Golf Mk1

|

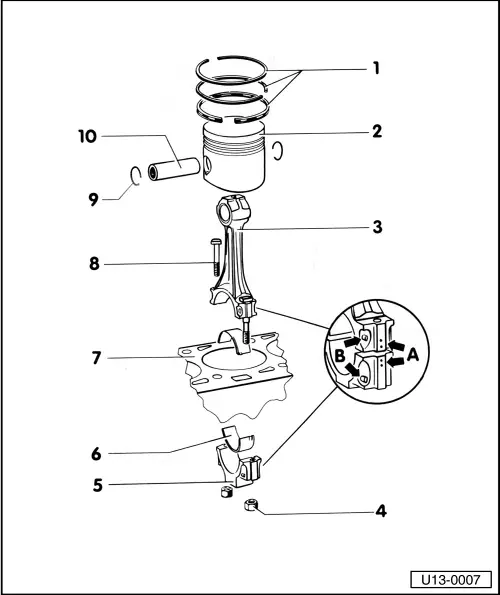

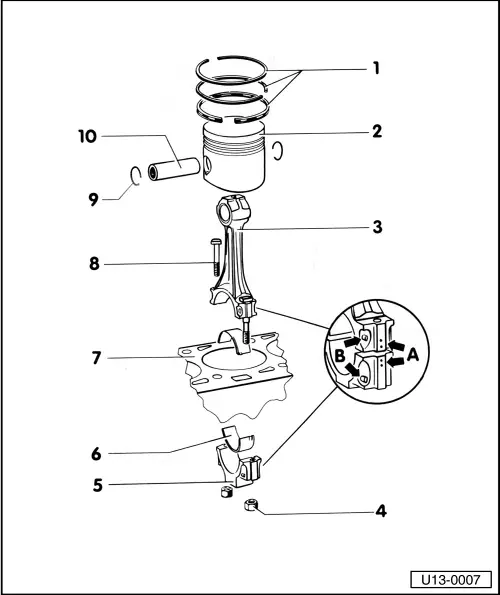

Dismantling and assembling pistons and conrods

Dismantling and assembling pistons and conrods

|

|

|

|

Note: Do not rotate crankshaft when measuring radial clearance. |

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

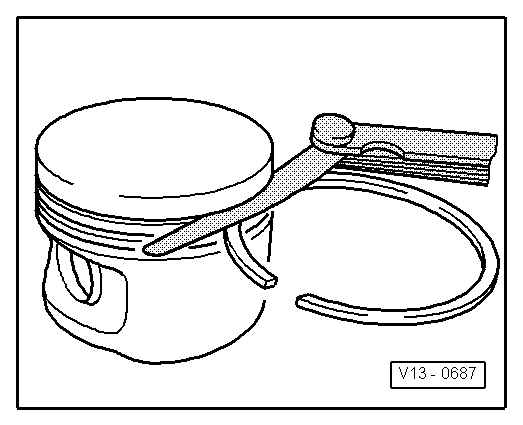

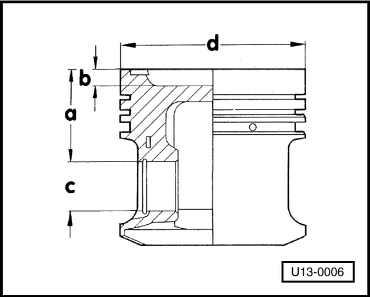

→ Fig.2 Piston rings - Checking ring groove clearance New: 0.02...0.05 mm Wear limit: 1.50 mm | ||||||||||||||||||

|

|

|

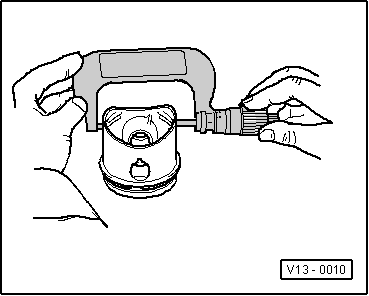

→ Fig.3 Checking piston Measure approx. 10 mm the lower edge at an angle of 90° to the piston axis. Maximum deviation from specification = |

|

|

|

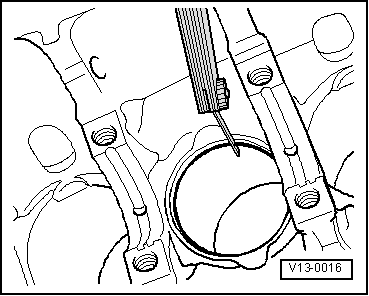

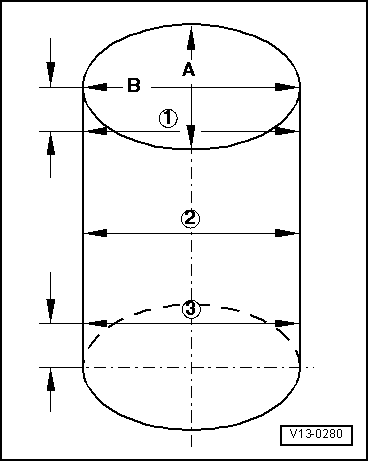

→ Fig.4 Checking cylinder bore

Use internal dial guage 50...100 mm. Maximum deviation from specifications is 0.08 mm Note: Measurements of cylinder bore should not be performed when cylinder block is attached to engine stand with VW 540, as incorrect measurements could result. |

|

||||||||||||||||||||||||

|

→ Fig.5 Pistons identification characteristics

Only pistons and pistons rings of the same version and pistons of the same weight rating should be installed the engine. | ||||||||||||||||||||||||

|

||||||||||||||||

|

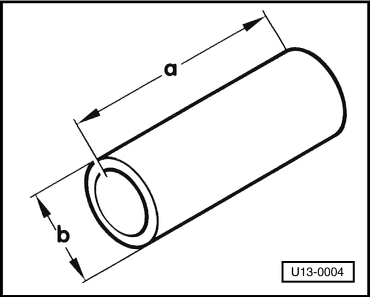

→ Fig.6 Pistons pins-Identification characteristics

| ||||||||||||||||

|

||||||||||||||||||||

|

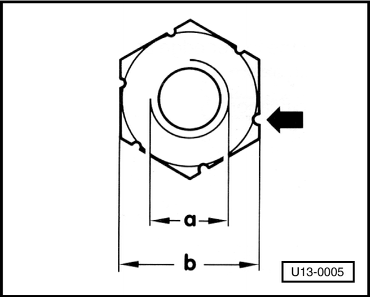

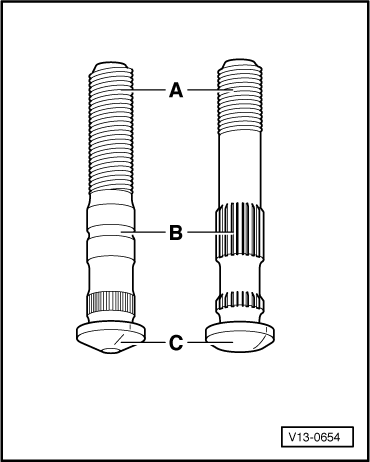

→ Fig.7 Bearing cap bolts - Identification charateristics

| ||||||||||||||||||||

|

||||||||||||||||||||

|

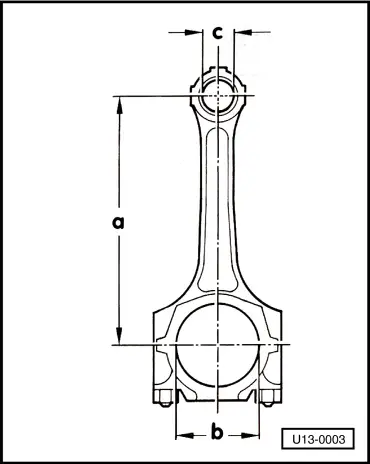

→ Fig.8 Conrod - identification characteristics

| ||||||||||||||||||||

|

||||||||||||||||||||

|

→ Fig.9 Conrod bolts - Identification characteristics

| ||||||||||||||||||||