-

‒ →

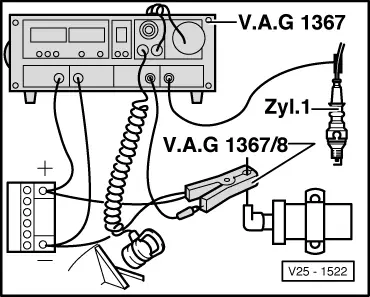

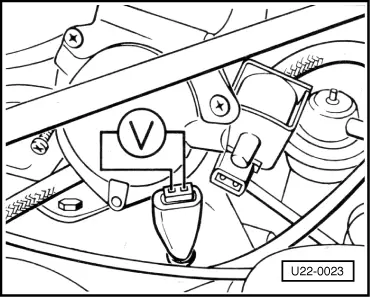

Pull plug off control valve and use auxiliary leads form V.A.G 1594 to connect up hand multimeter V.A.G 1526 for voltage measurement to both plug contacts.

-

‒ Start engine and let it idle.

Specification: approx. battery voltage

-

‒ If necessary, located and eliminate open circuit in wiring using CFD:

-

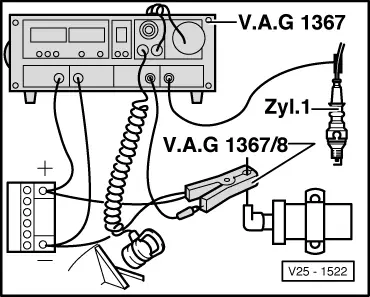

‒ Slow increase speed/let it drop off and determine switching speeds of control unit.

|

Specifications for increasing speed:

|

|

with overrun mixture valve

|

|

|

above 1750 rpm

|

=

|

0 volts

|

|

with throttle valve positioner

|

|

|

above 1900 rpm

|

=

|

0 volts

|

|

|

Specifications for decreasing speed:

|

|

with overrun mixture valve

|

|

below 1500 rpm

|

=

|

approx. battery voltage

|

|

with throttle valve positioner

|

|

|

below 1750 rpm

|

=

|

approx. battery voltage

|

-

‒ Renew control unit if the specifications are not attained.

Checking control valve

(for overrun boost with throttle valve positioner)

-

● Voltage supply Ok; checking =>page 22-87

-

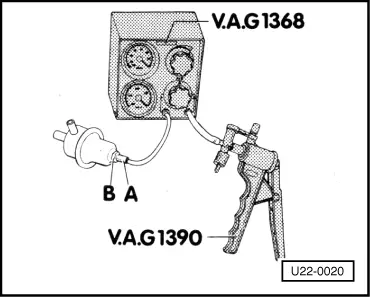

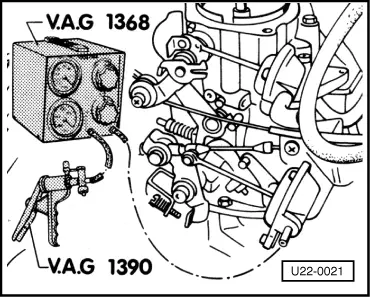

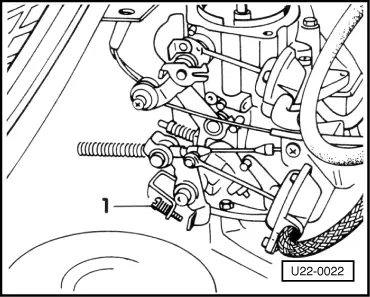

‒ Remove air cleaner.

-

‒ Start engine and let it idle.

-

‒ Pull plug off control valve.

-

‒ Pull vacuum hose (control valve/retard valve) off retard valve.

-

‒ Pull vacuum hose (control valve/servo unit line) off servo unit line.

-

‒ Pull vacuum hose (control valve/carburettor) off T piece and blow into hose. The valve must be tight; otherwise the valve is defective (renew) or the vacuum hose is leaking.

-

‒ Connect plug to control valve and simultaneously blow intro vacuum hose (control valve/carburettor).

The valve must be heard to click and open up. If not, control valve is defective (renew) or vacuum connections/hoses are clogged.

Note:

If the valve is blown into from the retard valve end, the valve must be open both with and without voltage supply. If not, renew valve.

Checking control valve

(for overrun boost with overrun mixture valve)

-

● Voltage supply Ok; checking =>page 22-87

-

‒ Remove air cleaner.

-

‒ Start engine and let it idle.

-

‒ Pull plug off control valve.

-

‒ Pull valve hose (control valve/overrun mixture valve) off overrun mixture valve.

-

‒ Pull vacuum hose (control valve/servo unit line) off servo unit line and blow into hose. The valve must be open. If not, valve is defective (renew) or vacuum hose is clogged.

-

‒ Attach plug to control valve and simultaneously blow into vacuum hose (control valve/servo unit line). The valve must be heard to click and be sealed off. If not, control valve is defective (renew) or vacuum connections/hoses are leaking.

Note:

If the valve is blow into from the overrun mixture valve and, the valve must be open both with and without voltage supply. If not, valve is defective (renew) or vent cap at 3rd vacuum connection is clogged.

|