Golf Mk3

|

Dismantling and assembling gearbox

Assembly sequence

|

|

|

|

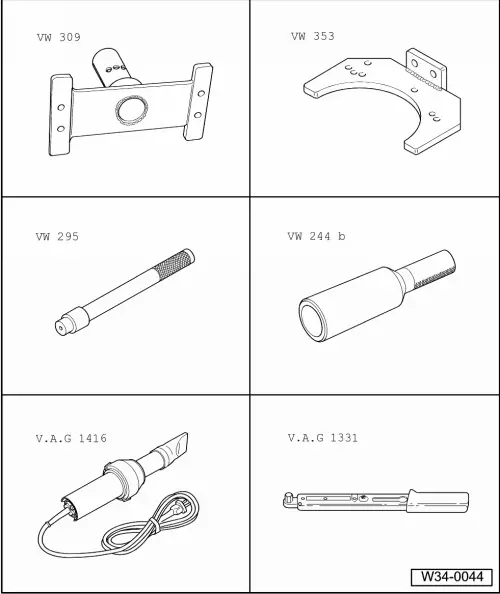

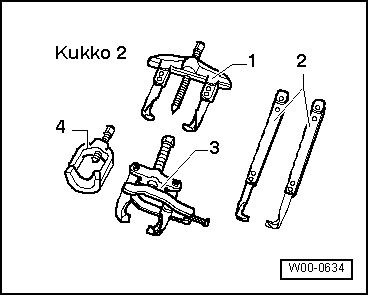

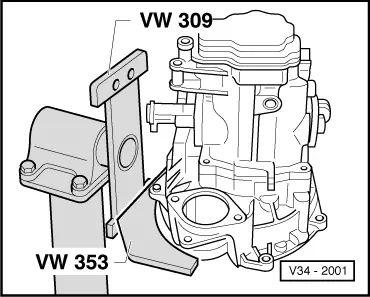

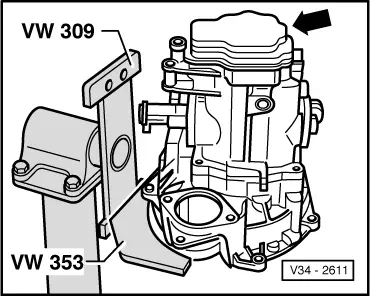

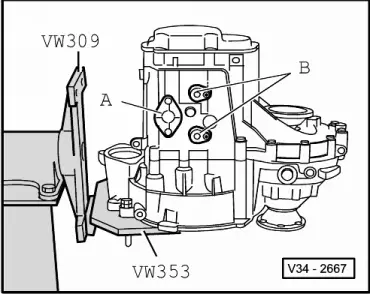

Special tools and workshop equipment required

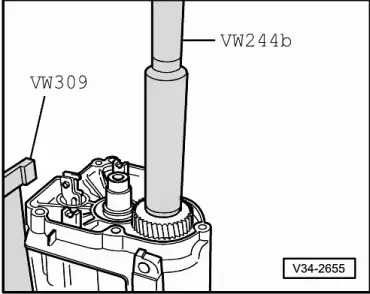

with Matra V170 hooks |

|

|

|

Dismantling

|

|

|

|

|

|

|

|

|

|

|

|

|

|

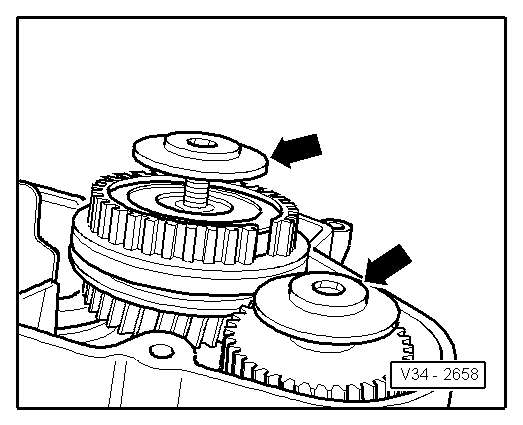

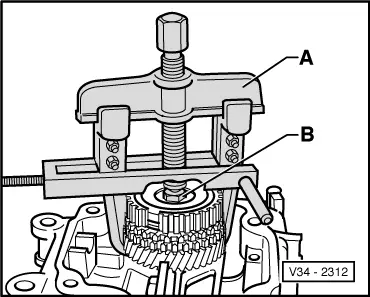

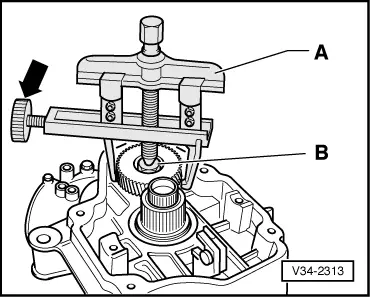

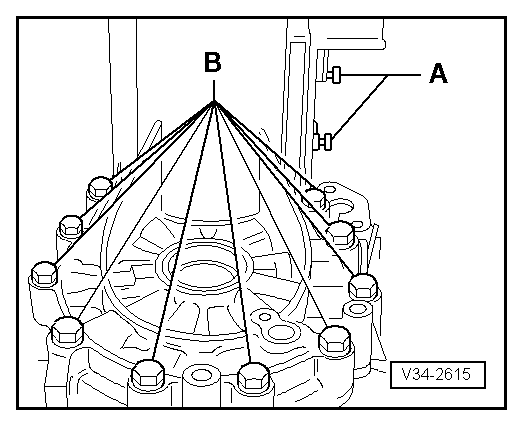

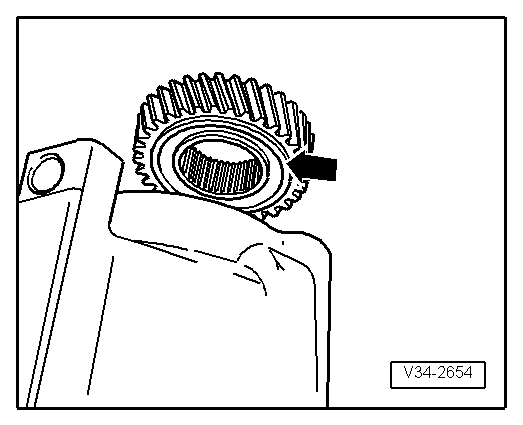

Note: When pulling off the gear wheel ensure that the hooks do not bend outwards, if necessary tighten screw (arrow). After 5th gear wheel has been removed check for damage. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

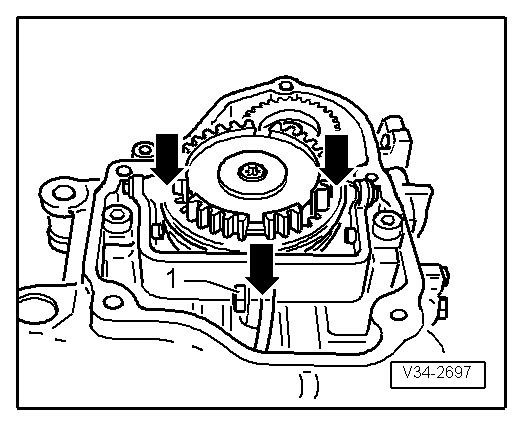

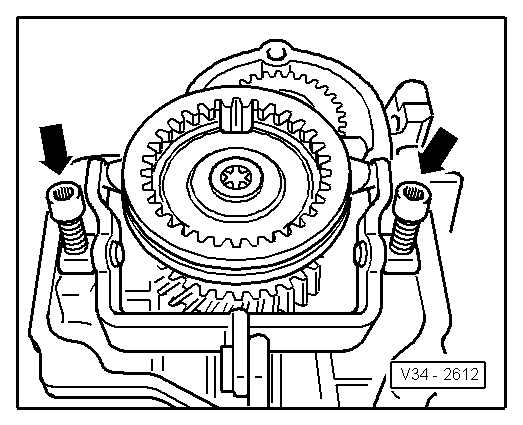

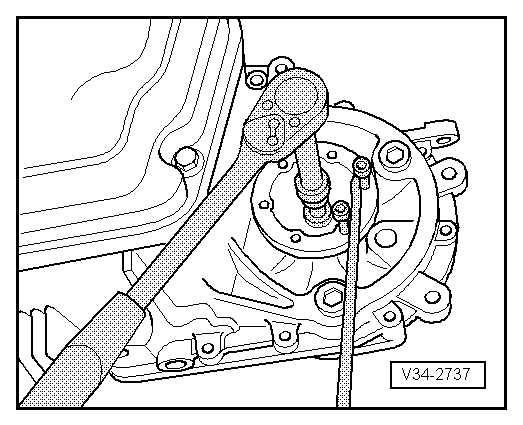

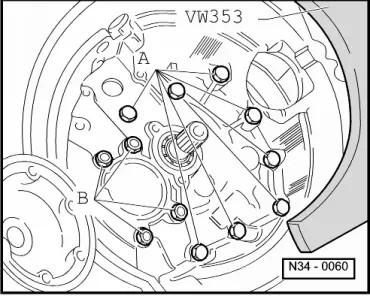

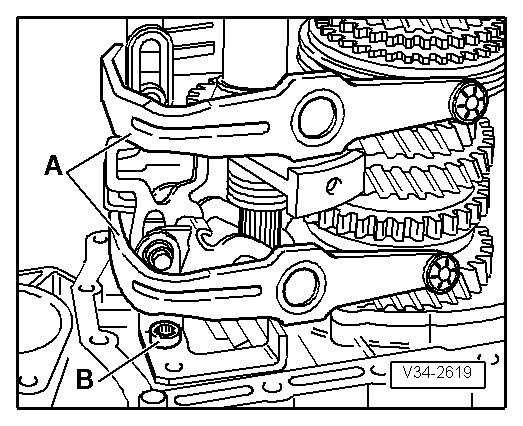

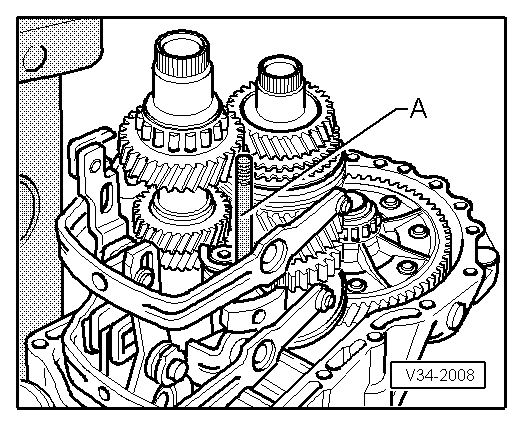

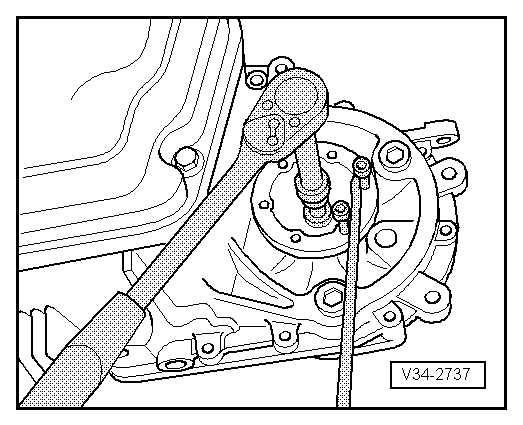

Note: Do not remove nuts -B- for output shaft bearing support. |

|

|

|

|

|

|

|

Assembling

|

|

|

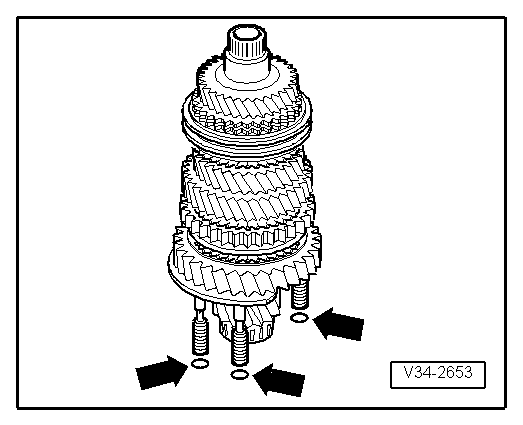

Note: The illustration only shows 3 of the 4 sealing rings.

|

|

|

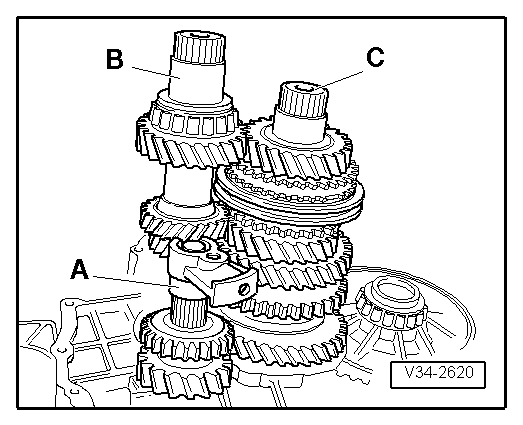

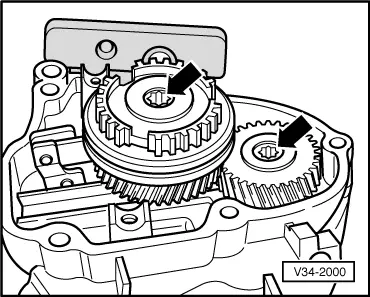

→ Installation position reverse gear

|

|

|

Note: The selector segments must be positioned in the grooves on the locking collars.

|

|

|

|

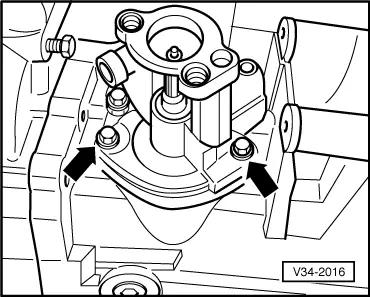

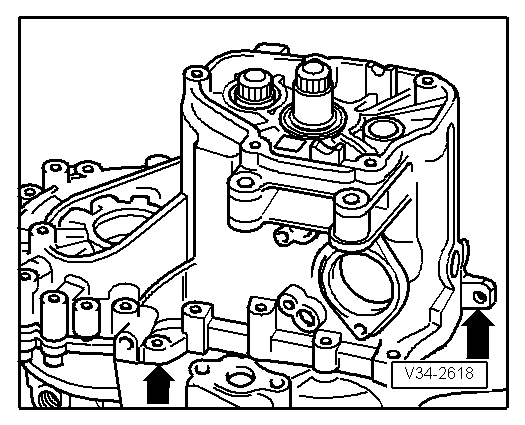

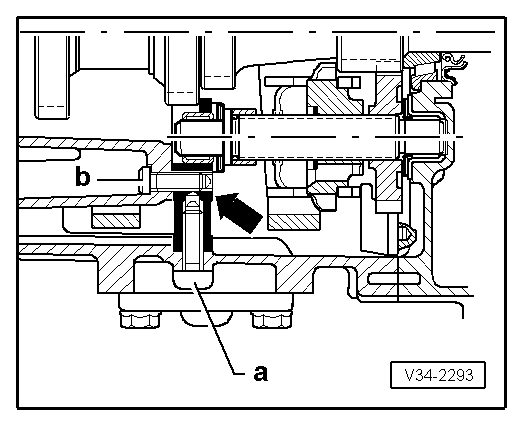

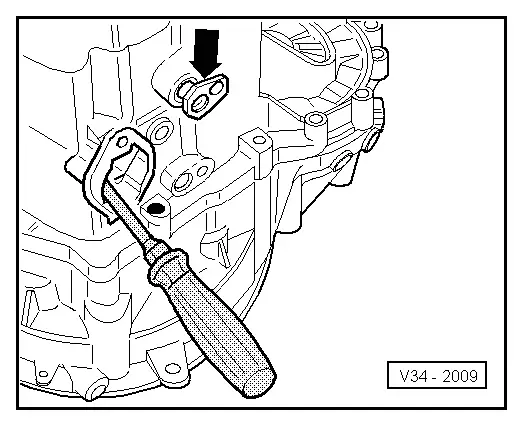

Install reverse shaft support bolts (arrow) as follows:

|

|

|

|

|

|

|

→ Install selector shaft as follows:

|

|

|

|

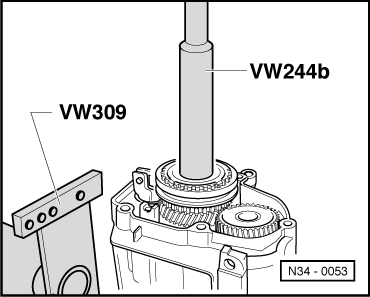

→ Installation position 5th gear wheel The circumferential groove (arrow) faces to gearbox housing. |

|

|

|

|

|||||||

|

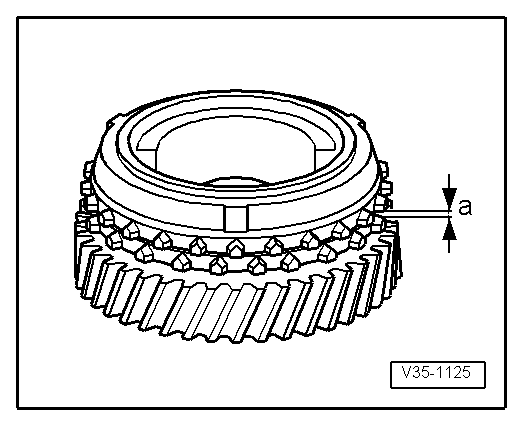

Checking 5th gear synchro-ring

|

|

|

|

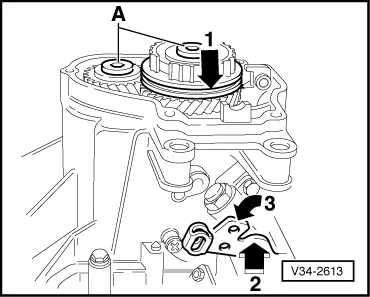

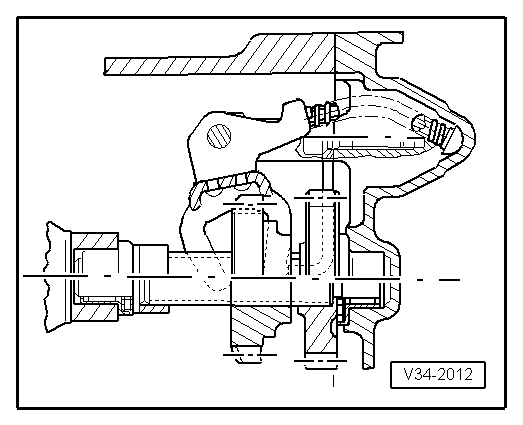

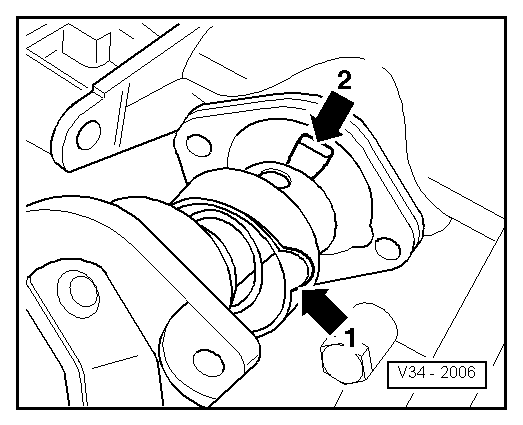

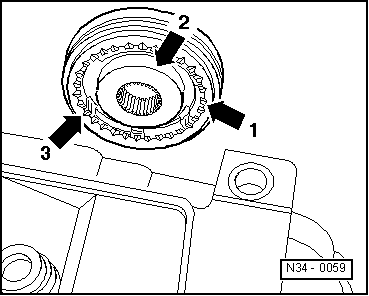

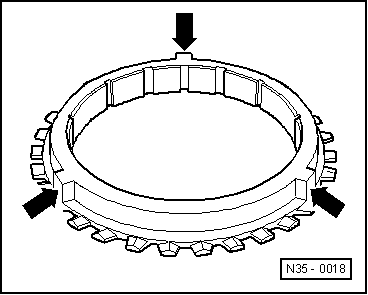

→ Installation position 5th gear synchro-hub/locking collar The pointed teeth of the locking collar (arrow 1) and the high shoulder of the synchro-hub (arrow 2) face the gearbox housing. The syncro-hub mountings (arrow 3) align with the synchro-ring cast locking pieces (=>arrows on Illustration N35-0018, Page 34-78 ). |

|

|

|

→ 5th gear synchro-ring with cast locking pieces (arrows) |

|

|

|

Note: When driving on ensure synchro-ring is free to move. |

|

|

|

|

|