 turn

| – |

Camshaft must be evenly released from the bearing seats

|

|

|

| 14. |

Remove intake camshaft

| • |

Remove camshaft bearing cap

|

| • |

Release camshaft bearing cap working in inward spiral from

outside in steps of 1/2 to 1 turn

| – |

Camshaft must be evenly released from the bearing seats

|

|

|

|

|

| 15. |

Remove 12x roller cam followers

Note: Observe

allocation.

|

| 16. |

Remove 3x spark plugs with KM-194-E

|

| 17. |

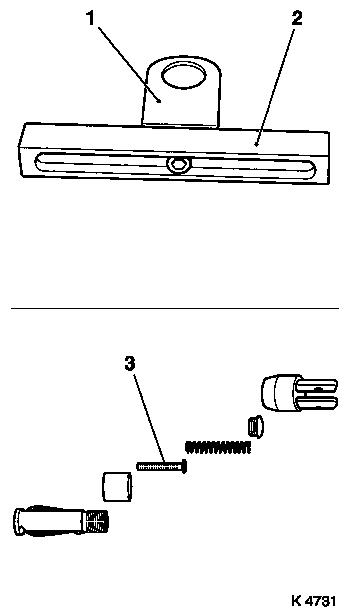

Complete automatic valve spring compressor

| • |

Adjust supports

| – |

Position support heads (1) in centre of support bases (2) and

tighten

|

|

| • |

Complete lever arm

| – |

Using joint, removal head

|

|

| • |

Insert assembly head MKM-6086-200

Note: Comply with

manufacturer's instructions

| – |

Insert thrust piece -5a (3)

|

|

|

|

|

|

| 18. |

Attach automatic valve spring compressor

| • |

Attach supports

| – |

Insert installation shaft in supports

|

| – |

Line up assembly shaft in central position above spark plug

hole

|

|

| • |

Install lever arm

Note: Removal head must

point to intake side

|

| • |

Secure installation shaft

|

|

| 19. |

Install compressed air adapter

| • |

Screw into spark plug thread of 1st cylinder

|

| • |

Apply compressed air to 1st cylinder

|

|

|

| 20. |

Remove 2x cylinder no.1 intake valve springs

| • |

Carefully push valve spring down with lever arm (1)

| – |

Removal head (2) must be vertically above the valve stem

|

|

Important: Observe

allocation.

|

| • |

Remove valve head, valve spring

Note: Do not use

magnetised tools

|

|

|

|

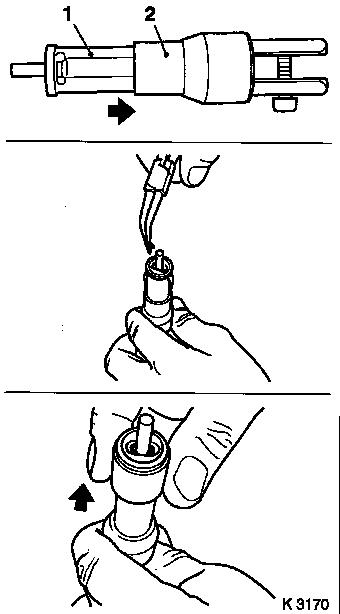

| 21. |

Replace 2x valve stem seals

| • |

Attach new valve stem seal to valve stem

|

| • |

Drive in to stop using KM-958

|

|

|

|

| 22. |

Install intake valve springs for cylinder no.1

| • |

Insert valve spring, valve head

|

| • |

Insert valve keepers in assembly head MKM-6068-200 (1)

| – |

Push plastic clamping sleeve (2) towards lever arm mounting

|

| – |

Insert valve keepers with taper facing the valve

|

| – |

Push plastic clamping sleeve towards valve

|

|

|

|

|

| 23. |

Install valve keepers

| • |

Attach assembly head (1) to lever arm

|

Important: Assembly head must be

vertically above the valve stem. Valve keepers (2) must audibly

engage.

|

| • |

Carefully push valve spring down with lever arm (arrow)

|

|

Important: Do not make 2nd

attempt without checking that both valve keepers are in the

assembly head

|

| 24. |

Check installation position

| • |

Check seat of valve keepers

|

| • |

Ensure that pressure is being applied

|

|

|

|

| 25. |

Transfer lever arm

| • |

Install lever arm

Note: Dismantling head

must point to the exhaust side

|

|

| 26. |

Remove exhaust valve springs for no.1 cylinder

| • |

Carefully push valve spring down with lever arm

Note: Removal head must

be vertically above the valve stem

|

Important: Observe

allocation.

|

| • |

Remove valve keepers, valve head, valve spring

Note: Do not use

magnetised tools

|

|

| 27. |

Replace 2x valve stem seals

| • |

Attach new valve stem seal to valve stem

|

| • |

Drive in to stop using KM-958

|

|

| 28. |

Install exhaust valve springs for cylinder no.1

| • |

Insert valve spring, valve head

|

| • |

Insert valve keepers in assembly head MKM-6068-200 (1)

| – |

Push plastic clamping sleeve (2) towards lever arm mounting

|

| – |

Insert valve keepers with taper facing the valve

|

| – |

Push plastic clamping sleeve towards valve

|

|

|

| 29. |

Install valve keepers

| • |

Attach assembly head to lever arm

|

Important: Assembly head must be

vertically above the valve stem. Valve keepers must audibly

engage.

|

| • |

Carefully push valve spring down with lever arm

|

|

Important: Do not make 2nd

attempt without checking that both valve keepers are in the

assembly head

|

| 30. |

Check installation position

| • |

Check seat of valve keepers

|

| • |

Ensure that pressure is being applied

|

|

| 33. |

Set cylinder no.3 to TDC

Note: Second person

required

| • |

Pull timing chain upwards

|

| • |

Turn crankshaft evenly (120°)

Note: Guide mark on

crankshaft belt pulley must line up with lug on timing case

|

|

| 35. |

Lock crankshaft

Note: Wheels must be in

contact with ground

|

| 36. |

Transfer compressed air adapter

| • |

Interrupt compressed air feed

|

| • |

Unscrew from spark plug thread of 1st cylinder

|

| • |

Screw into spark plug thread of 3rd cylinder

|

| • |

Apply compressed air to 3rd cylinder

|

|

| 37. |

Remove exhaust valve springs for cylinder no.3

|

| 38. |

Interrupt compressed air feed

|

| 41. |

Set cylinder no.2 to TDC

| • |

Pull timing chain upwards

|

| • |

Turn crankshaft evenly (120°)

Note: Guide mark on

crankshaft belt pulley must line up with lug on timing case

|

|

| 43. |

Lock crankshaft

| • |

Tighten parking brake

Note: Wheels must be in

contact with ground

|

|

| 44. |

Transfer compressed air adapter

| • |

Interrupt compressed air feed

|

| • |

Unscrew from spark plug thread of 3rd cylinder

|

| • |

Screw into spark plug thread of 2nd cylinder

|

| • |

Apply compressed air to 2nd cylinder

|

|

| 45. |

Replace 4x cylinder no.2 valve stem seals

|

| 46. |

Remove automatic valve spring compressor

|

| 47. |

Remove compressed air adapter

| • |

Interrupt compressed air feed

|

|

| 50. |

Lock crankshaft

| • |

Pull timing chain upwards

|

| • |

Turn crankshaft uniformly until KM-952 engages

|

|

| 52. |

Install spark plugs

| • |

Tighten using spark plug spanner KM-194-D 25 Nm

|

|

| 54. |

Check and rework for cylinder head

Note: If cylinder head

is to be checked and overhauled : Remove all outer attaching parts

from cylinder head

| • |

Camshafts, camshaft covers, cylinder head, roller cam

followers

|

|

| 55. |

Insert roller cam followers

| • |

Coat sliding surfaces with MoS2 lubricating paste

|

| • |

Caution! Observe allocation

|

|

| 56. |

Install intake camshaft

| • |

Coat sliding surfaces with MoS2 lubricating paste

|

| • |

Insert camshaft, camshaft bearing cap

|

| • |

Caution! Observe installation position and allocations

|

| • |

Install camshaft bearing cap

Note: Tighten camshaft

bearing caps in stages in spiral pattern from inside to outside

8 Nm

|

|

| 57. |

Install exhaust camshaft

| • |

Coat sliding surfaces with MoS2 lubricating paste

|

| • |

Insert camshaft, camshaft bearing cap

|

| • |

Caution! Observe installation position and allocations

|

| • |

Install camshaft bearing cap

Note: Tighten camshaft

bearing caps in stages in spiral pattern from inside to outside

8 Nm

|

|

|

| 58. |

Adjust camshafts

| • |

Insert KM-953 (1)

| – |

"Turn" the camshafts at hexagonal section (arrows)

|

|

|

|

| 59. |

Attach camshaft sprockets

| • |

Attach intake camshaft sprocket with phase sensor disc (2)

| – |

Note! It must be possible to turn phase sensor disc

manually

|

|

| • |

Attach exhaust camshaft sprocket

|

|

| 62. |

Replace seal ring

| • |

Tighten chain tensioner closure bolt 50

Nm

|

|

| 63. |

Attach KM-954

Note: Rotate phase

sensor disk (2) until KM-954 (1) can be

attached to timing case

|

|

|

| 64. |

Fasten camshaft sprockets

| • |

Tighten bolts (2) (10 Nm / 7.5 lbf. ft.)

Note: First tighten

intake camshaft sprocket bolt

| – |

Counterhold camshafts at hexagonal section (1)

Note: Tightening torque

of 10 Nm is used to secure camshaft sprockets and phase sensor

disk

|

|

|

| 65. |

Remove retaining tools

| • |

KM-952, KM-953, KM-954

Note: Caution!

Retaining tools must not be used to counterhold

|

|

| 66. |

Fasten camshaft sprockets

| • |

Tighten bolts 50 Nm + 60°

| – |

Counterhold camshafts at hexagonal section

Note: First tighten

intake camshaft sprocket bolt

|

|

|

|

|

| 69. |

Attach closure bolt of crankshaft bearing bridge

|

| 70. |

Install ribbed V-belt cover

Note: With "ECO" model

variant - install lower engine compartment cover

|

| 72. |

Attach cylinder head cover (1)

| • |

Renew gasket (2) and seal rings

|

| • |

Apply sealant (dimension l = 2 mm)

Note: Caution! Complete

assembly operations within 10 minutes

|

| • |

Attach engine vent hose

|

|

| 73. |

Attach ignition module

|

| 74. |

Install engine management wiring harness

| • |

Connect wiring harness for engine management

| – |

Connect 4 wiring harness plugs

|

|

|

|

|

| 75. |

Install air cleaner housing

| • |

Attach suction pipe

| – |

Tighten nuts (8 Nm / 5.9 lbf. ft.)

|

| – |

Attach engine vent hose

|

|

| • |

On Z 10 XEP: Fit air intake hose

|

| • |

Connect 2x wiring harness plugs

|

|

| 77. |

Program volatile memory

|

| 78. |

Check and correct engine oil level

| • |

Observe specified engine oil quantity

|

|

|