Checking Regulated Exhaust System for Golf Mk1 (Engine Code: JH)

|

K-jetronic injection system

Checking regulated exhaust system (engine code: JH)

Notes for vehicles 08.87 ▸: The follow components which improve acceleration during the warm-up phase, can be retrofitted:

|

|

|

|

→ Relay locations Relay location 2:

|

|

|

Notes: On the Scirocco the connector -1- is located near the ignition coil on the wiring loom. Attention!

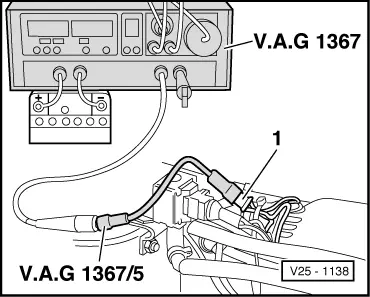

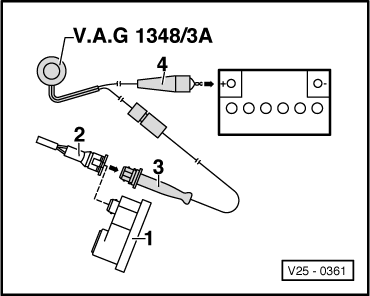

The cable clamp for N Connect remote control V.A.G 1348/3A |

|

|

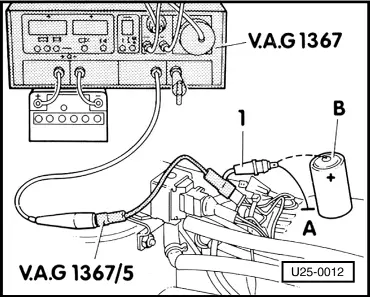

Checking frequency valve

If the valve clicks the check is completed. |

|

|

If the voltage supply is OK, renew control unit -J21-. Checking emergency running function of control unit

|

|

|

Checking full throttle enrichment of the control unit

|

|

|

If not:

If no open circuit is present and the full throttle switch is OK, replace control unit -J21-. Checking Lambda regulation function of the control unit |

|

|

|

|

|

If not:

If no open circuit is present, replace control unit -J21-. Checking cold running enrichment function of the control unit -J21- |

|

|

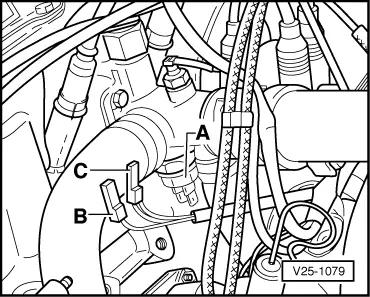

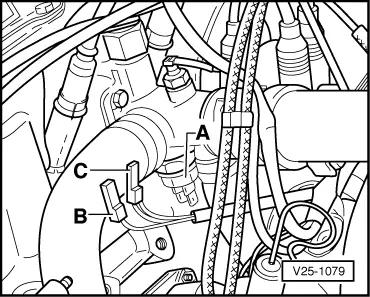

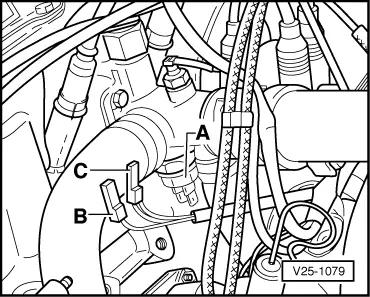

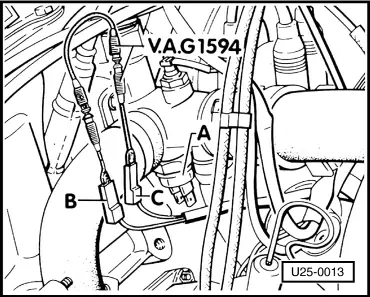

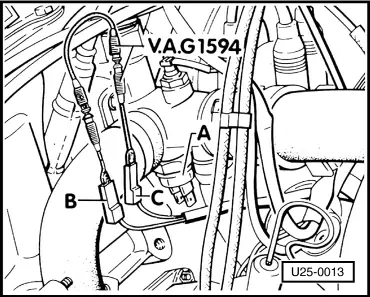

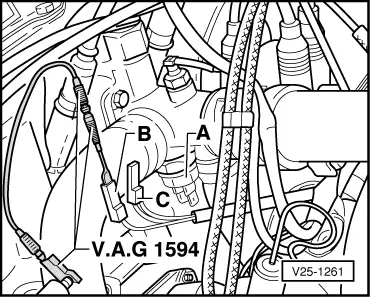

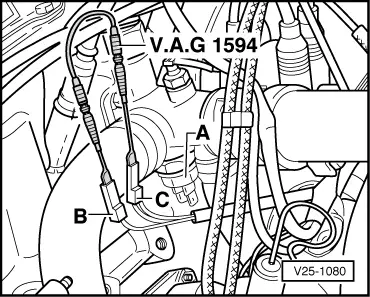

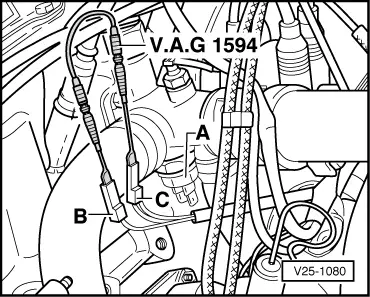

▸07.88 Version with one wire on connector -C- |

|

|

08.87▸Version with two wires on connector -C- |

|

|

If no open circuit is present, replace control unit -J21-. Checking cold running enrichment function though the vacuum switch -F128- (Only on version with two wires on connector -C- from thermo switch) |

|

|

|

|

|

|

|

|

|

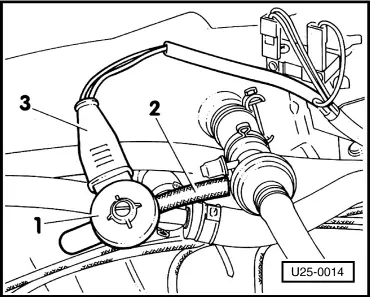

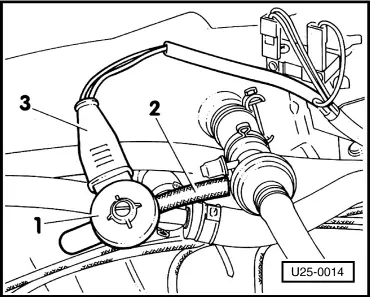

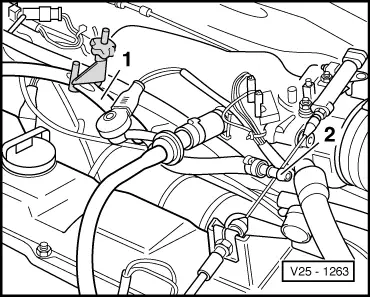

→ If only 50 ± 2% or only 65 ± 2% is indicated, pull connector -3- off vacuum switch -1- and check duty cycle at idling speed.

If OK, The vacuum switch -1- -F128- or the vacuum pipe -2- is defective. If the specifications are not attained, locate and eliminate open circuit or short circuit in wiring to vacuum switch -F128- using CFD Checking cold start enrichment function of control function -J21- |

|

|

|

→ (Only on version with two wires on connector -C- from thermo switch)

If a duty cycle of 50 % is indicated, locate and eliminate open circuit for relay 53 -J199- using current flow diagram. If no open circuit is found, replace relay 53 for cold start enrichment -J199-. Checking Lambda probe -G39-

|

|

|

If the duty cycle does not drop, replace lambda probe -G39- (the Lambda probe wiring connect must be connected during the test). |