|

High Pressure Pump, Replace (Z 17 DTH, With Air

Conditioning, LHD)

Remove Remove

Important: In vehicles as of

model year 04 with ESP - every time the battery is disconnected,

the steering angle sensor loses its basic setting and must be

recalibrated

|

| 1. |

Open bonnet

|

| 3. |

Detach front right wheel

|

| 5. |

Remove right front wheel

|

| 7. |

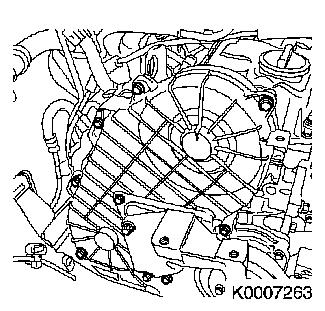

Remove ribbed V-belt cover

|

|

|

| 8. |

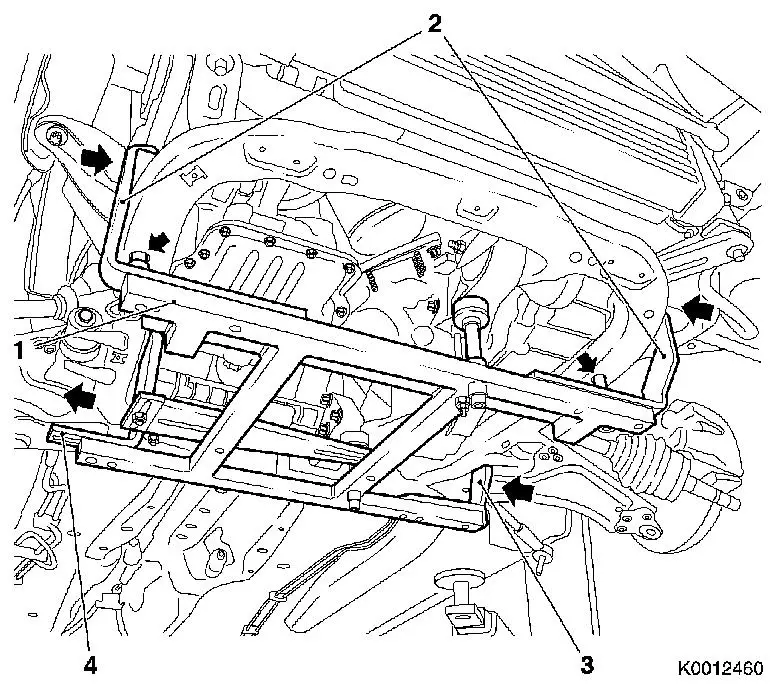

Attach KM-6394

| • |

Position KM-6394 (1) at the front on

the front axle body

Note: Both locating

pins (arrows) must be seated in the holes in the front axle

body

|

| • |

Push front bracket (2) in the direction of the arrow

|

| • |

Place rear bracket (4), right hand side, on front axle body

|

| • |

Attach rear bracket (3), left hand side

|

|

|

|

|

| 9. |

Install support

| • |

On KM-6394

| – |

Adjust bracket (2) for support

|

|

|

| 10. |

Adjust 3x support

| • |

Transmission side

Note: Turn spindles

until mounts (3) are positioned at guide journals free of play

|

| • |

Engine timing side

| – |

Insert journal of the support in the bore of the cylinder block

free of play (arrow)

|

|

|

|

| 11. |

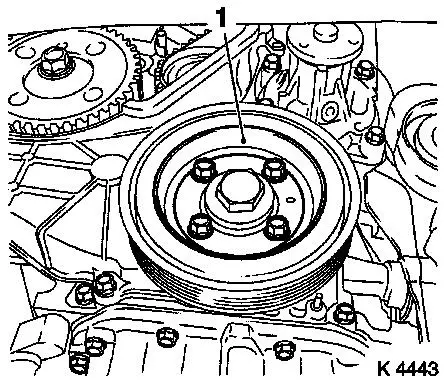

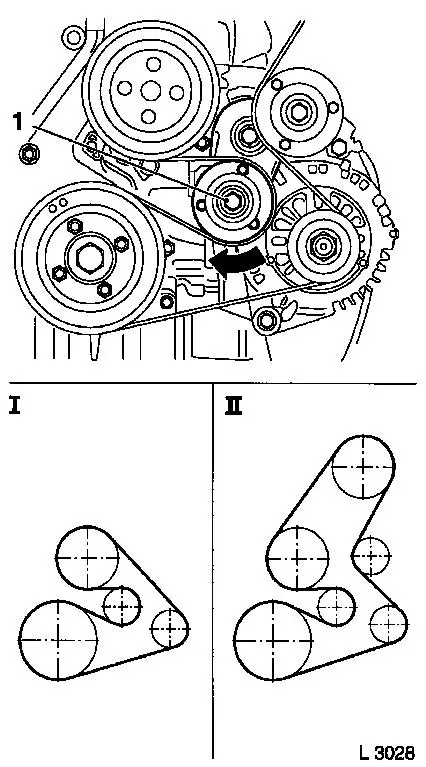

Loosen coolant pump ribbed V-belt pulley (1)

|

|

|

| 12. |

Remove ribbed V-belt

| • |

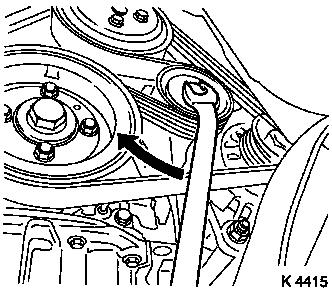

Tension ribbed V-belt tensioner in direction of arrow

Note: Mark running

direction.

|

|

|

|

| 13. |

Detach coolant pump ribbed V-belt pulley

|

| 15. |

Remove air cleaner housing

|

|

| 16. |

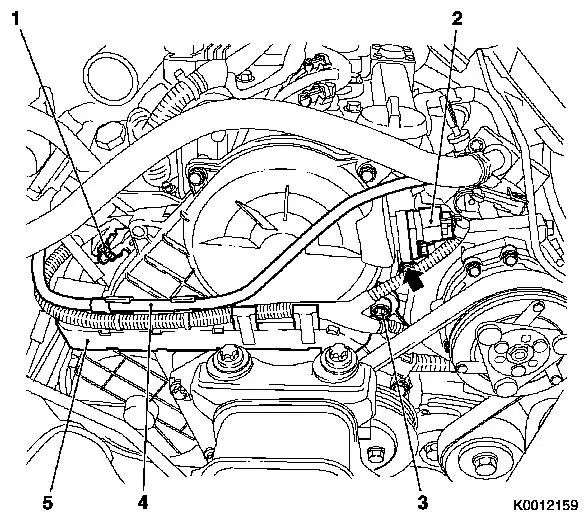

Remove wiring trough

| • |

Unclip wiring trough (5)

|

| • |

Disconnect 2 wiring harness plugs

| – |

Charge pressure sensor (1)

|

|

|

| 17. |

Remove camshaft sensor

|

|

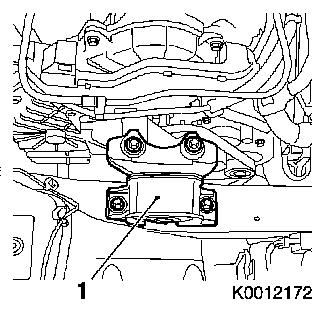

| 18. |

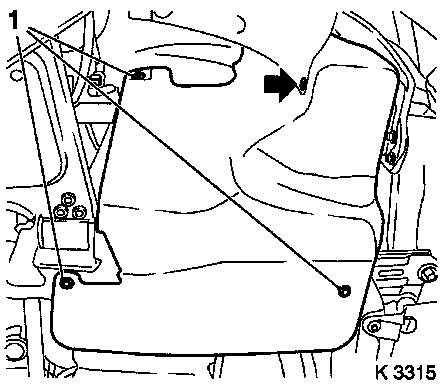

Remove right engine damping block (1)

|

|

|

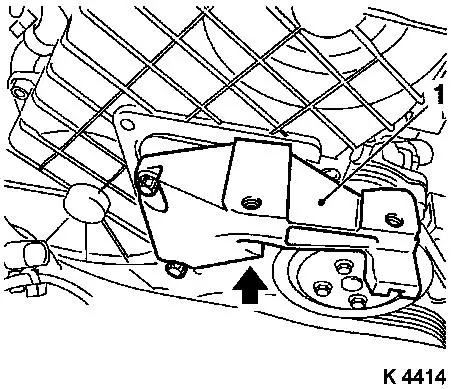

| 19. |

Detach right engine bracket (1)

| • |

Unscrew 3 bolts

Note: Lower bolt cannot

be removed

|

| • |

With right engine bracket adapter

|

|

|

|

| 20. |

Remove upper toothed belt cover

Important: Take care not to

damage the increment counter on the camshaft sprocket when removing

the upper toothed belt cover

|

| • |

Unscrew 8 bolts

Note: Note dissimilar

bolt lengths

|

|

|

|

| 22. |

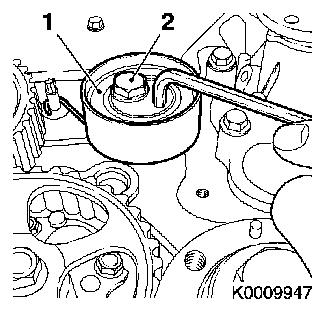

Remove torsional vibration damper (1)

|

|

|

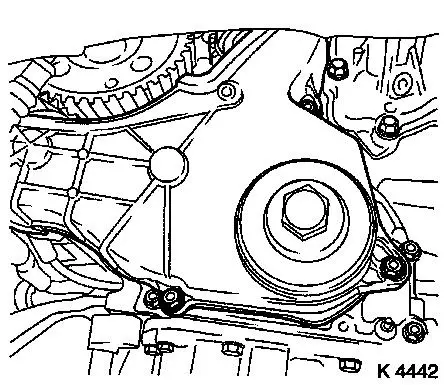

| 23. |

Detach lower part of toothed belt cover

|

|

|

| 24. |

Remove right engine bracket

|

| 25. |

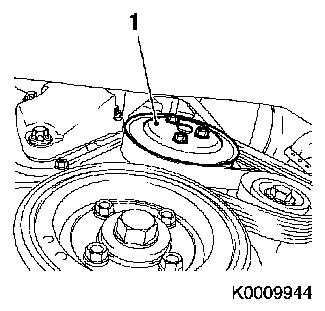

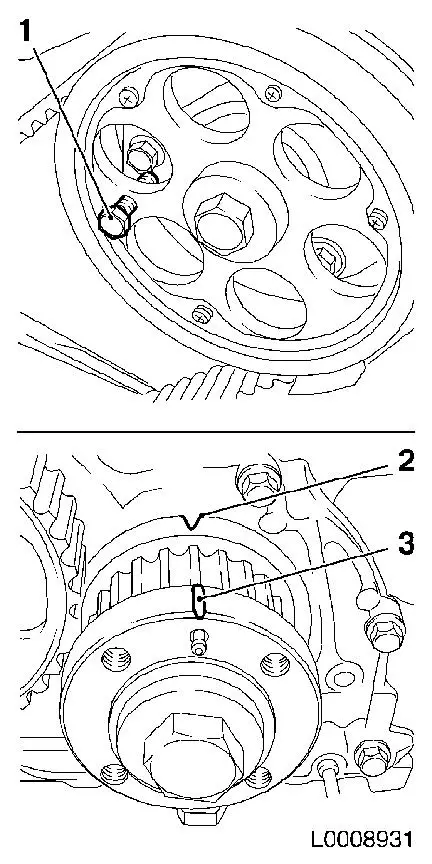

Set 1st cylinder to TDC

| • |

Turn crankshaft evenly until TDC fixing bolt (1) can be screwed

in

Note: Mark (3) on

toothed belt drive gear must align with mark (2) on oil pump

cover

|

|

|

|

| 26. |

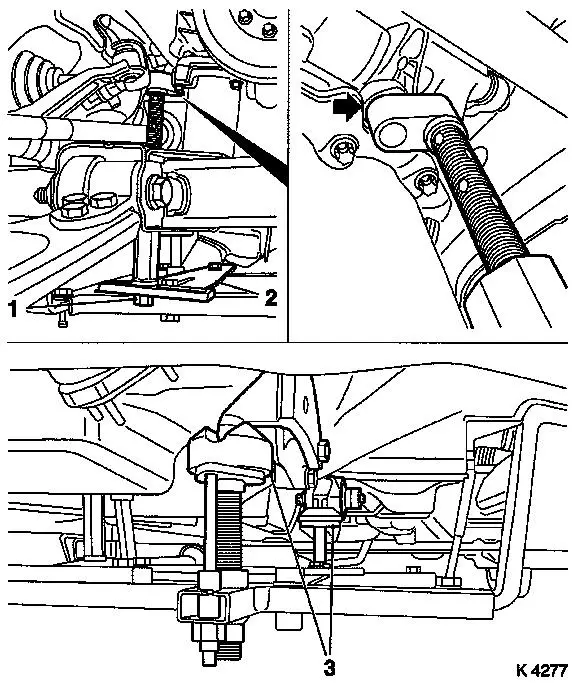

Loosen toothed belt tension roller (1)

| • |

Loosen bolt of toothed belt tension roller (2)

|

| • |

Rotate toothed belt tension roller anticlockwise approx.

90°

|

| • |

Tighten bolt of toothed belt tension roller

|

|

|

|

| 27. |

Remove toothed belt

Note: Mark running

direction.

|

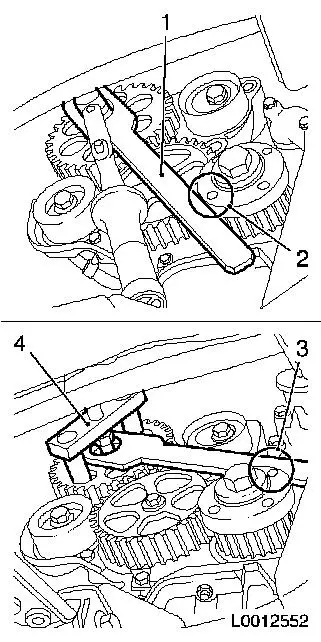

| 28. |

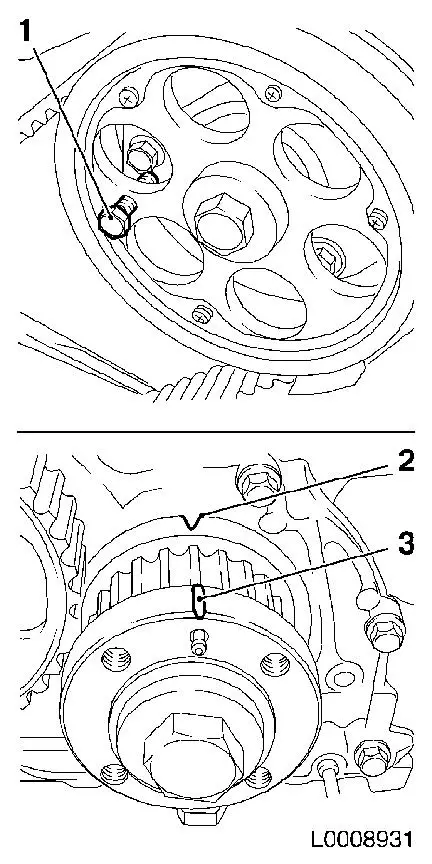

Remove high pressure pump drive gear

| • |

Unscrew nut

| – |

Counterhold with KM-6603 (1)

Note: Allow KM-6603 to lie in position (2) against toothed

belt drive gear

|

|

Important: Note woodruff key

|

| • |

Disengage high pressure pump drive gear using KM-6602 (4)

| – |

Counterhold with KM-6603

Note: Allow KM-6603 to lie in position (3) against toothed

belt drive gear

|

|

|

|

|

| 30. |

Remove 2 blank holders

| • |

Unscrew and remove 2 stud bolts

|

| • |

Disconnect 6 wiring harness plugs

|

| • |

Remove fuel line spacer

|

|

Important: Be sure not to damage

the high pressure line (2)

|

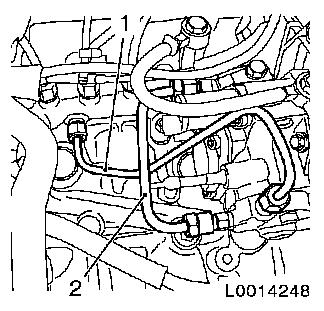

| 31. |

Detach high pressure line (1) from high pressure pump at

accumulator

| • |

Remove union nut from accumulator using KM-812 and from high pressure pump using KM-6098

|

| • |

Seal connection of high pressure pump

|

|

|

|

| 32. |

Detach fuel supply line

|

| 33. |

Detach fuel return line (1)

|

|

|

Important: Be sure not to damage

the high pressure line (2)

|

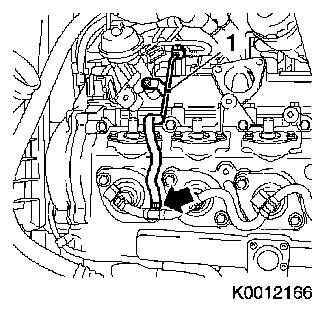

| 34. |

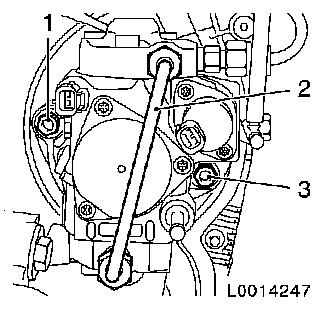

Detach high pressure pump housing

| • |

Unscrew 2 nuts (1 and 3)

|

|

|

|

Install

Install

| 35. |

Attach high pressure pump

|

| 36. |

Attach fuel return line

| • |

Tighten banjo bolt 14.7 Nm

|

|

| 37. |

Attach fuel supply line

|

| 38. |

Install high pressure line

| |

Diameter

|

Torque

|

|

Version 1

|

6.00 mm

|

30 Nm

|

|

Version 2

|

6.35 mm

|

25 Nm

|

Important: Ensure that no dirt

enters when inserting the line

|

| • |

Use KM-6098

|

|

| 39. |

Fit 2 blank holders

| • |

Connect 6x wiring harness plugs

|

|

| 41. |

Install high pressure pump drive gear

Note: Note woodruff

key

Note: Counterhold with

KM-6603

|

| 42. |

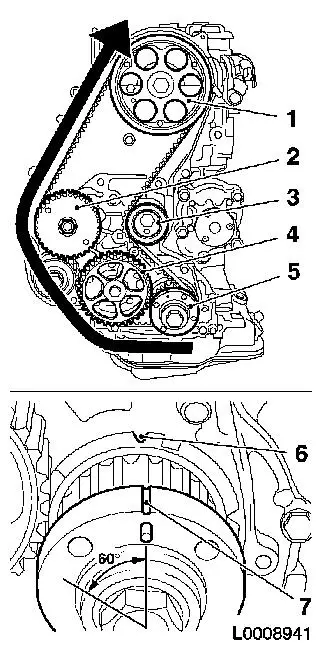

Install toothed belt

Note: TDC locking bolt

must be installed in the camshaft sprocket and marking (6) and (7)

must align.

| • |

Position toothed belt

| – |

Toothed belt must be tensioned in the direction of the arrow

from the toothed belt drive gear (5) via the oil pump drive gear

(4), via the high pressure pump drive gear (2) to the camshaft

sprocket (1)

|

|

| • |

Loosen toothed belt tension roller (3)

|

| • |

Remove TDC locking bolt

|

| • |

Rotate crankshaft 60° against direction of engine

rotation

|

| • |

Tighten toothed belt tension roller 38Nm

|

|

|

|

| 43. |

Timing, Check

| • |

Turn crankshaft approx. 780° in direction of engine

rotation

|

| • |

Mark on toothed belt drive gear (3) must align with cast lug

(2) on oil pump cover

|

| • |

Screw in TDC fixing bolt (1)

Note: If the TDC fixing

bolt cannot be screwed in, basic adjustment must be repeated

|

| • |

Unscrew TDC-fixing bolt

|

|

|

|

| 44. |

Attach right engine bracket

| • |

Insert lower bolt

| – |

Into right engine bracket and right engine bracket adapter

|

|

| • |

Fit right engine bracket with adapter

|

|

| 45. |

Attach lower part of toothed belt cover

|

| 47. |

Install upper toothed belt cover

| • |

Tighten 8 bolts 9.8 Nm

Note: Note dissimilar

bolt lengths

|

|

| 48. |

Fasten right engine bracket

| • |

Tighten 2 upper bolts 40 Nm

|

|

| 49. |

Install camshaft sensor

|

| 50. |

Attach wiring trough

| • |

Connect 2 wiring harness plugs

|

|

| 51. |

Install right engine damping block

| • |

On engine bracket

| – |

Tighten 2 bolts 60

Nm+30°+15°

|

|

|

| 53. |

Fasten right engine bracket

| • |

Tighten lower bolt 40 Nm

|

|

| 54. |

Attach coolant pump ribbed V-belt pulley

|

| 55. |

Install torsional vibration damper

| • |

Tighten 4 bolts 19.6 Nm

|

|

| 56. |

Install ribbed V-belt

Note: Observe running

direction and installation position

| • |

Release tension from ribbed V-belt tensioner (1)

| – |

I Ribbed V-belt without AC

|

| – |

II Ribbed V-belt with AC

|

|

|

|

|

| 57. |

Fasten coolant pump ribbed V-belt pulley

|

| 60. |

Attach ribbed V-belt cover

|

| 62. |

Attach front right wheel

|

| 64. |

Fasten right front wheel

|

| 65. |

Install air cleaner housing

|

Important: Wear protective

goggles

|

| 67. |

Carry out leak test on high pressure system

Note: Engine must be at

operating temperature

| • |

Carry out actuator test (fuel leak)

|

| • |

Inspect high pressure system for fuel leak

|

|

| 69. |

When replacing the high pressure pump:

| • |

Use TECH 2 to reset the learning values for the high pressure

pump in the engine control unit

|

|

| 70. |

Program volatile memory

|

|