Golf Mk3

|

Adjusting final drive

Adjusting input gear

|

|

|

|

|

||||||

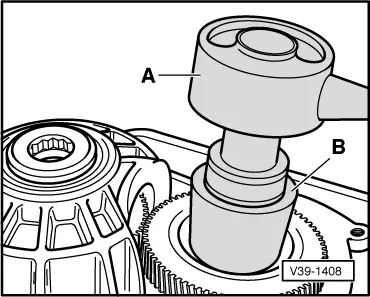

Determining shim The specified bearing preload is achieved if the bearing preload of 0.18 mm is deducted from the figure obtained from the measurement (dished washer + reading) of 2.50 mm. Example:

Note: Insert axial needle bearing for input shaft before tightening socket head fastener. Installation position => Removing and installing input gear, Page 39-8. |

|

||||||||

|

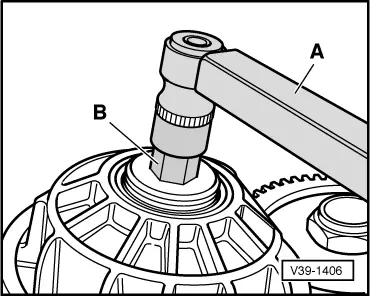

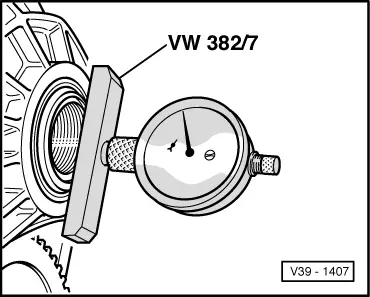

→ Checking friction torque A - Torque gauge, commercially available 0...600 Ncm B - Wrench socket (41 mm AF) The friction torque of new taper roller bearings must be 180...220 Ncm greater than at the pinion shaft. Example:

1) Insert the friction measured for the drive pinion in the case of used bearings. |