Repairing and Assembling Differential for Golf Mk1 Manual Gearbox

|

Repairing differential

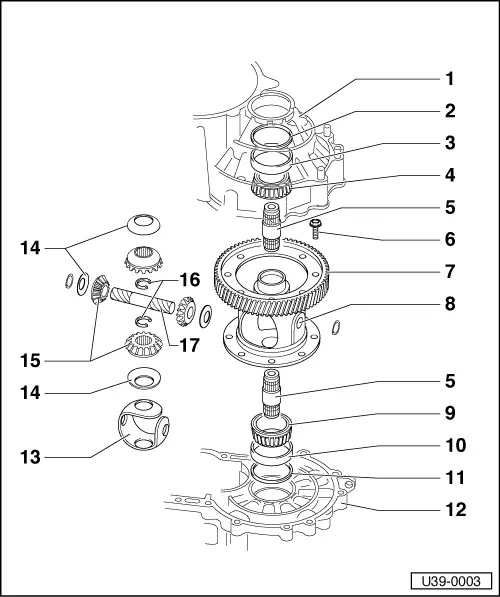

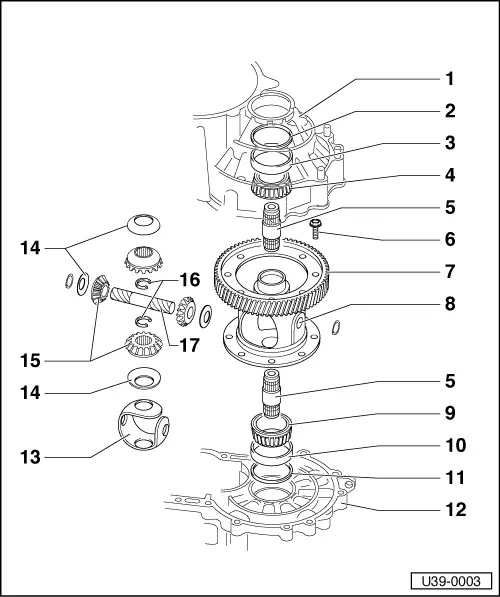

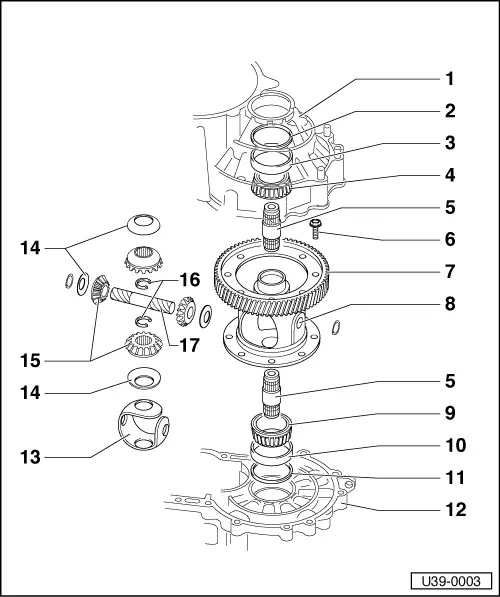

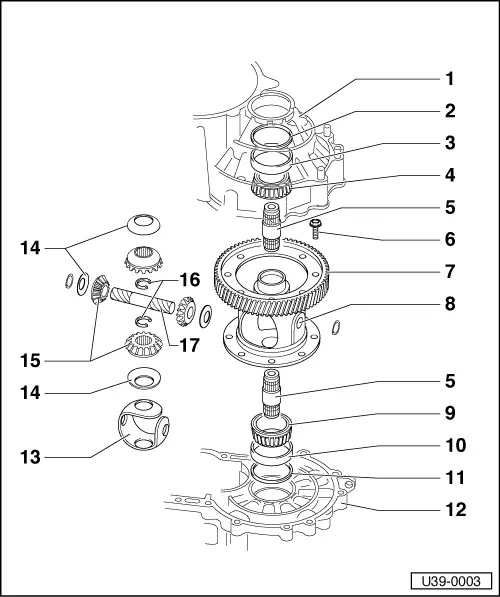

Dismantling and assembling differential

|

|

|

|

Caution

The inner and outer races of the taper roller bearings are matched and must not be interchanged. |

|

|

|

|

|

|

|

|

|

|

|

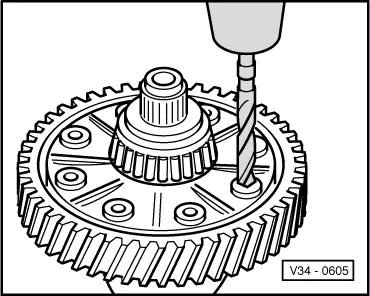

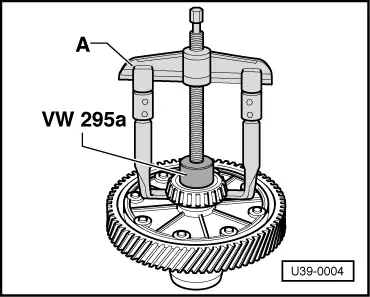

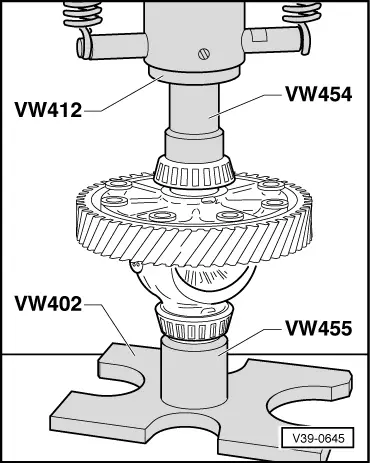

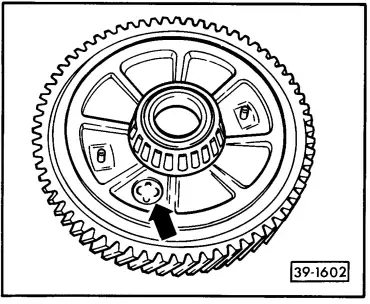

→ Fig.1 Pulling inner race off

|

|

|

|

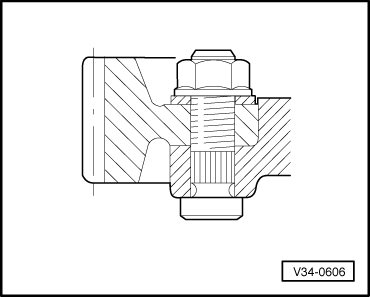

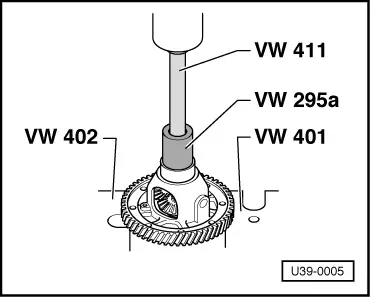

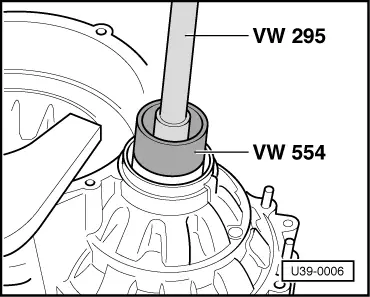

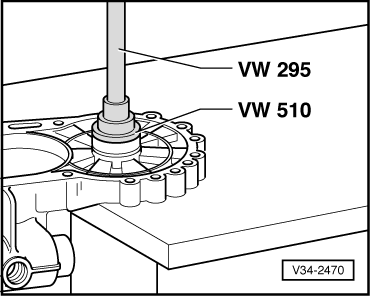

→ Fig.2 Pressing inner race home

|

|

|

|

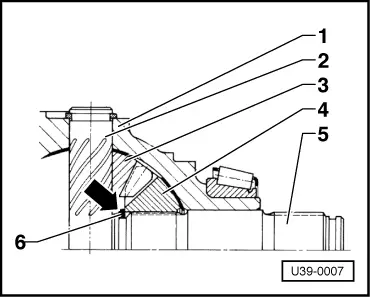

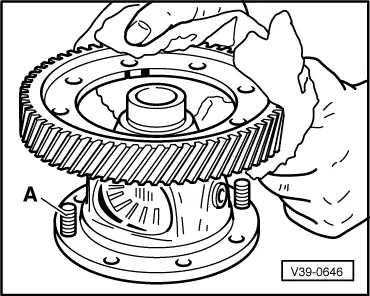

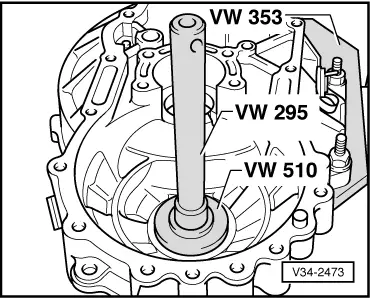

→ Fig.3 Pressing crown wheel off |

|

|

|

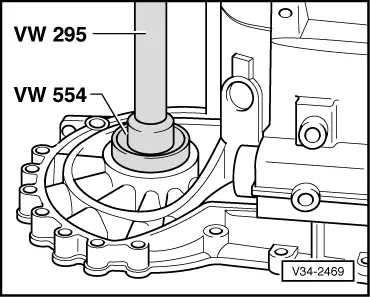

→ Fig.4 Heat crown wheel to about 100°C and install

Modification |

|

|

|

→ Fig.7 Installing differential pinions

Note: In differential with thrust washer mark =>Fig.8 , lubricate washer with gear oil and install first. Mod.: From gearbox 13 12 6 Differential with one-piece thrust washer |

|

|

|

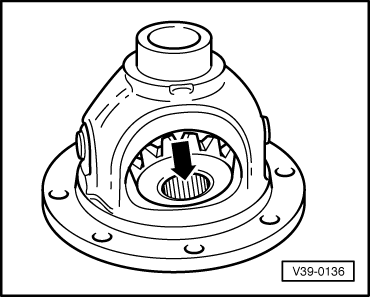

→ Fig.8 Differential housing mark In housing with this mark, install one-piece plastic thrust washer. |

|

|

|

→ Fig.10 Knocking out differential bearing outer race |

|

|

|

→ Fig.11 Knocking in differential bearing outer race |

|

|

|

→ Fig.12 Knocking out differential bearing outer race |

|

|

|

→ Fig.13 Knocking in differential bearing outer race |