|

Replace differential gear (F23)

Remove Remove

| 1. |

Dismantle transmission

|

|

| 2. |

Determine setting of pressure collar and initial bearing stress

of old differential gear

| • |

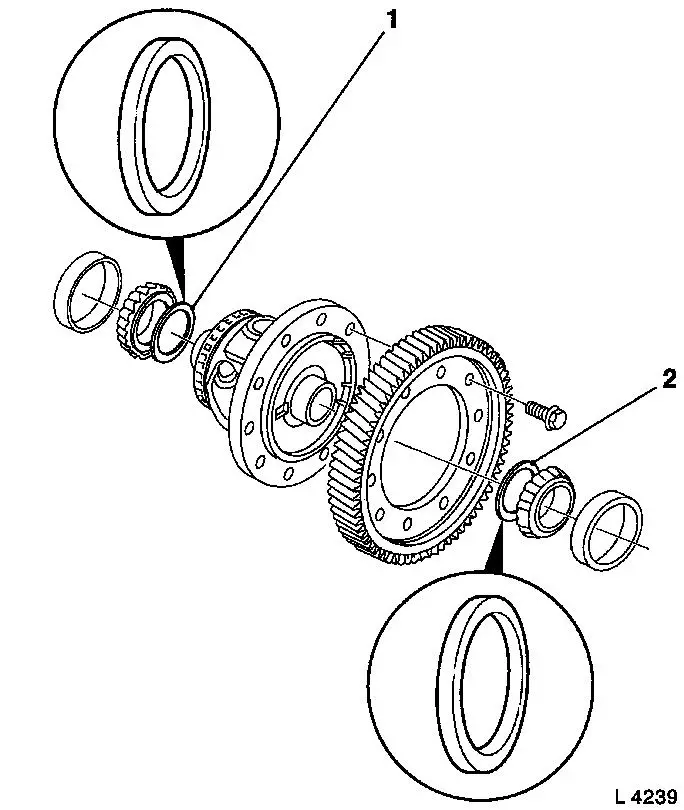

Remove tapered roller bearing from differential gear

|

| • |

Measure and note down thickness of shim (2) on transmission

housing side

| – |

Remove shim

Note: The shim on the

transmission housing side (2) is used for setting the pressure

collar. The thickness of the shims must be determined with a

micrometer as they are not marked.

|

|

| • |

Measure and note down thickness of shim (1) on clutch housing

side

| – |

Remove shim

Note: The shim on the

clutch housing side (1) is used for setting the initial tension of

the differential gear tapered roller bearing.

|

|

|

|

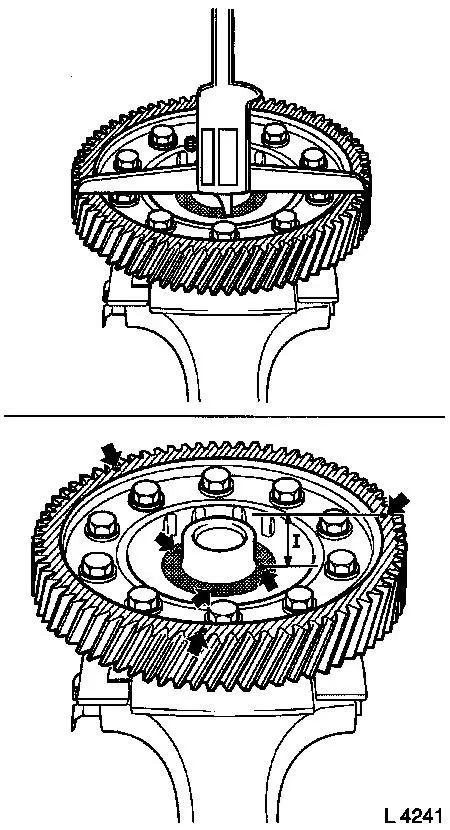

| 3. |

Determine dimension (I) from the outside of the ring gear to

the bearing seating on the old differential gear

| • |

Use a standard commercial digital depth micrometer

Note: Micrometer range

at least 250 mm, 0.01 mm graduations

|

| • |

Perform measurement 3 times - space measuring points evenly

around ring gear (arrows)

|

| • |

Add all measured values together

|

| • |

Divide by the number of measurements

|

| • |

Note down the average for the old differential gear

Note: The table below

is a specimen calculation. You can enter the actual measurement

results in the blank column on the right of the printout and

perform the calculation there.

|

Example

|

Your values for the old differential

|

|

1st measurement

|

15.02mm

|

+

|

1st measurement

|

|

|

|

|

|

|

|

mm

|

+

|

|

2nd measurement

|

15.06mm

|

+

|

2nd measurement

|

|

|

|

|

|

|

|

mm

|

+

|

|

3rd measurement

|

15.05mm

|

=

|

3rd measurement

|

|

|

|

|

|

|

|

mm

|

=

|

|

Total

|

45.13mm

|

:3=

|

Total

|

|

|

|

|

|

|

|

mm

|

:3=

|

|

Average

|

15.04mm

|

|

Average

|

|

|

|

|

|

|

|

mm

|

|

|

|

|

|

|

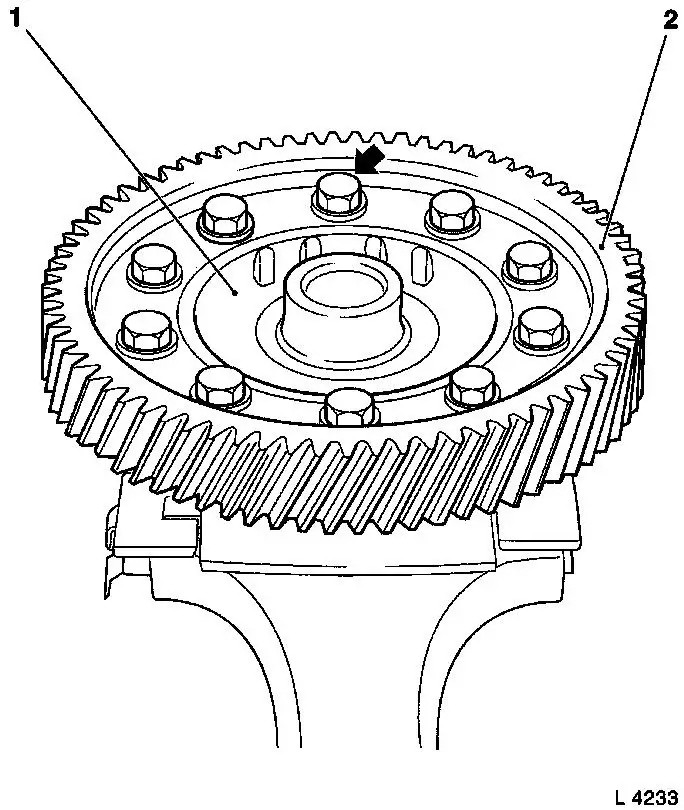

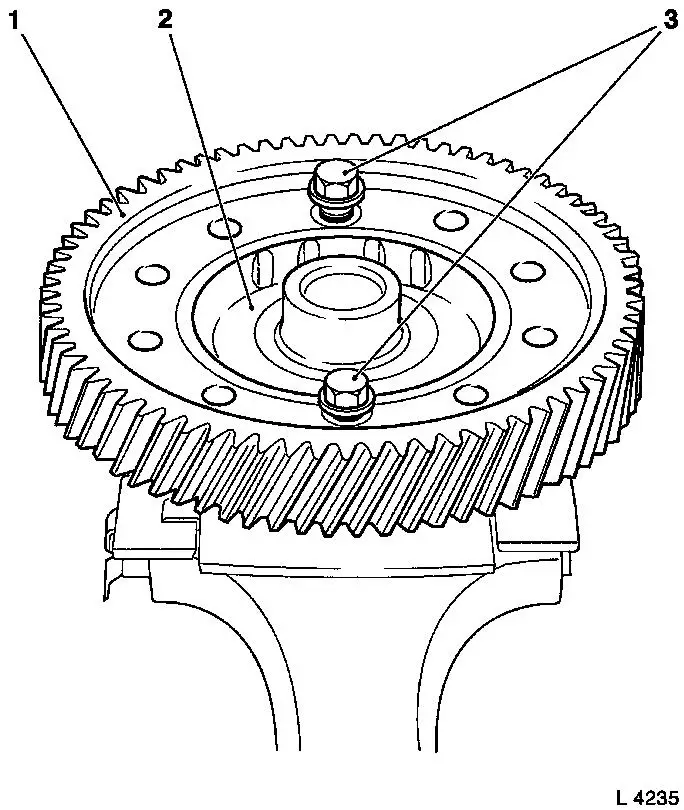

| 4. |

Remove the ring gear from the old differential gear

| • |

Clamp differential gear (1) in a vice

|

| • |

Unscrew 10x bolt (arrow)

|

| • |

Drive ring gear (2) off differential gear with plastic

hammer

|

| • |

Clean the ring gear and check for damage

Note: An intact ring

gear can be re-used

|

|

|

|

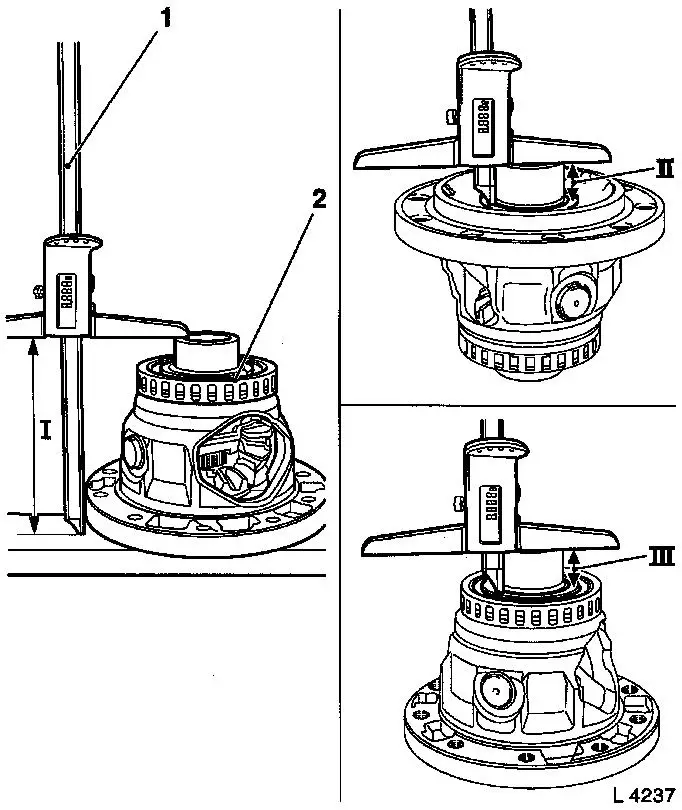

| 5. |

Determine the bearing seating distance for the new/old

differentials

| • |

Use a standard commercial digital depth micrometer (1)

Note: Micrometer range

at least 250 mm, 0.01 mm graduations

|

| • |

Measure lengths (I, II, III)

|

| • |

Deduct dimension (II) and dimension (III) from dimension

(I)

Note: The table below

is a specimen calculation. You can enter the actual measurement

results in the blank column on the right of the print-out and

perform the calculation there. The calculated dimension IV is the

bearing seating distance for the differential gear concerned.

|

Dimension I

|

210.25mm

|

-

|

Dimension I

|

|

|

|

|

|

|

mm

|

-

|

|

Dimension II

|

18.25mm

|

-

|

Dimension II

|

|

|

|

|

|

|

mm

|

-

|

|

Dimension III

|

18.30mm

|

=

|

Dimension III

|

|

|

|

|

|

|

mm

|

=

|

|

Dimension IV

|

173.70mm

|

|

Dimension IV

|

|

|

|

|

|

|

mm

|

|

|

| • |

Perform measurement 3 times - space measuring points evenly

around differential gear

|

| • |

Add all measured values together

|

| • |

Divide by the number of measurements

|

| • |

Determine and note down the average bearing seating distances

for the new and old differentials

Note: The table below

is a specimen calculation. You can enter the actual measurement

results in the blank column on the right of the printout and

perform the calculation there.

|

For example

|

|

Your values

|

|

Dimension IV 1st measurement

|

90.02mm

|

+

|

Dimension IV 1st measurement

|

|

|

|

|

|

|

mm

|

+

|

|

Dimension IV 2nd measurement

|

90.05mm

|

+

|

Dimension IV 2nd measurement

|

|

|

|

|

|

|

mm

|

+

|

|

Dimension IV 3rd measurement

|

90.05mm

|

=

|

Dimension IV 3rd measurement

|

|

|

|

|

|

|

mm

|

=

|

|

Total

|

270.13mm

|

:3=

|

Total

|

|

|

|

|

|

|

mm

|

:3=

|

|

Average

|

90.04mm

|

|

Average

|

|

|

|

|

|

|

mm

|

|

|

| • |

Calculate the difference between the bearing seating distances

for the new/old differentials

| – |

Subtract the average bearing seating distance of the old

differential from the average bearing seating distance of the new

differential

Note: If the difference

between the bearing seating distances for the old and new

differentials is more than +/- 0.04 mm, the initial stress of the

bearing for the new differential must be adjusted in a subsequent

step. If the distance is +/- 0.04 mm or less this is not necessary;

the total thickness of the shims in the old differential is then

kept the same.

|

|

|

|

|

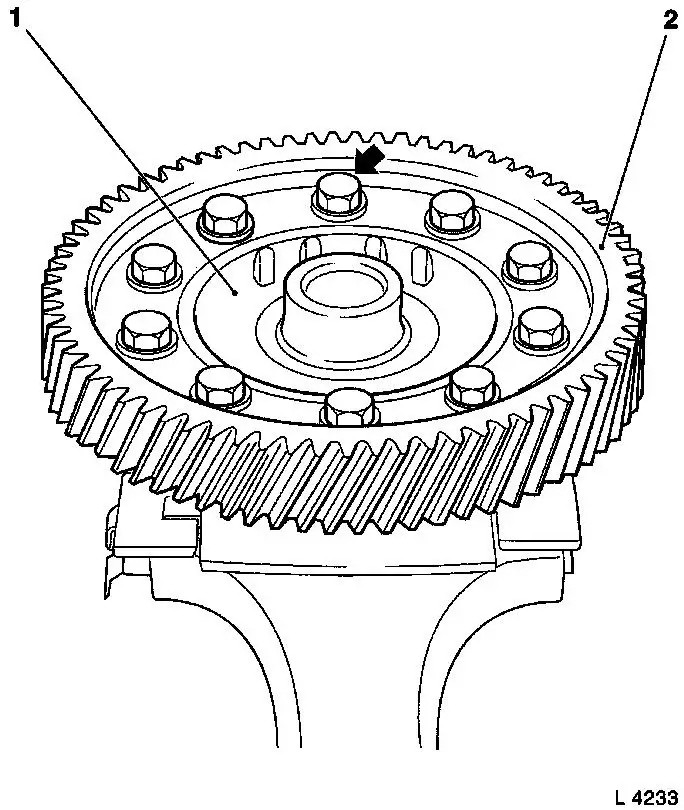

| 6. |

Install ring gear in new differential

| • |

Clamp the new differential (2) in a vice using protective

jaws

|

| • |

Place the ring gear (1) on the differential gear

| – |

If necessary, use a new ring gear.

|

|

| • |

Screw in 2x bolt (3) to secure

|

| • |

Drive ring gear onto differential gear with plastic hammer

|

| • |

Continue until the ring gear is touching the differential

|

|

|

|

| 7. |

Insert 10x new screws (arrow)

| • |

Screw in 10x bolts with locking compound

|

| • |

Tighten 10 bolts evenly in crosswise formation 95 Nm

|

|

|

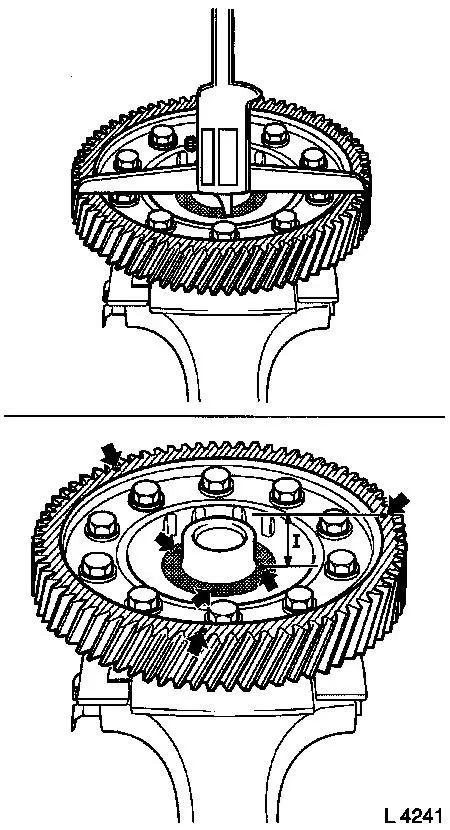

| 8. |

Determine dimension (I) from the outside of the ring gear to

the bearing seating on the new differential gear

| • |

Use a standard commercial digital depth micrometer

Note: Micrometer range

at least 250 mm, 0.01 mm graduations

|

| • |

Perform measurement 3 times - space measuring points evenly

around ring gear (arrows)

|

| • |

Add all measured values together

|

| • |

Divide by the number of measurements

|

| • |

Note down the average for the new differential gear

Note: The table below

is a specimen calculation. You can enter the actual measurement

results in the blank column on the right of the printout and

perform the calculation there.

|

Example

|

Your values

|

|

1st measurement

|

15.02mm

|

+

|

1st measurement

|

|

|

|

|

|

|

|

mm

|

+

|

|

2nd measurement

|

15.06mm

|

+

|

2nd measurement

|

|

|

|

|

|

|

|

mm

|

+

|

|

3rd measurement

|

15.05mm

|

=

|

3rd measurement

|

|

|

|

|

|

|

|

mm

|

=

|

|

Total

|

45.13mm

|

:3=

|

Total

|

|

|

|

|

|

|

|

mm

|

:3=

|

|

Average

|

15.04mm

|

|

Average

|

|

|

|

|

|

|

|

mm

|

|

|

|

|

|

| 9. |

Determine setting of pressure collar

| • |

Calculate the difference between the averages

| – |

Subtract the average noted down for the old differential from

the average noted down for the new differential

Note: If the difference

exceeds +0.02/-0.06mm, the pressure collar must be adjusted. If it

is less, the old shims can be re-used.

Note: The table below

can be used as a specimen calculation. The actual measurement

results can be entered in the blank column on the right of the

printout and calculation performed.

|

Average

|

New differential

|

15.16mm

|

-

|

|

-

|

|

Average

|

Old differential

|

15.04mm

|

=

|

|

=

|

|

Difference in dimensions

|

+ 0.12 mm

|

|

|

|

|

|

|

|

| 10. |

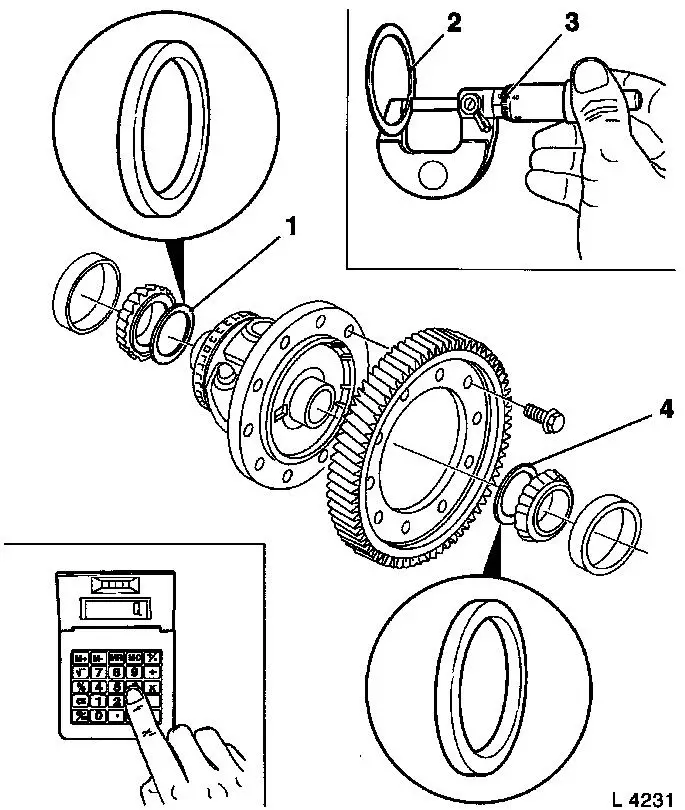

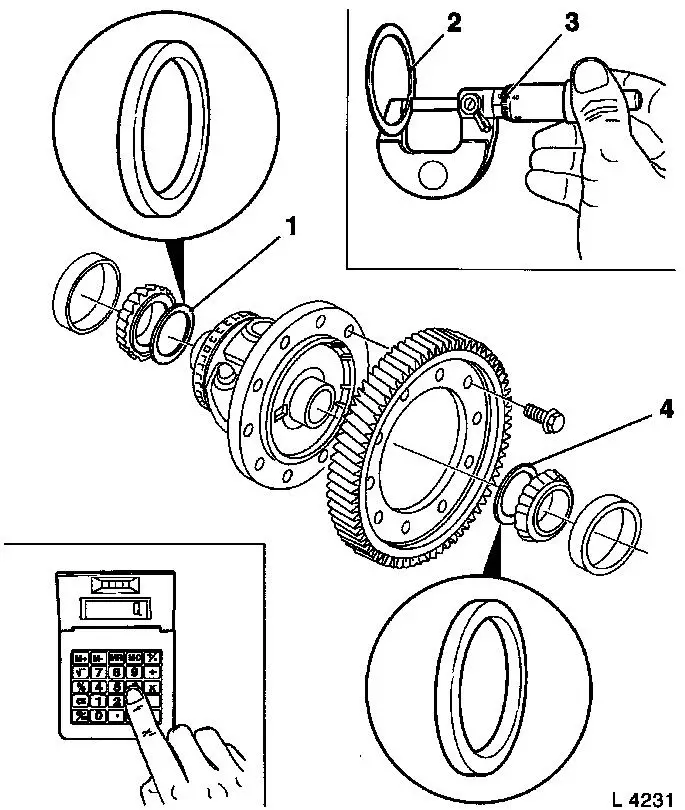

Insert 2x shim (1, 4)

Important: Make sure that the

correct shims are fitted on the clutch housing side and the

transmission housing side

|

| • |

If necessary, reset pressure collar

| – |

Determine the thickness of the new shims and insert them

Note: If the difference

between the dimensions is positive, choose a shim (4) that is the

same dimension thicker than the old one. If the difference is

negative, a correspondingly thinner shim must be used. The total

thickness of both shims must remain constant as this determines the

prestressing of the differential gear tapered roller bearing.

Therefore if a thicker shim (4) is used on the transmission housing

side, fit a clutch housing side shim (1) that is thinner by the

same amount. If a thinner shim is used on the transmission housing

side a correspondingly thicker shim must be installed on the clutch

housing side.

Note: The shims can be

obtained from "Aftersales". The thickness of the shims (2) must be

determined with a micrometer (3) as there is no marking on them

Note: The table below

contains a few examples from the range of shims that can be

supplied. When adjusting, the shims must be selected to achieve the

smallest tolerance possible. Undamaged used shims can be

re-used.

|

Difference in dimensions

|

Shim (on transmission housing side)

|

Shim (on clutch housing side)

|

|

- 0.25 mm

|

old

|

0.90mm

|

new

|

0.65 mm

|

old

|

0.75mm

|

new

|

1.00mm

|

|

+ 0.20 mm

|

old

|

0.90mm

|

new

|

1.10 mm

|

old

|

0.75mm

|

new

|

0.55mm

|

|

+ 0.13mm

|

old

|

0.90mm

|

new

|

1.05 mm

|

old

|

0.75mm

|

new

|

0.60mm

|

|

+ 0.12 mm

|

old

|

0.90mm

|

new

|

1.00mm

|

old

|

0.75mm

|

new

|

0.65 mm

|

|

|

|

|

|

| 11. |

If necessary: adjust initial pressure of differential gear

tapered roller bearing

Note: If the difference

between the bearing seating distances for the old and new

differentials is more than +/- 0.04 mm, the initial stress of the

bearing for the new differential must be adjusted now. If the

distance is +/- 0.04 mm or less this is not necessary; the total

thickness of the shims in the old differential is then kept the

same.

Important: The shim (4) on the

transmission housing side that is determined for the pressure

collar setting is not changed for setting the initial stress of the

bearing.

|

| • |

Determine the thickness of the new shim (1) on the clutch

housing side

| – |

Compare the average bearing seating distance noted down for the

new differential with the average noted down for the old

differential.

Note: If the value for

the new differential is greater than that for the old one, the

clutch housing side shim chosen must be thinner by the difference

in the values. If the bearing seating difference for the new

differential is less than that for the old one, the clutch housing

side shim chosen must be correspondingly thicker.

Note: The shims can be

obtained from "Aftersales". The thickness of the shims (2) must be

determined with a micrometer (3) as there is no marking on them

Note: The table below

contains a few examples from the range of shims that can be

supplied. When adjusting, the shims must be selected to achieve the

smallest tolerance possible. Undamaged used shims can be

re-used.

|

Average bearing seating distance, old

|

Shim (on clutch housing side), old

|

Average bearing seating distance, new

|

Shim (on clutch housing side), new

|

|

90.10 mm

|

0.75mm

|

90.03mm

|

0.80mm

|

|

90.07mm

|

0.85mm

|

90.15mm

|

0.75mm

|

|

90.21mm

|

0.90mm

|

90.08mm

|

1.05 mm

|

|

|

|

|

| 12. |

When the differential gear tapered roller bearing is being

replaced, remove 2 differential gear tapered roller bearing outer

rings from the clutch housing and the transmission housing

|

Install

Install

| 13. |

Install differential gear tapered roller bearing

|

| 14. |

Assemble transmission

|

|