|

Notes:

-

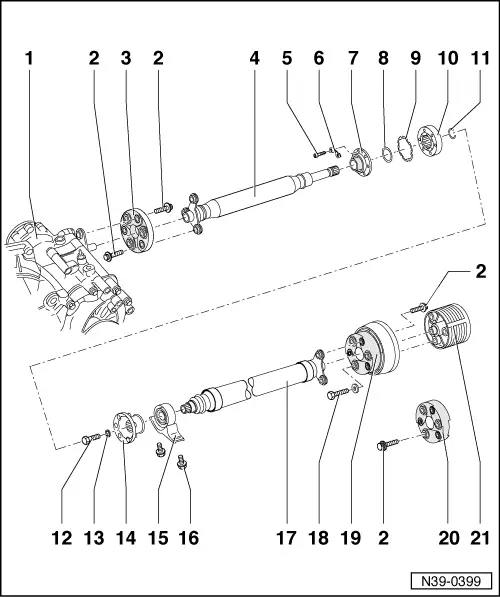

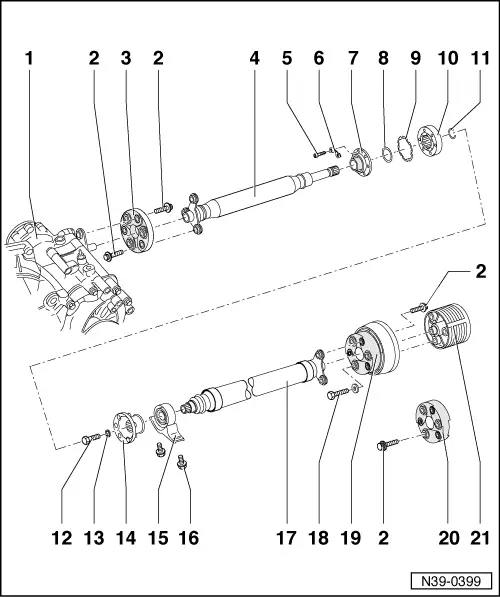

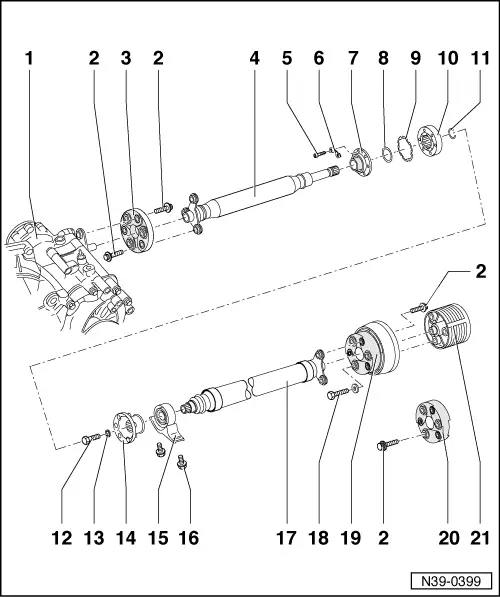

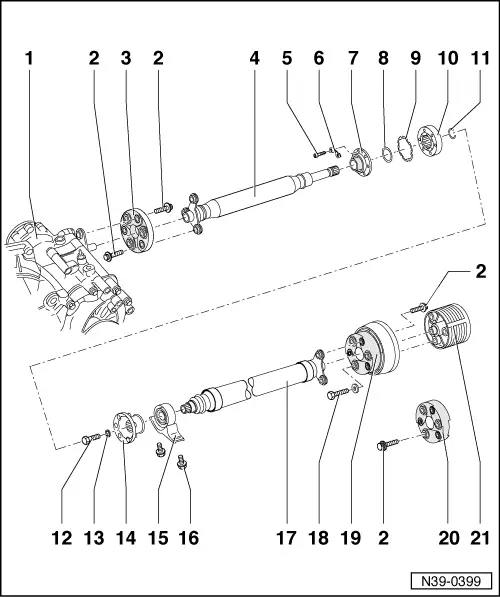

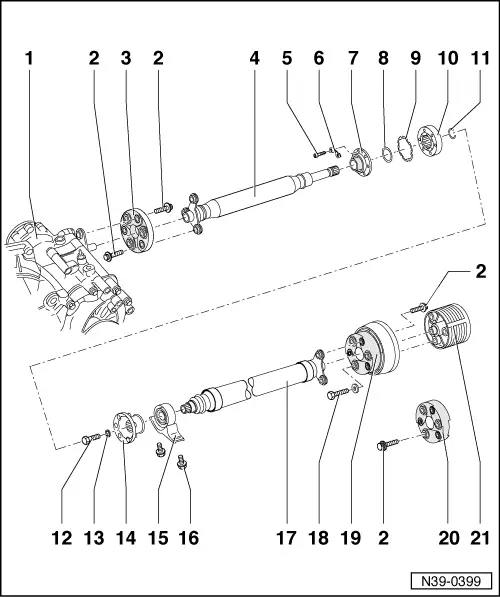

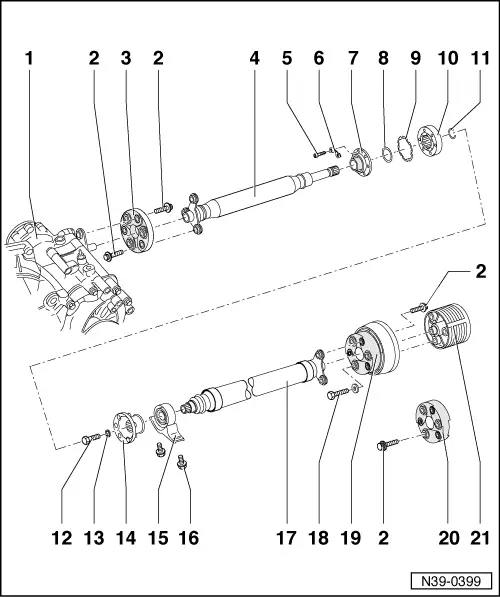

◆ To obtain the quietest possible running, the entire propshaft is balance during manufacture. It is not possible to balance the entire propshaft or the individual propshaft sections using workshop equipment, therefore if a front or rear propshaft section is damaged then the complete propshaft must be renewed.

-

◆ Keep propshaft straight, only store and transport fully extended.

-

◆ Before removing, mark the positions of all parts in relation to each other. Reinstall in the same position otherwise imbalance will be excessive, creating rumbling noises and possibly damaging mountings.

|