Golf Mk1

|

Controls, Housing

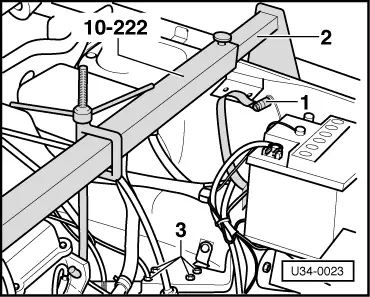

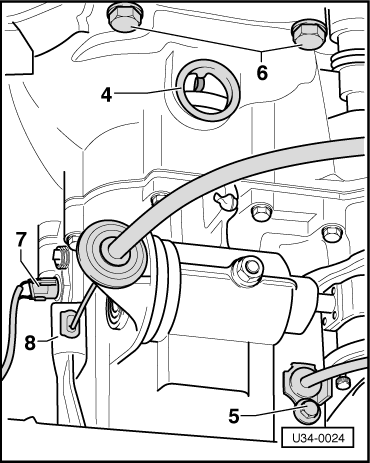

Removing and installing gearbox

Service installation of the 5 speed manual gearbox . Removing |

|

|

|

|

|

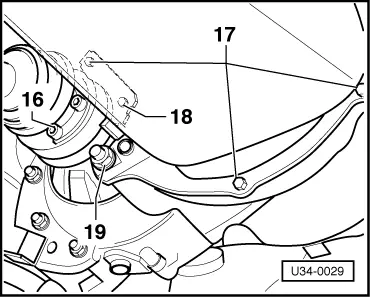

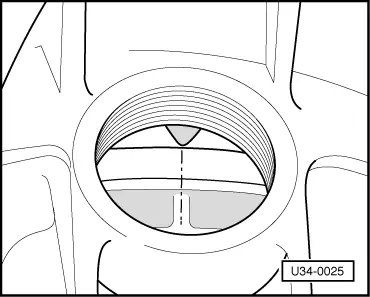

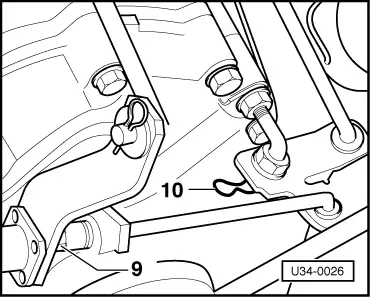

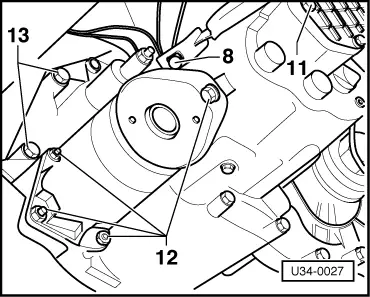

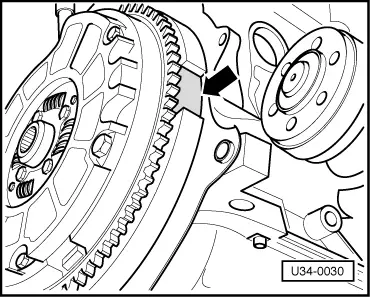

Note: The engine and gearbox can only be separated whit flywheel in this position. On vehicles with 81 KW engine the drive flange on engine side has a flat on it. To separate engine and gearbox, position flat towards flywheel.

Modification |

|

|

|

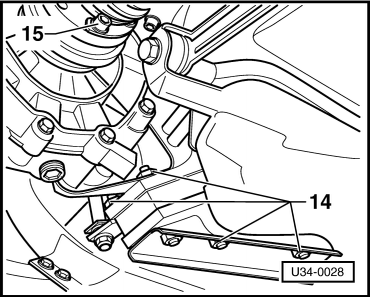

From 9/74 (Except 81 KW engine) → Depression 76° before TDC instead of lug 33° before TDC (3 recesses on flywheel instead of 2, => page 34-34 ). Mod.: From 11.78 securing point 18 changed from stud and nut to bolt (M 12 x 58). At the same time the recess ( => page 34-34 ) and the lug 76° before TDC in flywheel, were discontinued. When removing gearbox, turn it until there is sufficient clearance between flywheel and drive flange. Its is no longer necessary to align flywheel or flange. |

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

→ Install by reversing the removal sequence Caution

The recess in the flywheel must be positioned level with the drive flange -arrow-. Tightening torques:

When gearbox has been installed, check length of selector rod (b) and adjust if necessary => page 34-8 Renewing gearbox From assembly date 07 085 to 24 085, gearboxes with high-mounted starter and side pressure shift system where installed. When renewing, use Port No. 020 300 043 B - for downward pressure system ( without reverse catch). This box must be converted to side pressure system as follows:

This conversion is essential as otherwise there is no reverse catch. | |||||||||||||||