Dismantling and assembling pistons and conrods in Golf Mk1

|

Dismantling and assembling pistons and conrods

Dismantling and assembling pistons and conrods

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

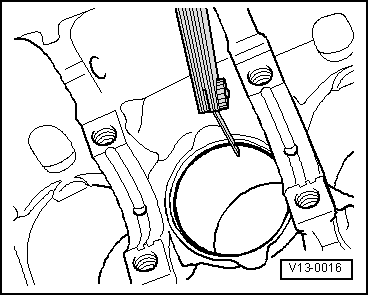

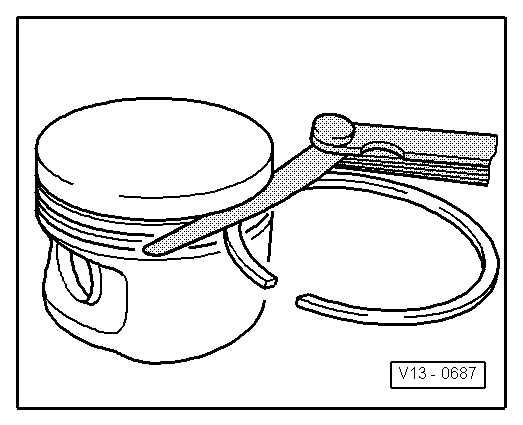

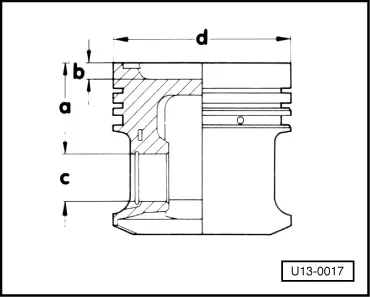

→ Fig.2 Checking piston ring groove clearance Clean groove before checking.

| |||||||||||||||||

|

|

|

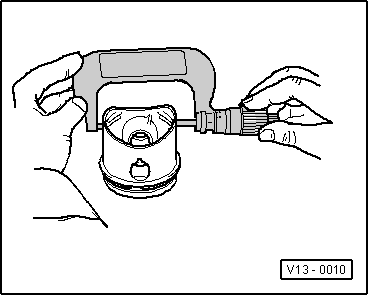

→ Fig.3 Checking pistons Check approx. 10 mm from bottom of skirt offset by 90° with respect to piston pin axis. Deviation from specified dimension: max. 0.04 mm. |

|

||||||||||||||||||||||||||||||||||||||||||||||

|

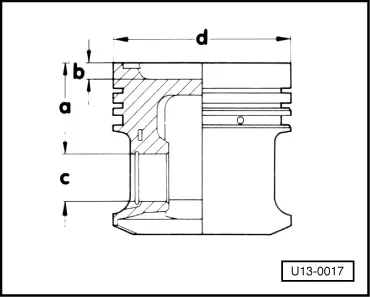

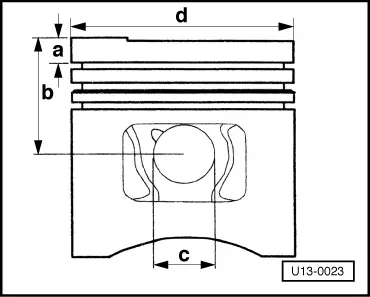

→ Fig.4 Piston distinguishing features

1) Flat piston | ||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||

|

||||||||||||||||

Bore ø= 76.5 mm | ||||||||||||||||

|

|||||||||||||||||||||

Bore ø= 76.5 mm Note: When performing repairs, an engine may only be fitted with pistons and piston rings of the same desin and pistons from the same weight category. | |||||||||||||||||||||

|

|||||||||||||||||

|

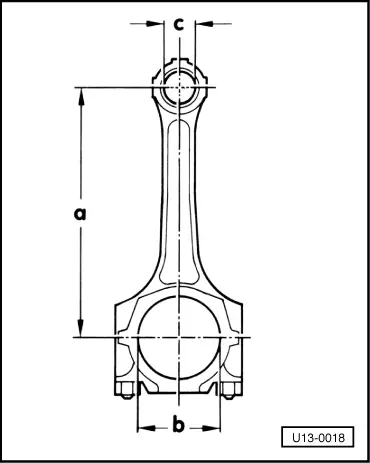

→ Fig.5 Connecting rod distiguishing features

| |||||||||||||||||

|

||||||||||||

|

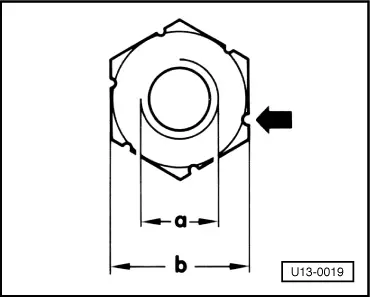

→ Fig.6 Conrod nut distinguishing features

|

|

|

|

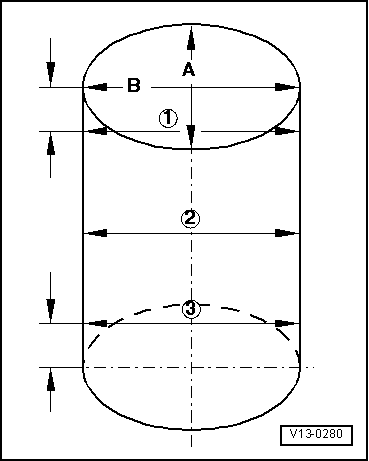

→ Fig.7 Checking cylinder bore

Note: Measuring the cylinder bore must not be done when the cylinder block is attached to repair stand with adapter VW 540 as incorrect measurements may then result. |

|

|||||||||||||||

|

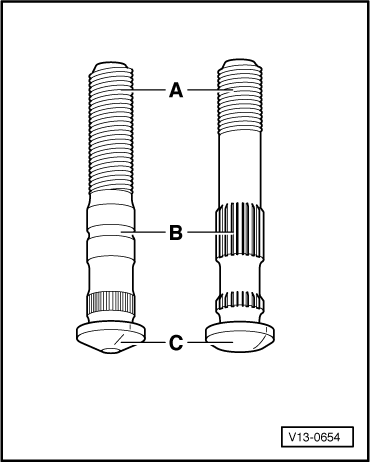

→ Fig.8 Conrod bolt distinguishing features

|

|

||||||||||||||||

|

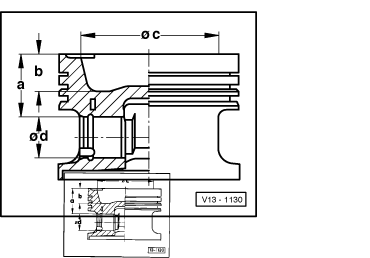

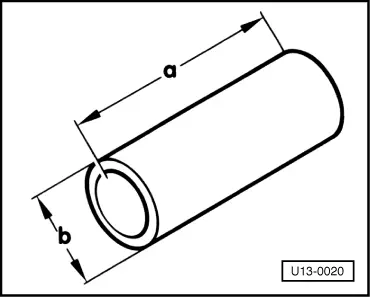

→ Fig.9 Piston pin distinguishing features

| ||||||||||||||||

|

|

|

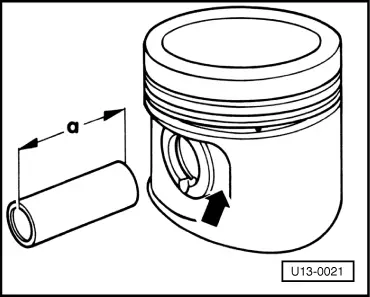

→ Fig.10 Piston with short piston pin With a = 55 m piston pin the piston was flattened off in the area of the piston pin bore -arrow-. Note: When performing repairs, an engine may only be fitted with pistons and piston rings of the same desing and piston from the same weight class. |