|

End Shield, Disassemble and Assemble (F17+)

Note: Transmission

remains installed.

Remove Remove

|

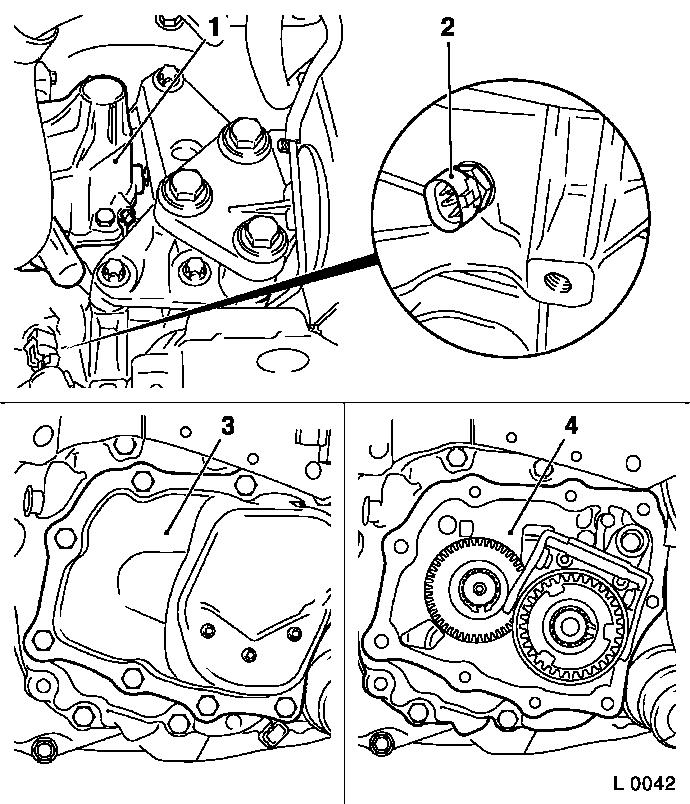

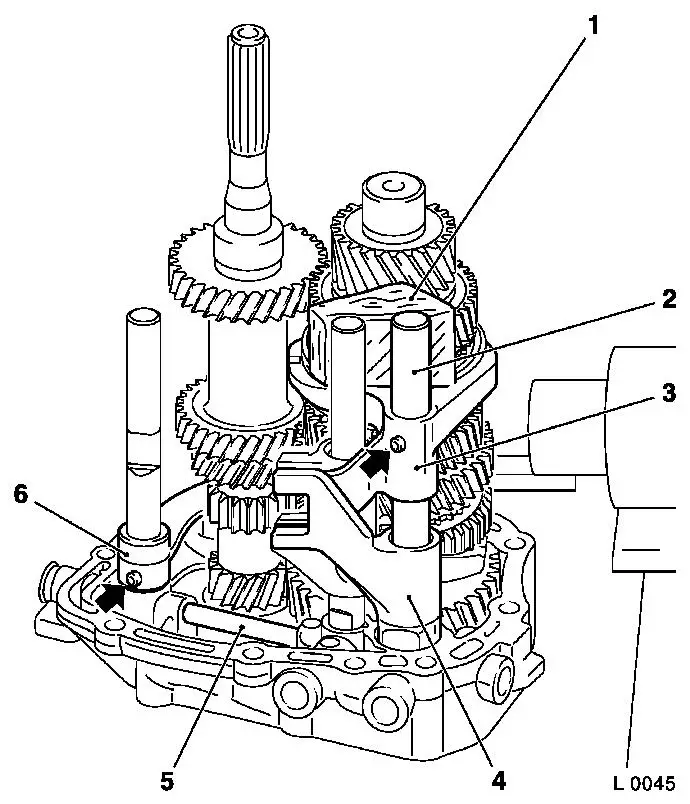

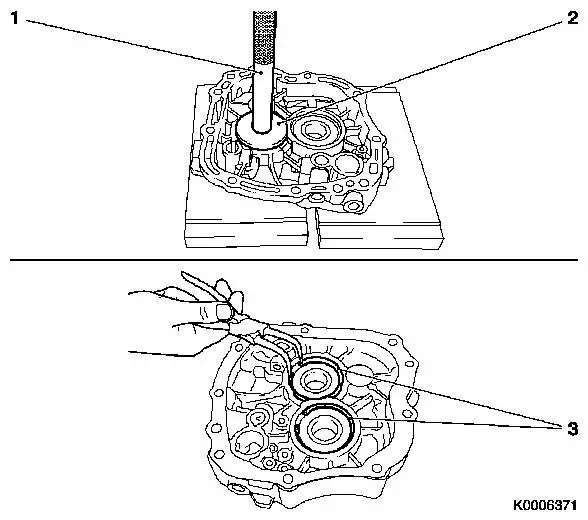

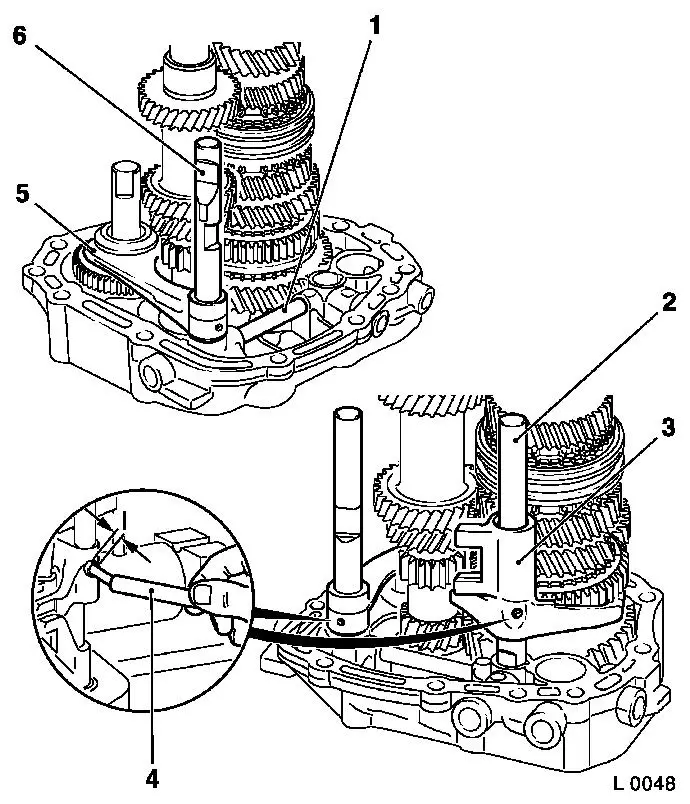

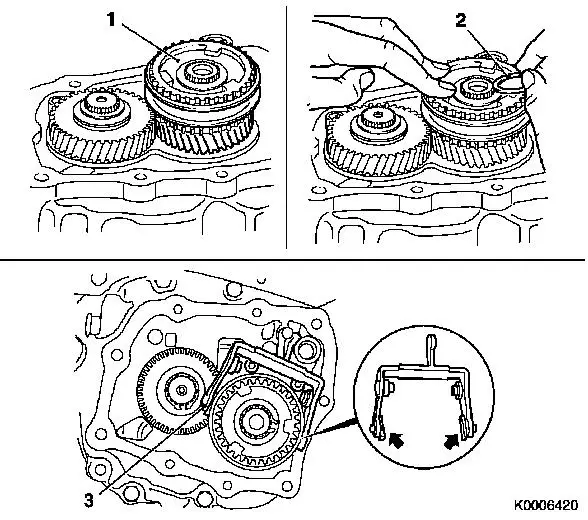

| 1. |

Remove shift mechanism cover (1)

|

| 2. |

Remove reversing lamp switch (2)

| • |

Disconnect wiring harness plug for reversing lamp switch

|

| • |

Unscrew reversing lamp switch

|

|

| 3. |

Remove end shield cover (3)

|

|

|

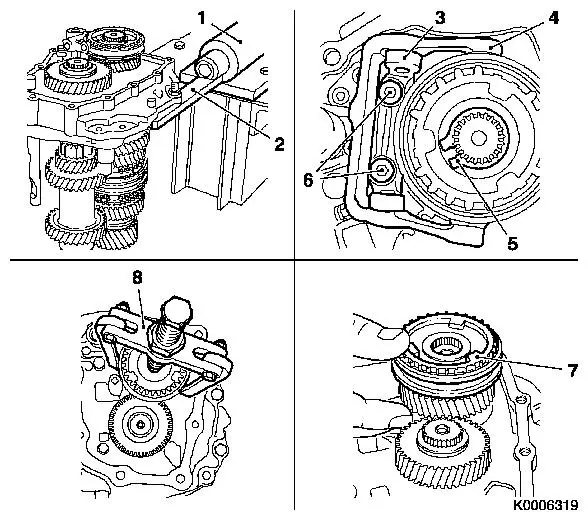

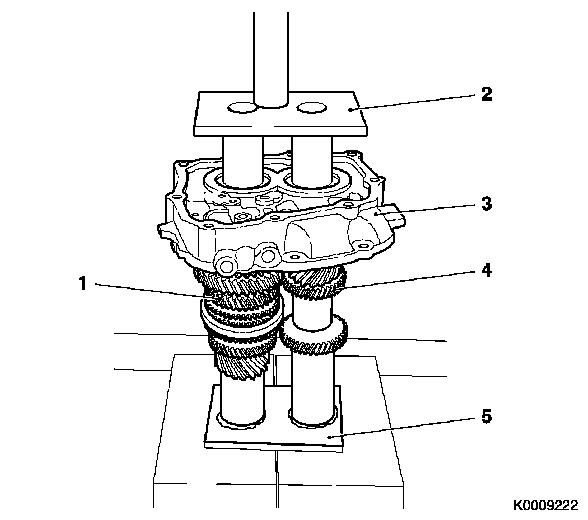

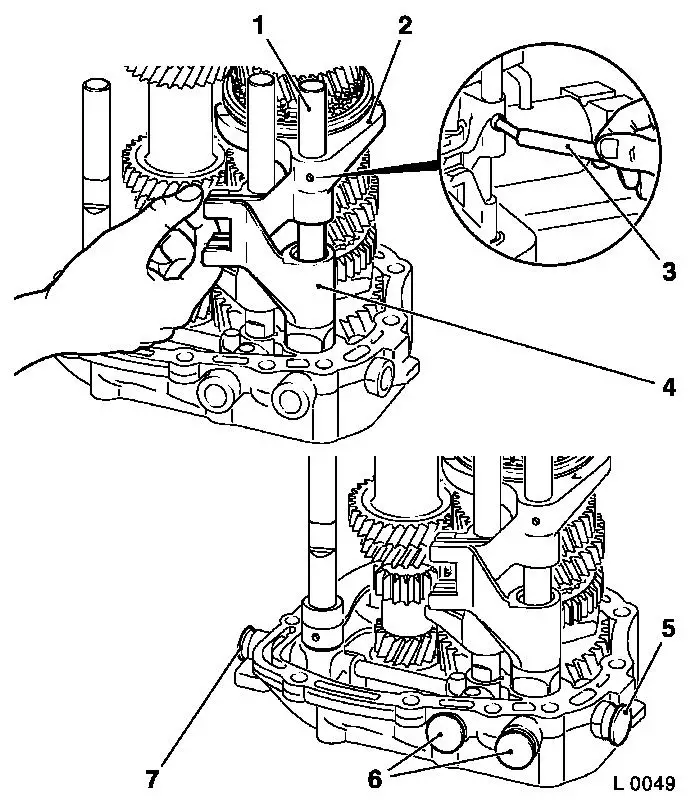

| 5. |

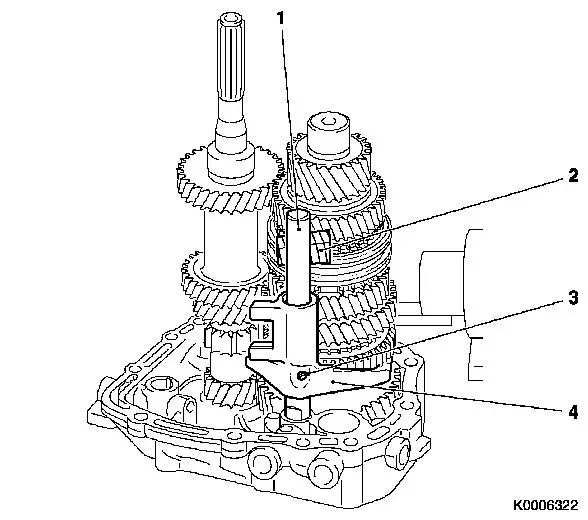

Attach end shield to KM-113-2

| • |

Attach end shield to KM-552 (2)

|

| • |

Attach end shield with KM-552 to

KM-113-2 (1)

|

|

| 6. |

Remove bearing block (3) with pivoting lever (4) from end

shield

Note: Microencapsulated

bolts. If the bolts are difficult to move, heat the end shield to

approx. 80°C with an industrial hot-air blower.

|

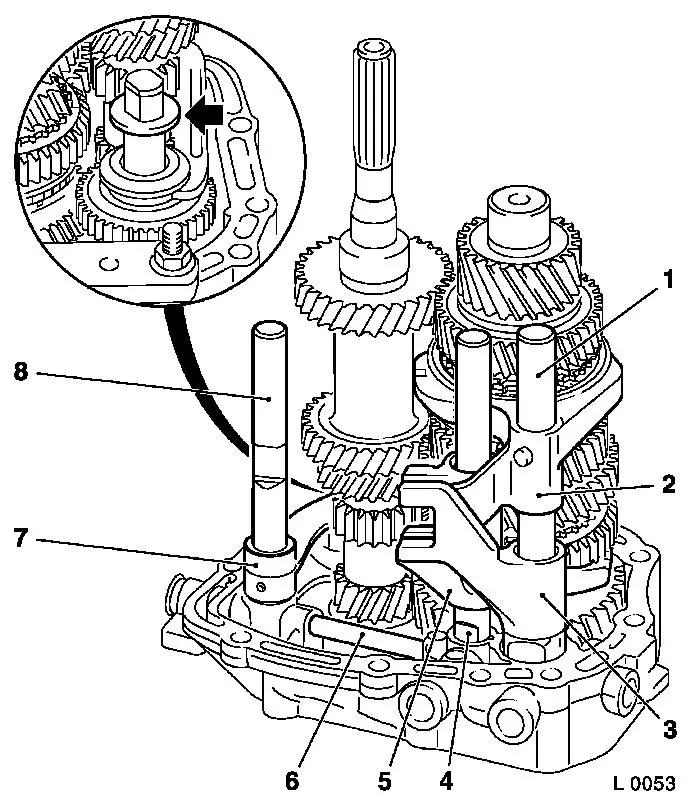

| 7. |

Remove 5th gear gearwheel (driven)

| • |

Detach retainer (5) from synchro body

|

| • |

Pull 5th gear gearwheel and 5th gear synchro body from main

shaft using KM-559-A (8)

|

| • |

Remove both needle cages for 5th gear

|

|

|

|

| 8. |

Remove bearing block (2) with latch (1) from end shield

Note: Microencapsulated

bolts. If the bolts are difficult to move, heat the end shield to

approx. 80°C with an industrial hot-air blower.

| • |

Unscrew 2x bolt (arrow)

|

|

| 9. |

Engage 2 gears

| • |

Engage reverse gear and 4th gear so that transmission is

immobilized

|

|

| 10. |

Remove 5th gear gearwheel (driving) (5)

| • |

Remove retainer(7) from drive shaft (6)

|

| • |

Set KM-553-A (4) with thrust piece

(3) on drive shaft and gearwheel

Note: Ensure that it is

correctly seated

|

| • |

Remove 5th gear gearwheel from drive shaft with KM-553-A

|

|

|

|

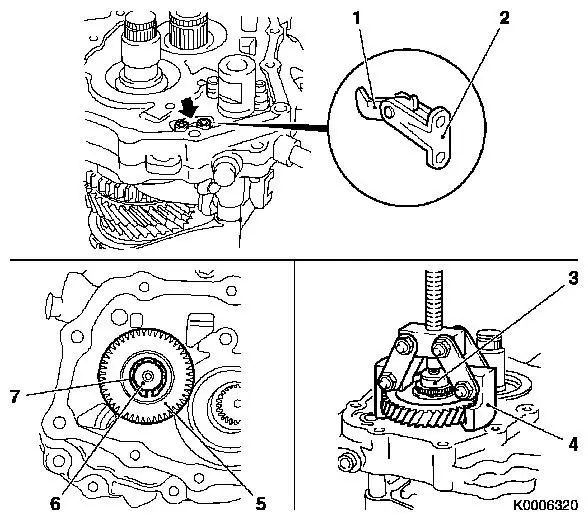

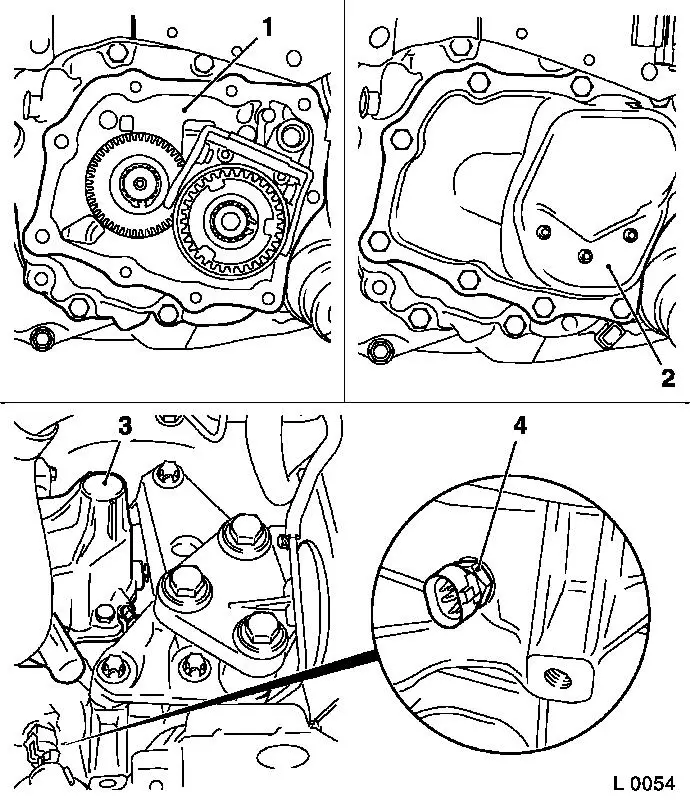

| 11. |

Remove locking plugs (arrows)

| • |

Pull plugs out of end shield with KM-727 (2) and KM-328-B

(1)

|

|

| 12. |

Remove bridge for locking bolts (3)

Note: Microencapsulated

bolts. If the bolts are difficult to move, heat the end shield to

approx. 80°C with an industrial hot-air blower.

| • |

Unscrew 2x bolt (4)

Note: Turn the end

shield on its side

|

| • |

Engage 2nd gear and 5th gear (with shift driver)

|

| • |

Engage 3rd gear and remove bridge

|

|

|

|

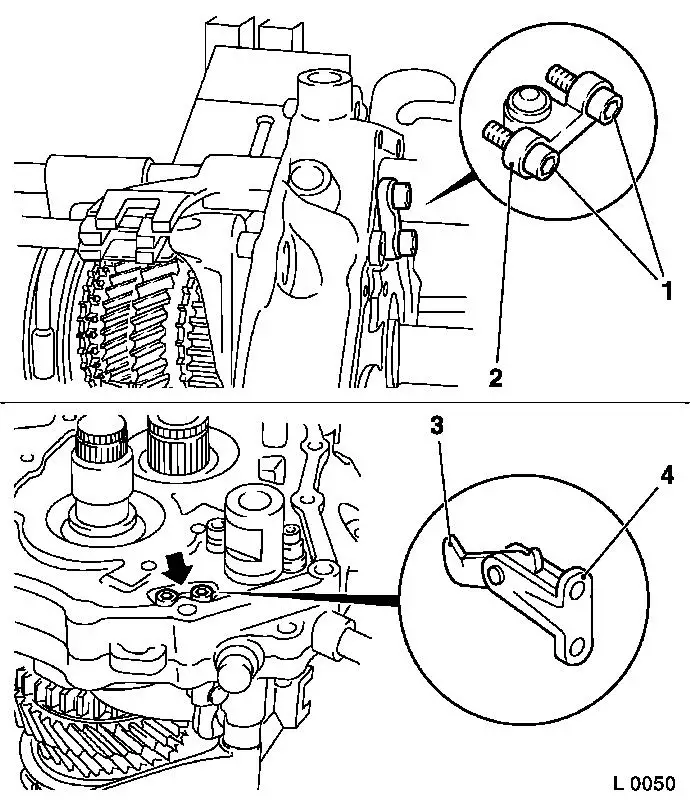

Important: Relieve the gearshift

rod guide by supporting the tops of the rods with a wooden wedge

(1)

|

| 13. |

Remove the shift forks for 3rd/4th gear and reverse

| • |

Knock out the locating pins from the 3rd/4th gear shift lever

(3) and the reverse gear lever (6), using KM-308

|

| • |

Remove shift rod (2), reverse gear shift rod and shift fork

|

|

| 14. |

Remove gear shift driver

| • |

Remove 5th gear shift driver (4) from end shield

|

|

| 15. |

Remove locking bolt (5)

| • |

Remove locking bolt from end shield

|

|

|

|

Important: Relieve the gearshift

rod guide by supporting the top of the rod (1) with a wooden wedge

(2).

|

| 16. |

Remove 1st/2nd gear shift fork

| • |

Knock out the locating pin (3) from the 1st/2nd gear shift

lever (4), using KM-308

|

| • |

Remove shift fork with shift rod

|

|

|

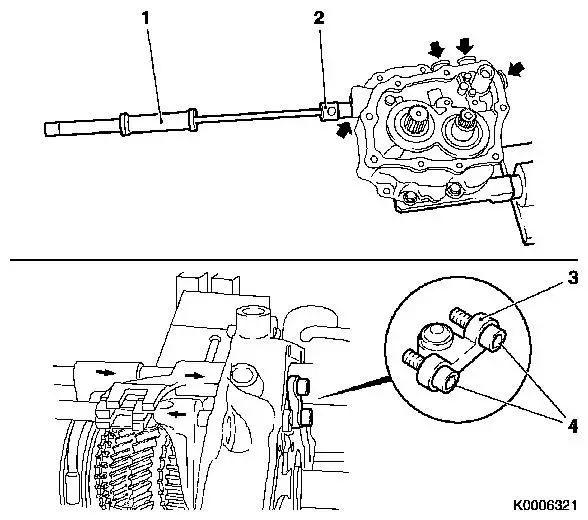

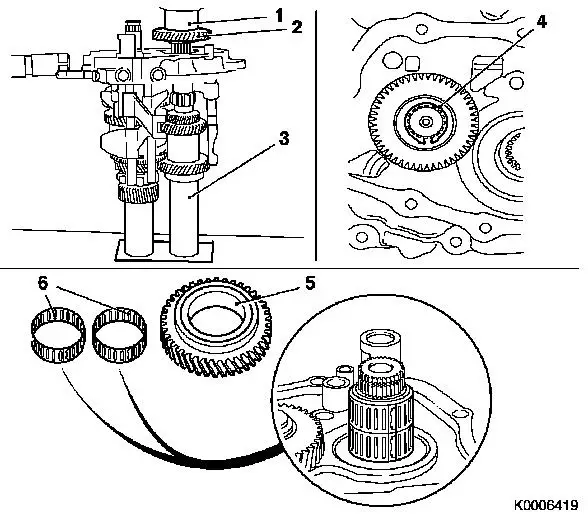

Warning: Remove main shaft, drive

shaft and reverse gearwheel.

|

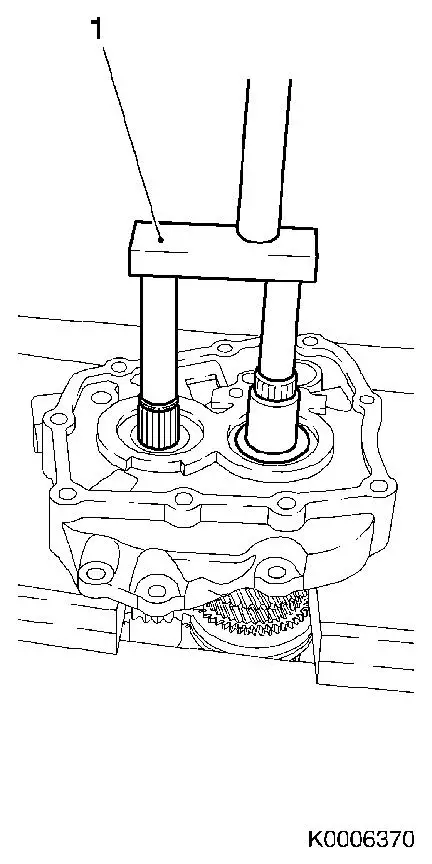

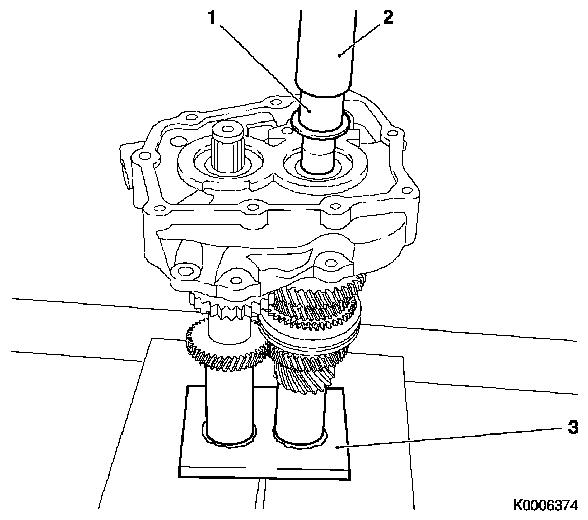

| 17. |

Dismantle main shaft and drive shaft

| • |

Detach end shield from KM-552

|

| • |

Push main shaft and drive shaft out as shown, using KM-6335 (1)

Note: In order to press

out both shafts simultaneously, apply more pressure with the press

on the side of the main shaft. Make sure that the 1st gear

gearwheel is not in contact with the press.

|

| • |

Collect main shaft, drive shaft and reverse gearwheel

|

|

|

|

|

Important: Note that retaining

ball is released.

|

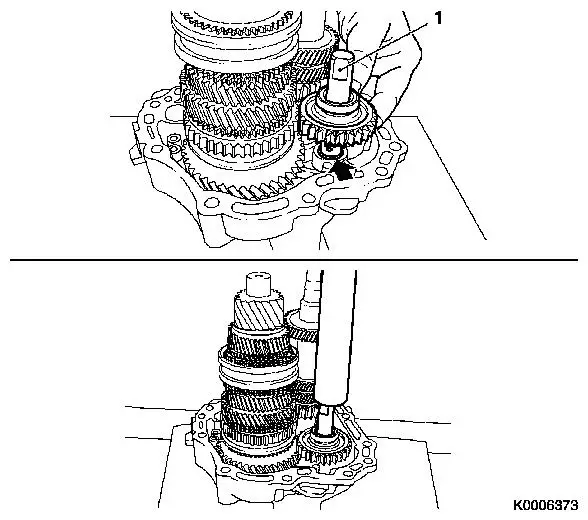

| 18. |

Remove reverse gear wheel (1)

| • |

Tension reverse gear wheel axle with protective jaws in a

vice

|

| • |

Carefully knock out end shield with brass drift

|

|

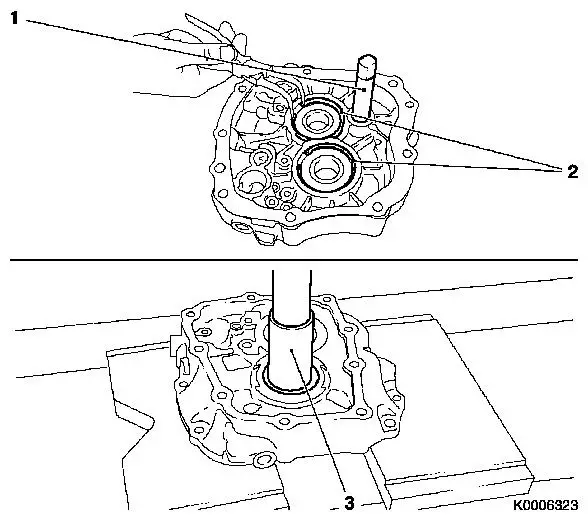

| 19. |

Dismantle main shaft and drive shaft bearings

| • |

Press out 2x bearing with KM-500-5

(3)

|

|

|

Install

Install

| 20. |

Clean all parts and sealing surfaces

|

| 21. |

Inspect parts

| • |

Check all parts for wear, damage and signs of scuffing -

replace if necessary

|

|

|

Important: Coat the bearing,

running or seating surfaces of rotating parts and surfaces under

pressure with transmission fluid.

|

| 22. |

Install the main shaft and drive shaft bearings

| • |

Press in 2x bearing with KM-523-1 (1)

and KM-6336 (2)

|

| • |

Install 2x retainer (3)

Note: Ensure that the

retainers are correctly seated

|

|

|

|

Important: Ensure that the shafts

are correctly seated

|

| 23. |

Install the main shaft and drive shaft

| • |

Set main shaft (1) and drive shaft (4) on KM-6337 (5)

|

| • |

Set end shield (3) on main shaft and drive shaft and press on

with KM-6338 (2)

|

|

|

|

| 24. |

Install 5th gear bushing (1)

| • |

Place end shield on KM-6337 (3)

|

| • |

Push bushing with KM-6339 (2) onto

main shaft

|

|

|

|

Important: Note installation

position.

|

| 25. |

Install reverse gear wheel axle (1)

| • |

Place reverse gear wheel on axle

Note: Note position,

ensure that shift fork groove faces upwards

|

| • |

Press the reverse gear wheel axle, with the securing ball

inserted (arrow), until it comes to the stop in the end shield

|

|

|

|

| 26. |

Attach end shield to KM-113-2

| • |

Attach end shield to KM-552

|

| • |

Attach end shield with KM-552 to

KM-113-2

|

|

| 27. |

Fit locking bolt (1)

| • |

Insert locking bolts for 3rd/4th gear and reverse

|

|

| 28. |

Install shift fork for reverse gear

Important: Support shift rods

with a wooden wedge when inserting pins to relieve the gearshift

rod guide.

|

| • |

Insert shift fork (5) and reverse gear shift rod (6)

|

| • |

Insert new locating pin with KM-308

(4)

Note: Allow pin to

project approx. 2 mm (dimension I)

|

|

| 29. |

Install 1st/2nd gear shift fork

Important: To relieve pressure on

shift rod guides in end shield, support shift rods with wooden

wedge when securing with pin.

|

| • |

Insert 1st/2nd gear shift fork (3) and shift rod (2)

|

| • |

Insert new locating pin with KM-308

(4)

Note: Allow pin to

project approx. 2 mm (dimension I)

|

|

|

|

| 30. |

Insert 5th gear shift driver (4)

|

| 31. |

Install 3rd/4th gear shift fork

Important: To relieve pressure on

shift rod guides in end shield, support shift rods with wooden

wedge when securing with pin.

|

| • |

Insert gear shift fork (2) and shift rod (1) for 3rd/4th

gear

|

| • |

Insert new locating pin with KM-308

(3)

Note: Allow pin to

project approx. 2 mm.

|

|

| 32. |

Install locking plugs

| • |

Install 4x locking plugs (5, 6) and (7)

Note: Drive in as far

as the stop, using a plastic hammer or soft metal drift.

|

|

| 33. |

Move the gear shift forks to neutral position

|

|

|

| 34. |

Engage 2nd, 3rd and 5th gears

Note: Turn the end

shield on its side

|

| 35. |

Install bridge for locking bolt

| • |

Insert bridge for locking bolt (2) in end shield in order to

move the gear shift forks to neutral position

|

|

| 36. |

Attach bearing block (4) with latch (3)

| • |

Insert 2x screw (arrow) with locking compound

|

| • |

Tighten 2x bolts (arrow) 7 Nm

|

|

|

|

| 37. |

Attach 5th gear gearwheel (driving) (2)

Important: Observe direction of

installation. The long gearwheel hub points towards the end

shield.

|

| • |

Insert end shield with main shaft and drive shaft in KM-6337 (3)

|

| • |

Press on 5th gear wheel with KM-473

(1)

|

| • |

Fit new retainer (4)

Note: Retainer must

engage fully.

|

|

| 38. |

Attach 5th gear gearwheel (driven) (5)

| • |

Coat needle bearings (6) with transmission fluid and place on

main shaft

Note: Ensure that the

slotted needle bearings are correctly seated.

|

| • |

Place 5th gear gearwheel and 5th gear synchro ring on main

shaft

|

|

|

|

| 39. |

Push on 5th gear synchro body assembly

| • |

Insert end shield in KM-6337

|

| • |

Place synchro body assembly (1) on main shaft

|

Important: Lugs on synchro ring

must be flush with grooves on synchro body

|

| • |

Push synchromesh body in KM-473 onto

main shaft

|

| • |

Fit new retainer (2)

Note: Retainer must

engage fully.

|

|

| 40. |

Attach bearing block with pivoting lever

| • |

Insert 2x sliding shoe (arrow) in 5th gear shift fork (3)

|

| • |

Insert bearing block with pivoting lever in end shield

|

| • |

Insert 2x screw with locking compound

|

|

|

|

| 41. |

Install friction washer and magnet

| • |

Fit friction washer (arrow) on reverse gear axle with

grease

|

| • |

Insert magnet with grease

|

|

Important: Before installing the

end shield, check the position and seating of the following:

| 1. |

3rd/4th gear shift fork |

| 2. |

3rd/4th gear shift rod |

| 3. |

5th gear shift driver |

| 4. |

1st/2nd gear shift rod |

| 5. |

1st/2nd gear shift fork |

| 6. |

Lock pin for gear stop |

| 7. |

Reverse gear shift fork |

| 8. |

Reverse gear shift rod |

|

| 42. |

Detach end shield from KM-113-2

| • |

Detach end shield from KM-552

|

|

|

|

| 43. |

Install end shield (1)

Note: Observe the

magnet

|

| 44. |

Install end shield cover (2)

|

| 45. |

Install gearshift cover (3)

|

| 46. |

Transmission Fluid Level, Check and Correct

|

| 47. |

Install reversing lamp switch (4)

| • |

insert with new seal ring

|

| • |

Tighten reversing lamp switch 20

Nm

|

| • |

Connect wiring harness plug

|

|

| 48. |

Check ease of gear shifting

|

|

|