|

Overhaul differential gear up from model year

2007,5 (F17+)

Note: Transmission

remains installed.

Remove Remove

|

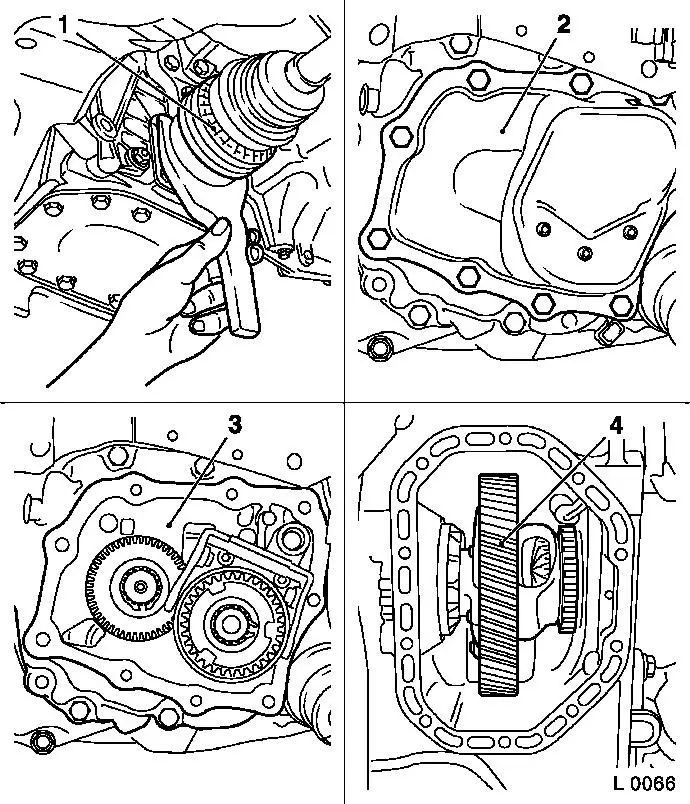

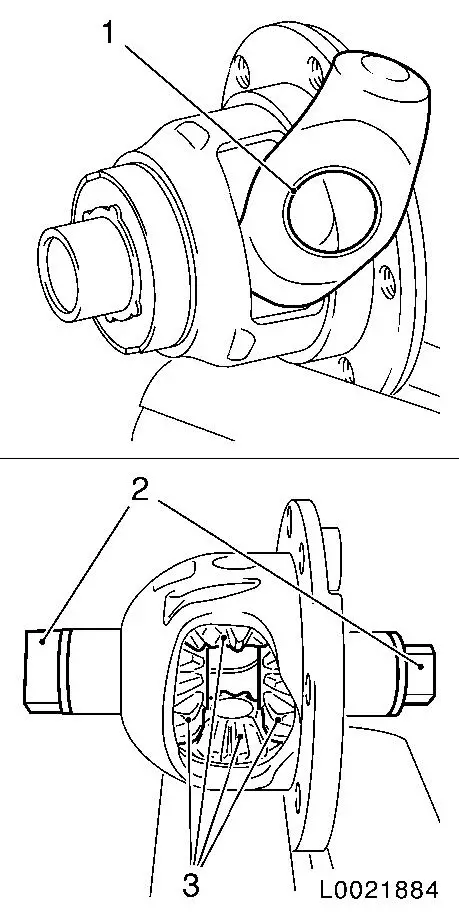

| 1. |

Detach axle shafts (1) from transmission

Note: Axle shafts

remain in wheel hub.

|

| 2. |

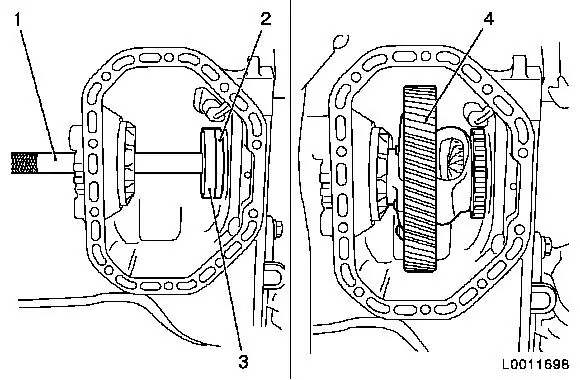

Remove end shield cover (2)  . .

|

| 4. |

Remove differential (4)

|

|

| 5. |

Remove 2x axle shaft sealing rings from bearing ring (3) and

transmission

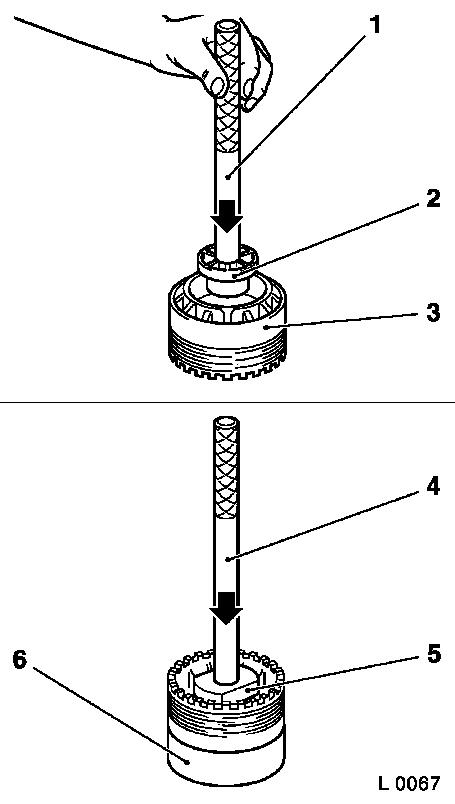

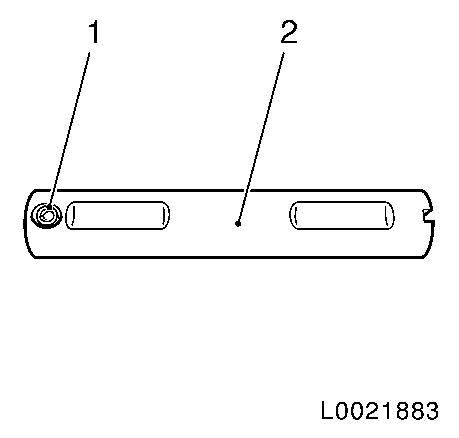

| • |

Remove axle shaft seal ring with KM-454-2 (1) and KM-454-4

(2)

|

|

| 6. |

Remove tapered roller bearing outer race from bearing ring

Note: Only necessary

when replacing bearing in bearing ring.

| • |

Place outer race of tapered roller bearing with KM-303 (6)

|

| • |

Remove tapered roller bearing outer race from transmission with

KM-304 (4) and KM-451 (5)

|

|

| 7. |

Remove tapered roller bearing outer race from transmission

Note: Only necessary

when replacing bearing in transmission.

| • |

Remove tapered roller bearing outer race from transmission with

KM-305 and KM-451

Note: If the

transmission has been removed, use KM-304

and KM-451 .

|

|

|

|

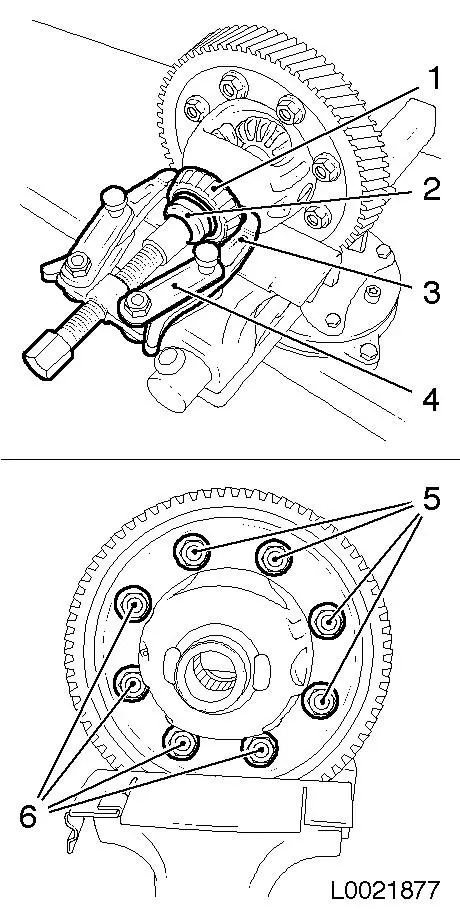

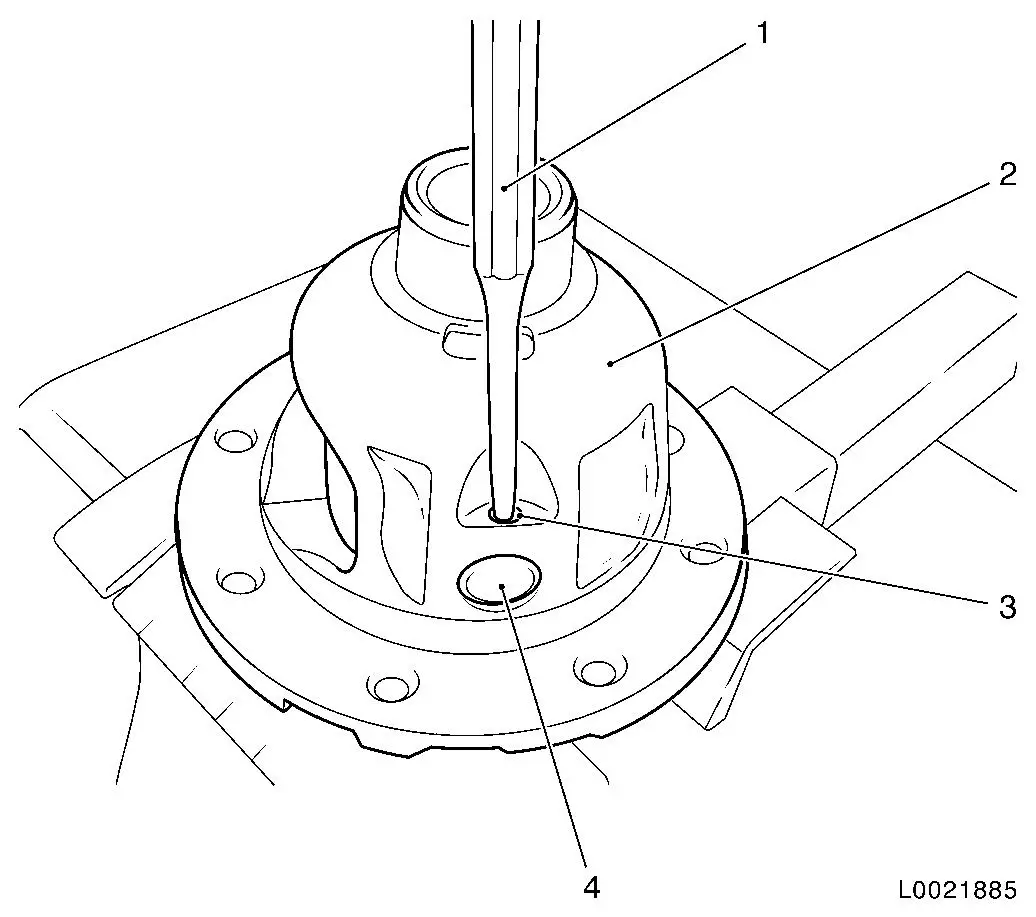

| 8. |

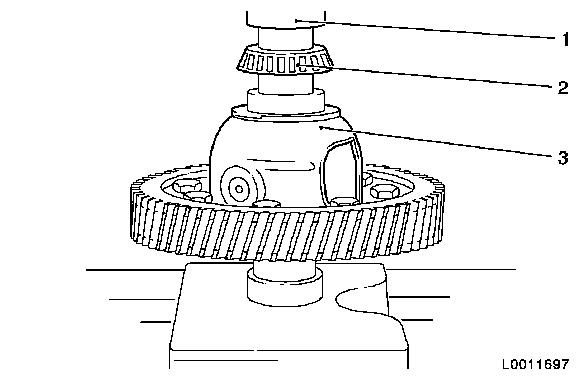

Detach 2x tapered roller bearing inner ring (1) from

differential gear

Note: Only necessary

when replacing.

Do not interchange outer and inner races respectively when re-using

tapered roller bearings.

| • |

Pull off tapered roller bearing inner ring with KM-161-B (4), KM-161-3 (3)

and KM-161-4 (2)

|

|

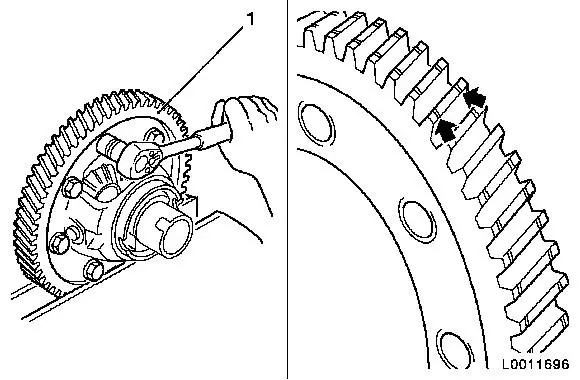

| 9. |

Detach ring gear from differential housing

| • |

Clamp differential housing in vice

Note: Use protective

jaws.

|

|

|

|

|

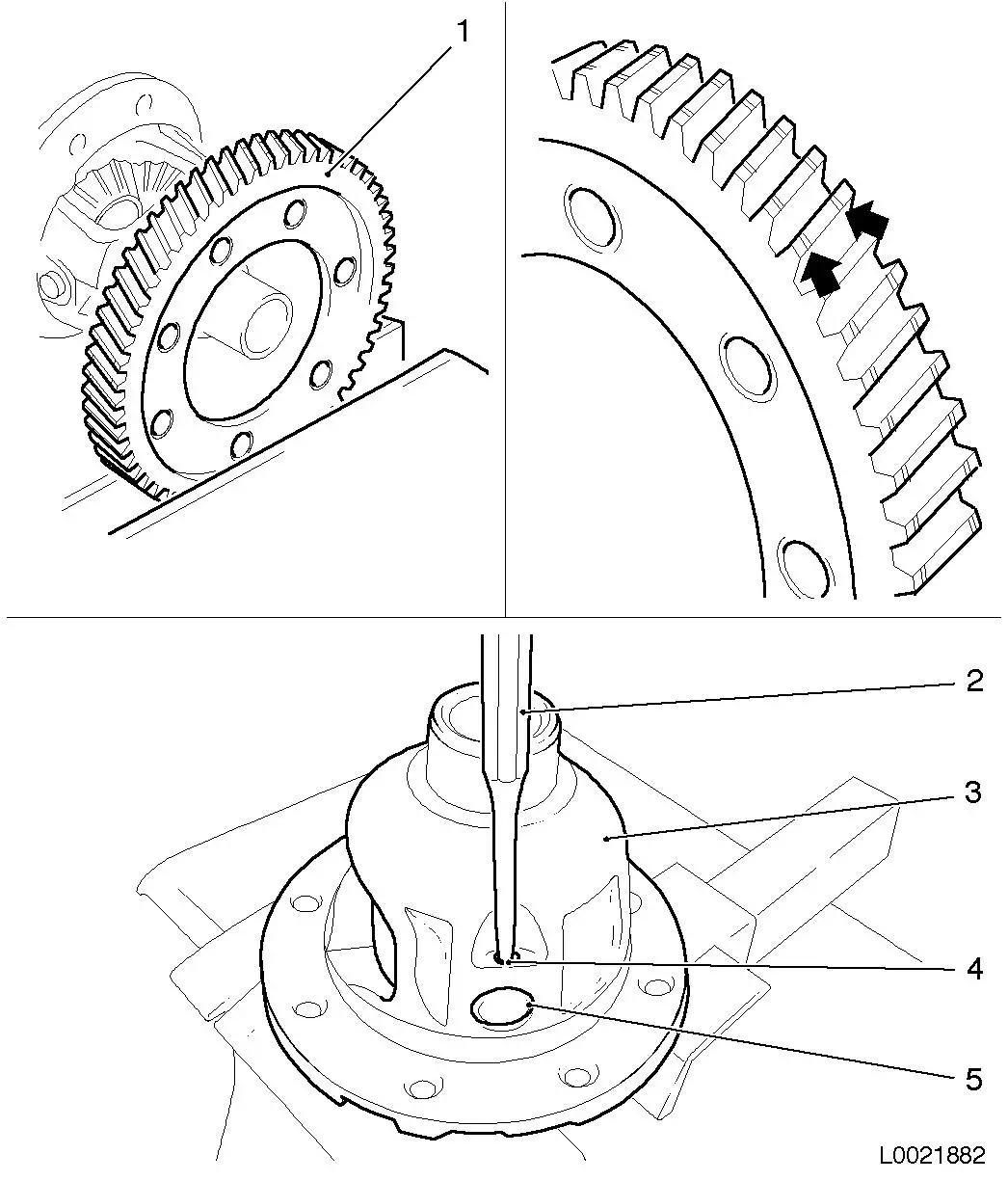

| 10. |

Separate ring gear (1) from differential housing with plastic

hammer

Note: Note peripheral

groove marking (arrows) on gear head.

| • |

Clamp ring gear in vice

Note: Use protective

jaws.

|

|

| 11. |

Dismantle differential housing (3)

| • |

Clamp differential housing in vice

Note: Use protective

jaws.

|

| • |

Drive lock pin (4) into bevel gear shaft (5) using suitable

drift (2) up to the stop.

|

| • |

Remove bevel gear shaft from differential housing

|

| • |

Remove axle shaft and differential bevel gears with KM-458-A

|

|

|

| 12. |

Clean all parts and transmission housing

|

| 13. |

Check all parts for damage

Note: Replace damaged

parts.

|

Install

Install

| 14. |

Drive locking pin (1) out of bevel gear shaft (2)

| • |

Clamp bevel gear shaft in vice

Note: Use protective

jaws.

|

| • |

drive out with suitable drift

|

|

|

|

Important: Lubricate bearing,

running, seating, and pressure surfaces of rotating parts with

transmission fluid.

|

| 15. |

Insert plastic cage in differential gear

Note: It must be

possible to insert collar (1) of plastic cage into guide for axle

shaft bevel gears in housing.

|

| 16. |

Assemble differential housing

| • |

Clamp differential housing in vice

Note: Use protective

jaws.

|

| • |

Insert axle drive and differential bevel gears (3) into

differential housing

|

| • |

Use 2x KM-458-A (2) to screw in

differential bevel gears

|

|

|

|

|

| 17. |

Install bevel gear axis (4)

| • |

Drive new lock pin into bevel gear shaft using suitable drift

(1)

Note: Drive pin (3)

flush into differential housing (2)

|

|

|

|

| 18. |

Attach ring gear (1) to differential housing

Note: Replace drive

gears only in pairs (driving and driven). Note identification

groove (arrows) running around tip of tooth.

| • |

Tighten 8x new bolts evenly 70 Nm +

(30° - 45°)

Note: Insert bolts with

locking compound

|

|

|

|

| 19. |

Attach 2x tapered roller bearing inner races (2)

| • |

Press 2x inner races of tapered roller bearings onto

differential housing (3) using KM-453

(1)

|

|

|

|

| 20. |

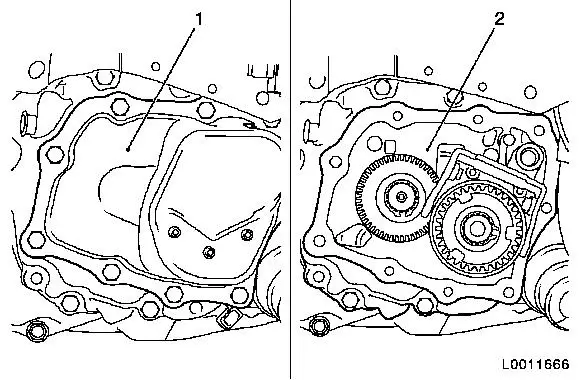

Attach 2x tapered roller bearing outer races

| • |

Install tapered roller bearing outer race (2) into transmission

and/or bearing ring with KM-304 (1) and

KM-451 (3)

|

|

| 21. |

Fit axle shaft seal rings

| • |

Install axle shaft seal rings into bearing ring and

transmission housing with KM-446

|

|

| 22. |

Install differential (4)

|

|

|

| 23. |

Install end shield (2)

|

| 24. |

Attach end shield cover (1)

|

|

| 26. |

Check transmission fluid level

|

|