|

Replace differential gear ring gear (F23)

Remove Remove

| 1. |

Dismantle transmission

|

|

| 2. |

Determine setting of pressure collar and initial bearing stress

of differential gear

| • |

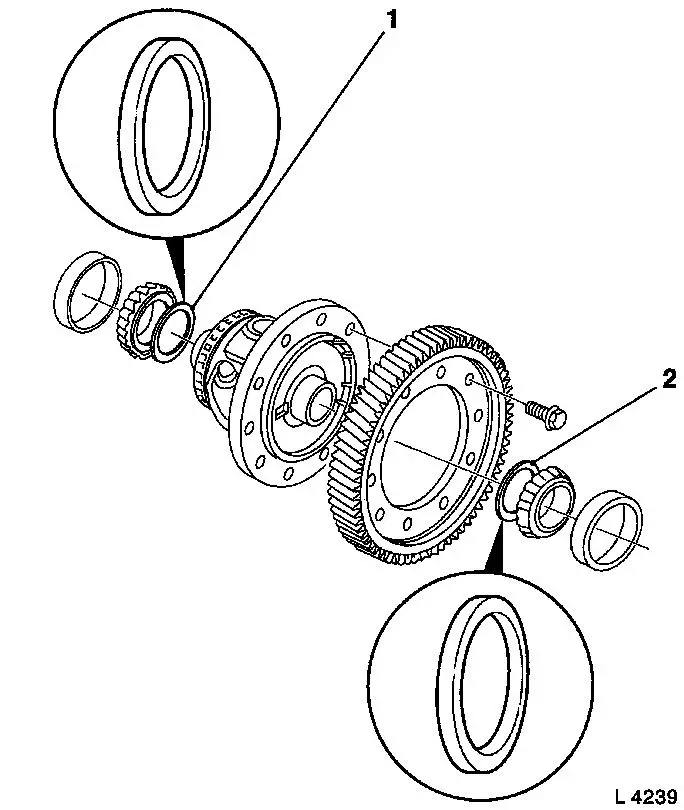

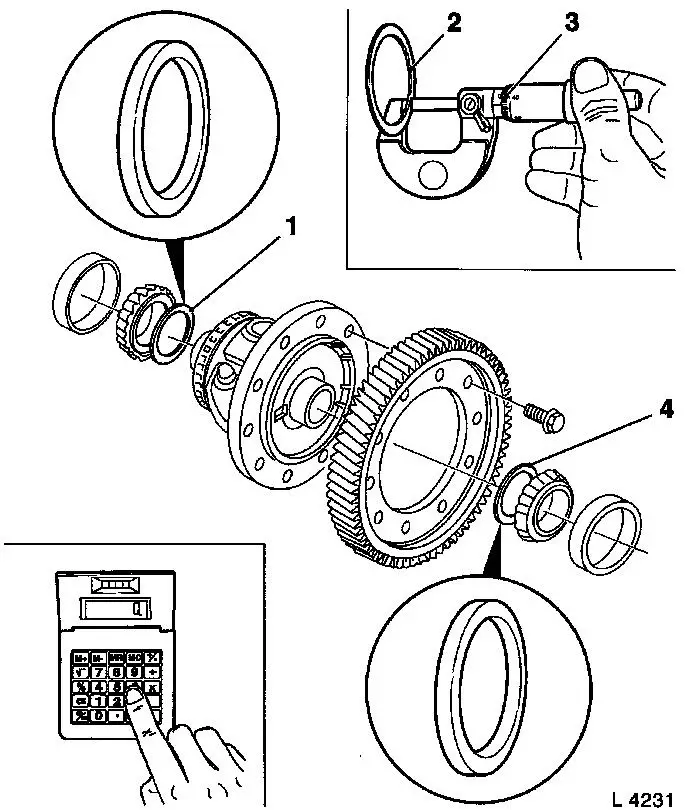

Remove tapered roller bearing from differential gear

|

| • |

Measure and note down thickness of shim (2) on transmission

housing side

| – |

Remove shim

Note: The shim on the

transmission housing side (2) is used for setting the pressure

collar. The dimensions of the shims must be determined with a

micrometer as there is no marking on them

|

|

| • |

Measure and note down thickness of shim (1) on clutch housing

side

| – |

Remove shim

Note: The shim on the

clutch housing side (1) is used for setting the initial tension of

the differential gear tapered roller bearing.

|

|

|

|

| 3. |

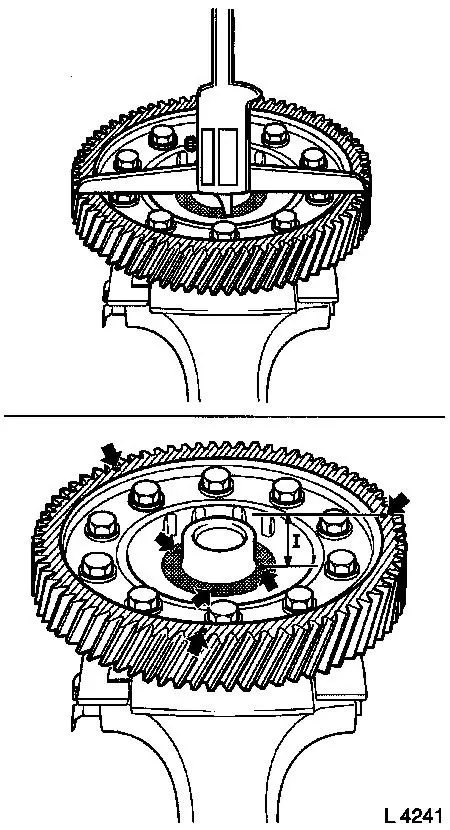

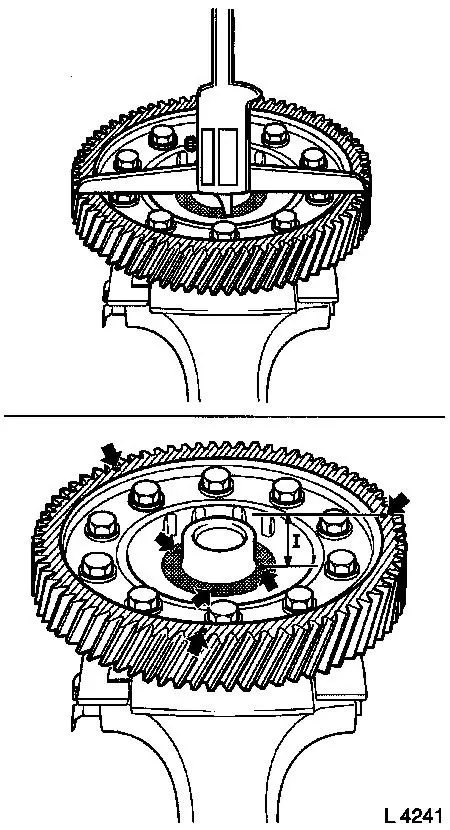

Determine the distance (I) from the outside of the ring gear to

the bearing seating on the differential gear

| • |

Use a standard commercial digital depth micrometer

Note: Micrometer range

at least 250 mm, 0.01 mm graduations

|

| • |

Perform measurement 3 times - space measuring points evenly

around ring gear (arrows)

|

| • |

Add all measured values together

|

| • |

Divide by the number of measurements

|

| • |

Note down the average for the old ring gear

Note: The table below

is a specimen calculation. You can enter the actual measurement

results in the blank column on the right of the printout and

perform the calculation there.

|

Example

|

Your values

|

|

1st measurement

|

15.02mm

|

+

|

1st measurement

|

|

|

|

|

|

|

|

mm

|

+

|

|

2nd measurement

|

15.06mm

|

+

|

2nd measurement

|

|

|

|

|

|

|

|

mm

|

+

|

|

3rd measurement

|

15.05mm

|

=

|

3rd measurement

|

|

|

|

|

|

|

|

mm

|

=

|

|

Total

|

45.13mm

|

:3=

|

Total

|

|

|

|

|

|

|

|

mm

|

:3=

|

|

Average

|

15.04mm

|

|

Average

|

|

|

|

|

|

|

|

mm

|

|

|

|

|

|

|

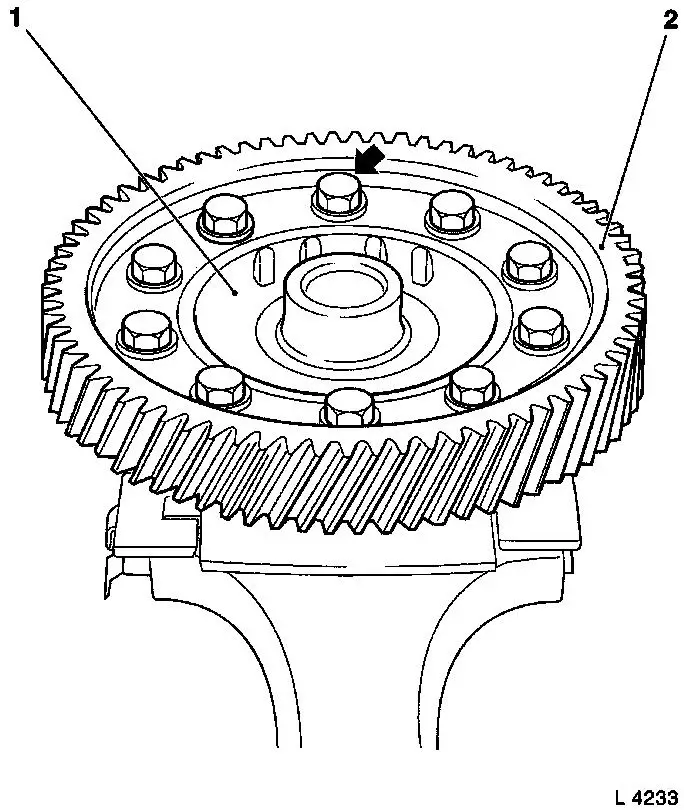

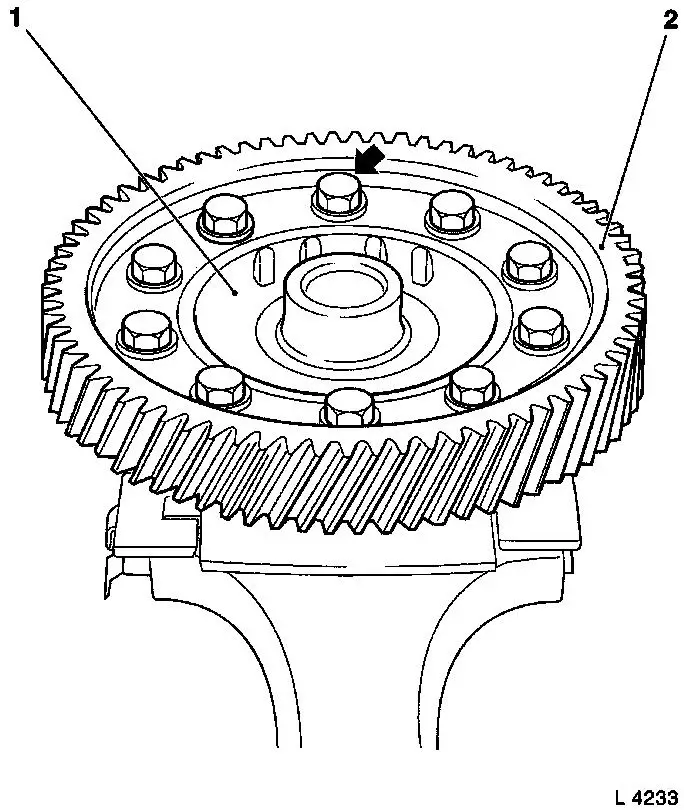

| 4. |

Remove the ring gear from the differential

| • |

Clamp differential gear (1) in a vice with protective jaws

|

| • |

Unscrew 10x bolt (arrow)

|

| • |

Drive ring gear (2) off differential gear with plastic

hammer

|

| • |

Clean differential gear and inspect for damage

|

| • |

If necessary: replace differential gear

|

|

|

|

| 5. |

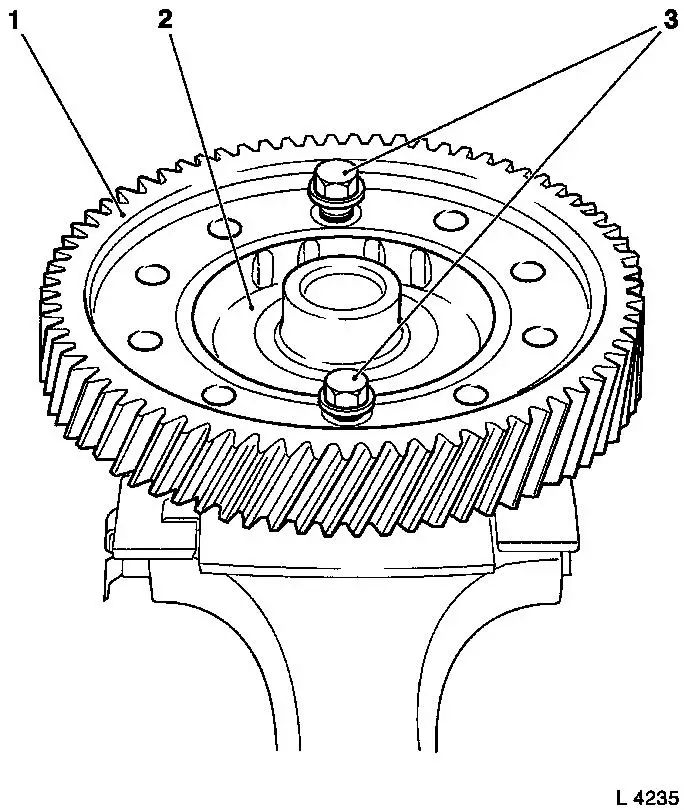

Install new ring gear in differential

| • |

Place the ring gear (1) on the differential gear (2)

|

| • |

Screw in 2x bolt (3) to secure

|

| • |

Drive ring gear onto differential gear with plastic hammer

|

|

|

|

| 6. |

Insert 10x new screws (arrow)

| • |

Screw in 10x bolts with locking compound

|

| • |

Tighten 10 bolts evenly in crosswise formation 95 Nm

|

|

|

| 7. |

Determine the distance (I) from the outside of the new ring

gear to the bearing seating on the differential gear

| • |

Use a standard commercial digital depth micrometer

Note: Micrometer range

at least 250 mm, 0.01 mm graduations

|

| • |

Perform measurement 3 times - space measuring points evenly

around ring gear (arrows)

|

| • |

Add all measured values together

|

| • |

Divide by the number of measurements

|

| • |

Note down the average for the new ring gear

Note: The table below

is a specimen calculation. You can enter the actual measurement

results in the blank column on the right of the printout and

perform the calculation there.

|

Example

|

Your values for new ring gear

|

|

1st measurement

|

15.02mm

|

+

|

1st measurement

|

Your values

|

|

|

|

|

|

|

mm

|

+

|

|

2nd measurement

|

15.06mm

|

+

|

2nd measurement

|

|

|

|

|

|

|

|

mm

|

+

|

|

3rd measurement

|

15.05mm

|

=

|

3rd measurement

|

|

|

|

|

|

|

|

mm

|

=

|

|

Total

|

45.13mm

|

:3=

|

|

Total

|

|

|

|

|

|

|

mm

|

:3=

|

|

Average

|

15.04mm

|

|

|

Average

|

|

|

|

|

|

|

mm

|

|

|

|

|

|

| 8. |

Determine pressure collar setting for new ring gear

| • |

Calculate the difference between the averages

| – |

Subtract average noted down for old ring gear from average

noted down for new ring gear

Note: If the difference

exceeds +0.02/-0.06mm, the pressure collar must be adjusted. If it

is less, the old shims can be re-used.

Note: The table below

is a specimen calculation. You can enter the actual measurement

results in the blank column on the right of the printout and

perform the calculation there.

|

Average

|

New ring gear

|

15.16mm

|

-

|

|

-

|

|

Average

|

Old ring gear

|

15.04mm

|

=

|

|

=

|

|

Difference in dimensions

|

+ 0.12 mm

|

|

|

|

|

|

|

|

| 9. |

Insert 2x shim (1, 4)

Important: Make sure that the

correct shims are fitted on the clutch housing side and the

transmission housing side

|

| • |

If necessary, reset pressure collar

| – |

Determine the thickness of the new shims and insert them

Note: If the difference

between the dimensions is positive, choose a shim (4) that is the

same dimension thicker than the old one. If the difference is

negative, a correspondingly thinner shim must be used. The total

thickness of both shims must remain constant as this determines the

prestressing of the differential gear tapered roller bearing.

Therefore if a thicker shim (4) is used on the transmission housing

side, fit a clutch housing side shim (1) that is thinner by the

same amount. If a thinner shim is used on the transmission housing

side a correspondingly thicker shim must be installed on the clutch

housing side.

Note: The shims can be

obtained from "Aftersales". The thickness of the shims (2) must be

determined with a micrometer (3) as there is no marking on them

Note: The table below

contains a few examples from the range of shims that can be

supplied. When adjusting, the shims must be selected to achieve the

smallest tolerance possible. Undamaged used shims can be

re-used.

|

Difference in dimensions

|

Shim (on transmission housing side)

|

Shim (on clutch housing side)

|

|

- 0.25 mm

|

old

|

0.90mm

|

new

|

0.65 mm

|

old

|

0.75mm

|

new

|

1.00mm

|

|

+ 0.20 mm

|

old

|

0.90mm

|

new

|

1.10 mm

|

old

|

0.75mm

|

new

|

0.55mm

|

|

+ 0.13mm

|

old

|

0.90mm

|

new

|

1.05 mm

|

old

|

0.75mm

|

new

|

0.60mm

|

|

+ 0.12 mm

|

old

|

0.90mm

|

new

|

1.00mm

|

old

|

0.75mm

|

new

|

0.65 mm

|

|

|

|

|

Important: If the inner rings of

the differential gear tapered roller bearing are replaced, the

outer rings must be replaced too.

|

| 10. |

When the differential gear tapered roller bearing is being

replaced, remove 2 differential gear tapered roller bearing outer

rings from the clutch housing and the transmission housing

|

Install

Install

| 11. |

Install differential gear tapered roller bearing

|

| 12. |

Assemble transmission

|

|