Golf Mk3

|

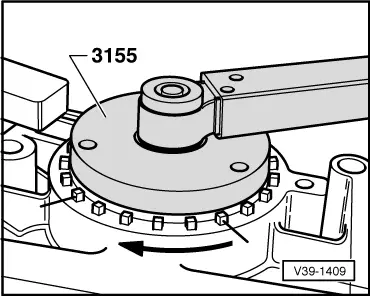

Adjusting final drive

Adjusting differential

|

|

|

Note: When performing measurement, do not turn differential otherwise the bearings will settle and the result of the measurement will be falsified.

|

|

||||||||

|

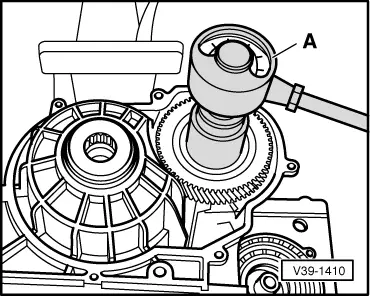

→ Checking friction torque A - Torque gauge, commercially available 0...600 Ncm The friction torque of new taper roller bearings must be 60...80 Ncm greater than at the drive pinion. Example:

1) Insert the friction torque measured for the drive pinion in the case of used bearings. |